Technical Contents

Engineering Guide: Custom Sheet Metal Punch

Engineering Insight Precision in Custom Sheet Metal Punching

Precision in custom sheet metal punching transcends mere dimensional accuracy; it is the foundational requirement for functional integrity, assembly efficiency, and long-term product reliability. In high-stakes applications across aerospace, defense, and advanced medical equipment, deviations measured in microns can cascade into catastrophic field failures or costly production line stoppages. The punch process inherently induces stresses into the material. Without exceptional control over force application, tool alignment, and positional repeatability, micro-burrs, dimensional drift, and material distortion become inevitable. These flaws compromise structural performance, hinder secondary operations like welding or coating, and ultimately erode the total cost of ownership despite seemingly competitive initial pricing. True precision engineering mitigates these risks at the source, ensuring every pierced hole, formed feature, and cut edge meets the exact specification without downstream correction.

Wuxi Lead Precision Machinery integrates precision into the core of our punching methodology. Our advanced CNC turret and hydraulic punch presses operate within rigorously maintained environmental controls, minimizing thermal drift and vibration. Critical to this capability is our proprietary tool management system and real-time process monitoring, which dynamically compensates for tool wear and material variation during extended production runs. This systematic approach delivers consistent results far exceeding standard industry benchmarks, as quantified below.

| Parameter | Typical Industry Standard | Lead Precision Capability | Impact on Final Product |

|---|---|---|---|

| Positional Repeatability | ±0.05 mm | ±0.01 mm | Ensures perfect component fitment; eliminates assembly shimming |

| Hole Diameter Tolerance | ±0.08 mm | ±0.03 mm | Guarantees precise fastener engagement; critical for pressure seals |

| Edge Burr Height | < 0.10 mm | < 0.03 mm | Eliminates secondary deburring; essential for fluid dynamics/safety |

| Tool Change Accuracy | ±0.03 mm | ±0.005 mm | Maintains feature consistency across multi-tool operations |

| Material Flatness (post-punch) | ±0.20 mm/m² | ±0.05 mm/m² | Meets stringent surface requirements for welding/painting |

This level of performance is not theoretical. It is proven daily through our execution of mission-critical components. We supplied precision-punched structural elements for Beijing Winter Olympic venue systems, where thermal cycling and seismic loads demanded absolute dimensional stability. Similarly, our partnership with Tier-1 defense contractors involves fabricating shielded enclosures for sensitive electronics, where EMI leakage tolerances necessitate micron-level hole pattern accuracy and edge quality unachievable through standard processes. These projects validate our engineering protocols under the most demanding scrutiny.

Achieving such precision requires more than advanced machinery; it demands an institutional culture focused on metrology and continuous process refinement. When specifying custom sheet metal punching, prioritize partners who treat precision as a non-negotiable engineering outcome, not just a marketing claim. Audit their capability to deliver documented, repeatable results within your specific tolerance envelope – the integrity of your final assembly depends on it. Wuxi Lead Precision Machinery stands ready to meet and exceed your most exacting requirements.

