Technical Contents

Engineering Guide: Plastic Injection Mold Retailer

Engineering Insight: The Critical Role of Precision in Plastic Injection Mold Manufacturing

In the world of custom metal manufacturing, particularly within the domain of plastic injection mold production, precision is not merely a quality objective—it is a fundamental engineering requirement. For plastic injection mold retailers serving high-performance industries such as aerospace, medical devices, and defense, the margin for error is effectively zero. The performance, consistency, and longevity of injection-molded components are directly tied to the dimensional accuracy, surface finish, and thermal stability of the molds themselves. At Wuxi Lead Precision Machinery, we understand that delivering excellence in mold manufacturing demands more than advanced equipment—it requires decades of refined craftsmanship, rigorous process control, and a deep commitment to engineering integrity.

Our expertise in producing high-precision molds is rooted in over 15 years of specialized experience serving clients with mission-critical applications. This includes participation in projects linked to Olympic-standard equipment manufacturing and precision components for military-grade systems. These engagements demanded not only adherence to international tolerances but also full traceability, material certification, and repeatable performance under extreme conditions. Such standards have shaped our approach to every mold we produce, ensuring that even in commercial applications, our clients receive engineering-grade reliability.

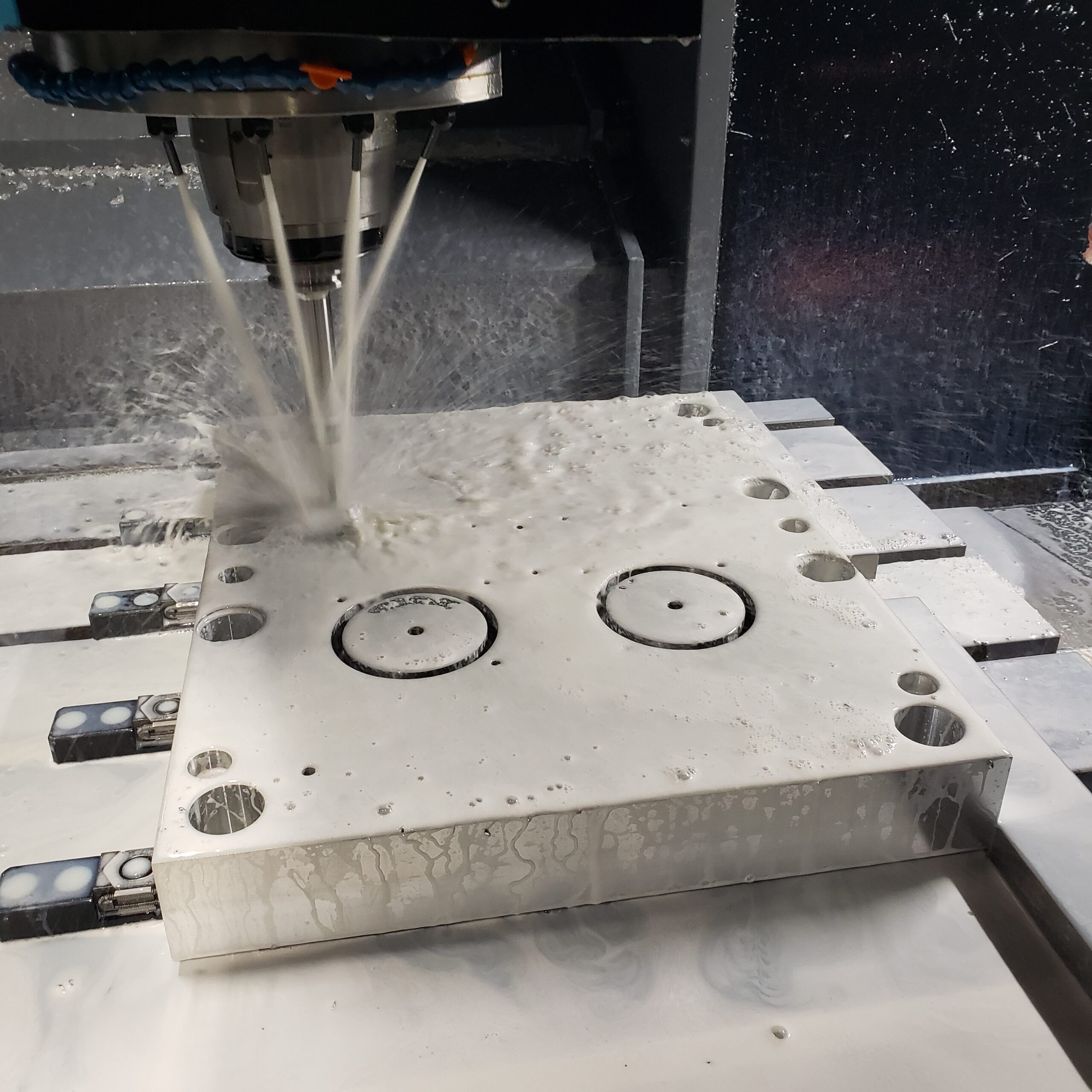

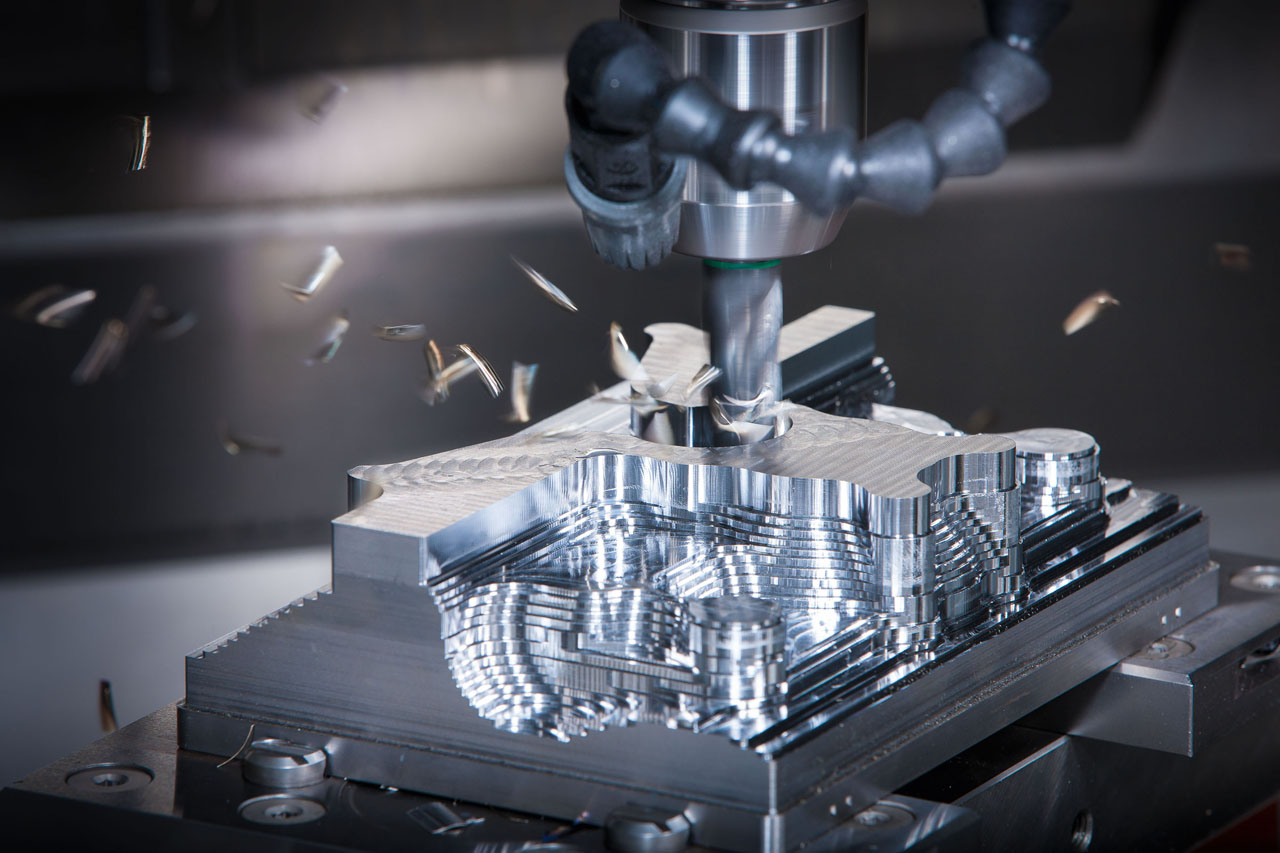

Precision in mold manufacturing begins with design validation and extends through material selection, CNC machining, EDM processing, polishing, and final assembly. Each phase requires micron-level accuracy and continuous metrological verification. At Lead Precision, we utilize state-of-the-art 5-axis CNC centers, high-speed milling systems, and laser measurement technology to maintain tolerances as tight as ±0.002 mm. Our engineering team employs advanced mold flow analysis and thermal simulation software to anticipate and correct potential defects before steel is cut, reducing time-to-market and enhancing part consistency.

