Technical Contents

Engineering Guide: Sheet Metal Box Design

Engineering Insight Precision in Sheet Metal Box Design

Achieving true precision in sheet metal box design transcends basic dimensional accuracy; it is the foundational element ensuring structural integrity, seamless assembly, optimal functionality, and long-term reliability in demanding applications. In high-stakes sectors like aerospace, defense, medical equipment, and advanced instrumentation, even minute deviations—measured in tenths of a millimeter—can cascade into catastrophic field failures, costly rework, or compromised system performance. Precision governs critical factors: consistent bend radii preventing material stress fractures, exact hole placement for flawless component integration, and uniform wall thickness ensuring electromagnetic shielding integrity or thermal management. It is not merely a manufacturing specification but an engineering imperative woven into the earliest design phases. Neglecting precision at the conceptual stage inevitably compounds costs and delays downstream, turning minor tolerances into major production bottlenecks.

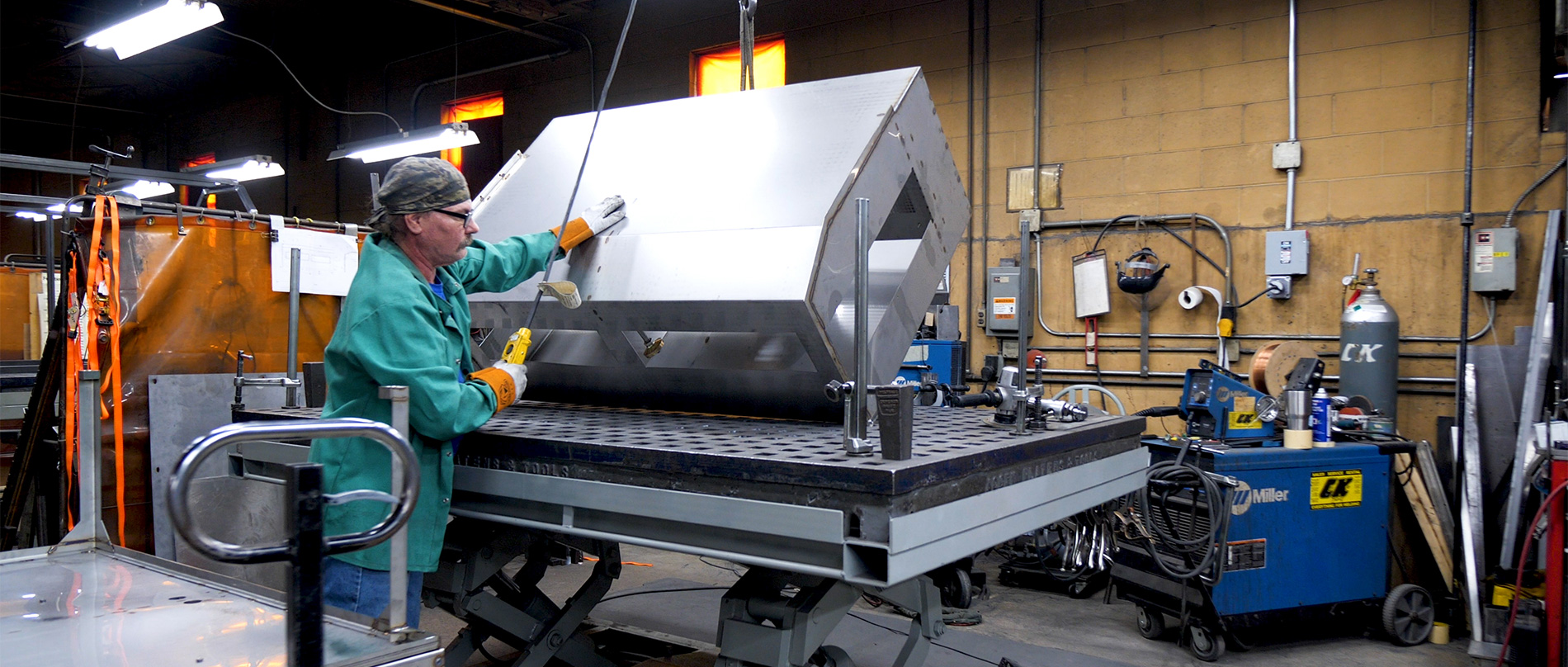

Wuxi Lead Precision Machinery operates at this pinnacle of exacting fabrication, where theoretical tolerances meet real-world consequences. Our engineering team possesses deep expertise in translating complex design intent into physically flawless enclosures, rigorously validated through advanced metrology. This capability is proven in projects where failure was not an option. We engineered and delivered precision sheet metal housings for timing and scoring systems deployed at the Beijing 2022 Winter Olympics, where environmental extremes and zero-margin-for-error reliability were mandated. Similarly, we fabricate mission-critical enclosures for military communication and sensor platforms, adhering to stringent MIL-STD specifications that demand absolute consistency under vibration, shock, and corrosive conditions. These engagements underscore our commitment: precision is non-negotiable when human safety, national security, or global event integrity depend on the enclosure’s performance.

