Technical Contents

Engineering Guide: Molded Inserts

Engineering Insight: The Critical Role of Precision in Molded Inserts

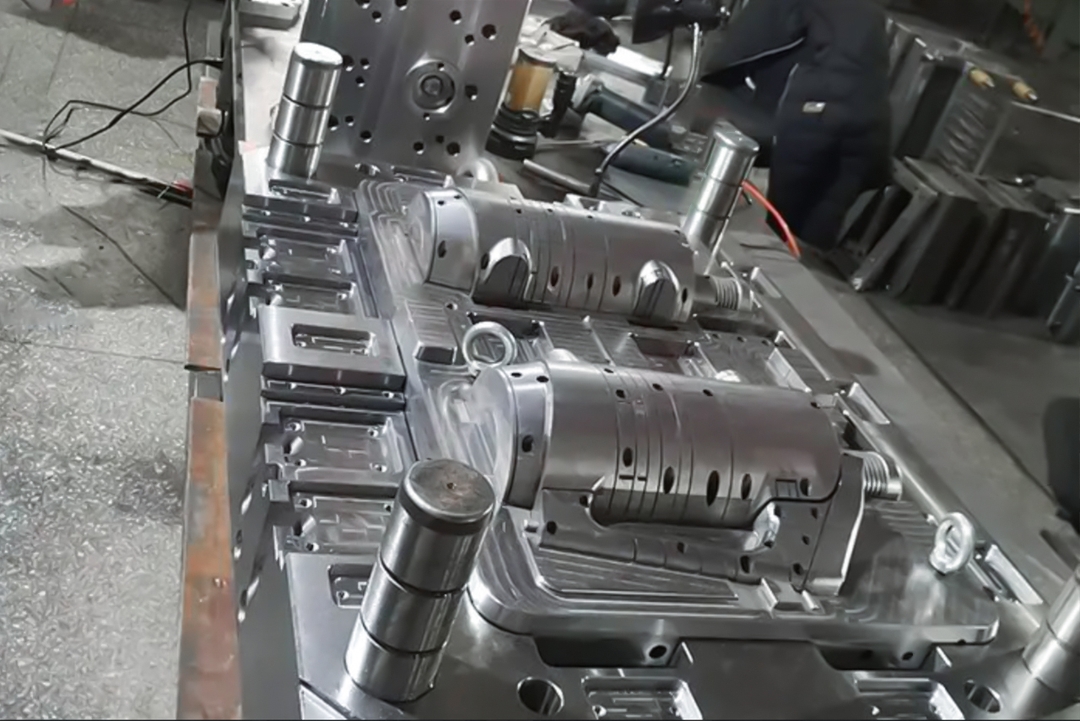

In high-performance manufacturing, molded inserts represent a critical interface between design intent and functional reliability. These precision-engineered metal components are embedded within molded parts—typically plastic or composite materials—to enhance structural integrity, improve wear resistance, and enable secure mechanical attachments. The success of such integration hinges entirely on dimensional accuracy, material compatibility, and long-term durability under operational stress. At Wuxi Lead Precision Machinery, we recognize that even micron-level deviations in insert geometry can lead to catastrophic failures in aerospace, defense, and high-load industrial applications.

Precision in molded inserts is not merely a manufacturing goal—it is a non-negotiable engineering requirement. Inserts must align perfectly with mold cavities, maintain concentricity during overmolding, and resist displacement under injection pressure. Thermal expansion differentials between metal inserts and polymer matrices further complicate the process, demanding careful material selection and geometric compensation. Our engineering team applies finite element analysis (FEA) and mold-flow simulation to anticipate these challenges, ensuring that every insert performs as intended in its final assembly.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in custom metal manufacturing, with a proven track record in mission-critical sectors. Our work has supported components used in Olympic-grade sporting equipment, where performance consistency is scrutinized at the highest level, and in military-grade systems, where failure is not an option. These applications demand extreme repeatability, certified material traceability, and rigorous quality control—all hallmarks of our production process.

We utilize multi-axis CNC machining, automated inspection systems, and in-process metrology to maintain tolerances as tight as ±0.002 mm. Our facility is equipped for high-mix, low-volume runs as well as scalable production, ensuring flexibility without compromising precision. Whether manufacturing threaded inserts, self-tapping designs, or custom geometries with integrated knurling or undercuts, our process is built around the principle that precision enables performance.

