Technical Contents

Engineering Guide: Cnc Precision Machined Components

Engineering Insight: The Non-Negotiable Imperative of Precision in CNC Machined Components

In the realm of advanced manufacturing, the term “precision” transcends mere marketing language; it represents the absolute foundation upon which mission-critical performance, safety, and longevity are built. For CNC machined components destined for aerospace, defense, medical, and high-performance industrial applications, dimensional accuracy measured in microns is not an aspiration—it is a non-negotiable engineering requirement. The consequences of tolerances exceeding specifications can cascade from minor assembly difficulties to catastrophic system failure. Consider an aerospace turbine blade: a deviation of mere thousandths of an inch in cooling channel geometry directly impacts thermal management efficiency, potentially leading to premature material fatigue and in-flight component rupture. Similarly, in medical implant manufacturing, surface finish and geometric fidelity dictate biocompatibility and osseointegration success. Precision machining ensures components function as designed within complex assemblies, maintaining critical clearances, load distributions, and sealing interfaces under extreme operational stresses—vibration, temperature fluctuations, and high pressure. It is the invisible enabler of reliability, where every micron held translates directly to extended service life, reduced maintenance costs, and uncompromised end-user safety. Achieving this level of consistency demands far more than advanced machinery; it requires a deeply integrated ecosystem of metrology, process control, material science expertise, and unwavering adherence to zero-defect culture.

Wuxi Lead Precision Machinery operates at this pinnacle of manufacturing rigor. Our engineering heritage is forged in projects demanding the absolute zenith of precision, where failure is not an option. We have successfully delivered components for Olympic timing systems, where nanosecond synchronization relies on flawless mechanical interfaces, and for classified military avionics programs, where component integrity under G-force and electromagnetic interference is paramount. These engagements are not merely credentials; they are the proving ground for our processes, validating our capability to consistently achieve and document tolerances down to ±0.0004 inches (10 microns) and surface finishes below Ra 0.4 µm on complex geometries in exotic alloys like Inconel 718 and titanium Grade 5. This experience directly benefits every client, embedding military-grade discipline into standard production protocols for all sectors.

Our commitment to precision is quantifiable and rigorously controlled. The table below outlines the core capabilities underpinning our high-accuracy production:

| Specification Category | Capability Range | Verification Standard | Relevance to Critical Applications |

|---|---|---|---|

| Dimensional Tolerance | ±0.0004″ (10 µm) standard | ISO 2768-mK / Custom Drawings | Ensures fit/function in tight-clearance assemblies |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin) | ISO 4287 / ASME B46.1 | Critical for sealing, fatigue life, biocompatibility |

| Geometric Tolerancing (GD&T) | Full compliance to ISO 1101/ASME Y14.5 | CMM (0.0001″ / 2.5 µm accuracy) | Guarantees form, orientation, location integrity |

| Material Certification | Full traceability to mill certs | ASTM, AMS, EN standards | Validates mechanical properties for critical loads |

| Non-Destructive Testing | Fluorescent Penetrant, X-Ray (on req) | ASTM E1417 / MIL-STD-2132 | Ensures internal/external defect freedom |

This disciplined approach ensures that every component leaving our facility meets not just the drawing, but the unspoken requirement of absolute functional certainty. Precision machining, executed at this level, is the silent guarantor of system performance in the world’s most demanding environments. At Wuxi Lead, we engineer certainty into every micron.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision CNC Machining

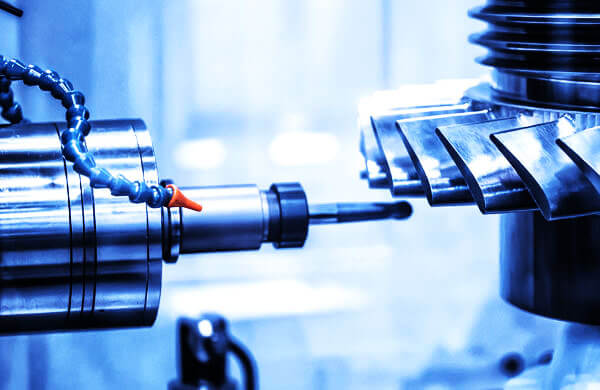

At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to meet the most stringent demands of high-precision manufacturing. Specializing in CNC precision machined components, we leverage state-of-the-art 5-axis CNC machining centers to deliver complex geometries with exceptional accuracy and surface integrity. Our multi-axis platforms enable simultaneous movement across five axes, allowing for intricate contouring, reduced setup times, and superior part consistency. This capability is particularly critical for industries such as aerospace, medical devices, and advanced automation, where component complexity and reliability are non-negotiable.