For plastic injection mold retailers, partnering with a manufacturer that upholds these standards is essential. It ensures that the molds delivered to end clients will support high-volume production with minimal downtime, reduced scrap rates, and long service life. In industries where component failure is not an option, the mold must perform flawlessly—cycle after cycle.

The table below outlines key precision specifications achieved at Wuxi Lead Precision Machinery:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.025 µm (mirror finish) |

| Mold Life Expectancy | Up to 1,000,000 cycles |

| Material Options | P20, 718H, S136, NAK80, H13 |

| CNC Machining Accuracy | 0.001 mm repeatability |

| Lead Time (Average) | 25–45 days, based on complexity |

By integrating military-grade discipline with industrial innovation, Wuxi Lead Precision Machinery sets a benchmark in the plastic injection mold sector. For retailers seeking to offer unmatched quality and reliability, our engineering rigor ensures that every mold is a testament to precision, durability, and performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Mold Excellence

Wuxi Lead Precision Machinery delivers the advanced technical foundation essential for producing high-performance plastic injection molds demanded by discerning retailers. Our integrated manufacturing ecosystem, centered on state-of-the-art multi-axis machining and rigorous metrology, ensures molds meet the exacting dimensional and surface quality requirements critical for consistent part production, extended tool life, and reduced downtime for your customers. We understand that mold precision directly translates to your end-users’ production efficiency and part quality, forming the cornerstone of our capability investment.