The following table outlines typical specifications and capabilities for our molded insert production:

| Parameter | Standard Capability | High-Precision Option | Notes |

|---|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.002 mm | Achieved via CNC micromachining |

| Material Options | Stainless Steel (304, 316), Brass, Aluminum, Titanium | Custom alloys available | Material certification provided |

| Insert Diameter Range | 1.5 mm – 25 mm | Up to 30 mm with support | Micro-inserts available on request |

| Surface Finish | Ra 0.8 µm | Ra 0.2 µm (polished) | Optional PTFE or anti-corrosion coating |

| Production Volume | Prototype to 500,000+ units | Scalable with automation | Rapid turnaround for pilot batches |

| Quality Standards | ISO 9001:2015 | MIL-STD-883 compliant | Full inspection reports available |

At Wuxi Lead Precision Machinery, we treat every molded insert as a load-bearing component, not just a consumable. Our engineering-first approach ensures seamless integration into your molding process and unmatched reliability in the field.

Precision Specs & Tolerances

Precision Engineered Molded Inserts: Technical Execution at Wuxi Lead

Wuxi Lead Precision Machinery delivers mission-critical molded inserts for demanding industrial applications where dimensional integrity and material performance are non-negotiable. Our technical capabilities are engineered specifically for the complex geometries and stringent tolerances inherent in high-value metal components embedded within polymer or composite assemblies. We eliminate the compromises often associated with off-the-shelf solutions through dedicated process control and advanced manufacturing infrastructure.

Our core manufacturing capability centers on state-of-the-art 5-axis CNC milling and turning centers. This technology is essential for molded inserts, which frequently feature deep cavities, compound angles, threaded features, and undercuts impossible to achieve in fewer axes. Simultaneous 5-axis movement allows us to machine intricate 3D contours in a single setup, drastically reducing handling errors and ensuring critical feature relationships are maintained. We routinely machine challenging materials including titanium alloys, hardened tool steels, inconel, and high-strength aluminum alloys to the exacting specifications required for reliable overmolding and long-term structural performance. Material-specific toolpath strategies and in-process probing guarantee optimal surface finish and dimensional stability, directly impacting the insert’s bond strength within the final molded part.

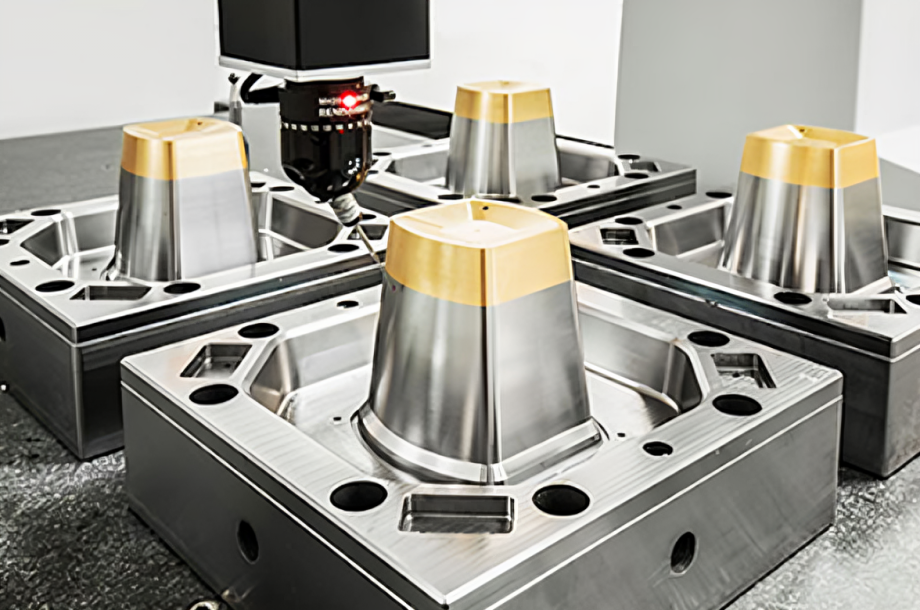

Quality verification is not a final step but an integrated process. Every critical dimension on molded inserts undergoes rigorous inspection using calibrated Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMM systems provide micron-level accuracy for geometric dimensioning and tolerancing (GD&T) verification, including true position, profile, and runout. Full first-article inspection reports (FAIR) with CMM-generated point clouds are standard, providing absolute traceability against your engineering drawings. This systematic approach ensures batch-to-batch consistency and meets the stringent documentation requirements of aerospace, medical, and automotive sectors. Our quality management system is ISO 9001:2015 certified, with processes designed for zero-defect delivery in high-mix, low-volume production environments typical of custom insert manufacturing.