Our machining fleet comprises advanced equipment from leading global manufacturers, ensuring thermal stability, high-speed spindle performance, and dynamic tool path control. These systems are integrated with intelligent tool monitoring and automated pallet changers, supporting continuous, lights-out production for improved throughput and delivery reliability. Materials ranging from aluminum alloys and titanium to stainless steel, Inconel, and engineering plastics are processed with optimized cutting strategies tailored to each application.

Quality assurance is embedded at every stage of production. All critical dimensions and geometric features are verified using Coordinate Measuring Machines (CMM) with full 3D measurement capability. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, ensuring traceability and compliance with ISO 17025 requirements. In addition to first-article inspection reports (FAIR), we provide comprehensive PPAP documentation and SPC data upon request, supporting customers in regulated sectors.

We maintain strict environmental controls in our inspection lab to minimize thermal drift, ensuring micron-level measurement repeatability. Real-time data from the shop floor is synchronized with our quality management system, enabling rapid feedback loops and continuous process improvement.

The following table outlines our standard and advanced tolerance capabilities across key machining parameters:

| Feature Type | Standard Tolerance | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.01 mm | ±0.003 mm | Air Gauges, CMM |

| Positional Tolerance | ±0.02 mm | ±0.008 mm | CMM, Optical Comparator |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm (polished) | Surface Roughness Tester |

| Flatness | 0.02 mm | 0.005 mm | CMM, Precision Blocks |

| Angular Features | ±0.05° | ±0.01° | CMM, Sine Plates |

These capabilities are supported by full digital workflow integration, from CAD/CAM programming to final inspection reporting. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize part geometry, reduce costs, and accelerate time to market. With a focus on precision, repeatability, and technical agility, Wuxi Lead Precision Machinery delivers CNC machined components that meet the highest standards of performance and reliability.

Material & Finish Options

Material Selection for Precision CNC Machined Components

Selecting the optimal material is foundational to achieving performance, durability, and cost efficiency in precision CNC machined components. At Wuxi Lead Precision Machinery, we prioritize material properties that align with your application’s mechanical demands, environmental exposure, and regulatory requirements. Below, we detail key considerations for aluminum, steel, and titanium alloys, alongside critical finishing processes like anodizing.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and thermal conductivity. These grades machine efficiently with high-speed CNC processes, minimizing tool wear and cycle times. Aluminum’s natural corrosion resistance is significantly enhanced through anodizing, which creates a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing offers standard corrosion and wear resistance, while Type III (hard coat) anodizing provides superior surface hardness for high-abrasion environments. We recommend aluminum for weight-sensitive applications requiring rapid prototyping and complex geometries.

Steel alloys, including 4140, 4340, and 17-4 PH stainless, deliver unmatched tensile strength and fatigue resistance for heavy-duty industrial and defense components. Low-carbon steels like 1018 offer excellent machinability for structural parts, whereas tool steels (e.g., A2, D2) excel in high-wear tooling applications. Stainless variants provide critical corrosion resistance in medical and marine settings. Steel’s higher density necessitates robust CNC tooling and slower feed rates, but our multi-axis machining centers optimize parameters to maintain tight tolerances. Post-machining heat treatments (e.g., quenching, tempering) are often essential to achieve specified mechanical properties.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are indispensable for extreme environments demanding high strength, low weight, and immunity to corrosion—such as aerospace actuators and biomedical implants. Titanium’s low thermal conductivity and chemical reactivity pose machining challenges, including built-up edge and heat concentration. We deploy specialized tool geometries, rigid setups, and controlled coolant strategies to prevent material galling and ensure surface integrity. While costly, titanium’s lifecycle value justifies its use where failure is not an option.

Anodizing remains the premier finish for aluminum components, but material choice directly impacts its effectiveness. Porous anodized layers absorb dyes for identification or aesthetics, while sealing in hot water or nickel acetate maximizes corrosion protection. For steel, alternatives like zinc plating or passivation are standard; titanium typically requires bead blasting or chemical etching for adhesion in subsequent coatings.

Key Material Properties Comparison

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Common Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (70) | Brackets, Housings, Drones |

| Steel 4140 | 7.85 | 655 | Good (65) | Shafts, Gears, Tooling |

| Stainless 304 | 8.0 | 505 | Moderate (45) | Medical Instruments, Valves |

| Titanium Ti-6Al-4V | 4.43 | 900 | Fair (20) | Aircraft Frames, Implants |

Material selection directly influences manufacturability, cost, and end-product reliability. At Wuxi Lead, our engineering team collaborates with clients to evaluate operational stresses, regulatory standards, and total cost of ownership—ensuring your components perform flawlessly in service. Leverage our decades of CNC expertise to transform material potential into precision reality.

Manufacturing Process & QC

From Design to Delivery: The Precision CNC Machining Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, our production process for CNC precision machined components follows a rigorous, integrated workflow designed to ensure zero defects and maximum performance. Rooted in engineering excellence and advanced manufacturing technology, our approach spans three core phases: Design, Prototyping, and Mass Production. Each stage is optimized for precision, repeatability, and compliance with the highest international standards.