Precision Specs & Tolerances

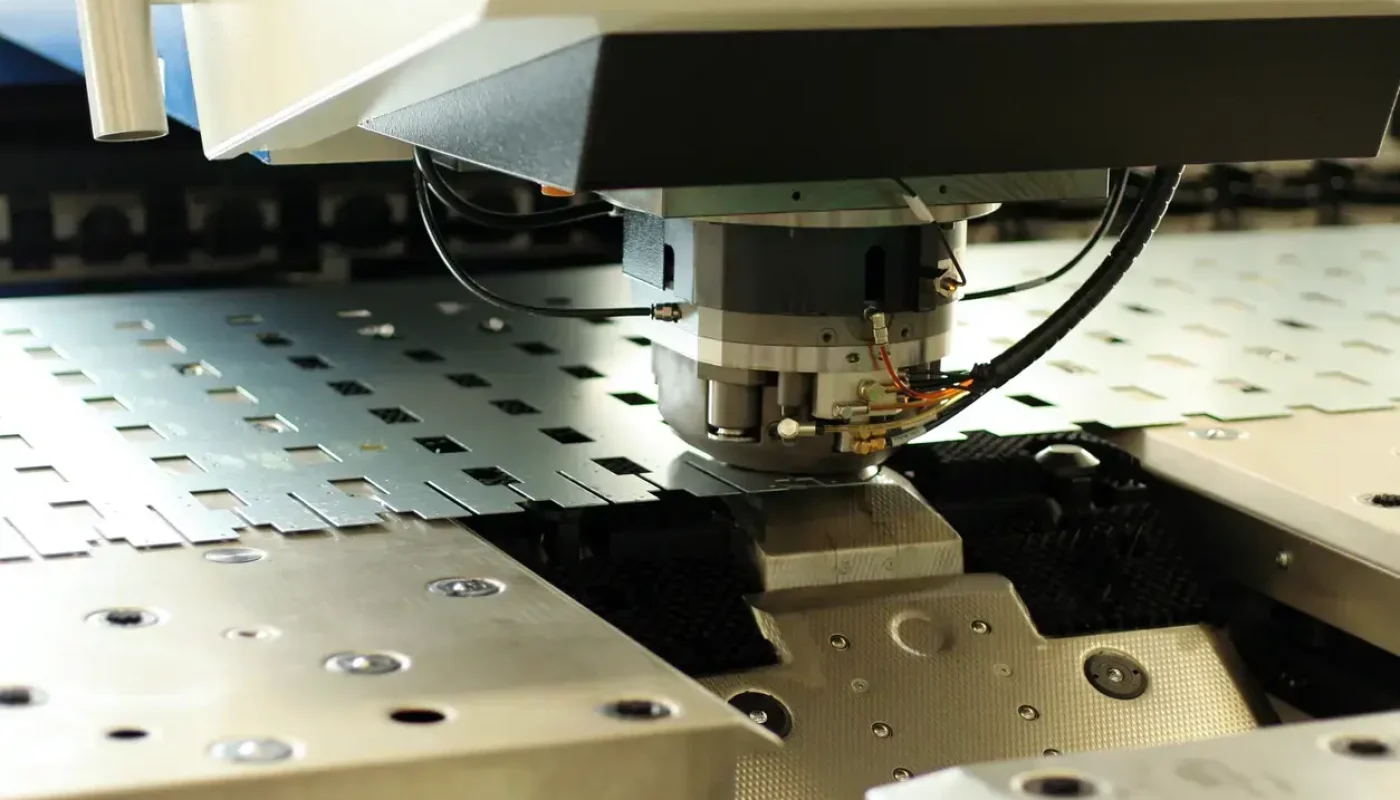

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom sheet metal punching, engineered to meet the exacting demands of high-performance industries such as aerospace, medical, automotive, and industrial equipment. Our facility is equipped with state-of-the-art 5-axis CNC punching and forming centers, enabling complex geometries, precision hole patterns, and multi-feature integration in a single setup. This level of automation ensures minimal handling, reduced cycle times, and unparalleled repeatability across production runs.

Our 5-axis CNC systems provide full rotational and linear control, allowing for compound angle punching, beveling, notching, and contour forming directly on sheet metal components. This eliminates the need for secondary operations in many cases, streamlining production and improving overall part accuracy. The integration of high-speed turret technology with multi-axis motion enables rapid tool changes and dynamic repositioning, supporting both low-volume prototypes and high-volume production with equal efficiency.

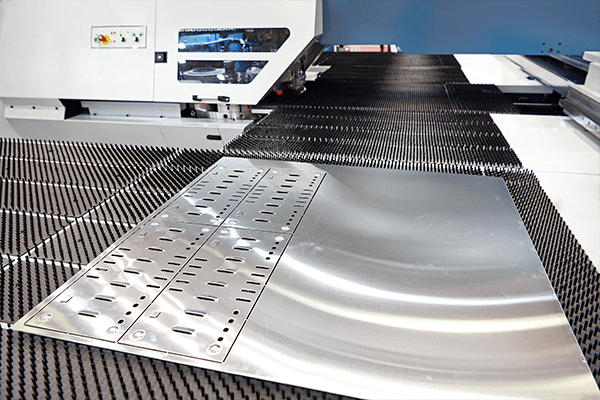

Material versatility is a cornerstone of our technical offering. We process a wide range of sheet metals, including cold-rolled steel, stainless steel, aluminum, copper, and brass, in thicknesses from 0.5 mm to 6.0 mm. Our machines support both standard and custom tooling, allowing for unique feature creation such as louvers, embossments, countersinks, and multi-hit perforation patterns. Advanced nesting software optimizes material utilization, reducing waste and lowering cost per part without compromising quality.

