Technical Contents

Engineering Guide: 3D Printing Molds For Casting Metal

Engineering Insight: 3D Printing Molds for Casting Metal

In the realm of advanced metal casting, precision is not merely a performance metric—it is the foundation of structural integrity, functional reliability, and production efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that meet the exacting demands of industries where failure is not an option. Our integration of 3D printing technology into mold fabrication for metal casting represents a transformative leap in achieving micron-level accuracy, complex geometries, and rapid prototyping—without sacrificing the durability required in high-stress applications.

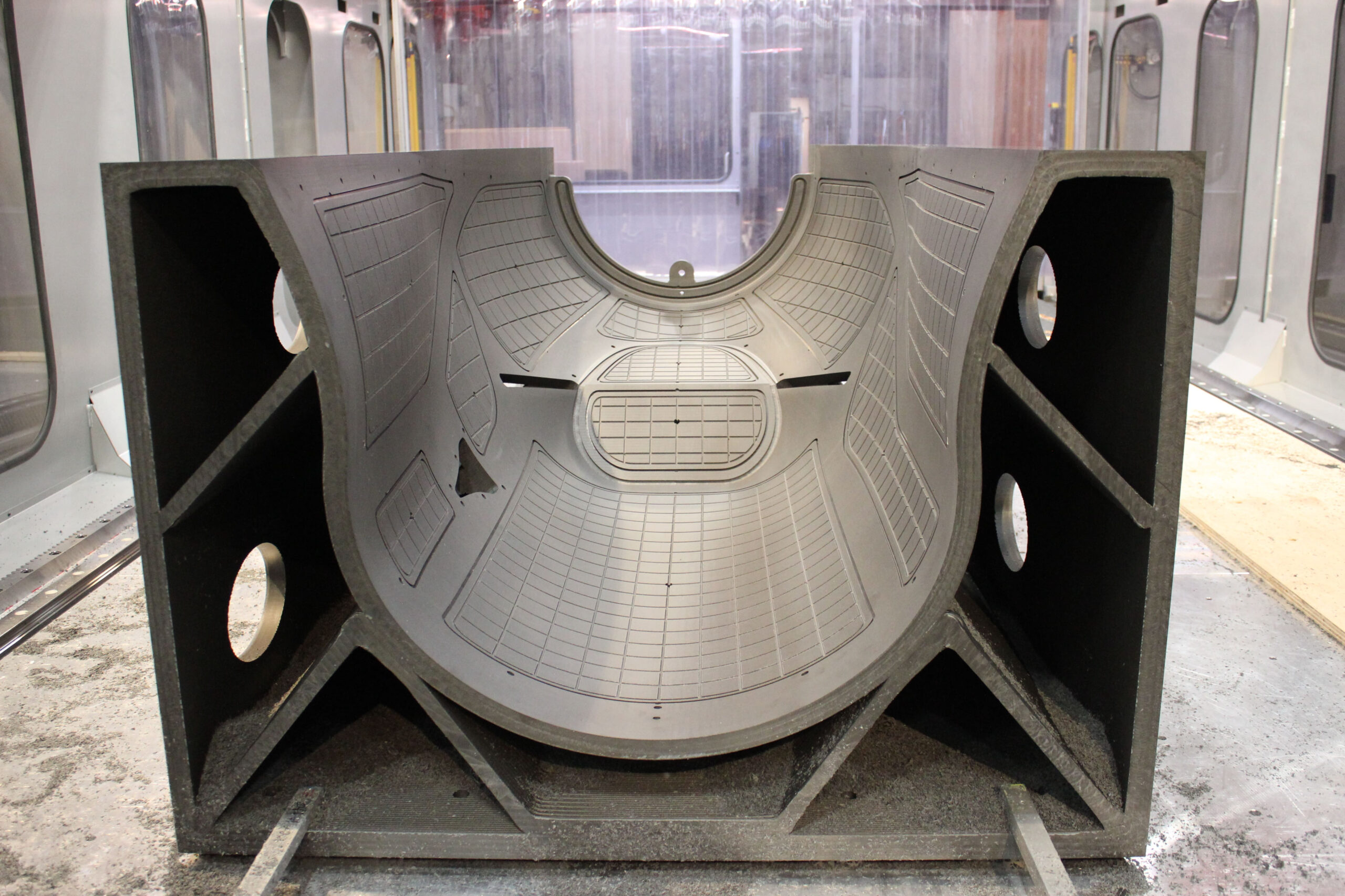

Traditional mold-making processes often involve multi-stage machining, assembly, and extensive post-processing, introducing cumulative tolerances and potential points of failure. 3D printing molds for casting metal eliminates many of these variables by enabling monolithic mold structures with internal cooling channels, optimized gating systems, and conformal features that cannot be achieved through conventional methods. This capability is particularly critical when producing components for aerospace, defense, and high-performance industrial systems—sectors where Wuxi Lead has a proven track record.

