Technical Contents

Engineering Guide: U.S. Range Parts

Engineering Insight: U.S. Range Parts – The Critical Role of Precision in Performance and Safety

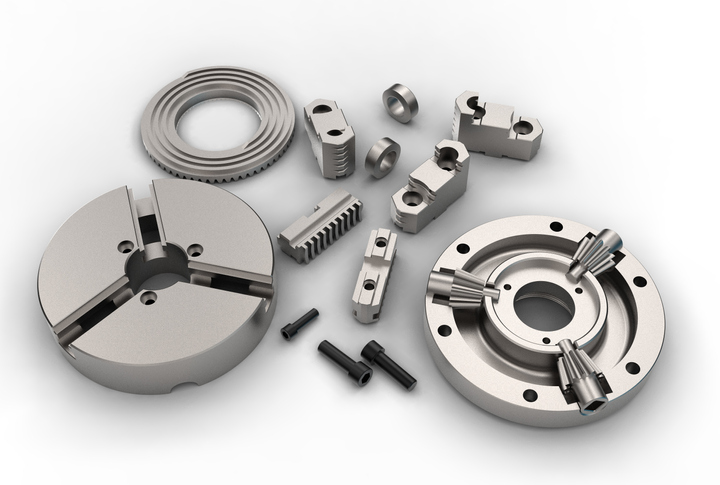

In the realm of custom metal manufacturing, U.S. range parts—components used in firearms, shooting range systems, and precision targeting equipment—demand an uncompromising standard of accuracy, durability, and repeatability. These parts are not only critical for optimal mechanical function but also directly influence user safety, consistency in performance, and long-term reliability under repeated stress. At Wuxi Lead Precision Machinery, we understand that manufacturing for this sector requires more than technical capability; it demands a philosophy rooted in precision engineering and material integrity.

Range parts such as barrel components, bolt carriers, trigger assemblies, and rail interfaces operate in high-stress environments where tolerances measured in microns can determine the difference between peak performance and catastrophic failure. Even minor deviations in dimensional accuracy or surface finish can lead to increased wear, misalignment, or malfunctions during operation. This is especially critical in military and law enforcement applications, where equipment must perform flawlessly under extreme conditions.

Our experience at Wuxi Lead has been shaped by years of delivering mission-critical components for defense systems and precision equipment used in international sporting events, including Olympic-level shooting disciplines. These high-stakes applications require components that meet exacting specifications, often exceeding MIL-STD and ISO standards. Our work with such clients has reinforced the principle that precision is not an incremental advantage—it is the foundation of trust in engineered systems.

We employ advanced CNC machining processes, including 5-axis milling and Swiss-type turning, combined with rigorous in-process inspection using coordinate measuring machines (CMM) and optical comparators. Material selection is equally critical; we routinely work with aerospace-grade alloys such as 4140, 4340, and 17-4 PH stainless steel, ensuring optimal strength-to-weight ratios and corrosion resistance. Each part undergoes full dimensional verification and, when required, non-destructive testing to validate structural integrity.

The following table outlines typical specifications we maintain for U.S. range parts, reflecting the precision and quality assurance standards central to our manufacturing philosophy.

| Specification | Standard Tolerance | Notes |

|---|---|---|

| Dimensional Accuracy | ±0.005 mm (±0.0002 in) | Achieved via CNC with real-time probing |

| Surface Finish | Ra 0.4 µm (16 µin) | Critical for moving parts and sealing surfaces |

| Geometric Tolerancing | GD&T per ASME Y14.5 | Applied to critical alignment and fit features |

| Material Certification | Mill Test Reports (MTR) | Provided for all high-performance alloys |

| Inspection Frequency | 100% in-process and final | Includes CMM, visual, and functional checks |

| Coatings & Treatments | HVOF, Nitriding, Passivation | Applied per application requirements |

At Wuxi Lead, we view every range part not merely as a component, but as a commitment to performance under pressure. Our engineering team collaborates closely with clients to translate functional requirements into manufacturable designs, ensuring that every piece meets or exceeds the operational demands of U.S. and international end-users. In the world of precision firearms systems, there is no margin for error—only the certainty of exactness.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for U.S. Range Parts

Wuxi Lead Precision Machinery delivers uncompromising precision for demanding U.S. range parts applications through advanced manufacturing technology and rigorous quality control. Our core strength lies in high-accuracy, complex component production, specifically engineered to meet the stringent dimensional and functional requirements inherent in aerospace, defense, and high-performance industrial sectors within the United States market. We understand the critical nature of these components, where failure is not an option, and our capabilities are structured to ensure absolute reliability and performance.

Our primary manufacturing platform centers on state-of-the-art 5-axis CNC machining centers. These systems enable the production of highly complex geometries in a single setup, significantly reducing cumulative error and secondary operations. Utilizing simultaneous 5-axis interpolation, we machine intricate contours, deep cavities, and undercuts common in range instrumentation housings, actuator components, and structural fittings with exceptional accuracy. This capability is essential for parts requiring tight alignment of multiple critical features across compound angles. We process a wide range of aerospace-grade materials including titanium alloys (Ti-6Al-4V), high-strength aluminum (7075-T7351), stainless steels (17-4PH, 304/316), and specialty alloys, maintaining strict material traceability and process control throughout machining. Our programming leverages advanced CAM software for optimized toolpaths, minimizing cycle times while maximizing surface finish and dimensional integrity, directly supporting demanding U.S. production schedules.

