Technical Contents

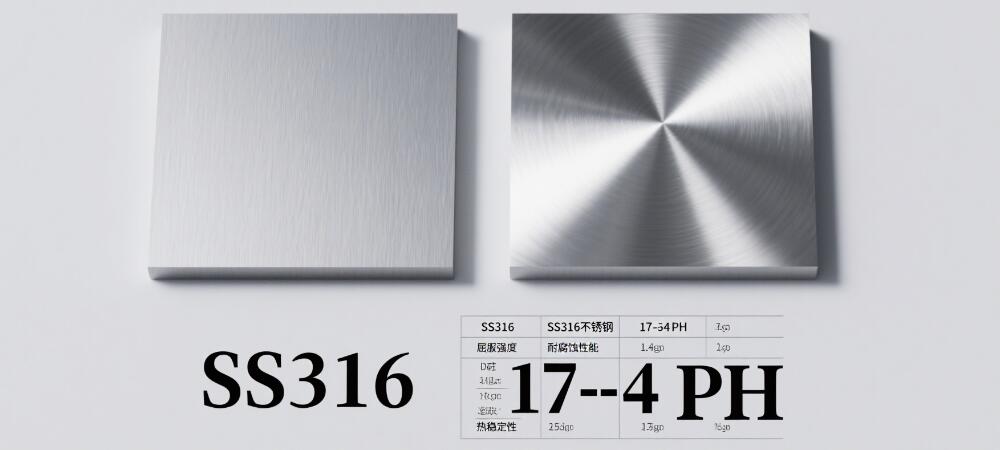

Engineering Guide: 17 4 Stainless Steel Vs 316

Engineering Insight: 17-4 PH vs 316 Stainless Steel – Precision in Material Selection

In high-performance manufacturing, the choice between 17-4 precipitation-hardening (PH) stainless steel and 316 austenitic stainless steel is not merely a matter of corrosion resistance or strength—it is a decision rooted in precision engineering. At Wuxi Lead Precision Machinery, we understand that selecting the correct alloy directly impacts the dimensional stability, longevity, and functional reliability of mission-critical components. With decades of experience in custom metal manufacturing for aerospace, defense, and high-precision industrial applications—including components used in Olympic-grade equipment and military systems—we emphasize that material selection must align with both environmental demands and manufacturing tolerances.

17-4 PH stainless steel is renowned for its exceptional strength and hardness, achieved through a precise heat treatment process. This alloy offers tensile strengths exceeding 130 ksi after aging, making it ideal for applications requiring high mechanical performance under stress. Its martensitic structure allows for tight tolerances and excellent machinability pre-aging, but demands exacting control during final heat treatment to avoid distortion. At Lead Precision, our CNC machining protocols are calibrated to account for microstructural changes during aging, ensuring parts meet exact dimensional specifications even after post-processing.

In contrast, 316 stainless steel excels in environments exposed to corrosive elements, particularly chlorides and acidic compounds. Its austenitic structure provides superior toughness and weldability, with consistent performance across a wide temperature range. While its tensile strength is lower than 17-4 PH—typically in the 75–80 ksi range—its resistance to pitting and crevice corrosion makes it the preferred choice for marine, medical, and chemical processing applications. However, its tendency toward work hardening requires advanced CNC strategies to maintain precision during machining.

The distinction between these alloys underscores a fundamental principle in precision manufacturing: material behavior must be anticipated and controlled at every stage. Whether managing the phase transformation in 17-4 PH or mitigating tool wear when cutting 316, our engineering team leverages real-time monitoring, adaptive toolpaths, and in-process metrology to ensure compliance with ISO and MIL-STD specifications.

