Technical Contents

Engineering Guide: Teflon Machined Parts

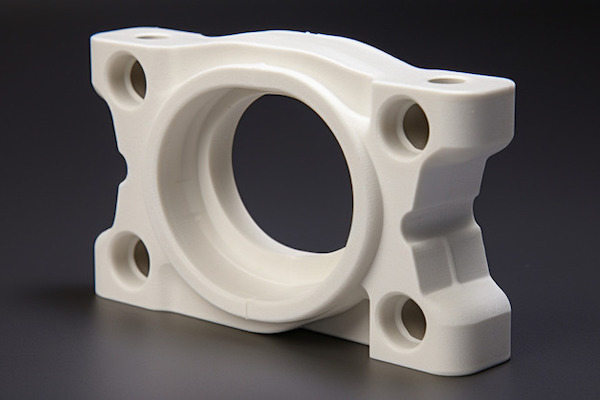

Engineering Insight: Precision Imperatives in Teflon Machined Parts

Teflon (PTFE) machining presents unique challenges that demand exceptional precision engineering far beyond standard polymers. Its low coefficient of friction, high thermal expansion coefficient, and susceptibility to deformation under conventional machining forces mean that tolerances achievable with metals or rigid plastics are often unattainable without specialized expertise. Minute vibrations or improper tool geometry induce chatter marks or dimensional drift, directly compromising critical sealing performance, chemical resistance, and longevity in demanding applications. At Wuxi Lead Precision Machinery, we recognize that success hinges on mastering these variables where others fail. Standard CNC protocols are insufficient; success requires purpose-built toolpaths, ultra-stable fixturing, and real-time thermal compensation strategies calibrated specifically for PTFE’s behavior.

Achieving micron-level tolerances in Teflon necessitates profound material science understanding integrated into every machining phase. Conventional high-speed steel tools cause excessive heat buildup, leading to melting or stringing. We exclusively utilize sharp, polished carbide tooling with optimized rake angles and controlled feed rates to shear cleanly without generating friction-induced softening. Crucially, our process accounts for PTFE’s significant thermal expansion (0.0002 in/in/°F) through adaptive in-process measurement and temperature-stabilized machining environments. This prevents post-machining dimensional shift when parts encounter operational temperatures – a failure point common with less rigorous suppliers. Our engineers develop custom support structures within the CNC program to counteract PTFE’s “cold flow” tendency, ensuring geometries remain true during and after cutting.

Wuxi Lead’s validation of these precision protocols extends to mission-critical sectors. We supplied dimensionally flawless Teflon seals for hydraulic systems in Beijing Olympic aquatic venue infrastructure, where failure would have caused catastrophic water leakage under constant pressure. Similarly, our classified defense contracts require PTFE components for aerospace actuators operating in extreme vacuum and thermal cycling conditions, demanding tolerances held to ±0.005mm. These projects prove our capability to deliver where dimensional stability directly impacts safety and system integrity.

The following table outlines key precision parameters essential for high-performance Teflon machined parts:

| Parameter | Critical Value Range | Industry Standard Risk if Uncontrolled |

|---|---|---|

| Dimensional Tolerance | ±0.005mm to ±0.025mm | Seal leakage, assembly failure |

| Surface Roughness (Ra) | 0.8 µm to 3.2 µm | Accelerated wear, compromised sealing |

| Thermal Expansion Comp. | 0.0002 in/in/°F (mandatory) | Post-machining distortion in service |

| Maximum Operating Temp | 260°C (500°F) | Material degradation, outgassing |

| Minimum Bend Radius | 3x material thickness | Cracking, loss of structural integrity |

Precision in Teflon machining is non-negotiable for applications in semiconductor manufacturing, pharmaceutical processing, or aerospace. At Wuxi Lead, our Olympic and military-grade execution ensures your PTFE components meet the exacting functional requirements of your most sensitive systems. We transform Teflon’s inherent challenges into reliable performance through process discipline that standard machine shops cannot replicate. Partner with us to eliminate field failures caused by inadequate machining tolerances. Your system’s integrity depends on it.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services tailored specifically for high-performance materials such as PTFE (Polytetrafluoroethylene), commonly known as Teflon. Our technical capabilities are engineered to meet the exacting demands of industries including semiconductor, aerospace, medical, and chemical processing, where dimensional accuracy, material integrity, and long-term reliability are non-negotiable.

