Technical Contents

Engineering Guide: Metal Fabrication Design

Engineering Insight Precision as the Non-Negotiable Foundation of Metal Fabrication Design

In high-stakes metal fabrication, precision transcends mere specification it is the absolute determinant of structural integrity, assembly success, and long-term performance. Compromised tolerances cascade into costly downstream failures: misaligned weldments, compromised load-bearing capacity, and field assembly delays that erode project timelines and budgets. For critical applications spanning aerospace, defense, and large-scale infrastructure, dimensional accuracy is not an engineering preference it is a contractual and safety imperative. At Wuxi Lead Precision Machinery, we enforce this reality daily. Our CNC fabrication cells operate under ISO 9001 and AS9100 certified protocols, where tolerances are validated through continuous in-process metrology, not merely inspected post-production. This discipline stems from direct experience delivering components where deviation measured in tenths of a millimeter dictated mission success.

Our facility executed precision sheet metal work for structural elements of the Beijing 2022 Winter Olympics venues, demanding flawless geometric consistency across thousands of components exposed to extreme alpine conditions. Similarly, ongoing military subcontracting requires adherence to MIL-STD-883 and ITAR-controlled workflows, where material traceability and repeatable accuracy under 0.1mm are non-negotiable. These projects instill a singular truth: precision must be engineered into the design phase, not corrected during manufacturing. Designers who specify realistic bend allowances, avoid acute internal radii, and account for material springback inherently reduce scrap rates and accelerate throughput. We collaborate with clients to optimize designs for manufacturability, ensuring tolerances align with our process capabilities rather than theoretical ideals.

The table below reflects our validated production standards for sheet metal fabrication, derived from 15+ years of Tier-1 supplier experience. These metrics represent achievable targets under controlled production conditions, not isolated laboratory results.

| Parameter | Standard Capability | High-Precision Capability | Key Application Context |

|---|---|---|---|

| Linear Tolerance | ±0.1 mm | ±0.05 mm | Aerospace brackets, sensor mounts |

| Angular Tolerance | ±0.5° | ±0.25° | Structural assemblies, hinges |

| Hole Position Tolerance | ±0.08 mm | ±0.03 mm | Bolted interfaces, alignment pins |

| Material Thickness | 0.5–12 mm | 0.8–6 mm | Steel, aluminum, stainless, titanium |

| Max Work Envelope | 3000 x 1500 mm | 2000 x 1000 mm | Large panels, precision enclosures |

Designing for precision demands mutual accountability. At Lead Precision, we provide DFM feedback within 48 hours of receiving CAD models, highlighting features that risk tolerance stack-up or tooling conflicts. This proactive engineering dialogue prevents costly revisions and ensures your design intent translates flawlessly into physical components. When Olympic venues withstand Siberian winds or military systems operate in contested environments, the margin for error is zero. Partner with a fabricator whose precision is proven where consequences matter most. Your design deserves manufacturing execution that matches its ambition.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in sheet metal fabrication, engineered to support high-precision industrial applications across aerospace, medical, energy, and automation sectors. Our facility integrates state-of-the-art 5-axis CNC machining with comprehensive sheet metal processing technologies, enabling the production of complex geometries with exceptional accuracy and repeatability. This level of precision ensures that components meet stringent design specifications while maintaining structural integrity and functional performance.

