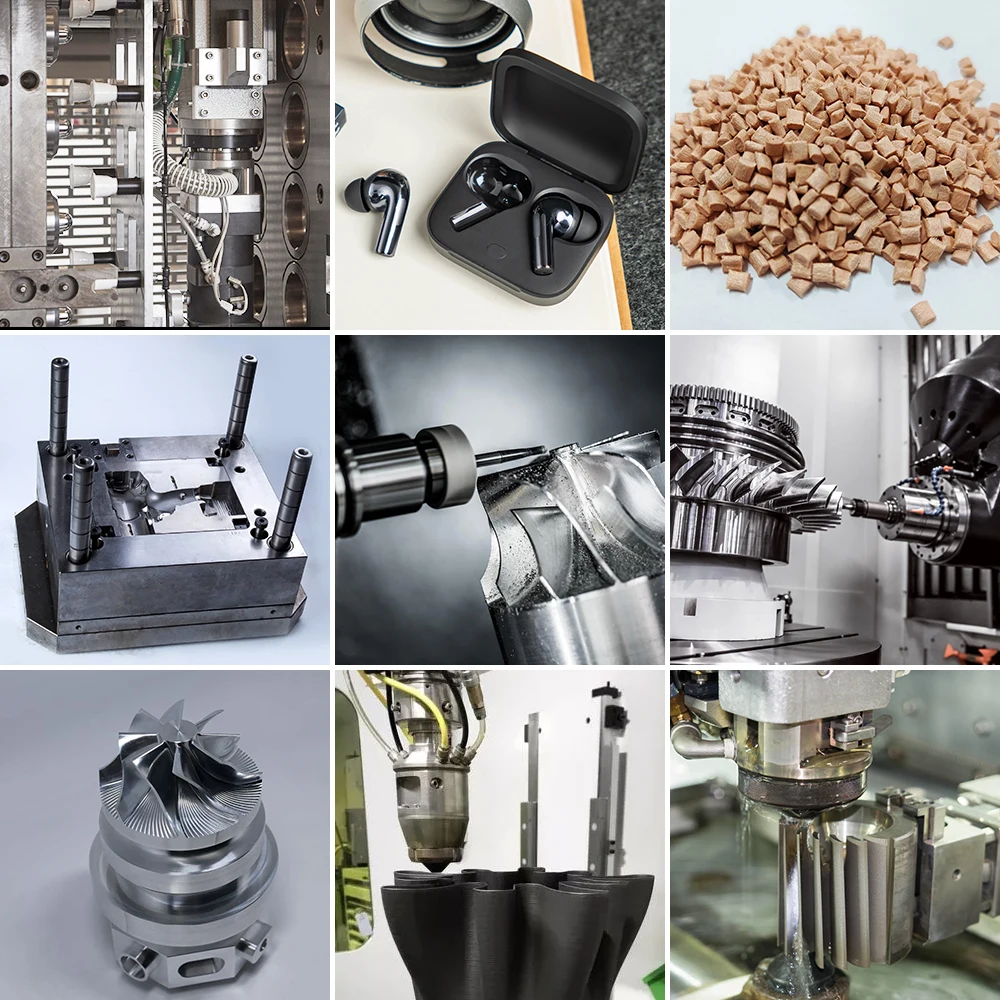

Technical Contents

Engineering Guide: Injection Moulding Defects

Engineering Insight: Precision as the Antidote to Injection Moulding Defects

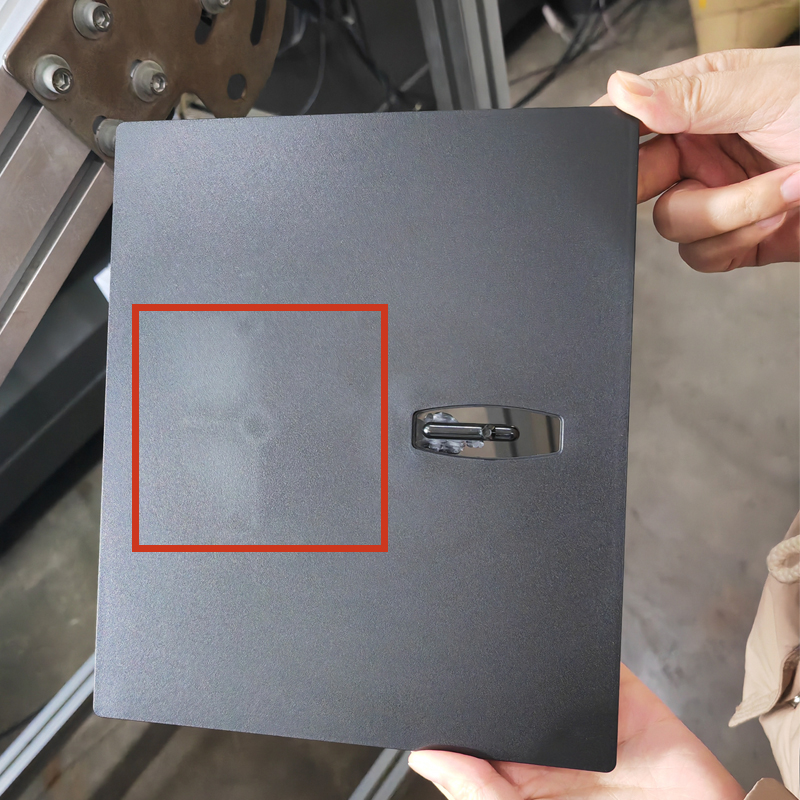

In high-stakes custom metal manufacturing for injection moulding applications, defects are not merely cosmetic imperfections—they represent critical failures in process control and component integrity. Sink marks, weld lines, flash, and short shots directly compromise part functionality, assembly compatibility, and end-product lifespan. These defects originate from microscopic deviations in tool geometry, thermal management, or material flow dynamics. For aerospace, medical, or defense sectors, where Wuxi Lead Precision Machinery operates, such flaws are unacceptable. The root cause consistently traces back to insufficient precision in the mould’s metallic core—the foundation dictating thermoplastic behavior under extreme pressure and temperature. Tolerances measured in microns, not millimeters, separate flawless production from costly scrap and delayed timelines. Achieving this demands more than standard machining; it requires integrated engineering mastery of material science, thermal dynamics, and CNC capabilities operating at the absolute edge of technical feasibility.

At Lead Precision, we treat defect prevention as a non-negotiable engineering discipline. Our approach begins with finite element analysis (FEA) to simulate cooling gradients and stress points before metal is cut. This predictive rigor, combined with 5-axis CNC machining holding tolerances to ±0.002mm, ensures uniform cavity wall thickness and exact gate geometry. Critical ejector pin bores and venting channels are machined in a single setup to eliminate alignment errors that cause flash or part sticking. The result is