Quality assurance is non-negotiable. Every critical feature on U.S. range parts undergoes comprehensive verification using Coordinate Measuring Machines (CMMs) certified to ISO 17025 standards. Our inspection protocols, aligned with AS9100 requirements, go beyond basic dimensional checks. We perform full geometric dimensioning and tolerancing (GD&T) analysis, including complex profile, position, and runout measurements, ensuring parts meet the exacting blueprint specifications. This data-driven approach provides documented evidence of conformance, crucial for U.S. regulatory compliance and customer acceptance. Our CMM operators are highly trained, utilizing the latest metrology software for efficient and precise reporting, enabling rapid feedback for process refinement.

The following table details the typical tolerance capabilities achievable across common materials for U.S. range parts, reflecting our standard production performance under controlled conditions. Actual tolerances for specific projects are confirmed during the quoting and process validation phase.

| Dimensional Range | Material Group | Typical Tolerance (Linear) | Typical Tolerance (Geometric) | Surface Finish (Ra) |

|---|---|---|---|---|

| < 50 mm | Aluminum Alloys | ±0.005 mm | ±0.010 mm (Profile) | 0.8 – 1.6 µm |

| 50 – 150 mm | Aluminum Alloys | ±0.010 mm | ±0.015 mm (Profile) | 0.8 – 1.6 µm |

| < 50 mm | Titanium/Steel Alloys | ±0.008 mm | ±0.012 mm (Position) | 1.6 – 3.2 µm |

| 50 – 150 mm | Titanium/Steel Alloys | ±0.012 mm | ±0.020 mm (Position) | 1.6 – 3.2 µm |

| All Ranges | Critical Datums | Verified via CMM | Full GD&T Analysis | Per Drawing |

This combination of advanced 5-axis CNC machining and metrology-grade CMM inspection forms the bedrock of our service for U.S. customers. We translate complex engineering requirements into flawless physical components, ensuring your range parts perform with the precision and reliability demanded by critical applications. Partner with Wuxi Lead for manufacturing execution where technical capability meets unwavering quality commitment.

Material & Finish Options

Material selection is a foundational decision in precision manufacturing, directly influencing performance, durability, and cost-efficiency of end components. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-demand industrial applications, supporting clients across aerospace, automotive, medical, and energy sectors. Our expertise enables informed decisions between aluminum, steel, and titanium—three of the most widely used engineering metals—paired with advanced surface treatments such as anodizing to enhance functionality and longevity.

Aluminum is favored for its lightweight properties and excellent strength-to-density ratio, making it ideal for applications where weight reduction is critical without sacrificing structural integrity. It exhibits superior machinability and thermal conductivity, and when combined with anodizing, delivers enhanced corrosion resistance and surface hardness. Commonly used alloys include 6061 and 7075, each suited to different load and environmental conditions. Anodized aluminum is particularly effective in outdoor and marine environments, where exposure to moisture and UV radiation demands robust protection.

Steel, particularly in its stainless and alloy forms, offers unmatched tensile strength and wear resistance. Stainless steel grades such as 304 and 316 are widely used in medical and food processing equipment due to their hygienic properties and resistance to oxidation. For high-stress mechanical systems, alloy steels like 4140 provide superior toughness and fatigue resistance. While steel is heavier than aluminum or titanium, its mechanical reliability and cost-effectiveness make it a preferred choice for structural and load-bearing components.

Titanium stands at the premium end of the material spectrum, offering an exceptional strength-to-weight ratio and extraordinary resistance to corrosion, especially in chloride-rich environments. Grade 5 titanium (Ti-6Al-4V) is widely used in aerospace and biomedical implants due to its biocompatibility and ability to withstand extreme temperatures. Though more challenging to machine and higher in cost, titanium’s long-term performance in aggressive environments justifies its use in mission-critical applications.

Surface finishing, particularly anodizing, plays a pivotal role in extending component life. Anodizing creates a controlled oxide layer on aluminum surfaces, increasing hardness and enabling color coding for part identification. This electrochemical process improves adhesion for paint primers and enhances electrical insulation.

The following table summarizes key mechanical and physical properties of commonly used materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Applications | Suitable for Anodizing |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Moderate to High | Aerospace, Automotive | Yes |

| Stainless Steel 304 | 8.0 | 505–860 | High | Medical, Food Processing | No |

| Steel 4140 | 7.85 | 655–1000 | Moderate | Oil & Gas, Machinery | No |

| Titanium Ti-6Al-4V | 4.43 | 900–950 | Very High | Aerospace, Biomedical | Limited |

At Wuxi Lead, we guide clients through material and finish selection based on operational demands, regulatory standards, and lifecycle requirements. Our engineering team supports prototyping and material testing to ensure optimal performance in real-world conditions.