Quality assurance is embedded into every stage of production. Each custom sheet metal component undergoes rigorous inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), ensuring dimensional compliance with tight tolerances. Our CMM system provides full 3D verification of critical features, including hole positioning, form heights, angular accuracy, and edge alignment. All inspection data is documented and traceable, supporting compliance with ISO 9001 standards and customer-specific quality requirements.

The combination of 5-axis precision, intelligent automation, and metrology-grade inspection enables Wuxi Lead to deliver custom sheet metal parts with exceptional consistency and technical fidelity. Whether producing intricate enclosures, structural brackets, or high-tolerance panels, our capabilities are designed to meet the most demanding engineering specifications.

Standard Tolerances for Custom Sheet Metal Punching

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Hole Diameter | ±0.1 mm | For diameters ≤ 6 mm; ±0.15 mm for larger holes |

| Hole Positioning | ±0.15 mm | Relative to datum; tighter tolerances achievable with CMM verification |

| Edge to Feature Distance | ±0.2 mm | Applies to notches, tabs, and embossments |

| Part Overall Dimension | ±0.3 mm | For parts up to 1000 mm in length |

| Bend Angle | ±1° | For standard tooling; ±0.5° with precision forming |

| Form Height | ±0.2 mm | For louvers, ribs, and embossed features |

| Angular Features (5-axis) | ±0.5° | For compound angle punching and beveling |

All tolerances are achievable on materials up to 6.0 mm thickness and are validated through first-article inspection and in-process CMM checks.

Material & Finish Options

Material Selection for Precision Sheet Metal Punching

Selecting the optimal material is foundational to achieving cost efficiency, dimensional accuracy, and long-term performance in custom sheet metal punching. At Wuxi Lead Precision Machinery, we prioritize materials that balance machinability, structural demands, and environmental resilience. Aluminum, steel, and titanium dominate high-end applications, each offering distinct advantages and punching considerations. Understanding these properties ensures seamless integration with CNC punching workflows while minimizing tool wear and secondary operations.

Aluminum alloys, particularly 5052 and 6061, are favored for lightweight enclosures, aerospace brackets, and electronics housings. Their excellent formability and corrosion resistance reduce punch force requirements by 40% compared to steel, enabling intricate geometries without cracking. However, aluminum’s softness necessitates sharp tooling and controlled feed rates to prevent burring. For marine or outdoor applications, we recommend pairing aluminum with anodizing to enhance surface hardness and chemical resistance.

Carbon steel (e.g., ASTM A36) and stainless steel (304, 316) deliver superior strength for structural components like chassis frames and industrial brackets. Steel’s higher shear strength demands robust tooling and precise tonnage calibration to avoid die deflection. Stainless variants introduce work-hardening challenges; we mitigate this through incremental punching strategies and cryogenic tool cooling. While steel requires post-punch treatments like powder coating, its affordability and weldability make it ideal for high-volume production where ultimate strength is critical.

Titanium Grade 2 and 5 excel in extreme environments—medical implants, defense systems, and chemical processing equipment. Despite exceptional strength-to-weight ratios and corrosion immunity, titanium generates intense heat during punching, accelerating tool wear. We deploy specialized cobalt-alloy punches with reduced clearance (4–6% of material thickness) and lower stroke speeds to maintain edge integrity. Titanium’s cost sensitivity necessitates meticulous nesting optimization, which our CNC systems achieve through AI-driven path planning.

Anodizing serves as the premier finish for aluminum components, transforming the surface into a durable, non-conductive oxide layer. Hard anodizing (Type III) achieves 50–70 μm thickness with 600–800 HV hardness, critical for wear-prone parts. Crucially, anodizing must follow punching; attempting it pre-punch risks electrolyte entrapment in micro-cracks. For steel, we advise zinc-nickel plating as an alternative, while titanium typically requires chemical passivation alone.