Below is a comparative overview of key mechanical and chemical properties:

| Property | 17-4 PH Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Tensile Strength (aged) | 130–150 ksi | 75–80 ksi |

| Yield Strength | 115–130 ksi | 30–40 ksi |

| Hardness (HRC) | 38–42 | 20–25 |

| Corrosion Resistance | Moderate | Excellent |

| Chloride Resistance | Limited | High |

| Heat Treatment Required | Yes (aging at 900–1150°F) | No |

| Typical Applications | Aerospace actuators, military fasteners | Marine fittings, medical implants |

At Wuxi Lead Precision Machinery, our expertise in handling both 17-4 PH and 316 stainless steel ensures that every component is manufactured to the highest standards of accuracy and performance. Precision is not just achieved—it is engineered.

Precision Specs & Tolerances

Precision Machining of 17-4 PH vs. 316 Stainless Steel: Wuxi Lead Capabilities

Selecting the optimal stainless steel grade is critical for high-integrity components in aerospace, medical, and energy applications. At Wuxi Lead Precision Machinery, our engineering team specializes in the distinct machining challenges presented by precipitation-hardening 17-4 PH stainless steel versus austenitic 316 stainless steel. Understanding these differences ensures manufacturability, dimensional stability, and final part performance. 17-4 PH offers exceptional strength after heat treatment but presents significant work-hardening and abrasive wear characteristics during machining. Its high hardness demands rigid setups, specialized carbide tooling with optimized geometries, and controlled cutting parameters to prevent tool fracture and maintain surface integrity. Conversely, 316 stainless steel exhibits superior corrosion resistance and weldability but is prone to galling, built-up edge, and long, stringy chip formation. Effective machining of 316 requires aggressive feeds to avoid work hardening, high-pressure coolant for chip evacuation and heat dissipation, and sharp, polished cutting edges to minimize adhesion.

Wuxi Lead leverages advanced 5-axis CNC milling and turning centers to overcome these material-specific hurdles. Our Haas and DMG MORI platforms feature high-torque spindles, dynamic tool compensation, and integrated probing for in-process verification. For 17-4 PH, we utilize solid carbide end mills with AlTiN coatings and precisely controlled step-overs to manage residual stress and prevent distortion during final heat treatment. Machining 316 employs high-feed milling strategies with specialized chip-breaker geometries and through-spindle coolant pressures exceeding 1,000 psi to ensure clean chip evacuation and thermal management. Every process is supported by comprehensive CAM simulation to validate toolpaths and avoid collisions, particularly for complex geometries inherent in 5-axis work.

Rigorous quality control is non-negotiable. All critical dimensions and geometric features undergo validation using our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM) with a 0.5 µm volumetric accuracy specification. This ensures compliance with stringent aerospace AS9100 and medical ISO 13485 standards. Surface roughness is verified via Mitutoyo SJ-410 profilometers, while material certification and post-machining hardness verification are standard for 17-4 PH components. Our metrology lab provides full first-article inspection reports (FAIR) and production part approval process (PPAP) Level 3 documentation upon request.

The achievable precision for both materials is demonstrated below, reflecting our standard production capabilities under controlled environmental conditions. These tolerances assume appropriate fixturing, optimized tooling, and adherence to our validated process parameters.

| Material | Dimensional Tolerance | Geometric Tolerance (GD&T) | Surface Finish (Ra) |

|---|---|---|---|

| 17-4 PH SS | ±0.005 mm (±0.0002 in) | ±0.010 mm (±0.0004 in) | 0.8 µm (32 µin) |

| 316 SS | ±0.008 mm (±0.0003 in) | ±0.012 mm (±0.0005 in) | 0.4 µm (16 µin) |

Wuxi Lead Precision Machinery delivers certified precision for mission-critical stainless steel components. Our integrated approach—combining deep material science expertise, advanced 5-axis CNC technology, and uncompromising CMM-based quality assurance—ensures your 17-4 PH or 316 stainless steel parts meet the most demanding functional and regulatory requirements. Partner with us for complex geometries where material integrity and micron-level accuracy are paramount.