The interplay between design choices and achievable precision is critical. The following table outlines key parameters and their impact:

| Parameter | Standard Tolerance Range | Critical Application Tolerance | Design Impact |

|---|---|---|---|

| Linear Dimension | ±0.1 mm to ±0.2 mm | ±0.05 mm or tighter | Affects panel fit, gasket compression, internal component alignment |

| Bend Radius Consistency | ±0.15 mm | ±0.05 mm | Critical for structural strength, avoiding cracks, ensuring smooth assembly |

| Hole Positional Accuracy | ±0.1 mm | ±0.03 mm | Determines bolt pattern fit, connector mating, PCB mounting reliability |

| Flatness (per 100mm) | 0.1 mm | 0.03 mm | Essential for sealing surfaces, EMI shielding effectiveness, optical alignment |

Understanding these tolerances during the design phase allows for intelligent trade-offs. Specifying tighter tolerances universally inflates cost; precision engineering identifies where microscopic accuracy is mission-critical versus where standard fabrication suffices. At Lead Precision, we collaborate closely with client engineering teams during DFM (Design for Manufacturability) reviews, leveraging our CNC turret punching, laser cutting, and robotic bending cells—calibrated to sub-0.02mm repeatability—to define achievable, cost-effective precision pathways. This proactive partnership ensures the final sheet metal box isn’t just dimensionally correct, but a perfectly integrated, reliable component of your larger system, built to perform flawlessly in the field. Your design integrity starts with our precision foundation.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-precision industrial applications. Our technical capabilities are built around state-of-the-art equipment, rigorous quality control protocols, and a deep understanding of complex design requirements. At the core of our production floor is a suite of 5-axis CNC machining centers, enabling us to handle intricate sheet metal box designs with superior accuracy and repeatability. These multi-axis systems allow simultaneous machining from multiple angles, minimizing setup changes and ensuring tight tolerances across complex geometries.

Our 5-axis CNC technology supports a broad range of materials, including stainless steel, aluminum, mild steel, and specialty alloys, accommodating diverse industry demands—from telecommunications enclosures to medical and aerospace components. The integration of high-speed cutting tools with dynamic workholding systems ensures efficient material removal while maintaining surface integrity and dimensional stability. This capability is particularly critical in sheet metal box fabrication, where features such as mounting flanges, ventilation patterns, and internal brackets require precise alignment and consistent edge quality.

Complementing our machining strength is a fully equipped metrology lab featuring Coordinate Measuring Machine (CMM) inspection systems. Every critical component undergoes comprehensive dimensional verification to ensure compliance with engineering specifications. Our CMM systems provide non-contact and tactile measurement options, capable of validating geometric dimensioning and tolerancing (GD&T) callouts, hole patterns, flatness, and profile deviations with micron-level accuracy. This closed-loop quality assurance process enables real-time feedback for process adjustment, reducing variability and ensuring batch-to-batch consistency.

We specialize in low-to-mid volume production runs where precision, reliability, and design complexity are paramount. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase, identifying potential challenges in sheet metal formability, weld distortion, or assembly interference before production begins. This proactive approach reduces lead times, lowers total cost of ownership, and enhances product performance in the field.

The following table outlines the standard technical specifications and achievable tolerances for our sheet metal box fabrication services:

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.1 mm | ±0.05 mm |

| Hole Diameter (drilled) | ±0.1 mm | ±0.05 mm |

| Hole Position Tolerance | ±0.15 mm | ±0.08 mm |

| Flatness (per 100 mm) | 0.1 mm | 0.05 mm |

| Edge Perpendicularity | ±0.2° | ±0.1° |

| Feature-to-Feature Alignment | ±0.1 mm | ±0.05 mm |

| Surface Roughness (machined) | Ra 3.2 µm | Ra 1.6 µm |

| Weld Distortion (post-process) | ≤0.5 mm/m | ≤0.3 mm/m |

All tolerances are validated through CMM inspection and documented in our quality reports, which are available to clients upon request. Wuxi Lead Precision Machinery remains committed to delivering engineered excellence in every sheet metal enclosure we produce.

