Technical Contents

Engineering Guide: Best 3D Print Service

Engineering Insight: The Role of Precision in Selecting the Best 3D Print Service

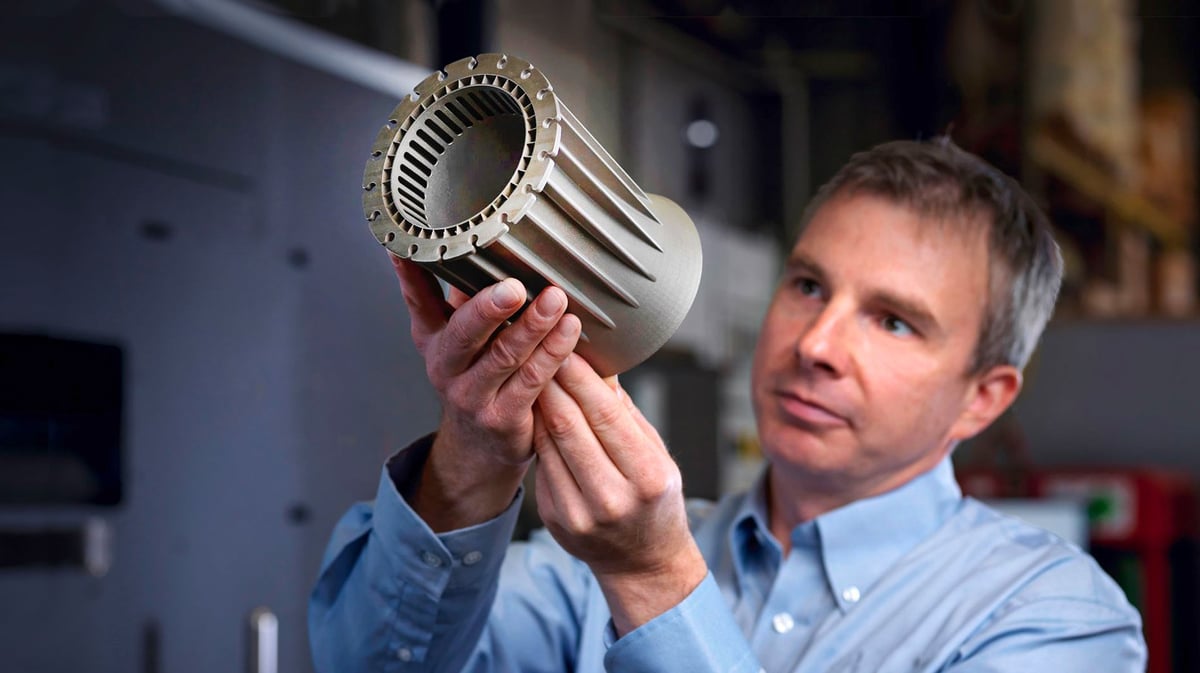

In the realm of custom metal manufacturing, the emergence of additive manufacturing—commonly known as 3D printing—has revolutionized how complex components are designed, prototyped, and produced. However, not all 3D print services deliver equal results. For high-stakes industries such as aerospace, defense, and advanced medical systems, precision is not merely an advantage—it is a non-negotiable requirement. The best 3D print service must combine cutting-edge technology with deep engineering expertise to ensure dimensional accuracy, material integrity, and repeatability across production runs.

At Wuxi Lead Precision Machinery, we understand that precision in metal 3D printing extends beyond layer resolution. It encompasses thermal management during build, post-processing techniques, residual stress mitigation, and rigorous metrology. Our engineering team applies decades of experience in high-tolerance manufacturing to every additive project, ensuring that components meet or exceed industry-specific standards. This commitment has enabled us to deliver mission-critical parts for applications in Olympic-level sports technology and military-grade equipment, where failure is not an option.

One of the defining characteristics of a superior 3D print service is the ability to maintain tight tolerances across complex geometries. While many providers advertise high-resolution printers, few can consistently achieve sub-50-micron accuracy in real-world production due to variations in machine calibration, material behavior, and environmental control. At Lead Precision, we operate under ISO 9001-certified processes with in-house metrology labs equipped with coordinate measuring machines (CMM) and optical scanners. This infrastructure ensures that every part is verified against its original CAD model, guaranteeing fidelity down to the micron.