Material properties directly dictate punching parameters. The table below summarizes key specifications for common alloys:

| Material | Typical Thickness Range | Tensile Strength (MPa) | Punch Force (kN/mm) | Critical Punching Consideration |

|---|---|---|---|---|

| Aluminum 5052 | 0.5–6.0 mm | 190–225 | 0.35 | Burr control via sharp tool edges |

| Steel ASTM A36 | 0.8–12.7 mm | 400–550 | 0.85 | Work-hardening management |

| Stainless 304 | 0.5–10.0 mm | 515–690 | 0.92 | Cryogenic tool cooling recommended |

| Titanium Grade 5 | 0.8–8.0 mm | 860–900 | 1.10 | Reduced clearance; low stroke speed |

Material choice is not merely a technical decision—it directly impacts lead times, tooling costs, and end-product reliability. Wuxi Lead Precision Machinery leverages decades of sheet metal expertise to guide clients through this selection, ensuring your design intent translates flawlessly from CAD to finished component. Contact our engineering team for a tailored material analysis based on your application’s thermal, mechanical, and regulatory demands.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, the custom sheet metal punch production process begins with meticulous design engineering. Our team collaborates directly with clients to translate conceptual requirements into manufacturable designs using advanced CAD software such as SolidWorks, AutoCAD, and Siemens NX. This phase emphasizes material selection, geometric feasibility, and compliance with industry standards such as ISO 2768 for general tolerances. Finite Element Analysis (FEA) is applied where necessary to simulate stress distribution and ensure structural integrity under operational loads. Design for Manufacturability (DFM) reviews are conducted to eliminate inefficiencies, reduce tooling complexity, and optimize nesting layouts for material utilization. Every design is validated through digital mockups and cross-functional review cycles to ensure alignment with functional, aesthetic, and assembly requirements before progressing to prototyping.

Prototyping: Validating Accuracy and Functionality

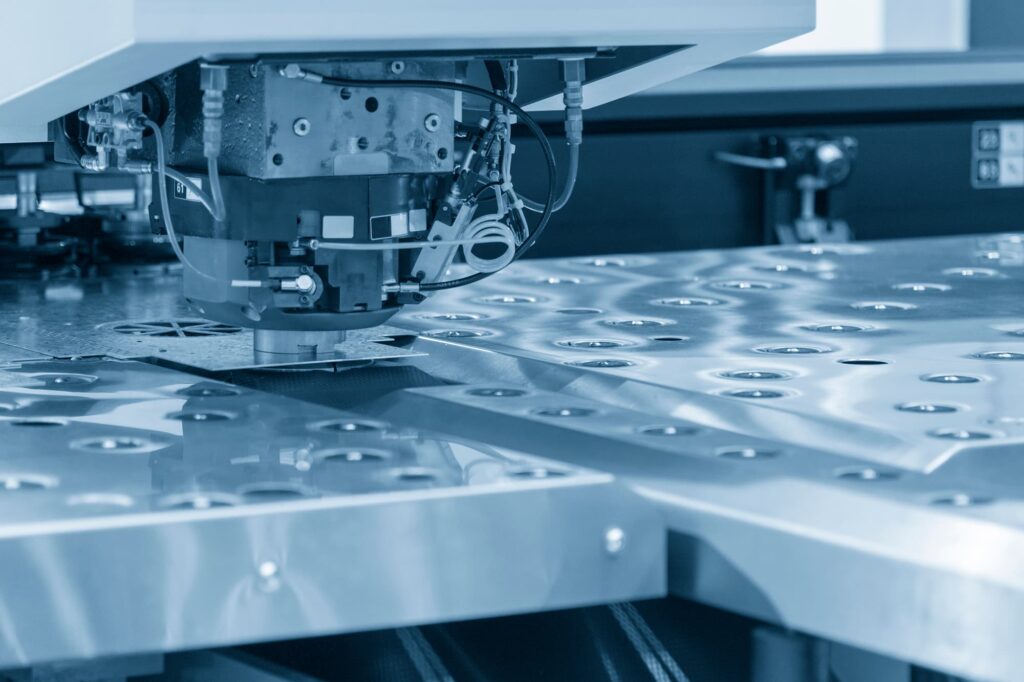

Once the design is finalized, we proceed to low-volume prototyping to verify form, fit, and function. Utilizing high-precision CNC turret punch presses from Amada and TRUMPF, we produce prototype parts with the same tooling and materials intended for mass production. This ensures that dimensional accuracy, edge quality, and hole tolerances are representative of the final output. Prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning to validate conformance to print specifications. Any deviations are traced back to the root cause—be it material springback, tool wear, or clamping distortion—and corrected in the digital model. Client feedback is integrated at this stage, allowing for iterative refinements without impacting production timelines. This closed-loop validation process ensures that only fully qualified designs advance to full-scale manufacturing.