Our core manufacturing strength lies in a dedicated fleet of high-precision 5-axis CNC machining centers. These systems enable the complete, single-setup machining of complex mold bases, intricate cavities, cores, sliders, and lifters with exceptional geometric accuracy. The simultaneous 5-axis capability eliminates cumulative errors inherent in multiple setups, critical for maintaining tight positional relationships between features like cooling channels, ejector pins, and parting lines. This technology is indispensable for machining deep ribs, undercuts, organic contours, and fine textures common in modern mold design, significantly reducing lead times while enhancing overall mold integrity and repeatability. Material versatility spans hardened tool steels (P20, H13, S136, etc.), aluminum alloys for prototypes, and specialty materials, all processed under strict environmental controls to minimize thermal distortion.

Quality assurance is not a final step but an embedded process, anchored by comprehensive Coordinate Measuring Machine (CMM) inspection. Every critical mold component undergoes full geometric dimensioning and tolerancing (GD&T) verification against the original CAD model. Our Zeiss and Hexagon CMMs provide micron-level accuracy in validating complex 3D profiles, flatness, parallelism, perpendicularity, true position, and critical bore alignments essential for mold stack assembly and function. This data-driven approach, coupled with Statistical Process Control (SPC) monitoring during machining, ensures consistent output and provides fully traceable inspection reports. Surface finish verification using profilometers guarantees optimal release characteristics and aesthetic part quality. This rigorous QC protocol mitigates risk for retailers by guaranteeing molds arrive ready for reliable, high-cavity production.

The table below details our standard achievable tolerance capabilities for critical mold features, reflecting our commitment to exceeding typical industry expectations. These values represent our standard internal control limits under stable production conditions; tighter tolerances are achievable for specific critical features upon engineering review.

