Technical Contents

Engineering Guide: Quoting Service

Engineering Insight: The Critical Role of Precision in Quoting Services

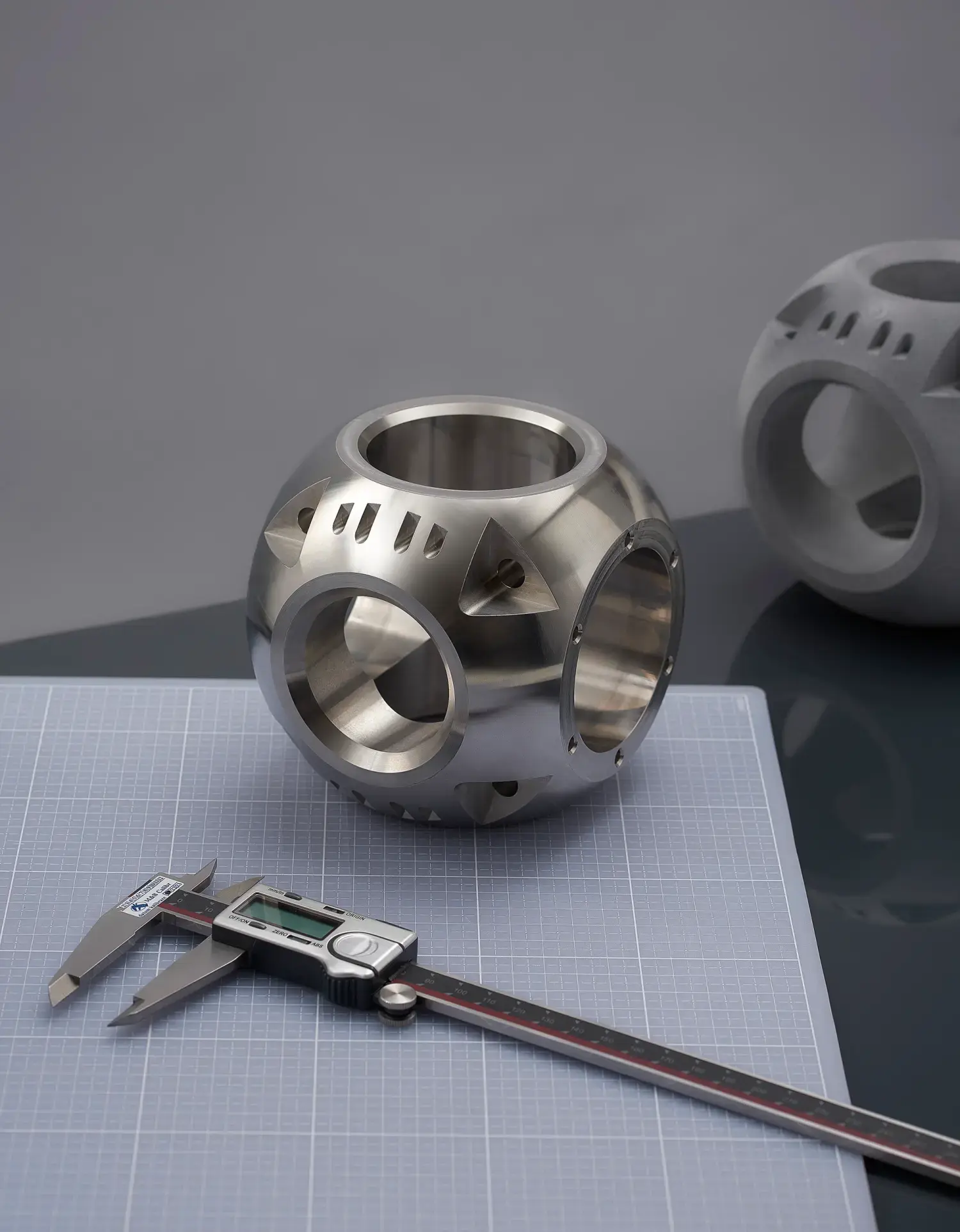

In the world of custom metal manufacturing, the quoting process is far more than a transactional exchange of price and lead time. It is the first technical engagement between a manufacturer and a client—an engineering dialogue that sets the foundation for quality, reliability, and long-term partnership. At Wuxi Lead Precision Machinery, we treat every quote as a precision engineering exercise, where dimensional accuracy, material integrity, and process capability are evaluated with the same rigor applied to the final component.