Manufacturing Process & QC

Precision Manufacturing Process for U.S. Range Components

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence for U.S. appliance range parts, ensuring absolute compliance with North American engineering standards and zero-defect delivery. Our integrated workflow begins with collaborative design validation. Engineering teams utilize Siemens NX and SolidWorks to meticulously review customer CAD models against ASME Y14.5 geometric dimensioning and tolerancing requirements. Critical features such as burner port geometry, valve seat interfaces, and high-temperature alloy flange surfaces undergo thermal stress simulation and manufacturability analysis. This phase includes formal documentation of material specifications per ASTM A240 for stainless steel grades 304/430 and AMS 5510 for heat-resistant alloys, ensuring seamless integration into U.S. assembly lines.

Prototyping transitions validated designs into physical verification using HAAS UMC-750 5-axis machining centers. We produce functional prototypes within 72 hours, incorporating in-process probing for real-time dimensional verification against first-article inspection (FAI) requirements per AS9102. Each prototype undergoes rigorous performance testing including thermal cycling validation to 500°C, leak testing at 15 PSI, and surface finish confirmation. Customer engineering sign-off on prototype functionality and dimensional conformance is mandatory before progression to series production, eliminating downstream rework risks.

Mass production leverages our ISO 9001 and IATF 16949 certified facility with embedded statistical process control. Machining cells operate under closed-loop monitoring using Renishaw probes and Mitutoyo CMM verification at defined intervals. Every component batch receives full material traceability documentation including heat numbers and mill test reports. Our zero-defect mandate is enforced through multi-stage inspection protocols: automated optical inspection for surface defects, 100% critical dimension checks via coordinate measuring machines, and batch-level destructive testing for metallurgical properties. Process capability is continuously maintained above Cpk 1.67 through real-time SPC charting of key characteristics.

The following specifications define our production capability for range components:

| Critical Parameter | Performance Standard | Verification Method | Compliance Standard |

|---|---|---|---|

| Dimensional Accuracy | ±0.005 mm (0.0002″) | CMM / In-Process Probing | ISO 2768-m |

| Surface Roughness (Ra) | 0.8 µm (32 µin) max | Portable Roughness Tester | ASME B46.1 |

| Material Traceability | Full Heat Number Tracking | Digital Mill Cert Archive | ASTM A240 |

| Process Capability (Cpk) | ≥ 1.67 sustained | Real-Time SPC Monitoring | AIAG SPC Manual |

This structured progression from design validation through rapid prototyping to statistically controlled mass production guarantees components that meet the exacting thermal, mechanical, and regulatory demands of U.S. range manufacturing. We deliver consistent zero-defect performance through engineering rigor and process discipline, ensuring seamless integration into your appliance assembly workflow.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When your U.S.-based operations demand precision-engineered metal components that meet the highest global standards, Wuxi Lead Precision Machinery stands as your trusted manufacturing partner. With over 15 years of expertise in custom metal fabrication, CNC machining, and precision sheet metal work, we deliver high-integrity parts built to your exact specifications. Our ISO 9001:2015-certified facility in Wuxi, China, combines advanced technology with rigorous quality control to ensure every component exceeds expectations for performance, durability, and repeatability.

We specialize in serving demanding sectors including aerospace, medical equipment, industrial automation, and advanced electronics—industries where tolerances matter, traceability is critical, and reliability is non-negotiable. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing systems adapt to your project’s scale and timeline without compromising on quality.

Our engineering team collaborates directly with your design and procurement staff to optimize manufacturability, reduce lead times, and lower total cost of ownership. From material selection and DFM analysis to final inspection and global logistics, we manage every phase with transparency and accountability. Our clients in the U.S. range parts market rely on us not just as a supplier, but as a strategic extension of their engineering and production capabilities.

At Wuxi Lead Precision Machinery, we understand the unique demands of U.S. regulatory environments and performance expectations. That’s why we invest in state-of-the-art 5-axis CNC machines, automated welding cells, and laser-cutting systems, all monitored through real-time SPC (Statistical Process Control) protocols. Every part is inspected using coordinate measuring machines (CMM) and optical comparators to ensure compliance with your prints and industry standards such as AS9100, ITAR, and RoHS.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Machining Tolerances | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 2000 x 1200 x 800 mm (78.7 x 47.2 x 31.5 in) |

| Materials Processed | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Carbon Steel |

| Finishing Options | Anodizing, Powder Coating, Passivation, Zinc Plating, Brushing |

| Quality Standards | ISO 9001:2015, ISO 13485 (Medical), AS9100D (Aerospace) |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (shipping included) |

We offer full documentation packages, including First Article Inspection (FAI) reports, material certifications, and PPAP submissions, ensuring seamless integration into your supply chain. Our bilingual project managers provide daily updates and real-time visibility into production status, making collaboration effortless across time zones.

If you are sourcing high-precision metal components for U.S. range parts applications, now is the time to partner with a manufacturer that combines technical mastery with operational reliability. Contact us today at [email protected] to discuss your next project. Let Wuxi Lead Precision Machinery become your long-term manufacturing solution—engineered for excellence, built for partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.