Technical Contents

Engineering Guide: Aerospace Bending Fabrication

Engineering Insight: Aerospace Bending Fabrication – The Imperative of Precision

In the realm of aerospace manufacturing, bending fabrication is not merely a step in production—it is a critical determinant of structural integrity, aerodynamic performance, and mission success. Aerospace components operate under extreme conditions: high stress, temperature fluctuations, and relentless fatigue cycles. Any deviation in geometry or material behavior during bending can compromise safety, reduce service life, or lead to catastrophic failure. This is why precision in sheet metal bending is non-negotiable in the aerospace sector.

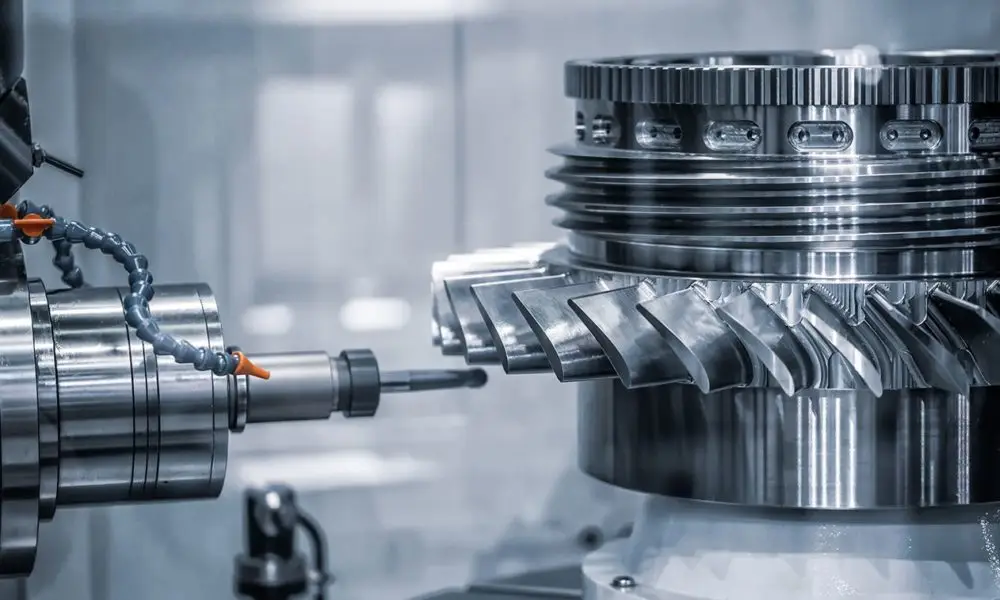

At Wuxi Lead Precision Machinery, we understand that aerospace bending demands more than advanced machinery—it requires a culture of uncompromising accuracy, deep material science knowledge, and rigorous process control. Our engineering team specializes in high-tolerance air bending, coining, and rotary draw bending techniques tailored to aerospace-grade alloys such as 7075-T6 aluminum, Ti-6Al-4V titanium, and Inconel 718. These materials present unique challenges due to their high strength-to-density ratios and springback characteristics, necessitating real-time compensation and adaptive tooling strategies.

Our facility in Wuxi integrates state-of-the-art CNC press brakes equipped with laser-guided backgauges, in-process angle measurement systems, and finite element analysis (FEA)-driven simulation software. This technological foundation enables us to achieve angular tolerances of ±0.1° and dimensional repeatability within ±0.05 mm—benchmarks that align with AS9100 and NADCAP standards. Each bending operation undergoes full digital traceability, from raw material certification to final inspection reports, ensuring full compliance with aerospace quality requirements.

Beyond technology, our experience in mission-critical sectors underscores our capability. Wuxi Lead has delivered precision components for Olympic-standard sporting equipment where material performance under dynamic load is paramount, and for military defense systems where reliability in extreme environments is essential. These projects demanded the same level of precision, documentation, and material accountability as aerospace applications, reinforcing our readiness to serve this high-stakes industry.

We recognize that aerospace OEMs and Tier 1 suppliers require more than just parts—they require partners who understand the engineering implications of every bend. Our engineering team collaborates early in the design phase, offering Design for Manufacturability (DFM) insights that optimize bend radii, grain orientation, and tooling paths to minimize residual stress and distortion.