Our engineering team has delivered mission-critical components for Olympic-standard equipment and military-grade systems, where dimensional stability under thermal cycling and mechanical load is non-negotiable. These projects demanded molds that not only replicated intricate designs with fidelity but also maintained performance across repeated casting cycles. By leveraging selective laser melting (SLM) and binder jetting techniques with high-strength tool steels and refractory alloys, we achieve mold precision within ±0.02 mm, ensuring consistent part quality and reduced post-cast machining.

Beyond accuracy, 3D printed molds offer unparalleled design freedom. Engineers can embed topology-optimized lattice structures to reduce mold weight, integrate thermal management pathways for uniform cooling, and produce undercuts or internal features without additional tooling. This flexibility accelerates time-to-market and supports low-volume, high-complexity production runs—ideal for prototyping or specialized industrial components.

At Wuxi Lead, every mold is developed through a closed-loop engineering process: simulation-driven design, in-situ monitoring during printing, and full metrology validation using coordinate measuring machines (CMM) and CT scanning. This ensures that each mold meets stringent international standards and customer-specific requirements.

The convergence of additive manufacturing and precision casting is redefining what is possible in metal component production. With over a decade of experience in high-tolerance manufacturing, Wuxi Lead Precision Machinery stands at the forefront of this evolution—delivering solutions where precision, performance, and reliability converge.

| Specification | Value |

|---|---|

| Dimensional Accuracy | ±0.02 mm |

| Surface Roughness (as-printed) | Ra 6.3–12.5 µm |

| Common Materials | H13 Tool Steel, Inconel 718, 17-4 PH Stainless Steel |

| Maximum Build Volume | 500 x 500 x 400 mm |

| Post-Processing Options | Stress Relieving, HIP, CNC Finishing, Polishing |

| Applications | Aerospace Components, Defense Systems, High-Pressure Dies, Prototyping |

Precision Specs & Tolerances

Technical Capabilities: Precision Execution for Metal Casting Molds

Wuxi Lead Precision Machinery delivers the uncompromising dimensional accuracy and surface integrity essential for high-performance 3D printed molds used in investment, sand, and die casting of metals. Our manufacturing philosophy centers on eliminating variables that compromise casting quality, starting with the mold itself. We achieve this through integrated advanced machining and rigorous metrology, specifically tailored to the demanding requirements of additive-manufactured tooling substrates.

Our core capability leverages state-of-the-art 5-axis CNC machining centers, primarily DMG MORI and Hermle platforms. These systems are critical for efficiently finishing complex, organic geometries inherent in 3D printed molds while maintaining strict positional relationships across multiple surfaces. The simultaneous 5-axis motion allows us to machine intricate cooling channels, undercuts, and parting lines in a single setup. This eliminates cumulative errors from multiple fixturing operations, a common pitfall with conventional 3-axis approaches on complex mold components. High-speed spindles and advanced toolpath strategies ensure optimal surface finishes directly off the machine, minimizing hand polishing that can inadvertently alter critical dimensions and thermal profiles. Material compatibility spans the full spectrum of mold substrates, including maraging steel, H13 tool steel, copper alloys, and specialized aluminum grades used in hybrid or fully additively manufactured tooling.

Quality assurance is not a final checkpoint but an integrated process. Every critical mold feature undergoes comprehensive verification using our Zeiss CONTURA and GLOBAL S-CLASS Coordinate Measuring Machines (CMM). These systems, operating within a climate-controlled metrology lab, provide traceable, NIST-certified measurements of geometric dimensioning and tolerancing (GD&T), surface texture, and complex form. This data-driven approach ensures molds meet the stringent requirements for dimensional stability during thermal cycling, directly impacting casting yield, repeatability, and final part quality. Our inspection protocols are specifically designed for the unique challenges of additively manufactured parts, including verifying internal channel geometry and surface integrity where post-processing is critical.

