Technical Contents

Engineering Guide: Injection Mold Maker

Engineering Insight Precision as the Non-Negotiable Foundation for Injection Mold Success

In high-volume injection molding, especially for complex automotive, medical, or consumer electronics components, mold precision is not merely desirable—it is the absolute cornerstone of profitability and product integrity. Minute deviations in cavity geometry, core alignment, or cooling channel placement directly translate into part warpage, flash, inconsistent wall thickness, and premature mold failure. These defects cascade into costly production downtime, scrap rates exceeding 5%, and ultimately, compromised end-product performance. Achieving micron-level tolerances consistently demands far more than advanced machinery; it requires an integrated engineering philosophy where material science, thermal dynamics, and ultra-precise manufacturing converge. At Wuxi Lead Precision Machinery, we recognize that the mold itself is the first critical component in the production chain. Its dimensional stability under repeated thermal cycling and mechanical stress dictates the entire manufacturing process’s viability. Compromising on mold precision inevitably leads to higher total cost of ownership through rework, secondary operations, and missed delivery windows.

Our approach integrates finite element analysis (FEA) for thermal and structural simulation during the design phase with rigorous in-process metrology throughout manufacturing. This ensures optimal cooling circuit design for uniform heat extraction and minimizes internal stresses within the mold steel. We utilize hardened, pre-hardened, and specialty alloys like NAK80, S136, and H13, meticulously heat-treated and stress-relieved to guarantee dimensional stability over millions of cycles. Every critical surface—cavities, cores, slides, and lifters—is machined using 5-axis CNC centers with sub-micron repeatability, followed by precision hand-finishing and polishing to achieve the required surface integrity. This meticulous process control is non-negotiable for molds destined for demanding applications where zero-defect production is mandatory.

Lead Precision’s commitment to this standard is validated through our execution of mission-critical molds for globally recognized programs. We engineered and manufactured complex, high-cavity molds for components used in the Beijing 2022 Winter Olympic Games infrastructure, where extreme environmental durability and absolute consistency were paramount. Similarly, our molds for defense sector applications adhere to stringent aerospace-grade specifications, producing parts where failure is not an option. These projects demanded and proved our capability to deliver molds meeting the most exacting international standards under rigorous quality audits. The table below outlines the precision benchmarks we consistently achieve for our injection mold customers.

| Parameter | Lead Precision Capability | Typical Industry Standard |

|---|---|---|

| Linear Tolerance | ±0.002 mm | ±0.005 mm to ±0.01 mm |

| Surface Roughness (Ra) | 0.05 µm (Mirror Polish) | 0.1 µm to 0.2 µm |

| Cavity/Core Parallelism | ≤ 0.003 mm over 100 mm | ≤ 0.01 mm over 100 mm |

| Mold Base Flatness | ≤ 0.005 mm per 300 mm | ≤ 0.02 mm per 300 mm |

| Critical Feature Repeatability | 100% within spec over 1M+ cycles | Variable, often degrades after 500k cycles |

This unwavering focus on precision engineering translates directly into tangible client value: extended mold life exceeding 2 million cycles, reduced cycle times through optimized thermal management, near-zero scrap rates from the first shot, and elimination of costly post-molding corrections. For injection mold makers serving high-stakes industries, partnering with a manufacturer that treats precision as a fundamental engineering requirement, not just a specification, is essential for sustainable success. Wuxi Lead Precision Machinery delivers this capability proven through the most demanding global applications.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery stands at the forefront of custom metal manufacturing, delivering precision-engineered components tailored to the demanding requirements of injection mold makers worldwide. Our technical capabilities are built on advanced machinery, rigorous quality control, and deep process expertise, ensuring every component meets the highest standards of accuracy and reliability.

