Technical Contents

Engineering Guide: Large Component Machining

Engineering Insight: Precision in Large Component Machining

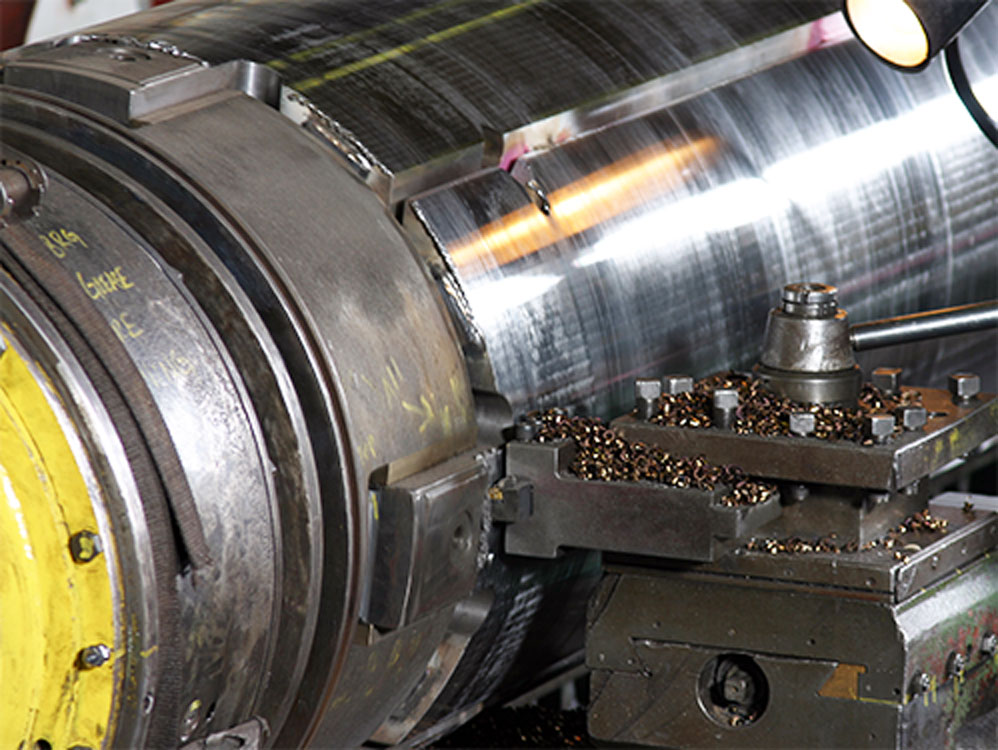

In the realm of custom metal manufacturing, large component machining represents one of the most demanding and technically sophisticated disciplines. Unlike standard machining operations, working with oversized parts introduces unique challenges related to structural rigidity, thermal stability, and geometric accuracy. At Wuxi Lead Precision Machinery, we understand that precision is not merely a performance metric—it is a foundational requirement for mission-critical applications in aerospace, defense, energy, and high-performance infrastructure.

The scale of a component directly impacts the complexity of maintaining tight tolerances. As dimensions increase, so do the risks of deflection, vibration, and thermal expansion. Even minute deviations—measured in microns—can compromise the functionality, safety, and longevity of the final assembly. This is especially critical in sectors such as military systems and large-scale sporting infrastructure, where failure is not an option.

Wuxi Lead Precision Machinery has cultivated deep expertise in this high-stakes domain. Our engineering team has successfully delivered large-scale machined components for Olympic-grade structural systems and advanced military platforms. These projects demanded not only the ability to process massive workpieces but also the precision to ensure flawless integration under extreme operational conditions. Our experience underscores a fundamental truth: large does not mean lenient. On the contrary, the larger the component, the more exacting the control must be across every phase of machining.

Our facility is equipped with multi-axis CNC gantry machines, high-torque spindle systems, and advanced probing technology capable of in-process verification. These tools, combined with rigorous thermal compensation protocols and finite element analysis (FEA)-driven fixturing, allow us to maintain tolerances that rival those of smaller, high-precision components—even on parts exceeding several meters in length.