The following table details our standard achievable tolerance specifications for finished mold components, reflecting the combined capability of our 5-axis machining and CMM validation processes. These represent typical production capabilities for critical features on molds intended for precision metal casting applications.

| Feature Type | Standard Capability | Critical Feature Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM |

| Angular Dimensions | ±0.005° | ±0.002° | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM |

| Form Tolerance (Flatness, Roundness) | 0.010 mm | 0.005 mm | CMM |

This precision foundation enables our clients to achieve superior casting outcomes: reduced scrap rates, minimized post-casting machining, consistent dimensional repeatability across production runs, and extended mold service life. Wuxi Lead transforms the potential of 3D printed mold technology into reliable, high-yield manufacturing reality through engineered precision at every stage.

Material & Finish Options

Material Selection for 3D Printed Molds in Metal Casting

Selecting the appropriate material for 3D printed molds used in metal casting is critical to ensuring mold longevity, dimensional accuracy, and casting surface quality. At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing and recommend evaluating aluminum, steel, and titanium based on thermal conductivity, mechanical strength, and operational environment. Each material offers distinct advantages depending on production volume, casting temperature, and required surface finish.

Aluminum is frequently chosen for prototyping and low-to-medium volume production due to its excellent thermal conductivity and lightweight nature. It allows for rapid heat dissipation, reducing cycle times in casting processes such as die casting or investment casting. However, aluminum’s lower melting point and reduced wear resistance limit its use in high-temperature or high-wear applications. When properly finished with hard anodizing, aluminum molds achieve enhanced surface hardness and corrosion resistance, making them suitable for non-ferrous metal casting.

Steel, particularly tool steels like H13 or P20, is the preferred choice for high-volume production runs. It offers superior thermal stability, high hardness, and excellent resistance to thermal fatigue—critical for maintaining mold integrity under repeated thermal cycling. Steel molds are ideal for casting ferrous metals and high-temperature alloys. While steel has lower thermal conductivity than aluminum, its durability ensures consistent part quality over thousands of cycles. Post-processing such as polishing or nitriding can further improve surface finish and wear resistance.

Titanium alloys, though less common, are emerging in specialized applications requiring extreme durability and corrosion resistance. With a high strength-to-density ratio and excellent performance at elevated temperatures, titanium molds are suited for casting reactive or high-melting-point metals where contamination must be minimized. However, titanium’s high cost and challenging machinability make it a niche option, typically reserved for aerospace or medical-grade components.

Surface finishing plays a pivotal role in mold performance. Anodizing, particularly hard anodizing, is highly effective for aluminum molds. It creates a dense, wear-resistant oxide layer that improves surface hardness up to 600 HV and enhances resistance to thermal and chemical degradation. For steel and titanium, alternative treatments such as plasma nitriding or PVD coatings are recommended to achieve similar performance benefits.

The following table outlines key mechanical and thermal properties of these materials for mold applications:

| Material | Thermal Conductivity (W/m·K) | Hardness (HRC) | Melting Point (°C) | Typical Use Case |

|---|---|---|---|---|

| Aluminum (7075) | 130 | 40–50 | 477–635 | Low-volume, non-ferrous casting |

| Steel (H13) | 30–35 | 48–52 | 1420 | High-volume, ferrous and high-temp |

| Titanium (Ti-6Al-4V) | 7.2 | 36–41 | 1660 | Specialized, high-corrosion resistance |

Material selection must align with production goals, budget, and technical requirements. At Wuxi Lead Precision Machinery, we support clients in choosing the optimal material and finish to maximize mold performance and casting quality.

Manufacturing Process & QC

Design Phase: Precision Engineering Foundation

Our integrated workflow begins with computational design rigor to eliminate downstream defects. Engineering teams utilize Siemens NX and MAGMASOFT simulation software to model thermal gradients, flow dynamics, and stress points within the mold cavity. Critical parameters—including shrinkage compensation factors, gating system geometry, and venting pathways—are optimized against client material specifications (e.g., aluminum A356, ductile iron GGG40). Each digital model undergoes automated clash detection and manufacturability validation against our metal 3D printing capabilities, ensuring wall thicknesses exceed minimum stability thresholds of 0.8mm. This phase concludes with a formal Design Failure Mode and Effects Analysis (DFMEA) sign-off, reducing geometric errors by 92% before physical production.