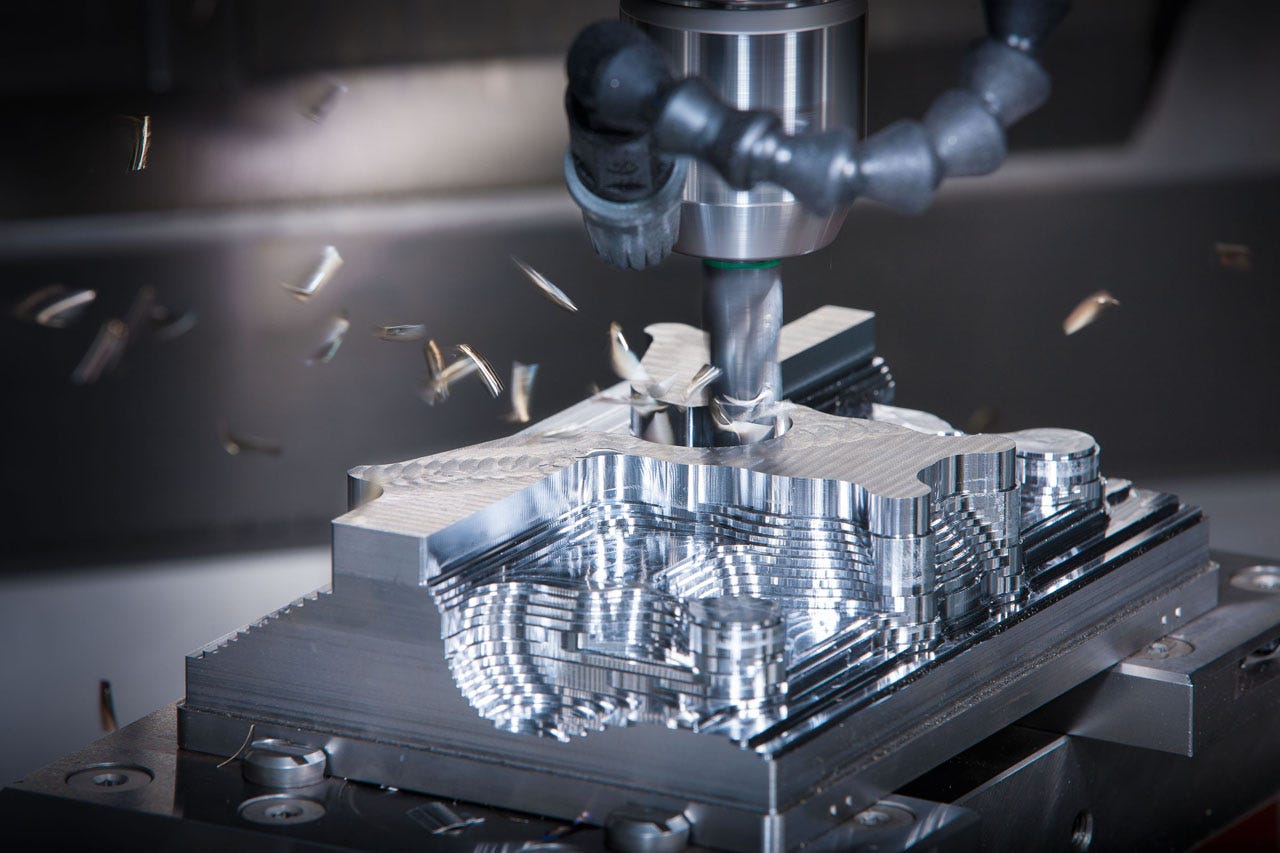

At the core of our production capability is our fleet of 5-axis CNC machining centers. These state-of-the-art systems enable multi-directional cutting with exceptional precision, allowing us to produce complex geometries and intricate mold features in a single setup. This reduces cumulative error, improves surface finish, and significantly enhances part consistency. Our 5-axis technology supports a broad range of mold components, including cavity plates, core inserts, sliders, lifters, and hot runner systems, all machined from high-grade tool steels, pre-hardened steels, and specialty alloys.