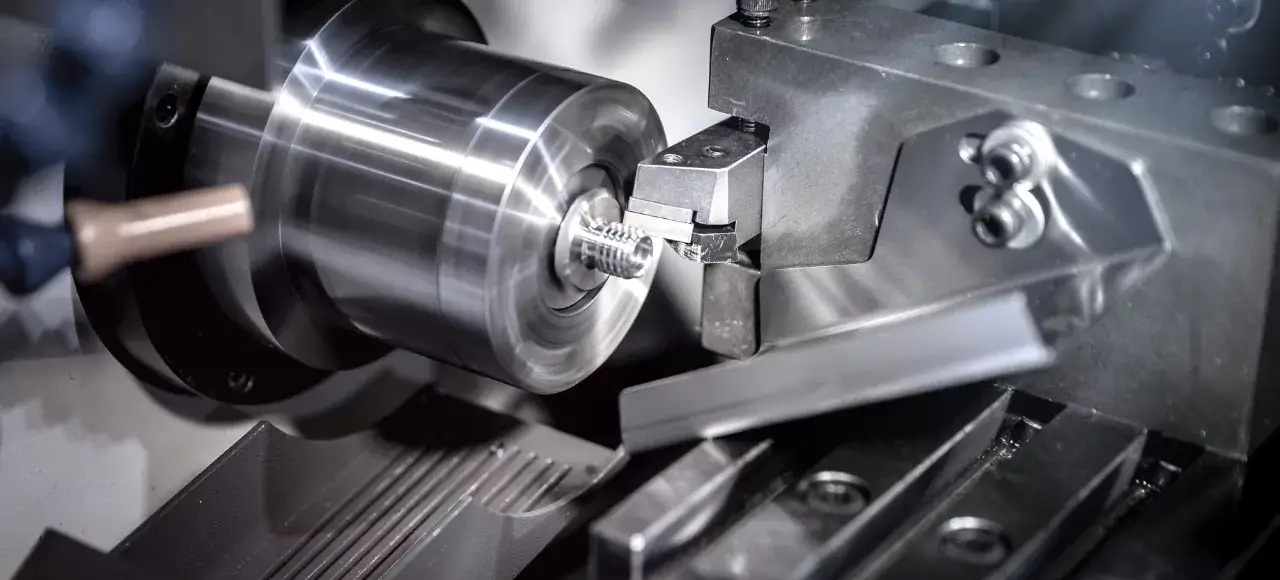

At the core of our manufacturing capability is a fleet of 5-axis CNC machining centers, which allow for simultaneous multi-directional cutting and contouring. This technology eliminates the need for multiple setups, reduces cumulative tolerances, and enhances surface finish quality. By maintaining a single workholding setup throughout the machining process, we achieve superior positional accuracy and reduce lead times significantly. These machines are ideal for fabricating intricate enclosures, brackets, housings, and structural components from a wide range of metals, including stainless steel, aluminum, carbon steel, and specialty alloys.

Complementing our machining power is a full suite of sheet metal processing equipment, including high-tonnage press brakes with CNC backgauges, automatic panel benders, laser cutting systems, and turret punching machines. These tools enable precise bending, cutting, and forming operations on materials ranging from 0.5 mm to 10 mm in thickness. Our engineers utilize advanced CAD/CAM software to simulate fabrication sequences, optimize toolpaths, and ensure manufacturability—minimizing waste and maximizing efficiency.

Quality control is embedded into every stage of production. All critical dimensions are verified using a Coordinate Measuring Machine (CMM) with sub-micron resolution, ensuring compliance with ISO 10360 standards. In addition to CMM inspection, we perform first-article inspections, in-process checks, and final audits based on AS9102 or customer-specific quality requirements. Dimensional reports, material certifications, and process validation documentation are provided with every batch.

Our commitment to precision is reflected in the tight tolerances we consistently achieve. The following table outlines our standard and high-precision capability ranges:

| Feature | Standard Tolerance | High-Precision Tolerance |

|---|---|---|

| Linear Dimensions (mm) | ±0.1 mm | ±0.05 mm |

| Hole Diameter | ±0.1 mm | ±0.03 mm |

| Positional Accuracy | ±0.15 mm | ±0.08 mm |

| Angular Tolerance | ±0.2° | ±0.1° |

| Sheet Metal Bend Angle | ±1° | ±0.5° |

| Surface Flatness (per 100mm) | 0.1 mm | 0.05 mm |

| Threaded Features | ±0.1 mm | ±0.05 mm |

With integrated 5-axis CNC machining, advanced sheet metal processing, and rigorous CMM-based quality assurance, Wuxi Lead Precision Machinery provides a technically robust foundation for mission-critical metal fabrication projects.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material choice fundamentally impacts the performance, cost, and manufacturability of sheet metal components. At Wuxi Lead Precision Machinery, we guide clients through this critical decision, balancing application demands with fabrication efficiency. Selecting the optimal base material and finish ensures longevity, functionality, and cost-effectiveness for your end product.