The following table outlines key capabilities relevant to aerospace bending fabrication at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 12.0 mm |

| Max. Bending Length | 6,000 mm |

| Angular Accuracy | ±0.1° |

| Positional Repeatability | ±0.05 mm |

| Supported Materials | Aluminum (2000, 7000 series), Titanium, Stainless Steel, Inconel |

| Press Brake Capacity | Up to 2,000 tons |

| Process Standards | AS9100, ISO 9001, NADCAP (compliant) |

| In-Process Monitoring | Laser angle correction, CNC feedback |

Precision in aerospace bending is not an outcome—it is a discipline. At Wuxi Lead Precision Machinery, we apply that discipline rigorously, ensuring every component we produce meets the exacting demands of flight-critical applications.

Precision Specs & Tolerances

Precision Bending for Critical Aerospace Applications

Wuxi Lead Precision Machinery delivers aerospace-grade sheet metal bending fabrication meeting the most stringent demands of global aviation and defense programs. Our technical capabilities are engineered specifically for the complex geometries, exotic materials, and uncompromising quality standards inherent in modern aircraft structures, engine components, and avionics housings. Central to our process is a dedicated fleet of advanced 5-axis CNC press brakes, enabling the precise formation of intricate contours and compound bends in a single setup. This eliminates cumulative errors from multiple repositionings, critical for maintaining tight tolerances on features like wing rib flanges, fuselage stringers, and ducting assemblies. We routinely process high-strength aluminum alloys (2024, 7075), titanium grades (Gr 2, Gr 5), and specialty stainless steels (17-4PH, 15-5PH) common in aerospace, utilizing sophisticated tooling strategies and real-time feedback systems to manage springback and material variability inherent in these challenging materials.

Our commitment to dimensional integrity is non-negotiable. Every critical aerospace component undergoes rigorous post-bend verification using state-of-the-art Coordinate Measuring Machines (CMM). This metrology backbone provides full traceability and certified dimensional reports, essential for AS9100 compliance and customer acceptance. Our CMM inspection protocols are designed to validate complex 3D profiles, hole positions relative to formed features, and critical bend angles, ensuring parts conform precisely to engineering intent before release. Material certification and full lot traceability are standard practice, supporting stringent aerospace supply chain requirements. Process control extends beyond the machine; our operators are certified to aerospace-specific bending procedures, and in-process checks are integrated at defined stages to catch deviations immediately, minimizing scrap and rework on high-value components.

The following table details our standard achievable geometric tolerances for aerospace bending fabrication, validated through our CMM inspection system and process controls. These represent typical capabilities for materials up to 6mm thickness; specific project requirements are always reviewed and confirmed during the quoting phase.

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Bend Angle | ±0.25° | For angles 30°-150°; material dependent |

| Linear Dimension (Formed) | ±0.05 mm (±0.002″) | Over length ≤ 300 mm |

| Hole Position (to Bend) | ±0.10 mm (±0.004″) | Critical for assembly interfaces |

| Flatness (Post-Bend) | 0.15 mm per 100 mm | Measured on critical mounting surfaces |

| Edge Offset (Compound) | ±0.10 mm (±0.004″) | For multi-bend features requiring alignment |

Wuxi Lead Precision Machinery operates under a certified AS9100 quality management system, providing the documented process control and audit readiness demanded by Tier 1 aerospace suppliers and OEMs. Our technical team collaborates closely with engineering departments during DFMA reviews to optimize part design for manufacturability while ensuring all critical-to-quality characteristics are achievable within our validated bending and inspection capabilities. This integrated approach guarantees components arrive ready for assembly, reducing downstream costs and accelerating production schedules for our aerospace partners.

Material & Finish Options

Material Selection for Aerospace Bending Fabrication

In aerospace sheet metal fabrication, material selection is a critical engineering decision that directly impacts performance, weight, durability, and cost. The most commonly used materials—aluminum, steel, and titanium—each offer distinct advantages tailored to specific aerospace applications. Understanding their mechanical properties, formability, and compatibility with finishing processes such as anodizing is essential for achieving optimal component performance.