All machining operations are supported by in-house programming using advanced CAM software, ensuring optimized toolpaths, minimized cycle times, and maximum material efficiency. Our skilled machinists bring decades of combined experience in mold-making applications, ensuring that every process decision is made with functional performance and longevity in mind. From prototype to high-volume production runs, our systems are designed for repeatability and scalability.

Quality assurance is integral to our manufacturing process. Every component undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing sub-micron level verification of dimensional accuracy. Our inspection protocols cover geometric tolerances, surface profiles, hole positioning, and critical form features, ensuring full compliance with customer drawings and international standards. All inspection data is documented and available with every shipment, providing full traceability and audit readiness.

We maintain strict environmental controls in our metrology lab to eliminate thermal drift, ensuring measurement stability. In addition to CMM inspection, we employ surface roughness testers, hardness testers, and optical comparators to validate material and surface integrity. Our quality management system is aligned with ISO 9001 standards, reflecting our commitment to continuous improvement and customer satisfaction.

The following table outlines our standard machining capabilities and achievable tolerances:

| Parameter | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm (up to 300 mm) |

| Geometric Tolerance (GD&T) | ±0.01 mm (flatness, parallelism, etc.) |

| Surface Roughness (Ra) | As low as 0.4 μm (polished finishes) |

| Minimum Feature Size | 0.2 mm (micro-features, undercuts) |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Material Compatibility | P20, H13, S136, 718, NAK80, Stainless, Aluminum, Brass |

Wuxi Lead Precision Machinery combines cutting-edge technology with disciplined process control to deliver injection mold components that perform reliably in high-cycle production environments. Our technical capabilities are engineered to reduce mold downtime, improve part consistency, and accelerate time-to-market for our global clients.

Material & Finish Options

Material Selection for Precision Injection Molds: Optimizing Performance and Longevity

Selecting the optimal material for injection molds is critical for balancing production efficiency, part quality, and total cost of ownership. At Wuxi Lead Precision Machinery, we leverage decades of CNC expertise to guide clients through material choices aligned with volume requirements, part complexity, and resin characteristics. Aluminum, steel, and titanium each offer distinct advantages, while surface finishes like anodizing enhance durability and release properties. Understanding these parameters ensures molds meet stringent industrial demands without over-engineering.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production. Their superior thermal conductivity accelerates cooling cycles by up to 30% compared to steel, reducing part cycle times significantly. While aluminum’s lower hardness limits mold life in abrasive applications, advanced CNC milling techniques at Wuxi Lead achieve micron-level precision for intricate geometries. This material is ideal for medical device prototypes or consumer electronics housings where speed-to-market is paramount.

Tool steels like P20, H13, and S136 dominate high-volume manufacturing due to exceptional wear resistance and polishability. Hardened to 28-54 HRC, these steels withstand abrasive resins and high-cavity pressures over millions of cycles. Our proprietary heat treatment processes ensure uniform hardness and minimize distortion during machining. For corrosive environments or optical-grade parts, pre-hardened stainless variants like 420SS deliver superior resistance to chloride-based resins without sacrificing dimensional stability.

Titanium alloys (e.g., Ti-6Al-4V) serve niche applications demanding extreme strength-to-weight ratios and corrosion resistance, such as aerospace components. Though costly and challenging to machine, titanium molds endure aggressive chemical exposure and high-temperature polymers where steel would degrade. Wuxi Lead’s specialized CNC toolpaths and coolant strategies mitigate titanium’s low thermal conductivity, preventing work hardening during fabrication.

Anodizing remains the premier finish for aluminum molds, adding a hard, non-conductive oxide layer that improves wear resistance and part release. Type II (sulfuric acid) anodizing offers 10-25µm thickness for general use, while Type III (hardcoat) achieves 50µm+ for abrasive resins. Critical considerations include dimensional tolerance control—accounting for 50% of coating growth inward—and avoiding sharp edges where coating adhesion weakens. Titanium anodizing creates decorative color finishes but provides minimal wear enhancement; steel typically requires alternative treatments like nitriding.