Below are representative specifications from our large component machining capabilities:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 8,000 mm × 3,500 mm × 1,500 mm |

| Maximum Workpiece Weight | 25,000 kg |

| Positioning Accuracy (X/Y/Z) | ±0.01 mm over full travel |

| Repeatability | ±0.005 mm |

| Spindle Power | Up to 70 kW |

| Tool Capacity | Up to 120 tools (automatic tool changer) |

| Control System | Siemens 840D Solution Line |

| In-Process Measurement | Touch probe and laser-based systems |

Precision in large component machining is not achieved through equipment alone. It is the result of integrated engineering intelligence—material science, dynamic load management, and real-time process control. At Wuxi Lead Precision Machinery, we combine decades of hands-on experience with cutting-edge technology to deliver components where size and accuracy coexist without compromise. For industries where performance is non-negotiable, our capabilities ensure that every large part meets the highest standards of dimensional integrity and functional reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Large-Scale Components

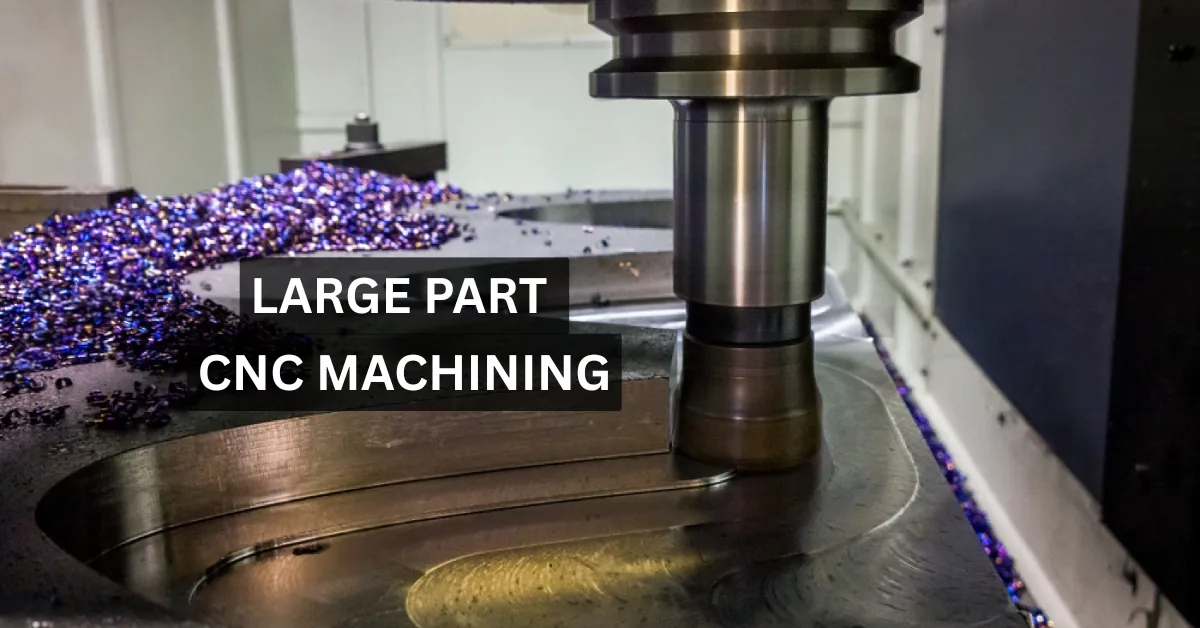

Wuxi Lead Precision Machinery delivers uncompromising precision for large component machining, leveraging advanced infrastructure and rigorous quality protocols. Our facility specializes in monolithic and complex assemblies exceeding 5 meters in length and 10 tons in weight, addressing the most demanding aerospace, energy, and heavy machinery applications. Central to our capability is a strategic fleet of 5-axis CNC machining centers, including DMG MORI CTX beta 2500 and Makino D200Z models. These systems integrate high-torque spindles, dynamic tool changers, and dual-pallet automation to maintain micron-level accuracy across extended work envelopes. All equipment features real-time thermal compensation and vibration-damping foundations, ensuring sub-micron repeatability during multi-day operations on massive castings or forgings.

Critical to large-part integrity is our end-to-end quality control ecosystem. Components undergo comprehensive dimensional validation via Zeiss CONTURA G3 and GLOBAL S series Coordinate Measuring Machines (CMM), equipped with 7-meter travel probes and optical scanning modules. This enables full-surface topography analysis and GD&T verification without part repositioning—a necessity for minimizing stack-up errors in oversized assemblies. Our metrology lab operates under ISO 17025 accreditation, with environmental controls maintaining ±0.5°C stability to eliminate thermal drift during inspection. Every project follows a documented First Article Inspection (FAI) protocol per AS9102 standards, with digital traceability linking machining parameters to final CMM reports.

Material versatility defines our operational scope. We routinely machine Inconel 718, titanium Ti-6Al-4V, hardened tool steels (up to 60 HRC), and aluminum 7000-series alloys, employing specialized toolpath strategies to manage residual stress and prevent distortion. For thin-walled structures, our adaptive high-speed machining (HSM) techniques reduce cycle times by 30% while maintaining flatness tolerances within 0.025 mm/m. All processes are validated through finite element analysis (FEA) simulations to predict and counteract deflection during cutting.