At the core of our manufacturing strength is a fully integrated 5-axis CNC machining platform. These multi-axis systems enable us to produce complex Teflon components with intricate geometries in a single setup, minimizing cumulative tolerances and ensuring superior surface finish. The simultaneous movement across five axes allows for optimal tool positioning and access, which is particularly critical when machining soft, low-friction materials like Teflon that require precise control to prevent deformation or burring. Our CNC machines are operated by experienced engineers who apply material-specific cutting strategies, including optimized feed rates, tool paths, and specialized tooling, to maintain part stability and dimensional fidelity throughout the machining process.

Quality assurance is embedded into every stage of production. Each machined Teflon component undergoes rigorous inspection using a Zeiss Coordinate Measuring Machine (CMM), ensuring compliance with tight tolerance requirements and international standards. The CMM provides traceable, high-resolution 3D measurements, allowing us to verify geometric dimensions, form accuracy, and positional tolerances with micron-level precision. All inspection data is documented and available with shipment, supporting full traceability for regulated industries.

We maintain strict environmental and process controls to address the unique challenges of Teflon machining, such as thermal expansion and post-machining stress relaxation. Our facility follows ISO 9001-certified procedures, and all operators are trained in handling fluoropolymers to prevent contamination and ensure consistent batch-to-batch quality.

The following table outlines the standard technical specifications and achievable tolerances for our Teflon machined parts:

| Parameter | Specification |

|---|---|

| Machining Process | 5-Axis CNC Milling and Turning |

| Material Compatibility | PTFE, Expanded PTFE, Filled Teflon (e.g., glass-filled, carbon-filled) |

| Standard Tolerances | ±0.025 mm (±0.001″) |

| Precision Tolerances (Tight) | Up to ±0.005 mm (±0.0002″) |

| Surface Finish (Ra) | 0.8–3.2 µm (32–125 µin) |

| Feature Accuracy (GD&T) | Compliant with ASME Y14.5 and ISO 1101 |

| Maximum Work Envelope | 800 mm × 500 mm × 400 mm |

| Inspection Method | Zeiss CMM, Optical Comparators, Micrometers |

| Quality Certification | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Level 3 available |

Our technical capabilities ensure that every Teflon machined part meets the highest standards of precision, performance, and reliability—engineered for mission-critical applications where failure is not an option.