Aluminum Alloys dominate applications requiring lightweight strength and excellent corrosion resistance. Series 5000 (e.g., 5052) offers superior workability for complex bends, while 6000 series (e.g., 6061-T6) provides higher structural strength post-heat treatment. Aluminum’s natural oxide layer offers decent protection, but anodizing significantly enhances surface durability and aesthetics. This is non-negotiable for aerospace, electronics enclosures, and architectural elements exposed to harsh environments. Anodizing creates a hard, porous oxide layer that can be dyed and sealed, providing exceptional wear resistance and electrical insulation. Type II (sulfuric acid) is standard for general use; Type III (hardcoat) delivers mil-spec performance for extreme abrasion resistance.

Carbon and Stainless Steels provide unmatched strength and cost efficiency for structural and heavy-duty applications. Low-carbon steel (e.g., ASTM A36) is highly formable and weldable, ideal for chassis and brackets. For corrosion resistance, 304 and 316 stainless steels are essential. 304 suits most indoor and mild outdoor uses, while 316’s molybdenum content makes it mandatory for marine or chemical exposure. Stainless steel fabrication requires precise laser parameters and clean tooling to prevent contamination and maintain its corrosion barrier. Powder coating or passivation are common finishes, though stainless often remains bare where its inherent properties suffice.

Titanium is specified for extreme environments demanding the highest strength-to-weight ratio and unparalleled corrosion resistance, particularly against chlorides and acids. Grade 2 (commercially pure) offers excellent formability for medical implants and chemical processing parts, while Grade 5 (Ti-6Al-4V) delivers aerospace-grade strength. Titanium’s reactivity necessitates dedicated fabrication tooling to avoid iron contamination and stringent inert gas shielding during welding. Its high cost dictates use only where alternatives fail, but its longevity often justifies the investment.

Material selection directly influences CNC punching, laser cutting, bending, and welding parameters. Incorrect choices lead to excessive tool wear, part distortion, or premature failure. Below is a comparative overview of key properties:

| Material | Common Alloys | Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 5052, 6061-T6 | 190-275 | 2.7 | Very Good (Anodized) | Enclosures, Aerospace, Automotive |

| Carbon Steel | ASTM A36, 1018 | 250 | 7.8 | Poor (Requires Coating) | Frames, Brackets, Industrial |

| Stainless Steel | 304, 316 | 215-620 | 8.0 | Excellent | Medical, Marine, Food Processing |

| Titanium | Gr 2, Gr 5 (Ti-64) | 275-880 | 4.5 | Exceptional | Aerospace, Medical, Chemical |

Partnering with an experienced fabricator like Wuxi Lead ensures your material and finish selection aligns with both functional requirements and efficient, high-yield manufacturing processes. We provide material certification and process validation to guarantee component integrity from design through delivery.

Manufacturing Process & QC

Design Phase: Precision Engineering as the Foundation

At Wuxi Lead Precision Machinery, the metal fabrication process begins with a comprehensive design phase that integrates engineering rigor with manufacturability analysis. Our engineering team collaborates closely with clients to translate conceptual drawings into detailed 3D models using advanced CAD software such as SolidWorks and AutoCAD. Each design undergoes a Design for Manufacturability (DFM) review to ensure optimal material usage, structural integrity, and compatibility with downstream processes such as laser cutting, bending, and welding. Tolerance analysis, bend allowance calculations, and material grain orientation are meticulously evaluated to eliminate potential production flaws before physical work begins. This proactive approach minimizes rework and ensures that every component meets exact performance and dimensional requirements.

Prototyping: Validating Design in Practice

Once the design is finalized, we proceed to prototyping—a critical stage that bridges theory and production. Wuxi Lead utilizes high-precision CNC laser cutting, turret punching, and press brake forming to produce functional prototypes from the same materials and processes intended for mass production. This ensures real-world validation of fit, form, and function. Prototypes are subjected to rigorous inspection using coordinate measuring machines (CMM), optical comparators, and first article inspection (FAI) reports. Feedback from clients and internal quality audits are integrated swiftly, allowing for rapid design iteration if necessary. The prototype phase not only confirms design accuracy but also verifies tooling setup and process stability, forming the basis for zero-defect scalability.

