Technical Contents

Engineering Guide: Injection Molding Maine

Engineering Insight: The Critical Role of Precision in Injection Molding

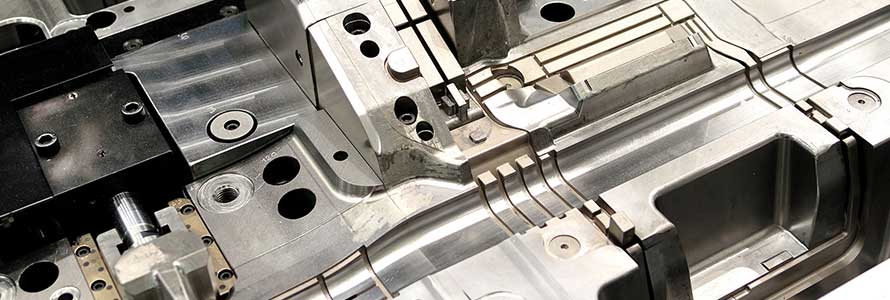

In the field of custom metal manufacturing, injection molding demands an uncompromising level of precision to ensure repeatable quality, structural integrity, and dimensional accuracy. This is especially critical in high-performance industries such as aerospace, defense, and medical device manufacturing—sectors where Wuxi Lead Precision Machinery has established a proven track record through projects tied to Olympic-standard equipment and military-grade components. The success of an injection molding operation hinges not only on material selection and mold design but also on the precision of the supporting metal components that form the backbone of the molding system.

At the core of every reliable injection molding process is a robust, dimensionally stable mold base, guide pins, ejector systems, and cavity inserts—all of which must be manufactured to exacting tolerances. Even micron-level deviations can lead to flash, part warpage, or premature tool wear, resulting in costly downtime and rejected batches. Wuxi Lead Precision Machinery leverages advanced CNC machining, wire EDM, and precision grinding technologies to produce custom metal components with tolerances as tight as ±0.002 mm. This level of accuracy ensures seamless integration into injection molding systems, enabling consistent cycle times and superior part quality.

Our experience in delivering components for Olympic-caliber manufacturing systems underscores our commitment to performance under extreme conditions. These systems required not only precision but also durability and thermal stability—qualities that are equally vital in industrial injection molding applications. Similarly, our work with military subcontractors has demanded compliance with rigorous quality standards, including full traceability, strict documentation, and adherence to ISO and AS9100 protocols. These disciplines are directly transferable to clients in the injection molding sector who require reliable, long-life tooling solutions.

Precision is not a single-step achievement but a continuous process embedded in design, material selection, machining, and quality control. At Wuxi Lead, we utilize 3D metrology, CMM inspection, and laser alignment systems to verify each component against original engineering specifications. This end-to-end quality assurance framework minimizes variability and maximizes tool longevity.

Below are key specifications that define our precision manufacturing capabilities for injection molding applications:

| Specification | Performance Value |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.05–0.8 μm |

| Material Compatibility | Tool Steel (H13, S136), Stainless Steel, Aluminum, Titanium |

| Maximum Part Weight | 5,000 kg |

| Machining Accuracy (CMM Verified) | ≤ 0.003 mm over 1,000 mm |

| Lead Time (Average) | 15–25 days, depending on complexity |

Wuxi Lead Precision Machinery brings world-class precision to the foundation of injection molding systems. Our engineering expertise, combined with a disciplined approach to quality, ensures that every metal component we produce supports the highest standards of manufacturing excellence.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Injection Molding Applications

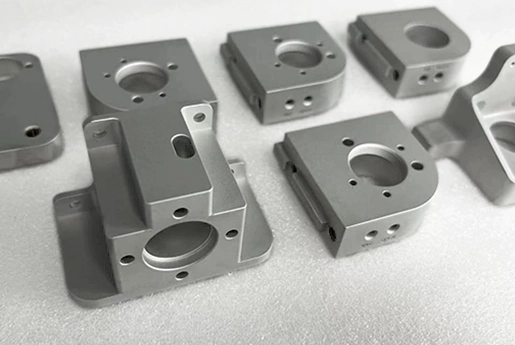

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered specifically for the demanding requirements of the injection molding industry, including key players in Maine. Our core competency lies in producing high-integrity mold bases, inserts, cavities, cores, and critical support components where dimensional accuracy, surface finish, and material performance are non-negotiable. Central to this capability is our investment in state-of-the-art 5-axis CNC machining centers. These systems provide the geometric complexity and simultaneous multi-directional toolpath control essential for creating the intricate contours, undercuts, and tight-tolerance features found in modern, high-cavitation molds. This technology significantly reduces the need for multiple setups, minimizing cumulative error and ensuring superior part consistency critical for maintaining tight shot-to-shot repeatability in production environments.