Precision begins at the quoting stage. Misinterpretation of tolerances, overlooked surface finish requirements, or underestimation of secondary operations can cascade into costly delays, rework, or component failure. Our quoting engineers are trained to scrutinize every GD&T annotation, assess manufacturability, and identify potential risk points before a single chip is cut. This proactive approach ensures that the quoted solution is not only competitive but also technically sound and production-ready.

With over 15 years of experience in high-stakes industries, Wuxi Lead has developed a quoting methodology refined through projects demanding uncompromising standards. Our work for Olympic-grade sports equipment and mission-critical military systems has instilled a culture where zero-defect performance is non-negotiable. These applications require materials such as titanium alloys, high-strength aluminum, and specialty stainless steels, often machined to tolerances within ±0.005 mm. The quoting process for such components integrates advanced CAM simulation, tooling lifecycle analysis, and in-process inspection planning—ensuring that every variable is accounted for before production begins.

Our clients benefit from a quoting system that balances technical depth with transparency. Each quote includes a detailed manufacturing route, material sourcing plan, quality control checkpoints, and a risk assessment report. This level of detail allows engineering teams to make informed decisions and accelerates time-to-approval.

Below are key specifications that define our precision manufacturing capabilities, all of which are evaluated during the quoting phase:

| Specification | Capability |

|---|---|

| Maximum Machining Envelope | 2000 mm × 1200 mm × 800 mm |

| Standard Tolerances | ±0.01 mm (tight-tolerance projects: ±0.005 mm) |

| Surface Finish (Ra) | As low as 0.4 µm |

| Materials Processed | Aluminum Alloys (6061, 7075), Stainless Steel (304, 316, 17-4PH), Titanium (Grade 5), Brass, Copper |

| Primary Processes | 3-axis to 5-axis CNC Milling, CNC Turning, Mill-Turning, Precision Grinding |

| Quality Standards | ISO 9001:2015, AS9100 (aerospace-compliant processes), Full CMM Inspection Reporting |

At Wuxi Lead Precision Machinery, we understand that trust is earned through consistency and competence. Our quoting service is engineered to reflect both—delivering not just a price, but a precision commitment backed by proven performance in the most demanding environments.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering Foundation for Accurate Quoting

At Wuxi Lead Precision Machinery, the quoting process begins with a rigorous technical assessment, not merely a price calculation. We understand that accurate, reliable quotations for complex custom metal components are fundamentally dependent on demonstrable manufacturing and quality control capabilities. Our engineering team meticulously evaluates every RFQ against our core technical infrastructure to ensure feasibility, identify potential process optimizations, and guarantee the quoted tolerances and finishes are consistently achievable. This proactive technical validation is critical for eliminating costly surprises during production and establishing realistic lead times from the outset.

Our primary machining capability centers on advanced 5-axis CNC milling and turning centers. These multi-tasking platforms enable the complete machining of highly complex geometries—such as impellers, turbine blades, medical implants, and aerospace structural components—in a single setup. Utilizing simultaneous 5-axis motion with high-precision spindles and robust machine structures, we eliminate cumulative errors inherent in multi-setup processes. This capability directly translates to reduced part handling, superior geometric accuracy, improved surface integrity, and ultimately, more predictable production cycles reflected accurately in our quotes. We program these machines using industry-leading CAM software, optimizing toolpaths for efficiency and surface finish while rigorously simulating for collision avoidance.

Integral to our quoting accuracy and production quality is our comprehensive metrology suite, anchored by state-of-the-art Coordinate Measuring Machines (CMMs). Every critical feature specified in a drawing undergoes verification against the quoted tolerances using these calibrated systems. Our CMMs, equipped with tactile and optical probes, provide traceable, high-resolution 3D data for complex contours, positional tolerances, and GD&T callouts. This rigorous inspection protocol, applied during first-article inspection and throughout production runs as required, ensures that the dimensional reality matches the engineering intent defined in the quotation. It provides the objective data necessary to confirm process capability and assures clients that the quoted specifications are not aspirational but demonstrably achievable.