| Feature Category | Dimensional Tolerance | Geometric Tolerance (GD&T) | Surface Roughness (Ra) |

|---|---|---|---|

| Core/Cavity Dimensions | ±0.005 mm | ±0.003 mm Position | 0.2 – 0.8 µm |

| Mold Base Critical Bores | ±0.003 mm | 0.002 mm True Position | 0.4 – 1.6 µm |

| Parting Line Flatness | N/A | 0.005 mm over 100mm | 0.8 – 3.2 µm |

| Slider/Lifter Alignment | ±0.005 mm | 0.005 mm Parallelism | 0.4 – 1.6 µm |

| Standard Machined Surfaces | ±0.010 mm | 0.02 mm | 1.6 – 6.3 µm |

This combination of advanced 5-axis CNC manufacturing and uncompromising CMM-based quality control delivers molds that perform predictably in high-volume production environments. For plastic injection mold retailers, partnering with Wuxi Lead means providing your customers with tools built to exact specifications, minimizing trial runs, reducing scrap rates, and ultimately strengthening your reputation for supplying reliable, high-value mold solutions. We translate technical precision into your competitive advantage.

Material & Finish Options

Material selection is a critical phase in the development of high-performance plastic injection molds, directly influencing mold longevity, production efficiency, and part quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the rigorous demands of injection molding applications. Our expertise spans the use of aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype and low-to-medium volume molds due to their excellent machinability and thermal conductivity. These properties allow for faster cycle times and reduced energy consumption during molding. While aluminum lacks the wear resistance of harder metals, its lightweight nature and cost-effectiveness make it ideal for rapid development cycles and short production runs. When enhanced with hard anodizing, aluminum molds achieve improved surface hardness and corrosion resistance, extending service life in aggressive molding environments.

Steel remains the standard for high-volume production molds, where durability and dimensional stability are paramount. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and the ability to maintain tight tolerances over millions of cycles. These materials are especially suited for complex geometries and abrasive engineering resins. Proper heat treatment and surface finishing further enhance steel’s performance, minimizing maintenance and downtime in continuous operation.

Titanium, though less common in mainstream mold construction, presents unique benefits in specialized applications. Its exceptional strength-to-density ratio, corrosion resistance, and performance at elevated temperatures make it suitable for extreme conditions, such as high-temperature resin processing or aerospace components. While higher in cost and more challenging to machine, titanium’s longevity in corrosive or high-stress environments justifies its use in niche, high-value manufacturing scenarios.

Surface treatment plays a complementary role in mold performance. Anodizing, particularly hard anodizing, is a key finishing process for aluminum molds. It forms a thick, wear-resistant oxide layer that improves surface hardness up to 60 HRC, enhances corrosion protection, and reduces friction between the mold and molten polymer. This results in smoother demolding, reduced part defects, and lower maintenance frequency.

The following table summarizes key material properties and applications for plastic injection mold construction:

| Material | Hardness (Typical) | Thermal Conductivity (W/m·K) | Best Use Case | Surface Treatment Compatibility |

|---|---|---|---|---|

| Aluminum 7075 | 150 HB | 130 | Prototypes, low-volume production | Hard anodizing, chromate conversion |

| P20 Steel | 28–32 HRC | 30 | Medium-to-high volume production | Nitriding, polishing, PVD coating |

| H13 Steel | 48–52 HRC | 35 | High-stress, high-temperature molds | Nitriding, plasma coating |

| Titanium (Grade 5) | 36 HRC | 7 | Corrosive environments, aerospace | Anodizing (specialized), coating |

Selecting the right material and finish requires a strategic balance of performance, cost, and production goals. At Wuxi Lead Precision Machinery, we work closely with clients to analyze application requirements and deliver optimized mold solutions that ensure reliability, precision, and long-term value.

Manufacturing Process & QC

Precision Injection Mold Production: From Concept to Zero-Defect Fulfillment

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production process for custom plastic injection molds, engineered to deliver flawless performance and eliminate costly field failures for our retail partners. Our methodology integrates advanced engineering with uncompromising quality verification at every stage, ensuring molds meet the exacting demands of high-volume manufacturing from day one. This systematic approach directly translates to reduced downtime and superior part consistency for your end customers.

The foundation is meticulous collaborative design. Our engineering team works directly with your specifications, utilizing 3D CAD/CAM software to optimize mold geometry, cooling channels, and ejection systems. Critical to success is comprehensive Mold Flow Analysis, simulating plastic fill, packing, and cooling behavior. This predictive step identifies potential defects like sink marks, warpage, or air traps before metal is cut, allowing design refinement to ensure cavity balance and optimal cycle times. Material selection for cores, cavities, and critical inserts is precisely matched to the polymer and production volume, considering wear resistance and thermal properties.