Precision is systematically embedded throughout our manufacturing process. We utilize advanced CAD/CAM software for optimized toolpath generation and rigorous simulation, ensuring efficient material removal and preventing collisions even on the most complex geometries. Our machining protocols are strictly controlled, with environmental monitoring to mitigate thermal drift and meticulous tool management systems guaranteeing consistent cutting performance. Crucially, dimensional integrity is not assumed but rigorously verified. Every critical component undergoes comprehensive Coordinate Measuring Machine (CMM) inspection. Our Zeiss and Hexagon CMMs provide metrology-grade verification against the original CAD model, capturing full 3D geometry data. This generates detailed inspection reports with GD&T analysis, offering complete traceability and objective proof of conformance to the most stringent specifications demanded by high-volume injection molding operations.

Our commitment to quality is certified under ISO 9001:2015, with documented procedures governing every stage from material certification through final inspection. We source premium mold steels (including P20, H13, S136, and specialized alloys) with full material test reports, ensuring optimal thermal stability and wear resistance for extended mold life. The combination of 5-axis precision, controlled processes, and rigorous CMM validation delivers components that directly contribute to reduced mold tryout time, minimized production scrap rates, and extended operational lifespan for our injection molding partners.

The following table details our standard achievable tolerances for machined components, reflecting the capability of our integrated 5-axis and CMM systems:

| Feature Type | Standard Tolerance | Typical Surface Finish (Ra) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | 0.8 µm (32 µin) | Up to 300 mm; tighter tolerances achievable with special process control |

| Geometric (GD&T) | ±0.010 mm (±0.0004″) | 0.4 µm (16 µin) | Includes flatness, parallelism, perpendicularity |

| Angular Dimensions | ±0.005° | 0.8 µm (32 µin) | Critical for alignment surfaces |

| Bore Diameters | H7 / h6 | 0.4 µm (16 µin) | Precision bores for pins and bushings |

| Profile Complexity | ±0.010 mm (±0.0004″) | 0.8 µm (32 µin) | Verified via full 3D CMM scan |

Partnering with Wuxi Lead provides Maine’s injection molding sector with access to offshore precision that meets or exceeds domestic standards. We bridge the gap between advanced Chinese manufacturing capability and the exacting quality expectations of North American production, ensuring your metal components perform flawlessly from the first shot to the millionth cycle.

Material & Finish Options

Material selection is a foundational decision in custom metal manufacturing, particularly for high-performance applications in injection molding. The choice of material directly impacts tool longevity, dimensional stability, thermal performance, and overall production efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-engineered metal components tailored to the rigorous demands of injection molding systems. Our expertise in aluminum, steel, and titanium enables us to support clients in Maine and beyond with optimized solutions that balance performance, cost, and manufacturability.

Aluminum is widely favored in injection mold manufacturing for its excellent thermal conductivity and lightweight properties. It allows for faster cooling cycles, reducing overall cycle times and increasing productivity. Its machinability also makes it ideal for prototyping and low-to-medium volume production runs. However, aluminum’s lower hardness compared to steel limits its use in high-wear applications. For molds requiring frequent use or abrasive materials, steel remains the preferred choice. Hardened tool steels such as P20, H13, and S136 offer superior wear resistance, toughness, and dimensional stability under thermal cycling. These properties make steel indispensable for high-volume production molds, especially when molding engineering-grade resins.

Titanium, while less common, offers a unique combination of high strength-to-density ratio, exceptional corrosion resistance, and thermal stability. It is particularly advantageous in specialized applications where weight reduction and resistance to aggressive environments are critical. Though more costly and challenging to machine, titanium’s longevity in corrosive or high-temperature molding environments can justify its use in select high-end tooling systems.

Surface finishing further enhances the performance and lifespan of injection molds. Anodizing is one of the most effective surface treatments for aluminum components. It creates a durable, corrosion-resistant oxide layer that improves wear resistance and allows for color coding or aesthetic customization. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with Type III providing greater thickness and hardness for molds subject to mechanical wear. For steel molds, alternatives such as nitriding, chrome plating, or PVD coatings are typically used, but anodizing remains exclusive to aluminum.

Below is a comparative overview of key material properties relevant to injection molding applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Applications in Molding |

|---|---|---|---|---|

| Aluminum (6061-T6) | 2.7 | 310 | 167 | Prototype molds, low-volume production, cooling inserts |

| Steel (P20) | 7.8 | 980 | 36 | High-volume molds, cavity and core blocks |

| Steel (H13) | 7.8 | 1,560 | 34 | Hot-runner systems, high-temperature resins |

| Titanium (Grade 5) | 4.5 | 1,000 | 7.2 | Corrosion-resistant inserts, aerospace tooling |

Selecting the right material and finish requires a thorough understanding of the molding process, resin type, production volume, and environmental conditions. Wuxi Lead Precision Machinery combines advanced CNC manufacturing with deep metallurgical expertise to deliver custom metal solutions that meet the exacting standards of modern injection molding operations.

Manufacturing Process & QC

Precision Metal Injection Molding: The Zero Defects Production Process

At Wuxi Lead Precision Machinery, our custom metal injection molding process for demanding sectors like aerospace and medical device manufacturing in Maine is engineered for absolute reliability. We achieve Zero Defects not through aspiration, but through a rigorously controlled, integrated workflow spanning design, prototyping, and mass production. This systematic approach eliminates costly iterations and ensures first-article perfection for your critical components.