Material & Finish Options

Material Selection for Precision Sheet Metal Enclosures

Selecting the optimal material for sheet metal box fabrication directly impacts structural integrity, environmental resilience, total cost of ownership, and manufacturing lead times. At Wuxi Lead Precision Machinery, we prioritize materials that balance performance with producibility on our state-of-the-art CNC punching, bending, and welding platforms. Below we detail critical considerations for aluminum, steel, and titanium—alongside essential finish specifications—to ensure your enclosure meets functional and longevity requirements.

Aluminum alloys, particularly 5052-H32 and 6061-T6, dominate applications requiring lightweight construction, corrosion resistance, and excellent thermal/electrical conductivity. These grades form cleanly on our Amada press brakes with minimal springback, reducing secondary correction time. While cost-effective for medium-volume production, aluminum requires protective finishes like anodizing in aggressive environments. Avoid 7075 for enclosures due to poor formability and weld cracking risks.

Carbon steel (SPCC, SPHC) remains the economic choice for high-strength structural housings where weight is non-critical. Its superior weldability and paint adhesion suit industrial control cabinets, though untreated steel demands rigorous surface preparation to prevent oxidation. We recommend galvannealed steel for outdoor applications requiring powder coating adhesion. Note that steel’s higher density increases shipping costs versus aluminum—a factor often overlooked in TCO calculations.

Titanium Grade 2 is reserved for extreme scenarios: aerospace, medical implants, or marine hardware exposed to saltwater. Its exceptional strength-to-weight ratio and biocompatibility justify costs 5–8x higher than aluminum, but titanium’s low thermal conductivity challenges welding and necessitates specialized tooling. Fabrication lead times increase by 30–40% due to slower machining speeds and stringent handling protocols to avoid contamination.

Critical Material Specifications Comparison

| Property | Aluminum 5052-H32 | Carbon Steel SPCC | Titanium Grade 2 |

|---|---|---|---|

| Typical Thickness Range | 0.8–3.0 mm | 0.5–4.0 mm | 0.8–2.5 mm |

| Tensile Strength (MPa) | 210–240 | 270–380 | 345–450 |

| Corrosion Resistance | Moderate (bare) | Low (bare) | Exceptional |

| Weldability | Good | Excellent | Moderate* |

| Relative Cost Factor | 1.8x | 1.0x | 5.5x |

Anodizing Finish Selection Guidelines

Anodizing transforms aluminum’s surface into a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing (5–25 μm) offers basic corrosion resistance and dye compatibility for aesthetic branding. For enclosures subjected to abrasion or chemical exposure, Type III (hard coat) anodizing (25–50 μm) is mandatory—achieving 500+ HV hardness while maintaining critical dimensional tolerances. Crucially, specify masking of threaded inserts and grounding points during anodizing to preserve electrical continuity. Wuxi Lead’s in-house finishing line ensures precise thickness control per MIL-A-8625 standards, eliminating adhesion failures common with third-party vendors.

Material choice must align with your enclosure’s operational lifecycle. Over-specifying titanium for indoor electronics housings inflates costs unnecessarily, while under-specifying steel for coastal deployments guarantees premature field failures. Consult our engineering team early for a free DFM review—we’ll identify cost-saving material alternatives without compromising performance.