Prototyping serves as the indispensable physical validation phase. Utilizing our high-precision CNC machining centers, EDM, and surface grinding capabilities, we produce a fully functional pre-series mold conforming to the validated design. This prototype undergoes rigorous testing on our in-house injection molding machines. We conduct systematic trials, adjusting process parameters while meticulously inspecting molded parts against dimensional blueprints and aesthetic requirements. Cavity pressure sensors and temperature monitoring provide real-time data to confirm the mold’s stability and repeatability under production-like conditions, verifying the elimination of issues predicted or identified during simulation.

Mass production deployment leverages our zero-defect manufacturing systems. Every component undergoes 100% dimensional inspection using calibrated CMMs and optical comparators against the master CAD model. Critical surfaces receive stringent surface finish verification. During assembly, precise alignment and fit are confirmed using laser alignment tools and torque-controlled assembly procedures. Final mold validation includes a comprehensive production trial run, generating a full statistical process control (SPC) report on critical part dimensions. Only molds consistently producing parts within specification across extended cycles receive final approval and shipment. This closed-loop process, combining predictive engineering, physical validation, and relentless in-process inspection, is our guarantee of operational readiness.

The following table details key specifications achievable through our integrated process:

| Parameter | Capability | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (Critical Features) | ISO 2768-mK / Custom Spec |

| Surface Finish (Cavity) | Ra 0.025 µm (Mirror Polish) | ISO 25178 / VDI 3400 |

| Runoff (Parting Line) | ≤ 0.01 mm | Dial Indicator / CMM |

| Mold Base Flatness | ≤ 0.015 mm over 500 mm | Surface Plate / CMM |

| Production Validation | 1000+ Consecutive Good Parts | SPC Charting (Cp/Cpk ≥ 1.67) |

This disciplined progression from intelligent design through validated prototyping to statistically proven mass production ensures Wuxi Lead delivers injection molds that operate reliably at peak efficiency, safeguarding your reputation for quality and performance in the competitive retail marketplace.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components tailored to the exacting demands of the plastic injection mold industry. As a trusted partner to mold retailers worldwide, we combine advanced CNC machining capabilities, rigorous quality control, and deep industry knowledge to transform your designs into reliable, high-performance parts. Our facility in Wuxi, China, operates under ISO 9001 standards, ensuring every component meets the highest benchmarks for accuracy, durability, and consistency.

When you collaborate with Lead Precision, you gain more than a supplier—you gain a strategic manufacturing partner. We understand that plastic injection mold retailers require components with tight tolerances, superior surface finishes, and rapid turnaround times to remain competitive. Our team of senior CNC engineers works closely with your design and procurement teams to optimize manufacturability, reduce lead times, and lower total production costs. From prototype development to high-volume production runs, we provide scalable solutions that align with your business objectives.

Our advanced manufacturing infrastructure includes multi-axis CNC machining centers, wire EDM, grinding, and automated inspection systems. This enables us to produce complex geometries and hardened steel components essential for mold bases, inserts, cores, and cavities. We support a wide range of materials, including P20, 718H, NAK80, H13, and custom alloys, with heat treatment and surface treatment options available in-house or through certified partners.

We are committed to transparency, responsiveness, and long-term partnership. Our project management system ensures real-time communication, detailed progress reporting, and on-time delivery—critical for maintaining your supply chain efficiency.

Below are key technical specifications that define our manufacturing capabilities:

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 μm (polished and machined) |

| Maximum Part Size | 1200 x 800 x 600 mm |

| Minimum Feature Size | 0.1 mm (micro-machining) |

| Materials Processed | P20, 718H, NAK80, H13, S136, Stainless Steel, Aluminum, Brass |

| Heat Treatment | Through-hardening, Nitriding, Annealing (in-house and partner facilities) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), CMM reporting |

| Lead Time (Typical) | 10–25 days (depending on complexity and volume) |

Partnering with Wuxi Lead Precision Machinery means securing a reliable, technically advanced manufacturing source in China that understands the unique challenges of the injection mold market. We are ready to support your next project with precision, speed, and engineering excellence.

Contact us today at [email protected] to discuss your requirements and receive a detailed quotation. Let Lead Precision be your trusted partner in custom metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.