The achievable precision for molded inserts is defined by our controlled processes and equipment capability. Standard tolerances are consistently held, with precision and ultra-precision options available for critical interfaces:

| Tolerance Class | Dimensional Range | Metric Tolerance | Imperial Tolerance |

|---|---|---|---|

| Standard | All Features | ±0.05 mm | ±0.002″ |

| Precision | Critical Features | ±0.0125 mm | ±0.0005″ |

| Ultra-Precision | Critical Interfaces | ±0.005 mm | ±0.0002″ |

These tolerances represent typical production capability per feature under controlled conditions; specific project requirements are validated during engineering review. Achieving these results requires our holistic approach: advanced 5-axis machining eliminates cumulative error from multiple setups, while CMM inspection provides objective data for process adjustment and validation. This capability translates directly to your success—ensuring perfect fit during overmolding, eliminating assembly scrap, and guaranteeing the long-term mechanical integrity of the final product. Partner with Wuxi Lead to transform your molded insert requirements from a potential failure point into a verified asset.

Material & Finish Options

Material selection is a critical step in the design and production of high-performance molded inserts, directly influencing durability, functionality, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-engineered metal components tailored to meet the demanding requirements of industries such as aerospace, automotive, and medical devices. Our expertise in custom metal manufacturing enables us to guide clients through optimal material choices based on application environment, mechanical load, thermal exposure, and longevity expectations.

Aluminum is often the preferred choice for molded inserts where weight reduction and thermal conductivity are priorities. Its low density and excellent machinability make it ideal for complex geometries and high-volume production runs. While not as hard as steel or titanium, aluminum offers a favorable strength-to-weight ratio and responds well to surface treatments such as anodizing, which significantly enhances wear and corrosion resistance. We recommend aluminum alloys such as 6061-T6 and 7075-T6 for applications requiring structural integrity combined with lightweight performance.

Steel, particularly tool steel and stainless steel variants, delivers superior hardness, tensile strength, and wear resistance. These properties make steel the material of choice for high-cycle molding applications where insert longevity is paramount. Stainless steels like 17-4 PH and 316L also offer excellent corrosion resistance, making them suitable for medical and marine environments. While heavier than aluminum, steel’s durability ensures minimal deformation under prolonged stress and elevated temperatures, reducing maintenance and replacement costs over time.

Titanium stands at the pinnacle of performance materials, offering an exceptional strength-to-density ratio and outstanding resistance to corrosion, even in extreme environments. Its biocompatibility and non-magnetic properties make it indispensable in aerospace and medical implant applications. Though more challenging to machine and higher in cost, titanium’s long-term reliability in aggressive chemical or high-temperature conditions justifies its use in mission-critical components.

Surface finishing plays a vital role in enhancing the functional lifespan of molded inserts. Anodizing, particularly Type II and Type III (hard coat), is a widely used electrochemical process for aluminum components. It creates a durable, insulating oxide layer that improves surface hardness, wear resistance, and adhesion for secondary coatings. Hard anodizing can achieve coating thicknesses from 25 to 100 microns with hardness values exceeding 60 HRC, making it suitable for high-abrasion environments.

The following table summarizes key mechanical and finishing properties of the primary materials we utilize:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Density (g/cm³) | Max Anodizing Thickness (µm) | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 15–20 | 2.7 | 50 | Lightweight structural inserts |

| Aluminum 7075-T6 | 570 | 15–20 | 2.8 | 50 | High-stress aerospace components |

| Stainless Steel 17-4 PH | 1300 | 38–42 | 7.8 | Not applicable | Medical, high-cycle tooling |

| Tool Steel H13 | 1600 | 48–52 | 7.8 | Not applicable | High-temperature molding |

| Titanium Grade 5 | 900 | 36–38 | 4.5 | 25 (limited) | Aerospace, marine, medical implants |

At Wuxi Lead Precision Machinery, we combine advanced CNC machining with expert material science to deliver molded inserts that meet exacting performance standards. Our engineering team collaborates closely with clients to select the optimal material and finish combination for long-term success.