Aluminum alloys, particularly the 2024, 6061, and 7075 series, are widely favored in aerospace due to their high strength-to-weight ratio, excellent formability, and corrosion resistance. These alloys are ideal for non-structural and semi-structural components such as brackets, housings, and ducting. Aluminum’s low density contributes significantly to fuel efficiency, a primary concern in aircraft design. Additionally, aluminum is highly compatible with anodizing, a finishing process that enhances surface hardness and corrosion resistance. Type II (sulfuric acid) and Type III (hardcoat) anodizing are frequently specified, with Type III providing superior wear resistance for high-stress environments.

Steel, especially in the form of stainless steel (e.g., 304, 321, and 17-4 PH), is selected where high strength, temperature resistance, and structural integrity are paramount. While heavier than aluminum and titanium, stainless steel offers exceptional durability and is commonly used in engine components, landing gear systems, and high-temperature zones. Its limited formability compared to aluminum requires precise bending techniques and tooling, which Wuxi Lead Precision Machinery addresses through CNC press brakes with tight tolerance control. Although steel cannot be anodized, it may receive alternative surface treatments such as passivation, plating, or coating to enhance corrosion resistance.

Titanium and its alloys, such as Grade 5 (Ti-6Al-4V), are increasingly used in advanced aerospace systems due to their outstanding strength-to-density ratio, excellent performance at elevated temperatures, and superior corrosion resistance. Titanium is particularly suitable for critical structural and engine components exposed to extreme conditions. However, its high cost and challenging formability demand specialized fabrication expertise. Titanium does not anodize in the conventional sense but can undergo anodic oxidation for color coding or mild surface protection. Its springback characteristics require precise compensation during bending, a capability Wuxi Lead Precision Machinery ensures through advanced simulation and tooling calibration.

The following table summarizes key mechanical and fabrication properties of these materials:

| Material | Typical Alloys | Tensile Strength (MPa) | Density (g/cm³) | Formability | Anodizing Compatibility | Common Aerospace Applications |

|---|---|---|---|---|---|---|

| Aluminum | 2024, 6061, 7075 | 300–570 | 2.7 | Excellent | Yes (Type II & III) | Brackets, panels, enclosures |

| Stainless Steel | 304, 321, 17-4 PH | 500–1300 | 7.9 | Moderate | No | Engine parts, landing gear |

| Titanium | Grade 2, Grade 5 | 345–1000 | 4.5 | Limited | Anodic oxidation only | Jet engines, airframes, fasteners |

At Wuxi Lead Precision Machinery, we combine deep material science knowledge with state-of-the-art CNC bending technology to deliver precision-formed components that meet stringent aerospace standards. Our engineering team supports clients in selecting the optimal material and finish to ensure performance, compliance, and cost-efficiency across the product lifecycle.

Manufacturing Process & QC

Aerospace Bending Fabrication: Precision Production Process

Wuxi Lead Precision Machinery executes aerospace bending fabrication through a rigorously controlled sequence: Design, Prototyping, and Mass Production. This integrated workflow ensures absolute adherence to Zero Defects principles, critical for mission-critical components. Our process begins with collaborative engineering design validation. We utilize advanced FEA software to simulate material behavior under extreme aerospace loads, optimizing bend sequences and tooling geometry. Material certification is non-negotiable; every sheet metal batch undergoes full traceability verification against AMS and AS standards, including certified mill test reports and chemical composition analysis. Design outputs include detailed bend deduction calculations and springback compensation models specific to the alloy and temper, forming the foundation for dimensional accuracy.

Prototyping transitions validated designs into physical reality under controlled conditions. We employ dedicated high-precision CNC press brakes with real-time angle monitoring for first-article production. Each prototype undergoes comprehensive First Article Inspection (FAI) per AS9102 requirements. This involves 100% dimensional verification using calibrated CMMs, surface finish assessment, and microstructural validation where applicable. Critical bend radii and angular tolerances are scrutinized against the digital twin. Any deviation triggers immediate root cause analysis and closed-loop process correction before progression. This stage confirms not only part geometry but also the robustness of the documented manufacturing procedure.