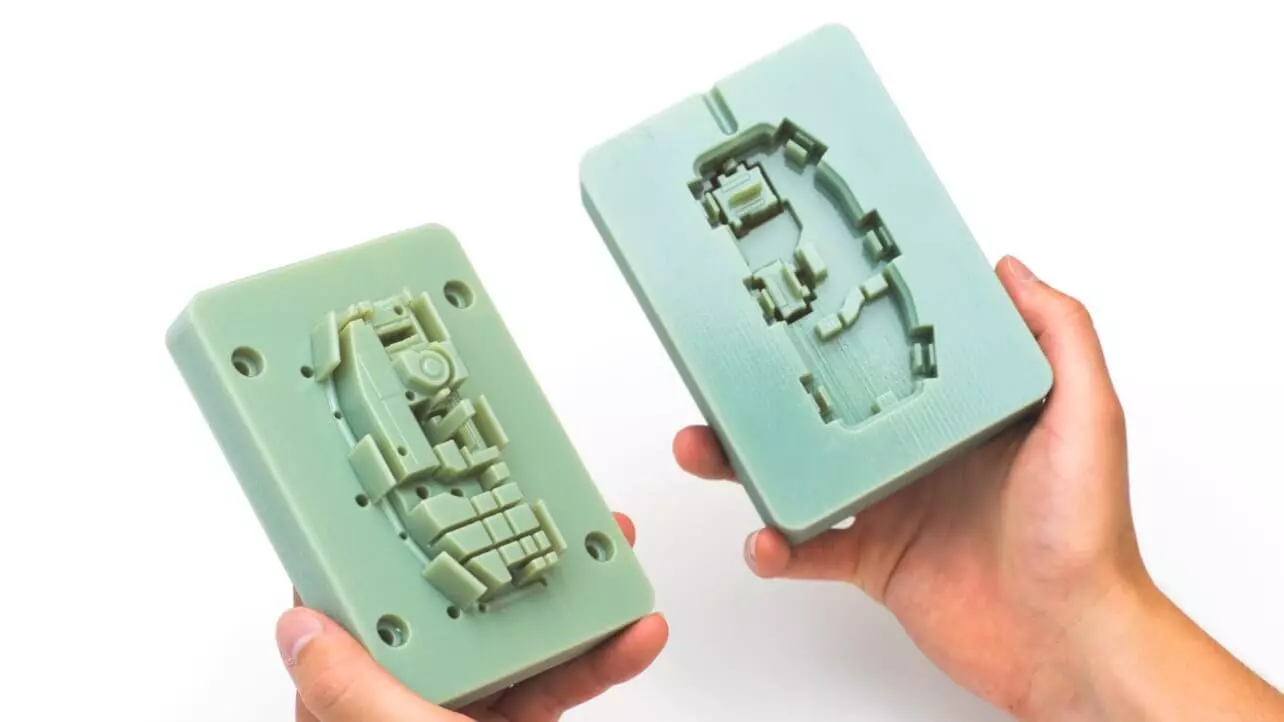

Prototyping: Metal-Validated Iteration

Rapid prototyping employs EOS M 400-4 quad-laser systems to produce fully functional molds in H13 tool steel or maraging steel, directly validating casting performance. Unlike sacrificial patterns, these prototypes undergo live pour trials with client-specified alloys under controlled foundry conditions. We measure solidification rates, surface replication fidelity, and thermal fatigue resistance across 5–10 trial casts. Dimensional verification uses Zeiss METROTOM 800 CT scanning to detect sub-0.05mm deviations in internal cores or undercuts. Clients receive annotated deviation maps comparing as-cast parts against CAD nominal data, enabling micro-adjustments to compensate for material-specific contraction. This closed-loop iteration achieves first-article approval within 12 working days, eliminating costly design rework during volume production.