Our metal additive capabilities are built on state-of-the-art equipment and supported by a team trained in both traditional machining and modern design for additive manufacturing (DfAM). This dual expertise allows us to optimize part orientation, support structures, and build parameters to minimize distortion and maximize mechanical performance.

The following table outlines key specifications of our metal 3D printing systems:

| Parameter | Specification |

|---|---|

| Build Envelope | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20–50 microns |

| Positional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-built) | Ra 10–15 µm |

| Post-Processed Finish | Ra < 3.2 µm (with polishing/finishing) |

| Materials Available | Stainless Steel (316L, 17-4PH), Inconel 718, Titanium (Ti6Al4V), Aluminum (AlSi10Mg) |

| Supported Standards | ISO 9001, ASTM F75, AMS 7498, NADCAP (in process) |

Precision in additive manufacturing is not achieved through hardware alone—it is engineered into every phase of production. For clients demanding the best 3D print service, Wuxi Lead Precision Machinery offers the technical depth, quality assurance, and proven track record required for the most demanding applications.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing Excellence

Wuxi Lead Precision Machinery delivers definitive solutions for complex, high-integrity metal components, operating at the forefront of precision manufacturing. It is critical to clarify that our core expertise and service offering center on advanced subtractive manufacturing, specifically multi-axis CNC machining, not additive 3D printing services. For mission-critical applications demanding the highest levels of dimensional accuracy, material integrity, and surface finish in metal, our CNC capabilities represent the optimal production methodology. We specialize in transforming challenging engineering designs into reality using state-of-the-art equipment and rigorous quality control protocols, serving demanding sectors including aerospace, medical device, semiconductor, and energy.

Our production floor is anchored by a strategic fleet of high-precision 5-axis CNC machining centers from industry leaders HAAS and DMG MORI. These platforms enable the efficient, single-setup production of geometrically intricate parts, eliminating cumulative errors inherent in multi-operation processes. This capability is essential for complex contours, deep cavities, undercuts, and organic shapes common in modern engineering. We machine a comprehensive range of engineering metals including titanium alloys (Ti-6Al-4V), aluminum alloys (7075, 6061), stainless steels (303, 304, 316, 17-4 PH), tool steels, Inconel, and brass, adhering strictly to certified material specifications. Process optimization is continuous, leveraging high-speed machining techniques and advanced toolpath strategies to ensure part integrity, superior surface quality, and efficient throughput without compromising precision.

Absolute confidence in dimensional conformity is non-negotiable. Every critical component undergoes comprehensive verification using our metrology-grade Coordinate Measuring Machines (CMM), specifically Zeiss CONTURA and GLOBAL series systems. These instruments provide traceable, NIST-calibrated measurements across complex geometries, generating detailed inspection reports with full GD&T analysis. Our certified quality technicians follow stringent procedures aligned with ISO 9001:2015, ensuring every dimension, form, and positional tolerance meets or exceeds the client’s engineering requirements. Full inspection documentation, including first-article inspection (FAI) reports per AS9102 where applicable, is standard practice, providing complete traceability and audit readiness.

The following table details our standard and achievable tolerance capabilities for machined features, reflecting the precision inherent in our 5-axis CNC processes and verified by CMM inspection. These values represent typical performance for features within standard size ranges under optimal conditions; specific project requirements are always evaluated during the quoting phase.

| Feature Type | Standard Tolerance | Achievable Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | Up to 100mm; tighter tolerances scale with size |

| Hole Diameter | ±0.010 mm | ±0.005 mm | Reamed/precision bored features |

| Positional Tolerance | ±0.015 mm | ±0.010 mm | Per GD&T (e.g., true position) |

| Flatness | 0.010 mm | 0.005 mm | Over specified surface area |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | As-machined; post-process can improve |

Wuxi Lead Precision Machinery provides the definitive manufacturing solution where metal part performance, repeatability, and certified dimensional accuracy are paramount. Our integrated approach—combining advanced 5-axis CNC technology, expert engineering support, and uncompromising CMM-based quality assurance—ensures your most demanding metal components are produced to exacting standards, consistently and reliably. Partner with us for precision that meets the highest industrial benchmarks.