Mass Production: Consistency at Scale with Zero Defects

Our mass production phase is engineered for repeatability, efficiency, and uncompromising quality. We deploy automated feeding systems, in-process gauging, and real-time monitoring via IoT-enabled machines to maintain tight control over every parameter. Each batch is produced under documented work instructions aligned with ISO 9001:2015 standards. Statistical Process Control (SPC) charts track key variables such as punch force, positional accuracy, and burr height to detect trends before defects occur. 100% visual inspection is performed on critical features, supported by automated vision systems where applicable. Final parts undergo first-article inspection (FAI) and batch-level sampling per ANSI/ASQ Z1.4. Our zero-defect philosophy is enforced through preventive maintenance schedules, operator certification programs, and traceability down to individual material heat lots.

Typical Production Specifications

| Parameter | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Hole Position) | ±0.1 mm |

| Minimum Hole Diameter | 1.0 mm (steel), 0.8 mm (aluminum) |

| Tooling Life | > 500,000 strokes (carbide dies) |

| Production Speed | Up to 600 hits per minute |

| Surface Finish | Ra ≤ 3.2 µm (as punched) |

| Supported Materials | Mild steel, stainless steel, aluminum, copper alloys |

Why Choose Wuxi Lead Precision

Elevate Your Production with Precision Sheet Metal Punching

In the competitive landscape of industrial manufacturing, selecting a sheet metal fabrication partner transcends simple procurement. It demands a strategic alliance grounded in engineering excellence, unwavering quality control, and responsive technical collaboration. Wuxi Lead Precision Machinery stands as your definitive partner for custom sheet metal punch solutions, engineered to meet the exacting demands of aerospace, medical device, and advanced electronics sectors. We understand that component integrity directly impacts your final product performance and market reputation. Our commitment extends beyond machinery supply; we integrate our deep process knowledge into your workflow, ensuring every punched feature meets micron-level tolerances and stringent material specifications from prototype through high-volume production.

Our advanced punching centers deliver exceptional versatility and repeatability. Capable of handling complex geometries in materials ranging from ultra-thin aluminum alloys to high-strength stainless steels, we eliminate secondary operations and accelerate time-to-market. The core of our capability lies in state-of-the-art turret punch presses, meticulously maintained and operated by certified technicians with decades of combined field experience. This technical foundation is complemented by our integrated quality management system, featuring real-time in-process inspection and comprehensive first-article reporting tailored to your engineering requirements.

Critical Punching Capabilities at a Glance

| Parameter | Specification Range |

|---|---|

| Material Thickness | 0.5 mm to 6.0 mm |

| Max Sheet Size | 2500 mm x 1250 mm |

| Positional Accuracy | ±0.05 mm |

| Tooling Capacity | 60-station automatic indexing |

| Material Compatibility | Steel, Stainless, Aluminum, Copper, Brass |

Partnering with Lead Precision means accessing more than equipment—it means leveraging our engineering team as an extension of your own. We conduct thorough design for manufacturability reviews during the quotation phase, identifying potential cost savings and yield improvements before metal touches tool. Our CNC programming specialists optimize nest patterns for minimal waste and maximum throughput, directly impacting your bottom line. When complex burr control, tight angular tolerances, or specialized forming sequences are required, our process engineers develop validated solutions, not just estimates. This proactive collaboration mitigates production risks and ensures seamless integration with your downstream assembly processes.

The true measure of a manufacturing partner is consistency under pressure. We maintain rigorous statistical process control across all punching operations, with documented traceability for every batch. Our ISO 9001-certified facility undergoes quarterly calibration audits by third-party metrology labs, guaranteeing measurement integrity. For projects demanding accelerated timelines, our dedicated project managers provide transparent communication and flexible scheduling without compromising quality benchmarks. This operational discipline translates to on-time delivery rates exceeding 98.5% for critical-path components.

Initiate your next high-precision sheet metal project with engineering certainty. Contact our technical sales team at Contact [email protected] to schedule a capability review. Include your engineering drawings or material specifications for a targeted assessment within 24 business hours. Let Wuxi Lead Precision Machinery transform your design intent into dimensionally perfect punched components, delivered with the reliability your production schedule demands. Your competitive advantage begins with a partner who treats your tolerances as non-negotiable.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.