The process begins with collaborative design engineering. Our Maine-based technical team partners with your engineers to conduct thorough Design for Manufacturability (DFM) analysis. We scrutinize part geometry, material selection (including specialty alloys like 17-4 PH stainless steel and Inconel), and tolerances early, leveraging advanced simulation software to predict flow, density, and potential defects. This phase is critical for metal injection molding, where nuances in wall thickness or gate location significantly impact final part integrity. We identify and resolve issues virtually, ensuring the design is optimized for both performance and flawless manufacturability before any metal is cut.

Prototyping transitions the validated design into physical reality under production-intent conditions. Using CNC-machined prototype molds crafted in our Wuxi facility to the same stringent standards as production tools, we produce functional parts for your dimensional, mechanical, and metallurgical validation. This stage is not merely a form check; it is a critical process window validation. We measure sintered density, microstructure, and critical dimensions against your specifications, fine-tuning debinding and sintering profiles. Rapid iteration based on tangible data ensures the production process parameters are locked and proven, mitigating risk before scale-up.

Mass production executes the perfected process with uncompromising discipline. Our fully automated lines integrate real-time monitoring of every critical parameter: feedstock viscosity, injection pressure profiles, temperature gradients during debinding, and sintering atmosphere control. Statistical Process Control (SPC) is mandatory, with 100% in-process dimensional verification on key features using calibrated CMMs and optical comparators. Final inspection employs metallurgical testing (including microhardness and porosity analysis per ASTM standards) alongside dimensional certification. Zero Defects is sustained through this closed-loop system, where data from every cycle feeds continuous refinement.

The table below highlights how our integrated process delivers superior outcomes compared to conventional approaches:

| Parameter | Typical Industry Standard | Wuxi Lead Precision Standard | Key Benefit |

|---|---|---|---|

| Dimensional Tolerance | ±0.025mm | ±0.005mm | Ensures seamless assembly |

| Surface Finish (Ra) | 1.6 µm | 0.8 µm | Meets critical cosmetic specs |

| Material Density | 95-97% Theoretical | ≥99.5% Theoretical | Maximizes mechanical properties |

| First-Time Yield | 85-90% | ≥99.8% | Eliminates scrap & rework cost |

| Cycle Time Consistency | ±5% Variation | ±1% Variation | Guarantees on-time delivery |

This seamless transition from validated design through rigorously proven prototyping to disciplined mass production forms the backbone of our Zero Defects commitment. For Maine manufacturers requiring mission-critical metal components, Wuxi Lead Precision Machinery delivers not just parts, but guaranteed performance and supply chain certainty. Contact our engineering team to integrate this proven process into your next project.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Molding Excellence in Maine and Beyond

When precision, reliability, and engineering excellence are non-negotiable, global manufacturers turn to Wuxi Lead Precision Machinery. As a leading provider of custom metal manufacturing solutions, we specialize in delivering high-performance components engineered specifically for the injection molding industry. Our advanced capabilities in CNC machining, tooling fabrication, and precision metalwork enable us to support injection molding operations across Maine and throughout North America with unmatched quality and responsiveness.

At Lead Precision, we understand the demanding requirements of modern injection molding systems—where tolerances are measured in microns and downtime is costly. Our engineering team collaborates directly with clients to design and produce critical components such as mold bases, ejector systems, core pins, and hot runner plates, all manufactured to meet the highest international standards. Whether you operate a high-volume production facility in Portland, Maine, or manage a specialized molding operation in the Northeast, our solutions are built to enhance your efficiency, reduce cycle times, and extend tool life.

Our facility in Wuxi, China, spans over 10,000 square meters and is equipped with state-of-the-art CNC machining centers, wire EDM systems, surface grinders, and CMM inspection equipment. This advanced infrastructure, combined with rigorous quality control protocols, ensures every part we produce meets exacting specifications for flatness, hardness, and dimensional accuracy. We work with a wide range of materials, including P20, H13, S136, and hardened tool steels, ensuring compatibility with your molding applications and resin types.

We pride ourselves on seamless global collaboration. Despite being based in China, we operate on a customer-first model with dedicated project managers who provide real-time updates, detailed inspection reports, and logistics coordination to ensure on-time delivery to Maine and across the U.S. Our clients benefit from reduced lead times, competitive pricing, and technical support that bridges time zones and industries.

Below are key technical specifications that define our manufacturing capabilities:

| Specification | Detail |

|---|---|

| Maximum Machining Size | 2000 mm × 1200 mm × 1000 mm |

| Tolerance Range | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 µm |

| Materials Processed | P20, H13, S136, 718H, Stainless Steel, Aluminum, Brass |

| Heat Treatment | Up to 58 HRC, Vacuum Hardened |

| Quality Standards | ISO 9001:2015 Certified, Full First Article Inspection (FAI) |

| Lead Time | 15–25 days (average, depending on complexity) |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic advantage in performance, cost-efficiency, and technical support. We are committed to becoming an extension of your engineering team—delivering precision components that keep your injection molding operations running at peak performance.

Contact us today at [email protected] to discuss your next project. Let Lead Precision be your trusted partner in manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.