Below summarizes key material specifications for injection mold applications:

| Material | Hardness Range (HRC) | Typical Mold Life (Cycles) | Best For Applications | Machinability Rating |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 | 10,000 – 100,000 | Prototypes, low-volume runs | Excellent (A) |

| P20 Steel | 28-32 | 100,000 – 1,000,000 | Medium-volume production | Good (B) |

| H13 Steel | 48-52 | 500,000 – 2,000,000+ | High-volume, hot-runner molds | Moderate (C) |

| Titanium | 32-36 | 500,000+ (corrosive env.) | Aerospace, chemical exposure | Poor (D) |

Material selection directly impacts your ROI through cycle time, maintenance frequency, and part consistency. Wuxi Lead Precision Machinery combines advanced CNC capabilities with material science expertise to optimize your mold’s performance profile. Consult our engineering team to evaluate resin interactions, thermal management, and cost-effective finishing strategies for your specific application.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process for injection mold makers is engineered to deliver precision, repeatability, and zero-defect performance across every phase. We integrate advanced engineering practices with rigorous quality control to ensure molds meet the highest global standards for durability, accuracy, and performance in high-volume production environments.

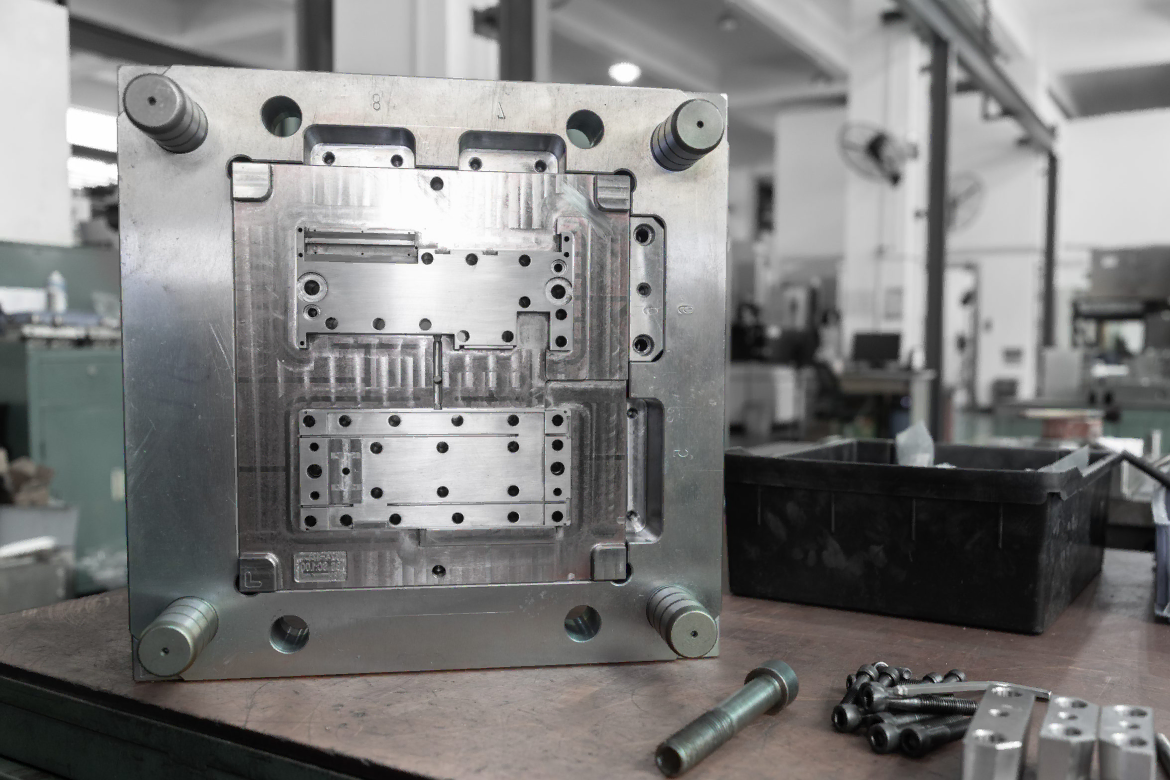

The process begins with Design, where our team collaborates closely with clients to translate technical requirements into optimized mold architectures. Using 3D CAD systems such as Siemens NX and SolidWorks, we conduct mold flow analysis, cooling simulation, and stress evaluation to anticipate potential defects and correct them