Manufacturing Process & QC

Production Process for Precision Molded Inserts

At Wuxi Lead Precision Machinery, our engineered approach to molded insert manufacturing guarantees dimensional integrity and functional performance from initial concept through high-volume delivery. We enforce a rigorously controlled three-stage workflow—Design, Prototyping, Mass Production—integrated with our Zero Defects Quality Management System. This methodology ensures seamless scalability while eliminating costly field failures for demanding applications in automotive, aerospace, and medical device assembly.

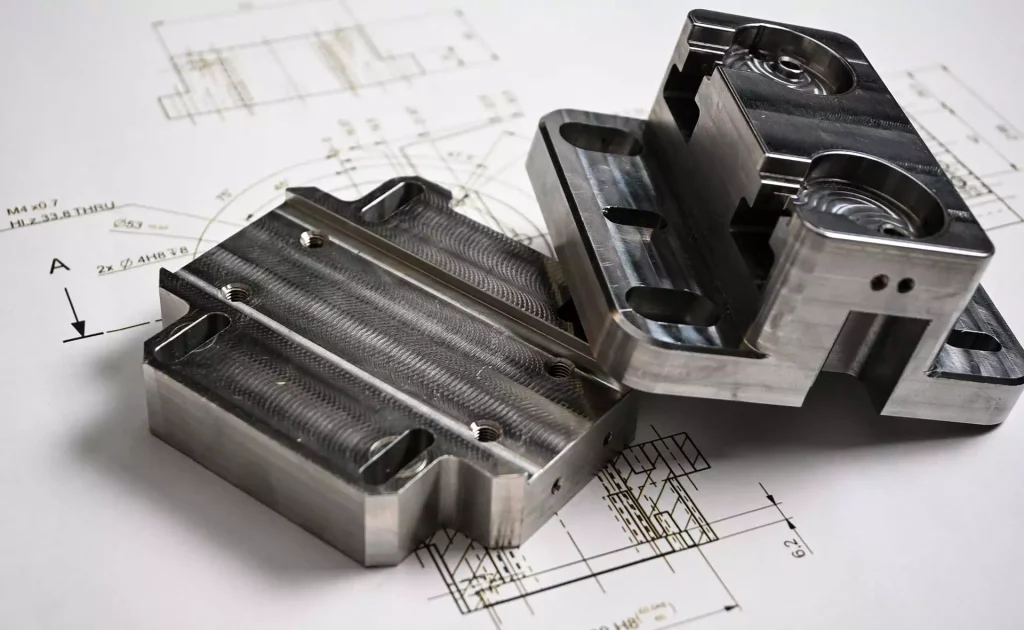

Design Phase

Our engineering collaboration begins with comprehensive analysis of your functional requirements, material compatibility, and assembly constraints. Using advanced CAD/CAM software including Siemens NX and Mastercam, we develop 3D models incorporating critical features like thread forms, undercuts, and press-fit geometries. Finite Element Analysis (FEA) validates structural performance under operational loads, while mold flow simulation optimizes gate placement and cooling channels for thermoplastic integration. Every design undergoes cross-functional review against Geometric Dimensioning and Tolerancing (GD&T) standards, ensuring manufacturability and compliance with ISO 2768-mK or customer-specific specifications before tooling initiation.

Prototyping Phase

Precision prototypes are machined using our HAAS UMC-750 5-axis universal machining centers, directly from the validated CAD model. This eliminates tooling variables during validation. Prototypes undergo full CMM inspection against all critical dimensions, including thread pitch diameters measured via optical comparators and surface roughness verified with Mitutoyo SJ-410 profilometers. We conduct functional assembly trials with mating components to confirm interference fits and torque specifications. Any deviations trigger immediate design iteration within 72 hours, documented through our non-conformance tracking system. This phase typically achieves 95% design freeze accuracy, preventing downstream production errors.