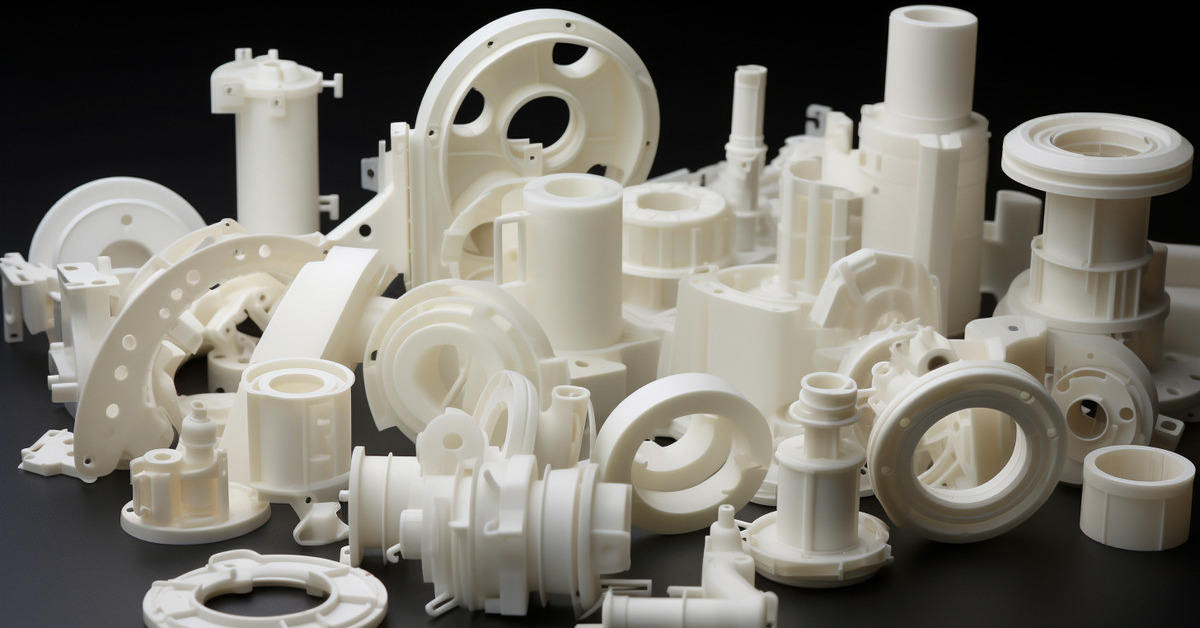

Material & Finish Options

Material Selection for High-Performance Teflon (PTFE) Machined Components

Selecting the optimal materials for components integrating machined Teflon (PTFE) parts is critical for achieving peak performance, longevity, and reliability in demanding industrial applications. While PTFE itself provides exceptional chemical resistance, low friction, and wide temperature tolerance, its interaction with mating components significantly impacts the overall system. At Wuxi Lead Precision Machinery, we emphasize that the choice of complementary structural or housing materials—primarily aluminum, steel, and titanium—must align precisely with the operational environment, mechanical loads, and thermal dynamics surrounding the PTFE element. Misalignment can lead to premature wear, seal failure, or chemical degradation, negating PTFE’s inherent advantages. Understanding the synergistic relationship between PTFE and its supporting structure is non-negotiable for mission-critical assemblies.

Aluminum alloys, particularly 6061-T6, offer an excellent balance of strength, weight, and machinability for housings, brackets, or lightweight fixtures holding PTFE seals or bearings. Its thermal expansion coefficient is relatively close to PTFE compared to other metals, reducing stress during temperature cycling. However, aluminum lacks inherent corrosion resistance in aggressive chemical environments; anodizing is often essential but requires careful specification. Steel, especially 303, 304, or 316 stainless grades, provides superior strength, rigidity, and broad chemical compatibility. 316 stainless is indispensable for marine, pharmaceutical, or highly corrosive settings where PTFE seals interface directly with fluids. Titanium (Grade 2 or 5) delivers the ultimate in strength-to-weight ratio and corrosion resistance, ideal for aerospace or extreme chemical exposure, though cost and machining complexity necessitate justified application.

Surface finish on mating metal components is equally vital. Anodizing aluminum enhances wear and corrosion resistance but introduces critical considerations for PTFE interfaces. Hard anodizing (Type III) creates a dense, wear-resistant layer suitable for high-load areas, yet standard sulfuric anodizing (Type II) leaves a porous surface. If pores are not fully sealed—using non-reactive sealants like nickel acetate or specialized polymers—they can trap contaminants or outgas, potentially contaminating the PTFE or compromising vacuum integrity. Unsealed anodized surfaces may also abrade softer PTFE. For direct PTFE contact zones, precision ground or polished bare metal surfaces (Ra < 16 μin) are often preferable to avoid interference. Always specify sealing requirements for anodized parts intended near PTFE elements.

Wuxi Lead Precision Machinery rigorously tests material pairings and finishes against your specific application parameters. The table below summarizes key considerations for common structural materials used with machined PTFE components.

| Material | Typical Use Case with PTFE | Key Property Advantage | Critical Teflon Compatibility Note |

|---|---|---|---|

| Aluminum 6061-T6 | Lightweight housings, brackets | Good strength-to-weight ratio | Requires anodizing for corrosion resistance; ensure pores are sealed if near PTFE interface to prevent contamination. |

| Stainless 316 | Pump bodies, valve components, marine | Excellent chemical resistance | Preferred for harsh chemical exposure; minimal interaction risk with PTFE. |

| Titanium Gr 5 | Aerospace seals, extreme corrosion | Highest strength/corrosion resistance | Costly; verify thermal expansion mismatch under extreme cycling; generally inert with PTFE. |

Material and finish selection is not generic. Partner with Wuxi Lead to analyze your operational stresses, chemical exposure, temperature range, and lifecycle requirements. We provide data-driven recommendations and prototyping to ensure your PTFE-integrated assembly delivers uncompromised performance. Contact our engineering team for a tailored material assessment.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept to CAD

At Wuxi Lead Precision Machinery, the production of high-performance machined PTFE (Teflon) components begins with an engineering-first approach. Our design phase integrates advanced CAD modeling with deep material science expertise. PTFE presents unique challenges—low stiffness, high thermal expansion, and a tendency to creep under load—requiring careful geometric compensation in the digital model. Our engineers collaborate directly with clients to interpret technical drawings, functional requirements, and application environments. Finite Element Analysis (FEA) is employed to simulate stress distribution, thermal behavior, and dimensional stability under real-world conditions. This ensures that every design accounts for PTFE’s inherent characteristics while meeting tight tolerances, typically within ±0.025 mm. All designs are validated through internal review protocols before advancing to prototyping.

Prototyping: Validating Performance Before Scale

Prototyping is a critical validation step in our zero-defect manufacturing philosophy. Using 5-axis CNC machining centers with sub-micron positioning accuracy, we produce functional prototypes from virgin or filled PTFE stock materials. Machining parameters—cutting speed, feed rate, tool geometry, and coolant strategy—are optimized to prevent smearing, burring, or dimensional distortion common in soft polymers. Each prototype undergoes rigorous dimensional inspection via coordinate measuring machines (CMM) and optical profilometry. Beyond geometry, prototypes are tested for chemical resistance, compression set, and electrical insulation properties when required. Client feedback is incorporated iteratively, allowing design refinements before committing to full-scale production. This phase minimizes risk, ensures fit-for-function performance, and accelerates time-to-market.