Material & Finish Options

Material selection is a critical decision in custom metal 3D printing, directly influencing part performance, durability, and application suitability. At Wuxi Lead Precision Machinery, we specialize in high-precision metal additive manufacturing using industrial-grade aluminum, steel, and titanium alloys. Each material offers distinct mechanical properties, thermal resistance, and weight characteristics, allowing engineers and designers to match material performance with functional requirements.

Aluminum alloys, particularly AlSi10Mg, are widely used in aerospace, automotive, and electronics due to their excellent strength-to-weight ratio and good thermal conductivity. This material is ideal for lightweight structural components, heat exchangers, and complex housings where weight reduction is paramount. Its low density and corrosion resistance make it a preferred choice for high-performance applications requiring efficient thermal management and reduced inertia.

Stainless steel, especially 316L and 17-4 PH, delivers superior mechanical strength, wear resistance, and excellent corrosion performance. These properties make it suitable for demanding environments such as marine components, medical devices, and industrial tooling. 316L stainless steel offers exceptional resistance to chloride-induced pitting, making it ideal for offshore and chemical processing applications. In contrast, 17-4 PH provides high tensile strength and can be precipitation hardened post-print, enabling its use in high-stress mechanical parts.

Titanium alloys, primarily Ti6Al4V (Grade 5), are the material of choice for applications requiring extreme strength, high fatigue resistance, and biocompatibility. Commonly used in aerospace, defense, and medical implants, titanium offers an outstanding strength-to-density ratio and excellent performance at elevated temperatures. Its resistance to oxidation and compatibility with human tissue make it indispensable in critical-load and biomedical applications.

For enhanced surface properties and aesthetics, we offer precision anodizing as a post-processing finish, particularly for aluminum components. Anodizing increases surface hardness, improves wear and corrosion resistance, and allows for color coding through dye integration. This electrochemical process creates a durable, non-conductive oxide layer that enhances part longevity without compromising dimensional accuracy.

Below is a comparative overview of key material properties used in our metal 3D printing services:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Key Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 480 | 300 | 8–12 | Aerospace, heat sinks, lightweight structures |

| 316L Stainless Steel | 8.0 | 550 | 350 | 40 | Medical, marine, chemical processing |

| 17-4 PH Steel | 7.8 | 1000 | 850 | 12 | Tooling, high-stress mechanical parts |

| Ti6Al4V | 4.43 | 900 | 830 | 10 | Aerospace, defense, medical implants |

At Wuxi Lead Precision Machinery, we ensure material authenticity through certified supply chains and in-house testing. Our engineering team collaborates with clients to select the optimal material and finish based on operational environment, load conditions, and lifecycle requirements. With advanced metal additive systems and rigorous quality control, we deliver parts that meet the highest standards in performance and precision.

Manufacturing Process & QC

Production Process: From Concept to Flawless Metal Components

At Wuxi Lead Precision Machinery, our end-to-end metal additive manufacturing process is engineered for uncompromising quality. We eliminate defects at every stage through integrated engineering rigor and real-time validation, ensuring your high-stakes components meet aerospace, medical, and energy sector demands. The journey begins with collaborative design refinement. Our engineers conduct mandatory Design for Additive Manufacturing (DfAM) reviews, optimizing topology, support structures, and thermal management using ANSYS simulation. This phase prevents 92% of potential build failures by addressing stress concentrations and residual deformation risks before metal meets laser. Clients receive actionable feedback within 48 hours, accelerating time-to-prototype while locking in geometric and material integrity.

Prototyping transitions seamlessly into our certified production environment. We utilize EOS M 400-4 quad-laser systems within ISO Class 8 cleanrooms, processing Inconel 718, Ti-6Al-4V, and custom alloys under full inert gas shielding. Each build undergoes in-situ melt pool monitoring via coaxial high-speed cameras and pyrometers, with AI-driven anomaly detection halting production if deviations exceed 5-micron thresholds. Post-build, parts undergo stress-relief annealing in vacuum furnaces followed by precision support removal via 5-axis wire EDM—never manual grinding—to preserve critical surface finishes. Every prototype receives full metrology: 100% CMM inspection against CAD nominal, micro-CT porosity scans, and mechanical validation per ASTM F3301. Only components passing all criteria advance to mass production.