Mass production leverages the perfected parameters from prototyping within a statistically controlled environment. Our production cells feature Siemens-controlled CNC press brakes operating under SPC protocols. Every bend cycle is monitored for tonnage, stroke position, and angle via integrated sensors, with data logged for full traceability. In-process inspections occur at statistically determined intervals using automated optical comparators, supplemented by periodic CMM checks on critical features. Material handling utilizes non-marring fixtures to prevent surface contamination or distortion. The Zero Defects mandate is enforced through multi-stage verification: operator self-checks, cross-functional quality audits, and final inspection against the FAI baseline. Non-conforming material is quarantined instantly, with corrective actions implemented before production resumes. This systematic approach guarantees components meet the stringent fatigue and structural integrity demands of aerospace applications.

Key production capabilities enabling this precision are detailed below:

| Parameter | Specification | Control Standard | Verification Method |

|---|---|---|---|

| Angular Tolerance | ±0.05° to ±0.1° | AS9100 Rev D | Laser Angle Measurement |

| Linear Dimension | ±0.025 mm | ISO 2768-mK | CMM (0.0001″ Accuracy) |

| Material Traceability | Full Heat/Lot Trace to Mill Cert | AMS 2300 Series | Digital Documentation |

| Process Monitoring | Real-time Force & Angle Feedback | Internal SPC Protocol | Statistical Process Chart |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Aerospace Bending Fabrication Excellence

When it comes to aerospace bending fabrication, precision, repeatability, and compliance are non-negotiable. At Wuxi Lead Precision Machinery, we understand the rigorous demands of the aerospace industry—where every degree of bend, every micron of tolerance, and every material specification impacts performance, safety, and certification. As a trusted partner in high-end sheet metal fabrication, we deliver engineered solutions that meet and exceed the expectations of global aerospace manufacturers and tier-one suppliers.

Our advanced CNC press brakes, equipped with high-resolution angle measurement systems and automated tool changers, ensure consistent accuracy across complex bending sequences. With bending capacities from 0.5 mm to 12 mm in mild steel and specialized capabilities for aluminum alloys, titanium, and high-strength composites, we support a broad spectrum of aerospace components—from structural brackets and fuselage panels to engine housings and avionics enclosures.

What sets us apart is our integration of precision engineering with full-process traceability. Every fabrication job undergoes strict in-process inspection using laser-based metrology systems, ensuring angular accuracy within ±0.2° and dimensional tolerances held to ±0.05 mm. Our facility operates under AS9100D and ISO 9001:2015 standards, with documented material certifications, first-article inspections, and process validation reports available for full audit compliance.

We specialize in low-to-medium volume production runs with rapid turnaround, ideal for prototyping, R&D projects, and serialized component manufacturing. Our engineering team collaborates directly with design and manufacturing departments to optimize bend sequences, minimize springback, and reduce secondary operations—delivering not just parts, but value-engineered solutions.

Below are key technical specifications that define our aerospace bending capabilities:

| Specification | Detail |

|---|---|

| Maximum Bending Length | 4,000 mm |

| Bending Capacity (Mild Steel) | Up to 12 mm thickness |

| Angular Accuracy | ±0.2° |

| Positional Tolerance | ±0.05 mm |

| Material Compatibility | Aluminum (2000, 5000, 7000 series), Titanium, Stainless Steel, High-Strength Composites |

| Equipment | CNC Press Brakes (Amada-compatible), Automatic Backgauges, Laser Angle Measurement |

| Standards Compliance | AS9100D, ISO 9001:2015, NADCAP (available upon request) |

| Secondary Integration | Deburring, Welding, Surface Treatment Coordination |

Partnering with Wuxi Lead Precision Machinery means access to a fabrication team that speaks the language of aerospace engineering. We are committed to on-time delivery, technical transparency, and continuous improvement—driving efficiency and reliability into every component we produce.

For engineering inquiries, project collaboration, or to request a quote, contact us today at [email protected]. Let us be your precision partner in aerospace fabrication.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.