Mass Production: Consistency, Control, and Zero Defects

Once the design is approved, we transition to high-volume CNC machining under strictly controlled conditions. Our facility maintains ISO 9001-certified processes, with each production run governed by documented work instructions and first-article inspections. PTFE parts are machined using diamond-coated or polished carbide tools to achieve superior surface finishes and edge definition. In-process gauging and statistical process control (SPC) monitor critical dimensions in real time, ensuring batch consistency. Every component undergoes 100% visual inspection and selective metrology sampling. Non-conforming parts are immediately quarantined and analyzed through root cause correction protocols. Final cleaning, packaging, and traceability labeling are performed in a low-contamination environment to preserve part integrity.

Typical Machining Specifications for PTFE Components

| Parameter | Specification Range |

|---|---|

| Material Types | Virgin PTFE, Filled PTFE (glass, carbon, bronze) |

| Tolerance | ±0.025 mm (standard), up to ±0.005 mm (tight) |

| Surface Finish (Ra) | 0.8 – 3.2 µm (standard), down to 0.4 µm (polished) |

| Maximum Part Size | 600 mm × 400 mm × 300 mm |

| Minimum Wall Thickness | 0.8 mm (with support design) |

| Production Lead Time | 3–5 days (prototype), 10–15 days (mass production) |

| Quality Standards | ISO 9001, Full inspection reports, PPAP available |

At Wuxi Lead, we combine precision engineering with disciplined process control to deliver flawless PTFE machined parts—ensuring reliability in aerospace, semiconductor, pharmaceutical, and high-vacuum applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Teflon Machined Components

Precision machining of PTFE and other fluoropolymer components demands more than standard CNC capabilities. Material characteristics like low friction, high thermal expansion, and susceptibility to deformation under pressure require specialized expertise, process control, and metrology. At Wuxi Lead Precision Machinery, we engineer solutions where dimensional stability and material integrity are non-negotiable. Our dedicated fluoropolymer production cell operates under strict environmental controls, including temperature-stabilized machining zones and vibration-damped workstations, ensuring consistent results even for the most complex geometries. We understand that a tolerance deviation of ±0.01mm in a valve seat or seal ring can compromise an entire aerospace hydraulic system or semiconductor processing tool. This is why every Teflon part undergoes rigorous in-process inspection using calibrated CMMs and non-contact optical systems, with full traceability from raw billet to final certification.

Our value extends beyond machining. Lead Precision provides material science consultation during your design phase, identifying potential manufacturability risks in PTFE components before prototyping begins. Whether you require virgin PTFE for ultra-pure medical applications, glass-filled grades for structural wear parts, or custom-modified compounds, our engineers optimize toolpaths and fixturing to minimize stress-induced warpage. We maintain ISO 9001-certified processes with documented validation for critical parameters like chip evacuation control and spindle thermal management—factors often overlooked by generalist machine shops but critical for fluoropolymer success. This systematic approach delivers parts that meet stringent industry standards while reducing your total cost of ownership through extended component lifespan and reduced assembly failures.

The following table outlines our core capabilities for precision Teflon machining:

| Parameter | Capability | Standard Compliance |

|---|---|---|

| Tolerance Range | ±0.005 mm to ±0.05 mm | ISO 2768-mK, ASME Y14.5 |

| Surface Finish | Ra 0.2 μm to Ra 3.2 μm | ASTM D2122, ISO 1302 |

| Material Grades | Virgin PTFE, FEP, PFA, ETFE, filled compounds | ASTM D1457, D3307, D3159 |

| Max Part Size | Ø 500 mm x 300 mm height | Custom fixturing available |

| Critical Feature Control | Runout ≤ 0.01 mm, Flatness ≤ 0.02 mm/m | GD&T per drawing |

When your application hinges on flawless fluoropolymer performance, partnering with a specialist eliminates costly iterations and production delays. Lead Precision has supported Tier-1 aerospace suppliers, semiconductor OEMs, and medical device innovators with mission-critical Teflon components for over 12 years. We don’t just machine parts—we solve material-specific engineering challenges through process innovation. Contact our applications engineering team directly to discuss your most demanding PTFE, PFA, or ETFE requirements. Submit your drawings and material specifications to Contact [email protected] for a detailed manufacturability analysis and timeline within 24 business hours. Let us demonstrate how precision fluoropolymer machining becomes your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.