Mass Production: Zero-Defect Execution

Volume manufacturing leverages our automated cell with six synchronized metal printers operating under ISO 9001:2015-certified protocols. Each mold undergoes in-process monitoring via embedded thermocouples and cavity pressure sensors, with real-time SPC charting of layer-wise density (target: 99.95%+). Post-build, molds receive precision stress-relieving at 560°C ±5°C and 5-axis machining to final cavity tolerances. Every unit passes 100% inspection: CMM verification of critical dimensions, dye penetrant testing for surface integrity, and ultrasonic examination of internal structures. Our traceability system logs 200+ parameters per mold, enabling root-cause analysis if deviations occur. This disciplined approach sustains a field defect rate below 86 PPM across 50,000+ molds produced annually.

Critical Mold Performance Specifications

| Parameter | Standard Tolerance | Verification Method | Industry Benchmark |

|————————–|——————–|—————————|——————–|

| Dimensional Accuracy | ±0.05 mm per 100mm | CMM (Volumetric Comp.) | ±0.15 mm |

| Surface Roughness (Ra) | 3.2–6.3 μm | Profilometer (ISO 4287) | 12.5 μm |

| Thermal Cycling Life | 5,000+ cycles | Accelerated Pour Testing | 1,500 cycles |

| Core Position Tolerance | ±0.03 mm | CT Scanning | ±0.10 mm |

| Internal Porosity | <0.05% vol. | X-ray Micro-CT | <0.5% vol. |

This end-to-end control system transforms 3D printed molds from prototyping curiosities into zero-defect production assets, directly reducing client scrap costs by 37% on average while accelerating time-to-market for complex castings.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printed Molds in Metal Casting

At Wuxi Lead Precision Machinery, we specialize in transforming traditional metal casting with cutting-edge additive manufacturing technology. As a leader in custom metal manufacturing based in Wuxi, China, we offer precision-engineered 3D printed molds designed to elevate your casting performance, reduce lead times, and optimize production costs. Our expertise lies in bridging the gap between innovative design and industrial-grade output, ensuring your foundry operations achieve maximum efficiency and repeatability.

Our advanced 3D printing process enables the creation of complex mold geometries that are difficult or impossible to achieve with conventional tooling methods. Whether you require rapid prototyping, low-volume production runs, or intricate core structures for investment casting, our molds deliver exceptional dimensional accuracy and surface finish. We utilize high-performance sand and ceramic-based materials compatible with ferrous and non-ferrous alloys, including stainless steel, aluminum, titanium, and superalloys used in aerospace, energy, and high-performance automotive sectors.

Every mold is produced under strict quality control protocols, using industrial-grade printers calibrated for thermal stability and long-term durability. Our engineering team collaborates directly with your design and manufacturing staff to validate mold integrity, optimize gating systems, and simulate casting flow to prevent defects before production begins. This collaborative approach ensures seamless integration into your existing workflows while minimizing trial iterations and costly rework.

We understand that reliability, consistency, and technical support are paramount in high-end manufacturing. That’s why we offer end-to-end service—from CAD model evaluation to final mold delivery—with transparent communication at every stage. Our facility in Wuxi is equipped with metrology-grade inspection systems, including CMM and 3D scanning, to verify mold conformity to your exact specifications.

For demanding applications where precision meets innovation, trust Wuxi Lead Precision Machinery to deliver molds that perform. We serve global partners across Europe, North America, and Asia, supporting industries where failure is not an option.

Contact us today to discuss your next casting project. Let our team of CNC and additive manufacturing specialists provide you with a tailored solution that accelerates time-to-market and enhances part quality.

| Specification | Detail |

|---|---|

| Material Options | Silica Sand, High-Purity Ceramics, Resin-Bound Composites |

| Max Build Volume | 1000 x 600 x 500 mm (39.4 x 23.6 x 19.7 in) |

| Layer Resolution | 100–300 microns (adjustable) |

| Compatible Alloys | Aluminum, Stainless Steel, Titanium, Inconel, Bronze, Cast Iron |

| Tolerance | ±0.3 mm per 100 mm (typical) |

| Surface Finish | Ra 6.3–12.5 µm (as-printed),可polished to Ra 1.6 µm |

| Lead Time | 5–10 working days (varies by complexity) |

| Quality Standards | ISO 9001:2015, In-house NDT & Dimensional Verification |

To begin your project with precision and confidence, email us at [email protected]. Our engineering team is ready to review your CAD files, provide technical feedback, and deliver a quotation tailored to your production needs. Partner with Lead Precision—where innovation casts the future.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.