Material & Finish Options

When selecting materials for precision manufacturing applications, understanding the mechanical, chemical, and environmental performance of available alloys is critical. At Wuxi Lead Precision Machinery, we specialize in custom metal components engineered to meet exacting industry standards. Among the most commonly specified stainless steels are 17-4 PH and 316, each offering distinct advantages depending on the operational demands.

17-4 PH stainless steel is a precipitation-hardening alloy known for its high strength, excellent fatigue resistance, and good corrosion resistance. It contains chromium, copper, and niobium, enabling it to achieve superior mechanical properties through heat treatment. This makes 17-4 PH ideal for aerospace components, high-performance shafts, and structural parts requiring long-term durability under stress. Its ability to maintain strength at elevated temperatures further enhances its suitability for demanding environments.

In contrast, 316 stainless steel is an austenitic alloy with superior corrosion resistance, particularly against chlorides and acidic compounds. The addition of molybdenum significantly improves its resistance to pitting and crevice corrosion, making it the preferred choice for marine, chemical processing, and medical applications. While 316 does not achieve the same tensile strength as 17-4 PH through heat treatment, it offers excellent formability, weldability, and performance in continuous service at elevated temperatures.

For applications involving aluminum or titanium, material selection shifts toward weight-sensitive industries such as aerospace and automotive. Aluminum alloys provide a high strength-to-weight ratio and are easily machined and anodized for enhanced surface hardness and corrosion resistance. Titanium, though more costly, delivers exceptional strength-to-density performance and unparalleled resistance to corrosion in aggressive environments, including seawater and chlorine-rich atmospheres.

Surface finishing plays a pivotal role in enhancing both performance and aesthetics. Anodizing, primarily applied to aluminum, creates a durable, non-conductive oxide layer that improves wear resistance and allows for color coding or branding. For stainless steel components, finishes such as electropolishing or passivation are recommended to maximize corrosion resistance and remove surface contaminants.

Below is a comparative overview of key material properties:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Heat Treatable | Common Applications |

|---|---|---|---|---|---|

| 17-4 PH | 1000–1300 | 850–1100 | Good (moderate chlorides) | Yes | Aerospace, valves, tooling |

| 316 | 570–690 | 240–310 | Excellent (chlorides) | No | Marine, medical, chemical processing |

| Aluminum 6061 | 310 | 276 | Moderate (anodized) | Yes (T6) | Enclosures, automotive parts |

| Titanium Gr5 | 895 | 828 | Exceptional | No | Aerospace, medical implants |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on functional requirements, environmental exposure, and lifecycle expectations. Our engineering team collaborates closely with partners to ensure every component meets the highest standards of precision and reliability.

Manufacturing Process & QC

Precision Manufacturing Process: 17-4 PH vs. 316 Stainless Steel

Material selection fundamentally dictates production success in mission-critical applications. At Wuxi Lead Precision Machinery, our integrated process for 17-4 PH precipitation hardening stainless steel and 316 austenitic stainless steel begins with rigorous Design engineering. This phase defines not only geometry but critical material-specific parameters. For 17-4 PH, we meticulously model thermal stability thresholds and aging cycle requirements to achieve target hardness without distortion. For 316, we prioritize corrosion exposure scenarios and chloride resistance validation in the CAD environment. Our engineers leverage material databases to anticipate machining stresses, ensuring designs account for 17-4 PH’s higher work-hardening rate versus 316’s greater ductility, preventing downstream failures.

Prototyping validates both design intent and process feasibility under production conditions. We machine functional prototypes using near-identical toolpaths, fixtures, and coolant strategies planned for volume runs. For 17-4 PH, this phase is critical for optimizing the solution treatment and aging sequence to hit precise mechanical properties like 58 HRC while maintaining dimensional stability. Prototypes undergo full non-destructive testing (NDT) and CMM inspection against GD&T callouts. For 316 components destined for marine or chemical environments, prototypes undergo accelerated corrosion testing per ASTM standards. Any deviation triggers immediate process recalibration before mass production commences, eliminating theoretical risks.