Mass Production Phase

Zero Defects execution relies on our integrated Smart Factory ecosystem. Production occurs on dedicated Okuma MULTUS U4000 CNC lathes with integrated robotic loaders, maintaining ±0.005 mm positional accuracy. In-process monitoring via Renishaw probes checks critical features after each machining stage, while SPC charts track Cp/Cpk values in real-time. Every batch undergoes 100% visual inspection under 10x magnification and random destructive testing for material hardness and thread strength per ASTM E18 and ASME B1.1 standards. Our traceability system logs machine parameters, operator IDs, and inspection data for full lot追溯ability, ensuring compliance with IATF 16949 requirements. This closed-loop control achieves PPM defect rates below 50 across 500,000+ annual units.

Critical Process Specifications

| Parameter | Capability Range | Measurement Standard | Inspection Frequency |

|---|---|---|---|

| Material | Stainless Steel (303, 316), Brass (C36000), Aluminum (6061-T6) | ASTM A276, B16, B22 | Per Lot Certificate |

| Tolerance | ±0.005 mm (critical features) | ISO 2768-mK | 100% CMM per batch |

| Surface Roughness | Ra 0.4 µm (mating surfaces) | ISO 4287 | 5% random sampling |

| Thread Accuracy | 6H/6g class | ASME B1.1 | 100% optical compar. |

| Production Volume | 1,000 – 500,000+ units | Customer Schedule | Continuous Monitoring |

This disciplined progression—from simulation-validated design through rigorously tested prototypes to intelligently monitored mass production—forms the foundation of Wuxi Lead’s Zero Defects commitment. We deliver molded inserts that consistently meet the exacting demands of global Tier 1 suppliers, reducing your total cost of ownership through unparalleled first-pass yield.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Molded Inserts Engineered to Perform

When your manufacturing demands require components that combine complex geometry, tight tolerances, and long-term durability, molded inserts are more than just fasteners—they are mission-critical elements in high-performance assemblies. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing with a focus on precision-engineered molded inserts designed for integration into plastic, composite, and elastomeric systems. Our expertise spans aerospace, automotive, medical devices, and industrial automation, where reliability under stress, heat, and dynamic loads is non-negotiable.

What sets Lead Precision apart is our end-to-end control over the manufacturing process. From initial design consultation to final inspection, every molded insert we produce is the result of advanced cold forming, CNC machining, and thread rolling technologies, all executed under strict ISO 9001:2015 standards. We work with a wide range of materials including stainless steel, brass, aluminum, and specialty alloys, ensuring optimal performance in corrosive, high-temperature, or high-vibration environments.

Our engineering team collaborates directly with your design and R&D departments to optimize insert geometry for molding compatibility, pull-out strength, and thermal expansion characteristics. Whether you require knurled bodies, undercut profiles, or custom thread types, we deliver inserts that embed seamlessly into your overmolded components—minimizing defects, reducing cycle times, and improving final product integrity.

We understand that in high-mix, low-volume production environments, flexibility and responsiveness are as important as precision. That’s why we maintain agile production lines capable of rapid prototyping, quick changeovers, and scalable batch runs—from pilot samples to millions of units—without compromising on quality or lead time.

Below are representative specifications for our standard molded insert capabilities. All parameters are fully customizable based on your application requirements.

| Specification | Capability |

|---|---|

| Outer Diameter Range | 2 mm – 25 mm |

| Insert Length | 3 mm – 50 mm |

| Materials | Stainless Steel (304, 316), Brass (C3604), Aluminum (6061, 7075), Inconel, Titanium |

| Tolerances | ±0.02 mm (critical dimensions) |

| Thread Types | Metric, UNC, UNF, NPT, Custom Profiles |

| Surface Treatments | Passivation, Zinc Plating, Black Oxide, PTFE Coating |

| Production Methods | Cold Forming, CNC Machining, Thread Rolling |

| Secondary Operations | Knurling, Grooving, Chamfering, Slotting |

| Quality Standards | ISO 9001:2015, Full First Article Inspection, Batch Traceability |

Partnering with Wuxi Lead Precision Machinery means gaining more than a supplier—you gain a precision manufacturing ally committed to innovation, consistency, and technical excellence. Our global clients rely on us to solve complex insert challenges that impact product performance and assembly efficiency.

Contact us today at [email protected] to discuss your next molded insert project. Let our engineers help you transition from concept to high-precision reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.