Mass Production: Consistency Through Control

With design and prototyping successfully completed, the project transitions into mass production. Wuxi Lead employs a lean manufacturing framework supported by automated production lines, real-time monitoring, and standardized work instructions. Each stage—from cutting to forming, welding, surface treatment, and final assembly—is governed by documented quality control checkpoints. Our ISO 9001-certified processes ensure full traceability, with batch records, material certifications, and inspection data maintained for every order. In-process inspections and statistical process control (SPC) are used to detect and correct deviations instantly, maintaining tight tolerances and eliminating defects before they propagate.

Production Specifications

| Parameter | Capability |

|---|---|

| Material Thickness | 0.5 mm – 25 mm (steel, stainless, aluminum) |

| Tolerance (Bending) | ±0.1 mm |

| Tolerance (Laser Cutting) | ±0.05 mm |

| Max Part Size | 4000 mm × 1500 mm |

| Welding Processes | MIG, TIG, Spot Welding |

| Surface Treatments | Powder Coating, Anodizing, Plating, Passivation |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

Through seamless integration of design validation, precision prototyping, and disciplined mass production, Wuxi Lead Precision Machinery delivers sheet metal components with uncompromising quality. Our zero-defect philosophy is not a target—it is a standard built into every phase of the process.

Why Choose Wuxi Lead Precision

Elevate Your Metal Fabrication with Lead Precision Engineering

In the demanding landscape of high-precision sheet metal fabrication, your designs demand more than standard manufacturing. They require a partner who merges engineering rigor with scalable production excellence. At Wuxi Lead Precision Machinery, we specialize in transforming complex technical drawings into mission-critical components with unwavering consistency. Our ISO 9001-certified facility in China leverages cutting-edge CNC technology and deep material science expertise to deliver parts that meet aerospace, medical, and industrial automation tolerances—without compromising speed or cost efficiency. When you partner with us, you gain direct access to our engineering team for collaborative design optimization, ensuring manufacturability from prototype to high-volume production.

Our technical capabilities are engineered for your most challenging projects. Below are key specifications demonstrating our precision sheet metal fabrication capacity:

| Process | Material Range | Thickness Range | Tolerance | Max. Part Size | Throughput Capacity |

|---|---|---|---|---|---|

| Fiber Laser Cutting | Carbon Steel, SS, Al | 0.5–25 mm | ±0.05 mm | 4000 x 2000 mm | 15,000 parts/week |

| CNC Press Braking | All sheet metals | 0.8–12 mm | ±0.1° angular | 3000 x 1500 mm | 8,000 bends/day |

| Robotic Welding | SS, Al, Ti alloys | 1.0–10 mm | ±0.2 mm gap | 2500 x 1200 mm | 500 welds/hour |

| Precision Forming | Custom alloys | 0.3–6 mm | ±0.03 mm feature | 1800 x 900 mm | 12,000 units/week |

This infrastructure enables us to solve persistent pain points: eliminating costly design revisions through DFM analysis, reducing lead times by 30% via integrated digital workflows, and ensuring zero-defect delivery through in-process CMM validation. We understand that your reputation hinges on component reliability—whether it’s a medical device enclosure requiring Ra 0.8 surface finishes or an aerospace bracket with tight positional tolerances. Our engineers proactively identify stress points, material grain direction impacts, and weld distortion risks before cutting begins, saving you time and rework costs.

Partnering with Lead Precision means engaging a team that speaks your technical language. We provide real-time production data sharing, material traceability documentation, and agile responsiveness to engineering change orders. Unlike commodity suppliers, we invest in understanding your end application to refine tolerances and material selections—turning your design intent into physical reality with minimal iteration. Our China-based operation delivers significant cost advantages while adhering to Western quality standards, making us the strategic choice for OEMs scaling global production.

Do not let subpar fabrication capabilities compromise your product’s performance or market entry timeline. Contact our engineering sales team today to submit your technical package for a rapid manufacturability assessment. Email [email protected] with your project specifications and CAD files. Within 24 business hours, you will receive a detailed process plan including cost analysis, lead time projection, and DFM recommendations tailored to your requirements. Let Lead Precision become your trusted extension—where precision engineering meets execution excellence. Act now to secure capacity for your next critical production run.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.