Mass Production executes with Zero Defects as the non-negotiable standard. Our CNC cells run validated programs with real-time in-process monitoring of tool wear, thermal drift, and surface integrity. For 17-4 PH, strict thermal control during machining prevents premature aging; parts proceed directly to precisely controlled heat treatment furnaces with NIST-traceable sensors. 316 production emphasizes maintaining passive layer integrity through optimized cutting parameters and post-machining passivation. Statistical Process Control (SPC) tracks critical dimensions and material properties batch-by-batch. Every component undergoes final CMM verification and batch-specific material certification. This closed-loop system, proven across aerospace and medical manufacturing, ensures every 17-4 PH valve stem or 316 surgical implant meets exacting global standards without compromise.

Key material properties directly influencing our production protocols include:

| Property | 17-4 PH Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Primary Advantage | High strength after aging | Superior corrosion resistance |

| Critical Process Focus | Precise aging cycle control | Chloride exposure management |

| Machinability (HRB) | 250-300 (Condition H900) | 85-95 (Annealed) |

| Key Production Risk | Distortion during aging | Galling during threading |

| Typical Lead Final Spec | 1275 MPa UTS, 45 HRC | 515 MPa UTS, 150 HB |

This disciplined Design-Prototype-Production cascade, deeply informed by material science, is how Wuxi Lead delivers uncompromised quality in every custom stainless steel component.

Why Choose Wuxi Lead Precision

When it comes to high-performance industrial applications, selecting the right stainless steel alloy is critical to ensuring longevity, reliability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that meet the exact demands of aerospace, medical, marine, and chemical processing industries. Our expertise in material science and precision engineering allows us to guide clients through the critical decision between 17-4 PH and 316 stainless steel—two alloys with distinct advantages depending on application requirements.

17-4 PH stainless steel is a precipitation-hardening alloy known for its exceptional strength and moderate corrosion resistance. It is ideal for components that require high mechanical properties, such as shafts, valves, and aerospace fittings. With the ability to achieve tensile strengths exceeding 1300 MPa through heat treatment, 17-4 PH delivers performance where structural integrity under stress is paramount. However, its corrosion resistance is less robust than 316, particularly in chloride-rich environments.

In contrast, 316 stainless steel excels in corrosion resistance due to its molybdenum content, making it the preferred choice for marine applications, pharmaceutical equipment, and environments exposed to acids or saltwater. While its strength is lower than 17-4 PH in hardened conditions, 316 offers superior ductility and weldability, along with excellent performance in cryogenic and high-temperature service.

Choosing between these alloys requires a deep understanding of operational conditions, load requirements, and environmental exposure. At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our team of CNC engineers and metallurgical specialists works closely with clients to analyze application parameters and recommend the optimal material and manufacturing process, whether it’s precision milling, turning, or complex multi-axis machining.

We combine advanced CNC technology with rigorous quality control to deliver components that meet ISO 9001 and international industry standards. Our facility in Wuxi, China, is equipped to handle low-volume prototypes and high-volume production runs with consistent accuracy and repeatability.

Below is a comparative overview of key mechanical and chemical properties:

| Property | 17-4 PH Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Tensile Strength (min) | 1300 MPa | 570 MPa |

| Yield Strength (min) | 1180 MPa | 240 MPa |

| Elongation at Break | 12% | 40% |

| Hardness (HRC, typical) | 32–38 | 70–90 HRB |

| Corrosion Resistance | Moderate | Excellent |

| Molybdenum Content | None | 2–3% |

| Primary Applications | Aerospace, military, tooling | Marine, chemical, medical |

Partner with Wuxi Lead Precision Machinery to ensure your next project is built on the foundation of expert material selection and precision manufacturing. Contact us today at [email protected] to discuss your requirements with our engineering team.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.