Achievable Tolerances for Large Components

| Process | Dimensional Tolerance | Geometric Tolerance | Surface Finish (Ra) |

|---|---|---|---|

| 5-Axis Milling | ±0.010 mm | 0.015 mm (Flatness) | 0.8–1.6 μm |

| Precision Turning | ±0.008 mm | 0.010 mm (Concentricity) | 0.4–0.8 μm |

| Critical Feature Finishing | ±0.005 mm | 0.005 mm (Position) | 0.2–0.4 μm |

Our engineering team collaborates directly with clients during Design for Manufacturability (DFM) reviews, identifying opportunities to simplify geometries without sacrificing performance—reducing cost and lead time by up to 25%. From initial material certification to final shipping cradle design, Wuxi Lead provides a single-source solution where precision is non-negotiable. All capabilities are supported by 24/7 technical oversight from our in-house CNC programming cell, utilizing Siemens NX CAM and Mastercam software to optimize tool engagement and surface integrity. This integrated approach ensures large components meet the most stringent global specifications while accelerating time-to-market for mission-critical projects.

Material & Finish Options

Material selection is a critical decision in large component machining, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision manufacturing of large-scale metal parts, where material properties must align with operational demands such as load-bearing capacity, corrosion resistance, and thermal stability. Aluminum, steel, and titanium are the most widely used materials in high-end industrial applications, each offering distinct advantages depending on the application.

Aluminum is favored for large components requiring a high strength-to-weight ratio and excellent machinability. Its natural corrosion resistance and ability to accept various surface treatments make it ideal for aerospace, transportation, and automation equipment. When weight reduction is a priority without sacrificing structural integrity, aluminum alloys such as 6061-T6 and 7075-T6 are commonly selected. These alloys respond well to precision CNC machining and are compatible with anodizing processes, enhancing surface hardness and wear resistance.

Steel remains the backbone of heavy industrial manufacturing due to its superior strength, toughness, and cost-effectiveness. For large components subjected to high mechanical stress—such as structural frames, gear housings, and machinery bases—alloy steels like 4140 and 4340 offer excellent hardenability and fatigue resistance. Stainless steels, particularly grades 304 and 316, are chosen when corrosion resistance is paramount, such as in marine or chemical processing environments. While heavier than aluminum, steel’s dimensional stability under load makes it indispensable in critical infrastructure applications.

Titanium stands at the premium end of material selection, offering exceptional strength-to-density ratios and outstanding resistance to extreme environments. Grade 5 titanium (Ti-6Al-4V) is widely used in aerospace, defense, and high-performance automotive sectors where components must endure high temperatures and aggressive corrosion conditions. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s longevity and reliability justify its use in mission-critical applications.

Surface finishing, particularly anodizing, plays a vital role in enhancing the functional lifespan of machined components. Anodizing is most commonly applied to aluminum, creating a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard options, with the latter providing superior wear resistance for components in high-friction environments.

The following table summarizes key mechanical and physical properties of commonly used materials in large component machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Typical Applications | Common Finishes |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Aerospace, automation, transport | Anodizing, powder coating |

| Steel 4140 | 655 | 7.85 | Machinery bases, shafts, tooling | Zinc plating, painting |

| Stainless 316 | 570 | 8.0 | Marine, chemical processing | Passivation, electropolishing |

| Titanium Ti-6Al-4V | 900 | 4.43 | Aerospace, defense, medical devices | Anodizing, shot peening |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on performance requirements, environmental exposure, and production scalability. Our engineering team provides consultation from design to delivery, ensuring every large component meets the highest standards of precision and reliability.

Manufacturing Process & QC

Large Component Machining: Precision Engineering from Concept to Completion

At Wuxi Lead Precision Machinery, our large component machining process is engineered for uncompromising quality and reliability, specifically addressing the stringent demands of aerospace, energy, and heavy industrial sectors. We execute a rigorously controlled workflow spanning Design, Prototyping, and Mass Production, all governed by our Zero Defects philosophy. This integrated approach ensures dimensional accuracy, structural integrity, and operational longevity for components where failure is not an option.

The Design Phase is foundational. Our engineering team collaborates closely with clients from the earliest concept stages, utilizing advanced CAD/CAM software (Siemens NX, Mastercam) to translate requirements into manufacturable designs. We conduct comprehensive Design for Manufacturability (DFM) and Finite Element Analysis (FEA) reviews, identifying potential stress points, optimizing material usage, and ensuring geometric complexity aligns with our machining capabilities. This proactive analysis prevents costly errors downstream and establishes the precise tolerances and material specifications critical for zero-defect outcomes. Client approval on the final digital model is mandatory before progression.