preemptively. This stage includes material selection, tolerance definition, and gating system design, all aligned with the intended production volume and part complexity. Our engineering review ensures manufacturability, minimizing cycle time and maximizing mold life.

Once the design is finalized, we proceed to Prototyping. A functional prototype mold is manufactured using high-precision CNC machining, wire EDM, and surface grinding, ensuring micron-level accuracy. This prototype is used to produce initial sample parts, typically within 15–20 production cycles. These samples undergo comprehensive inspection using CMM (Coordinate Measuring Machines), optical comparators, and 3D scanning to verify dimensional conformity, surface finish, and structural integrity. Any deviations are addressed through iterative adjustments to the mold geometry or process parameters. This phase is critical for validating the design under real production conditions and eliminating latent risks before full-scale rollout.

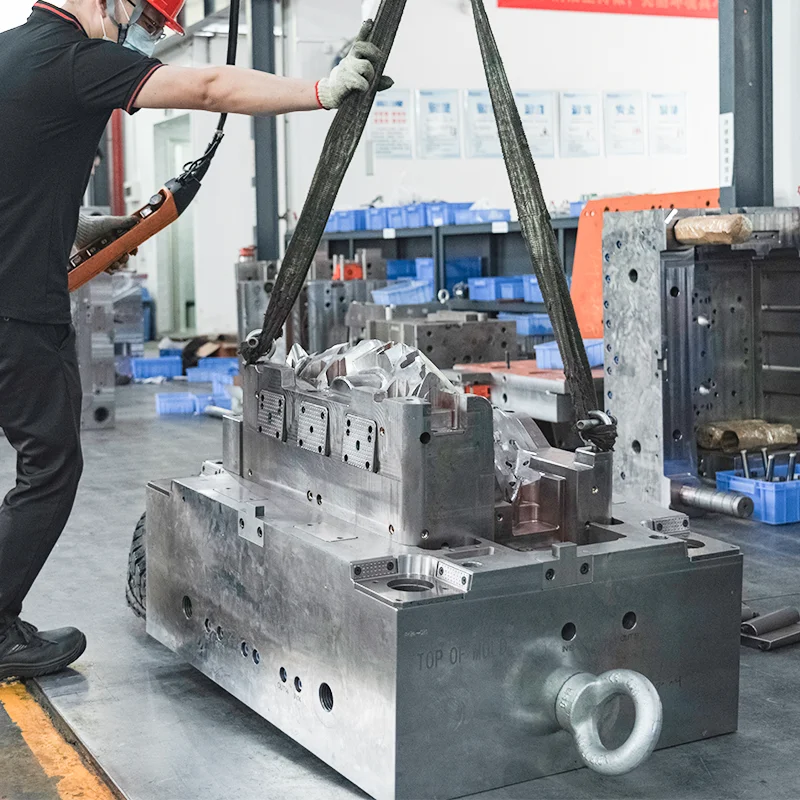

Upon client approval, we transition to Mass Production. Our automated production lines, equipped with multi-axis CNC machines and robotic part handling, ensure consistent output with minimal human intervention. Each mold is manufactured under strict ISO 9001-compliant procedures, with real-time monitoring of machining parameters, tool wear, and environmental conditions. In-process inspections occur at every critical stage—rough machining, finishing, assembly, and final testing—ensuring compliance with zero-defect objectives. Our molds are built to withstand over 1 million cycles with minimal maintenance, featuring hardened tool steels, precision-guided inserts, and optimized cooling channels.