The following table details our standard and precision tolerance capabilities, which form the technical basis for all dimensional quotes. These represent our proven, repeatable performance levels under controlled production conditions.

| Feature Type | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Hole Position | ±0.025 mm | ±0.010 mm |

| True Position (GD&T) | ±0.050 mm | ±0.015 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Angular Features | ±0.05° | ±0.01° |

| Profile of Surface | 0.050 mm | 0.015 mm |

This commitment to technical transparency ensures that Wuxi Lead’s quotations are grounded in verifiable manufacturing reality. By aligning quoted specifications precisely with our documented machine capabilities and stringent QC processes, we provide clients with confidence in deliverable quality, schedule adherence, and total project cost from the very first engagement. Our quoting service is an engineering commitment, not just a commercial offer.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing part performance, durability, and cost. At Wuxi Lead Precision Machinery, we guide clients through informed decisions based on application requirements, environmental exposure, mechanical loads, and finishing needs. The most commonly specified materials in precision machining are aluminum, steel, and titanium, each offering distinct advantages depending on the use case.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is widely used in aerospace, automotive, and consumer electronics where weight reduction is essential. Grade 6061-T6 is particularly popular due to its weldability and moderate strength, while 7075-T6 offers higher strength for more demanding structural applications. Aluminum’s natural oxide layer provides inherent corrosion protection, but for enhanced surface performance, anodizing is recommended.

Steel remains the backbone of industrial applications due to its high strength, wear resistance, and affordability. We commonly machine carbon steels such as 1018 and 4140, as well as stainless steels including 303, 304, and 17-4 PH. Stainless grades offer superior corrosion resistance and are ideal for medical, food processing, and marine environments. When strength and toughness under stress are required, alloy steels like 4340 are selected for shafts, gears, and high-load components.

Titanium, particularly Grade 5 (Ti-6Al-4V), is chosen for extreme environments where high strength, low density, and exceptional corrosion resistance are paramount. It performs reliably at elevated temperatures and resists fatigue, making it ideal for aerospace, defense, and medical implant applications. Though more challenging to machine due to its low thermal conductivity and tendency to gall, our CNC processes are optimized to maintain precision and surface integrity when working with titanium.

Anodizing is a key surface treatment for aluminum components, enhancing wear resistance, corrosion protection, and aesthetic quality. The process creates a hard, porous oxide layer that can be dyed in various colors and sealed for durability. Type II anodizing (sulfuric acid anodize) is suitable for most industrial applications, while Type III (hard anodize) provides a thicker, more wear-resistant coating for high-stress environments. Anodizing does not compromise dimensional accuracy when properly controlled, and we ensure tight tolerance adherence throughout the process.

Below is a comparative overview of key material properties to support selection:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Typical Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Aerospace, Electronics, Automotive | Anodizing, Bead Blast, Powder Coat |

| Steel | 1018, 4140, 304 | 400–1000 | 7.8–7.9 | Industrial Machinery, Tools | Zinc Plating, Passivation, Paint |

| Titanium | Ti-6Al-4V (Grade 5) | 900–1000 | 4.5 | Aerospace, Medical, Defense | Anodizing, Passivation, Polishing |

Selecting the right material and finish ensures optimal performance and longevity of machined components. Our engineering team at Wuxi Lead Precision Machinery collaborates closely with clients to match material properties with functional demands, ensuring every part meets the highest standards of precision and reliability.

Manufacturing Process & QC

Precision Manufacturing Process: From Design to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our quoting service integrates seamlessly with a rigorously defined production process designed to eliminate defects before metal meets tool. We understand that for high-stakes custom metal components, the path from concept to volume shipment must be predictable, controlled, and inherently quality-focused. Our three-phase methodology – Design Integration, Precision Prototyping, and Statistical Mass Production – ensures dimensional accuracy and functional reliability are engineered in from the outset, directly impacting quote feasibility and long-term cost efficiency.

Design Phase Integration

Our engineering team initiates collaboration during the quoting stage, conducting mandatory Design for Manufacturability (DFM) and Design for Assembly (DFA) analysis. We scrutinize CAD models for geometric feasibility, material suitability, and optimal CNC machining strategies. This proactive review identifies potential stress points, tolerance stack-ups, or secondary operation conflicts before tooling begins. By resolving these issues early, we prevent costly rework cycles and establish a validated digital twin of the component, forming the absolute baseline for zero-defect manufacturing. Clear communication on material certifications, surface finish requirements, and critical-to-quality (CTQ) dimensions is established within the quote parameters.