Manufacturing Process & QC

Design: Engineering Precision from Concept to CAD

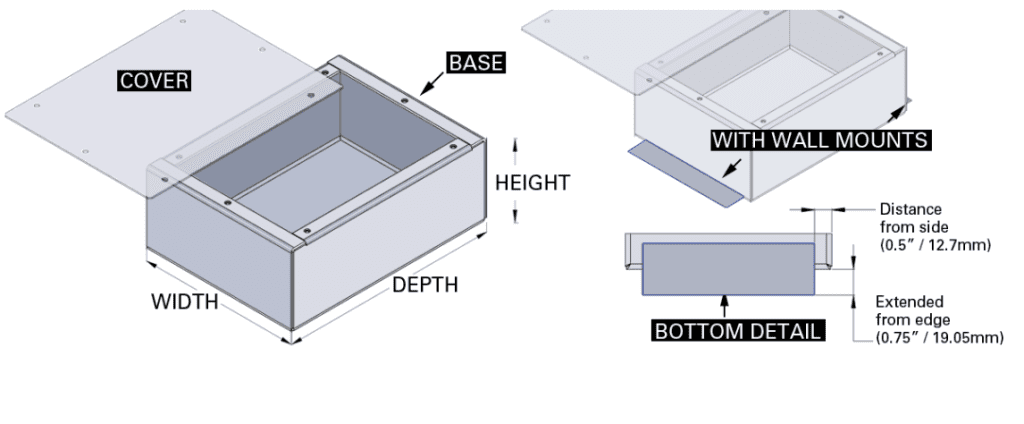

At Wuxi Lead Precision Machinery, the foundation of flawless sheet metal box production begins with precision engineering during the design phase. Our design team collaborates closely with clients to translate functional requirements into manufacturable, high-integrity enclosures. Using advanced CAD software such as SolidWorks and AutoCAD, we develop 3D models that incorporate critical factors including material selection, wall thickness, bend radii, and tolerance stacking. Every design is optimized for manufacturability, ensuring that features such as louvers, embosses, and mounting flanges are placed to minimize stress and deformation during fabrication. Thermal expansion, EMI shielding, and environmental resistance are also evaluated at this stage to ensure long-term performance in demanding applications. Design for Assembly (DFA) principles are applied to reduce part count and simplify integration, ultimately lowering total cost of ownership.

Prototyping: Validating Form, Fit, and Function

Once the design is finalized, a functional prototype is produced using our state-of-the-art CNC punching, laser cutting, and bending equipment. This phase is critical for verifying dimensional accuracy, structural integrity, and compatibility with downstream processes such as welding, surface treatment, and assembly. Prototypes undergo rigorous inspection using coordinate measuring machines (CMM) and laser scanning to confirm compliance with GD&T specifications. We also conduct fit checks with mating components and perform environmental simulations when required. Feedback from prototype testing is systematically incorporated into the final design, closing the loop on potential defects before mass production begins. This iterative validation ensures that every sheet metal box meets the exact performance and aesthetic standards expected in high-end industrial, medical, and telecommunications applications.