Throughout the entire process, traceability is maintained via our digital manufacturing execution system (MES), which logs all operations, inspection data, and material certifications. This enables full accountability and rapid root cause analysis if required.

Below are key specifications for our injection mold production:

| Parameter | Specification |

|---|---|

| Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished as required) |

| Tool Steel Options | P20, 718, H13, S136, 2344, or custom alloys |

| Mold Life | 500,000 – 1,000,000+ cycles |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–45 days |

| Quality Standard | ISO 9001:2015, ISO 13485 (medical-grade) |

Our end-to-end process is designed not only to meet specifications but to exceed expectations in reliability and performance, making Wuxi Lead Precision Machinery a trusted partner for high-end injection mold manufacturing.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Precision Injection Mold Manufacturing Authority

Achieving micron-level accuracy in complex injection molds demands more than advanced machinery—it requires a partner with deep technical mastery and unwavering commitment to your project’s success. At Wuxi Lead Precision Machinery, we engineer solutions for global injection mold makers who cannot compromise on precision, repeatability, or material integrity. Our dedicated CNC manufacturing ecosystem transforms your most challenging mold designs into flawless production assets, eliminating costly iterations and accelerating time-to-market.

We specialize in high-tolerance mold bases, cavities, cores, and inserts across aerospace-grade aluminum, P20, H13, S136, and exotic alloys. Every component undergoes rigorous in-process metrology, ensuring geometric deviations remain within ±0.001mm—a standard non-negotiable for zero-defect molding. Our technical team collaborates from initial design review through final validation, applying decades of mold-flow expertise to preempt stress points, thermal variances, and ejection complexities. This proactive engineering partnership minimizes risk while maximizing mold longevity and part consistency.

Core Manufacturing Capabilities for Injection Mold Excellence

| Parameter | Specification | Relevance for Mold Makers | Verification Method |

|---|---|---|---|

| Positioning Accuracy | ±0.001 mm | Ensures perfect cavity/core alignment for zero flash | Laser interferometer calibration |

| Surface Finish | Ra 0.05 µm (optical) | Critical for cosmetic parts and easy ejection | White light interferometry |

| Max Work Envelope | 2000 x 1200 x 1000 mm | Accommodates large, multi-cavity production molds | CMM full-volume mapping |

| Material Range | Aluminum to Tool Steel (up to 60 HRC) | Supports all mold steel requirements | Spectrographic analysis |

| Spindle Speed | 24,000 RPM | Enables fine-feature milling in hardened steels | Real-time spindle monitoring |

Unlike commodity manufacturers, we integrate mold-specific protocols into every process stage. Our thermal stability-controlled machining environment prevents micro-deformations during long-cycle operations, while proprietary electrode-less EDM strategies preserve critical surface textures. Each mold component receives a full GD&T inspection report traceable to ISO 17025 standards—delivering not just parts, but documented confidence for your quality auditors.

With 15+ years serving Tier-1 automotive, medical, and consumer electronics molders, we understand that your reputation hinges on mold performance. Our zero-defect quality management system and dedicated project engineering team ensure seamless scaling from prototypes to high-volume production. When dimensional drift or surface imperfections threaten your production schedule, we resolve root causes—not symptoms.

Elevate your mold manufacturing outcomes with a partner engineered for precision. Contact our technical sales team to schedule a confidential consultation on optimizing your next mold project. Share your CAD files and requirements to receive a process-specific capability analysis within 24 hours.

Initiate your precision partnership today: [email protected]

Wuxi Lead Precision Machinery—Where Microns Define Mastery.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.