Prototyping for Validation

Physical validation is non-negotiable. Using the exact production-grade CNC equipment and materials specified in the quote, we produce functional prototypes under controlled conditions. Each prototype undergoes comprehensive metrology, including full-spectrum CMM inspection against the approved CAD model and first-article inspection (FAI) per AS9102 standards where applicable. Dimensional reports, material test certificates, and process capability data (Cp/Cpk) are generated. This phase confirms the manufacturability defined in the design phase, validates fixture strategies, and provides tangible evidence of capability to the client. Only when prototype data meets or exceeds all specifications do we authorize progression to mass production.

Statistical Mass Production Execution

Volume manufacturing leverages the validated process from prototyping, governed by real-time Statistical Process Control (SPC). Every critical dimension is monitored via in-process gauging and periodic CMM verification, with data fed into control charts to detect any process drift before defects occur. Our ISO 9001-certified production cells utilize automated tool compensation, environmental controls, and operator certification protocols specific to the part family. End-of-line inspection employs multi-point verification, including visual, dimensional, and material property checks. This closed-loop system ensures sustained conformance, delivering consistent zero-defect output batch after batch, directly fulfilling the precision promise outlined in our initial quote.

Core Production Capabilities & Verification

| Process Phase | Key Capabilities | Quality Verification Standards |

|---|---|---|

| Design Integration | Advanced DFM/DFA, Material Optimization, Tolerance Stack Analysis | CAD Model Validation, CTQ Definition, Quoting Sign-off |

| Prototyping | Production-Intent Machining, Material Traceability | Full CMM Inspection, FAI Reports, Cp/Cpk Analysis |

| Mass Production | Real-time SPC, Automated Tool Compensation, Batch Traceability | In-Process Gauging, Final CMM Audit, Material Certs |

This integrated approach transforms the quotation from a price estimate into a binding commitment to defect-free delivery. By embedding quality verification at every transition point – design approval, prototype sign-off, and production release – Wuxi Lead eliminates uncertainty. Request a precision quote today, backed by a process engineered for zero defects from inception to shipment.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in high-end industrial manufacturing. As a globally recognized leader in custom metal fabrication and CNC machining, we specialize in delivering mission-critical components to industries where performance under extreme conditions is paramount. From aerospace and defense to medical devices and advanced automation, our engineering-driven approach ensures every part meets the highest standards of accuracy, durability, and consistency.

Our quoting service is designed for engineers, project managers, and procurement specialists who demand more than just a price—they require confidence. When you submit your request, you’re not just receiving a quotation; you’re initiating a partnership built on technical expertise, transparent communication, and rapid response. Our team of senior CNC engineers reviews every RFQ with meticulous attention to material selection, geometric complexity, surface finish requirements, and production scalability. This ensures that your quote is not only competitive but technically optimized for manufacturability and cost-efficiency.

We support a comprehensive range of materials including aerospace-grade aluminum, titanium, stainless steel, Inconel, and specialty alloys. Whether your project involves low-volume prototypes or high-volume production runs, our state-of-the-art facility in Wuxi, China, is equipped with multi-axis CNC machining centers, Swiss-type lathes, precision grinding equipment, and full in-house quality assurance labs compliant with ISO 9001:2015 standards.

Our commitment to speed does not compromise quality. With a typical quote turnaround time of under 12 business hours and prototyping cycles as fast as 7 days, we enable faster time-to-market without sacrificing precision. All parts are inspected using calibrated CMMs, optical comparators, and surface roughness testers to ensure complete conformance to your specifications.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Machining Tolerances | Up to ±0.005 mm |

| Maximum Work Envelope | 2000 x 1200 x 1000 mm |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Inconel 718, Brass, Copper, Tool Steels |

| Finishing Options | Anodizing (Type II, Type III), Passivation, Powder Coating, Polishing, Bead Blasting |

| Quality Standards | ISO 9001:2015 Certified, Full First Article Inspection (FAI) Reports, PPAP Level 3 Available |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity and volume) |

We invite you to experience a quoting process engineered for precision, speed, and trust. Contact us today at [email protected] to submit your drawings or discuss your project with one of our senior manufacturing engineers. Let Wuxi Lead Precision Machinery become your trusted partner in delivering custom metal solutions that perform—on time, every time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.