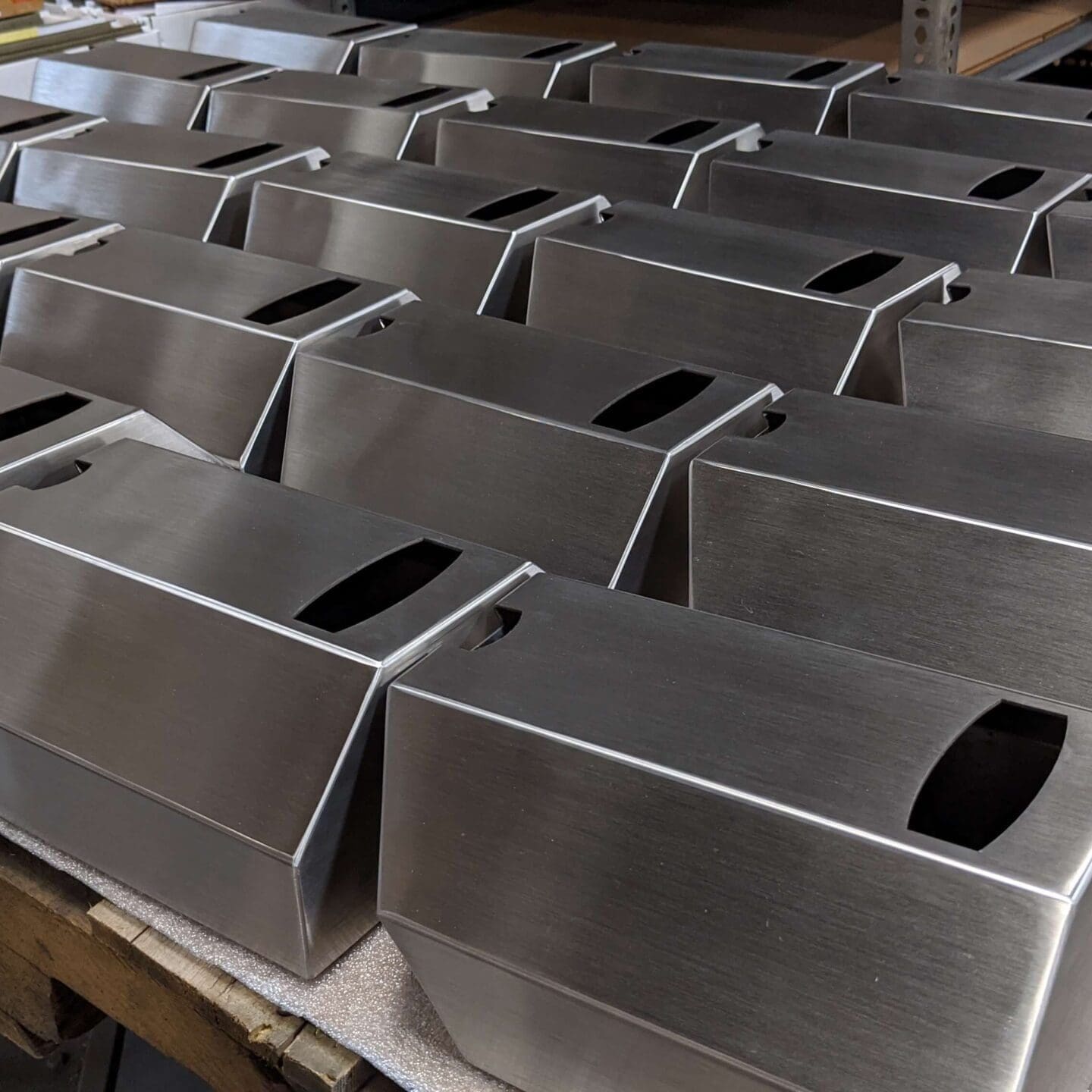

Mass Production: Zero Defects Through Process Control

With design and prototyping complete, we transition to high-volume manufacturing under a Zero Defects framework. Our production floor integrates automated material handling, real-time process monitoring, and in-line quality checkpoints to maintain consistency across thousands of units. Each stage—cutting, bending, welding, and finishing—is governed by standardized work instructions and operator certifications. Statistical process control (SPC) data is continuously collected to detect and correct deviations before they affect output quality. Final inspection includes full dimensional reporting, visual checks under controlled lighting, and functional testing where applicable. Traceability is maintained through batch coding and digital records, ensuring full accountability from raw material to finished product.

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Bending) | ±0.1 mm |

| Minimum Bend Radius | 0.5× material thickness |

| Surface Finish Options | Powder coating, anodizing, passivation, plating |

| Max Part Size | 1500 mm × 3000 mm |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001:2015, IATF 16949 |

Through disciplined execution across design, prototyping, and production, Wuxi Lead Precision Machinery delivers sheet metal enclosures that combine precision, durability, and scalability—engineered for perfection.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Box Projects Through Strategic Partnership

Precision sheet metal enclosures demand more than component sourcing they require a collaborative engineering partnership. At Wuxi Lead Precision Machinery, we transcend conventional fabrication to become your strategic extension in solving complex design and production challenges. Our integrated approach combines advanced CNC forming, robotic welding, and rigorous quality control to transform your specifications into mission-critical enclosures that meet exacting aerospace, medical, and industrial standards. With ISO 9001:2015 certification and 15 years of high-mix, low-volume expertise, we ensure every bend, cut, and finish aligns with your functional and aesthetic requirements.

Our technical capabilities are engineered for uncompromising performance. The table below outlines core specifications achievable across our production ecosystem:

| Specification Category | Capability Range | Industry Standard Compliance |

|---|---|---|

| Material Thickness | 0.5 mm – 6.0 mm | ASTM A653, EN 10143, JIS G 3141 |

| Dimensional Tolerance | ±0.1 mm (critical features) | ISO 2768-mK, DIN 1690-1 |

| Forming Complexity | Up to 8-axis CNC bending | Custom tooling for radii <1.5T |

| Surface Finishes | Anodizing, powder coating, passivation | ASTM B117, ISO 9227 |

| Welding Processes | TIG, MIG, laser | AWS D1.1, ISO 15609-1 |

This precision is sustained through proactive collaboration. Our engineering team engages during your design phase to optimize manufacturability, reduce assembly time, and prevent cost-overruns—addressing issues like flange interference, weld accessibility, and material grain direction before tooling begins. We deploy DFMA principles to eliminate non-value-added steps while maintaining structural integrity, directly impacting your time-to-market and total cost of ownership.

Partnering with Lead Precision means accessing a single-source solution for prototyping through serial production. Our facility in Wuxi integrates laser cutting, precision stamping, and automated finishing under one roof, ensuring consistent quality control and seamless process handoffs. Real-time production tracking and dedicated project management provide transparency from initial quote to delivery, with rapid response to engineering change orders.

For high-stakes applications where enclosure failure is not an option, trust a partner whose processes are validated by Tier-1 OEMs across Europe and North America. We invest in your success through continuous improvement cycles and technical resource sharing—transforming supplier relationships into growth catalysts.

Initiate your next-generation sheet metal enclosure project with confidence. Contact our engineering team directly at Contact [email protected] to discuss design validation, material selection, or production scaling. Include your project specifications and target timeline for a comprehensive capability assessment within 24 business hours. Let us demonstrate how precision partnership drives measurable value in your manufacturing ecosystem.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.