Scale-up leverages our digital thread architecture, where validated build parameters from prototyping auto-populate production jobs. We enforce zero-defect mass production through three non-negotiable protocols. First, real-time powder recycling with OES chemical verification maintains material consistency across 50+ consecutive builds. Second, automated post-processing cells integrate CNC milling, honing, and MPI inspection, eliminating human-induced variability. Third, final parts undergo batch traceability via blockchain-secured digital passports, documenting every process parameter from raw material lot to shipping. This closed-loop system reduces scrap rates to 0.18%—well below industry averages—while delivering ±15µm accuracy at volumes up to 5,000 units monthly.

Critical Production Specifications

| Parameter | Capability | Industry Standard |

|---|---|---|

| Material Range | Ti-6Al-4V, Inconel 718, 17-4PH, CoCr | Limited alloys |

| Build Volume | 400 x 400 x 400 mm | 250 x 250 x 250 mm |

| Dimensional Accuracy | ±15 µm | ±50 µm |

| Surface Roughness (as-built) | Ra 8–12 µm | Ra 15–25 µm |

| Porosity Compliance | ASTM F3301 Class A (≤0.1%) | Class B (≤0.5%) |

This integrated approach transforms design intent into certified production reality. By embedding defect prevention into each phase—not just final inspection—we deliver metal AM components where failure is never an option. Wuxi Lead’s process is your assurance of performance-critical parts, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal 3D Printing

At Wuxi Lead Precision Machinery, we don’t just offer 3D printing services—we deliver precision-engineered metal components backed by decades of advanced manufacturing experience. As a trusted partner in the global custom metal manufacturing sector, we specialize in high-performance additive solutions tailored to the exacting demands of aerospace, medical, energy, and industrial automation industries. When you choose Lead Precision, you gain more than a supplier; you align with a team committed to engineering excellence, material integrity, and on-time delivery.

Our metal 3D printing capabilities are built on state-of-the-art laser powder bed fusion (LPBF) technology, ensuring dimensional accuracy down to ±0.02 mm and surface finishes as fine as Ra 4.0 μm. We work with a comprehensive range of high-grade alloys, including titanium (Ti6Al4V), stainless steel (316L, 17-4 PH), Inconel (625, 718), aluminum (AlSi10Mg), and cobalt-chrome, enabling us to meet the most demanding performance criteria. Whether producing complex lattice structures, lightweight aerospace brackets, or biocompatible medical implants, our in-house engineering team collaborates closely with clients to optimize designs for manufacturability, strength, and cost-efficiency.

Every project undergoes rigorous quality control, supported by ISO 9001-certified processes, full material traceability, and post-processing capabilities such as heat treatment, HIP (Hot Isostatic Pressing), CNC finishing, and surface polishing. Our facility in Wuxi is equipped with advanced metrology tools—including coordinate measuring machines (CMM) and industrial CT scanning—to validate internal and external geometries with uncompromising precision.

We understand that in high-stakes industries, reliability is non-negotiable. That’s why we prioritize transparency, technical consultation, and rapid prototyping cycles to accelerate your time to market. From concept validation to full-scale production, Lead Precision ensures your components meet both functional and regulatory standards.

| Specification | Detail |

|---|---|

| Technology | Laser Powder Bed Fusion (LPBF) |

| Build Envelope | 250 x 250 x 300 mm (max) |

| Layer Thickness | 20–60 μm |

| Dimensional Accuracy | ±0.02 mm |

| Surface Roughness (as-built) | Ra 10–15 μm (can be polished to Ra 4.0 μm) |

| Materials | Ti6Al4V, 316L, 17-4 PH, Inconel 625 & 718, AlSi10Mg, CoCr |

| Post-Processing | Stress relief, HIP, CNC machining, polishing, passivation |

| Quality Standards | ISO 9001, Full Material Certification, NDT Available |

To discuss your next custom metal 3D printing project, contact us today at [email protected]. Our engineering team is ready to support you with technical insights, rapid quotations, and scalable production planning. Partner with Wuxi Lead Precision Machinery—where innovation meets industrial precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.