The process begins with Design, where our engineering team collaborates closely with clients to translate technical specifications into manufacturable solutions. Utilizing advanced CAD/CAM software, we develop 3D models and conduct comprehensive design validation, including tolerance analysis, material selection, and manufacturability review. This ensures that every component meets functional requirements while minimizing production risk. All designs are subject to internal DFM (Design for Manufacturability) checks to eliminate potential issues before machining begins.

Next is Prototyping, a critical step in verifying design integrity. We produce functional prototypes using the same CNC equipment and materials intended for full-scale production. This ensures accurate representation of final part performance. Prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy, fit, and function are validated against the original specifications. Any deviations are corrected through iterative refinement, with full traceability and documentation. Client approval is obtained before advancing to mass production.

Mass Production is executed under a fully controlled environment, leveraging high-speed CNC machining centers with automated tool management and real-time process monitoring. Our facility operates under ISO 9001-certified quality management systems, with in-process inspections at defined intervals to ensure consistency. Statistical Process Control (SPC) is applied to monitor critical dimensions, while First Article Inspection Reports (FAIR) and Production Part Approval Process (PPAP) documentation are provided upon request. Every batch is traceable by lot number, material certification, and inspection data.

To support high-precision outcomes, our equipment and process capabilities are maintained at industry-leading levels. Key specifications include:

| Parameter | Capability |

|---|---|

| Machining Tolerance | ±0.001 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Work Envelope | 1200 x 800 x 650 mm (5-axis) |

| Materials | Aluminum, Stainless Steel, Titanium, Inconel, Plastics |

| Equipment Types | 3-axis, 4-axis, 5-axis CNC Machining Centers, CNC Lathes |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), PPAP, FAIR, SPC |

At Wuxi Lead Precision Machinery, we treat zero defects not as an aspiration but as a standard. Through disciplined process control, advanced metrology, and deep technical expertise, we deliver CNC precision machined components that perform reliably in aerospace, medical, semiconductor, and high-end industrial applications.

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership

In the demanding landscape of high-precision component production, selecting a machining partner transcends basic capability—it requires a strategic alliance grounded in engineering excellence and unwavering reliability. Wuxi Lead Precision Machinery delivers this critical advantage through decades of specialized expertise in CNC-machined components for aerospace, medical, semiconductor, and advanced industrial sectors. We understand that your success hinges on components meeting exacting tolerances, stringent material specifications, and flawless repeatability—every time. Our commitment extends beyond machining; we integrate deeply with your engineering team to solve complex challenges, reduce time-to-market, and mitigate production risks from prototype through volume manufacturing.

Our technical infrastructure ensures uncompromised precision across your most demanding applications. The table below details our core capabilities, reflecting the rigor embedded in every process we execute.

| Parameter | Specification |

|---|---|

| Machining Tolerances | ±0.0001″ (2.5 µm) standard; sub-micron repeatability |

| Axis Capabilities | 3-axis to 5-axis simultaneous milling/turning |

| Material Expertise | Titanium, Inconel, PEEK, aluminum alloys, stainless steels, engineered plastics |

| Surface Finish | As low as Ra 0.4 µm (16 µin) |

| Quality Certifications | ISO 9001:2015, AS9100D, IATF 16949 |

| Max Work Envelope | 1200 x 800 x 600 mm (47″ x 31.5″ x 23.6″) |

| Lead Time Optimization | Rapid prototyping to high-volume production with JIT delivery |

Partnering with Lead Precision means accessing a co-engineering partnership where our technical team collaborates with yours from initial design review through final inspection. We deploy advanced metrology—including CMM, optical comparators, and surface roughness testers—to validate conformance against your most rigorous standards. Our closed-loop process control system ensures dimensional stability across batches, eliminating costly rework and supply chain disruptions. For mission-critical components, this level of precision isn’t optional; it’s the foundation of your product’s performance and safety.

The cost of precision failure—scrap, delays, or compromised end-product integrity—far outweighs the value of a truly capable partner. We eliminate this risk through proactive communication, transparent process documentation, and engineering resources dedicated to your project’s success. Whether you require single-source complex assemblies or high-mix/low-volume production, our facility in Wuxi operates under globally recognized quality frameworks to guarantee consistency for international supply chains.

Initiate a precision advantage for your next project. Contact our engineering sales team directly at [email protected] to discuss technical requirements, request a capability review, or schedule a virtual facility audit. Specify your component’s critical features, materials, and volume needs in your inquiry. Our team will respond within 24 business hours with a tailored manufacturing strategy and timeline. Trust Wuxi Lead Precision Machinery to transform your design intent into flawlessly executed reality—where precision is non-negotiable.

Contact Lead Precision today: [email protected]

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.