Prototyping is not merely a validation step; it is a critical quality gate. Using the approved digital model, we produce a functional prototype on our high-precision 5-axis machining centers. This phase involves rigorous first-article inspection (FAI) against all client specifications, employing Coordinate Measuring Machines (CMM), laser trackers, and surface roughness testers. Every dimension, feature, and material property is meticulously verified. Any deviation triggers immediate root cause analysis and process refinement. Only after the prototype meets or exceeds all specifications and receives formal client sign-off do we authorize the transition to full-scale production.

Mass Production leverages the validated process and tooling, executed within our ISO 9001:2015 and AS9100D certified facility. Our large-scale machining cells, featuring gantry mills and horizontal boring mills with travel exceeding 10 meters, operate under strict Statistical Process Control (SPC). Real-time in-process monitoring, coupled with 100% critical feature inspection using calibrated metrology equipment, ensures consistency. Automated tool wear compensation and environmental controls maintain stability. Every component undergoes final inspection against the FAI baseline before shipment. This closed-loop system, where data from production continuously feeds back into process optimization, is the cornerstone of our Zero Defects commitment, guaranteeing components perform flawlessly in the most demanding applications.

Wuxi Lead Large Component Machining Capabilities

| Parameter | Specification Range | Key Technology/Standard |

|---|---|---|

| Material Types | High-strength alloys (Ti, Inconel), Stainless Steel, Carbon Steel, Cast Iron | Material certification traceability |

| Max Work Envelope | 12,000 mm (L) x 4,500 mm (W) x 2,500 mm (H) | Gantry Mills, Horizontal Boring Mills |

| Positional Tolerance | ±0.02 mm over full travel | Laser interferometer calibration |

| Surface Finish | Ra 0.8 µm to Ra 6.3 µm (as specified) | Precision grinding & milling |

| Quality Assurance | 100% CMM inspection on critical features | ISO 10360-2 compliant CMMs |

| Certifications | ISO 9001:2015, AS9100D | Full material & process traceability |

This disciplined progression from collaborative design through validated prototyping to tightly controlled mass production embodies Wuxi Lead’s dedication to delivering large components that meet the highest global standards of precision and reliability, eliminating defects before they occur.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Large Component Machining Excellence

When your industrial operations demand precision-engineered large components, partnering with a manufacturer that combines technical mastery, advanced infrastructure, and unwavering quality assurance is not just an advantage—it’s a necessity. At Wuxi Lead Precision Machinery, we specialize in the custom machining of large-scale metal components for aerospace, energy, transportation, and heavy industrial sectors. Our engineering expertise, combined with state-of-the-art CNC equipment, ensures that every part we produce meets the most stringent dimensional, structural, and performance standards.

Our facility in Wuxi, China, is equipped with high-capacity machining centers capable of handling components up to 12 meters in length, with precision tolerances down to ±0.005 mm. We manage every phase of production in-house—from material sourcing and CAD/CAM programming to multi-axis milling, turning, boring, and final quality inspection. This vertical integration enables us to maintain full control over lead times, quality consistency, and project scalability, ensuring that your large component requirements are met with reliability and efficiency.

We understand that large component machining presents unique challenges: material stability, thermal deformation, fixturing complexity, and geometric accuracy over extended spans. Our engineering team applies decades of applied experience to anticipate and mitigate these challenges, using finite element analysis (FEA), real-time tool monitoring, and adaptive machining strategies to deliver components that perform under real-world conditions.

Our clients rely on us not only for our technical capabilities but also for our collaborative approach. We work closely with design and engineering teams to optimize manufacturability, reduce costs, and accelerate time to market—without compromising on quality. Whether you require single prototype units or high-volume production runs, we adapt our processes to align with your project’s scope, timeline, and performance requirements.

At Wuxi Lead Precision Machinery, we are committed to being more than a supplier—we are a strategic manufacturing partner. Our quality management system is ISO 9001:2015 certified, and we adhere to international standards including AS9100 for aerospace and ISO 13485 for precision medical components when applicable.

Explore how we can support your next large component project. Contact us today at [email protected] to discuss your specifications, request a quote, or schedule a technical consultation. Let our precision, capacity, and expertise become a critical advantage in your supply chain.

Key Capabilities for Large Component Machining

| Parameter | Specification |

|---|---|

| Maximum Workpiece Length | 12,000 mm (472 in) |

| Maximum Workpiece Weight | 25,000 kg (55,100 lbs) |

| CNC Machining Tolerance | ±0.005 mm (±0.0002 in) |

| Spindle Speed (Milling) | Up to 10,000 rpm |

| Axis Configuration | 3-axis, 4-axis, 5-axis simultaneous |

| Materials Processed | Steel, Stainless Steel, Aluminum, Titanium, Inconel, Brass, Bronze |

| Surface Finish | Ra ≤ 0.8 µm (32 µin) standard, finer on request |

| Quality Standards | ISO 9001:2015, AS9100, ISO 13485 (as required) |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.