consistent thermal transfer and balanced melt flow—directly neutralizing the primary mechanisms behind common defects. Our commitment extends beyond the blueprint; we validate every mould through iterative trial runs under production-equivalent conditions, fine-tuning parameters until defect rates reach zero.

This precision philosophy is proven under the most demanding scrutiny. Lead Precision engineered critical mould components for the Beijing 2022 Winter Olympics’ medical equipment supply chain, where zero-defect validation was mandated. Similarly, our tooling for classified military communication housings underwent rigorous MIL-STD-810G environmental testing, surviving extreme thermal cycling and vibration without dimensional drift or surface degradation. These projects demanded absolute fidelity to specification—defects would have meant mission failure.

The following table outlines how our precision engineering directly targets key defect origins:

| Defect Type | Primary Cause in Mould Design | Lead Precision Mitigation Strategy |

|---|---|---|

| Sink Marks | Non-uniform cooling rates | Precision-machined conformal cooling channels ±0.005mm tolerance |

| Weld Lines | Poor melt flow convergence geometry | Optimized gate placement & runner balance via FEA; mirror-finish cavity surfaces |

| Flash | Cavity-parting line misalignment | Single-setup machining of core/cavity halves; H7/g6 tolerance fits |

| Short Shots | Inconsistent material flow resistance | Exact gate dimensions; polished flow paths to Ra 0.05µm |

Defect elimination starts with the metal. When your application demands absolute reliability—whether for life-saving devices or national security infrastructure—partner with a manufacturer whose precision is validated where consequences matter most. Demand engineering, not just machining. Wuxi Lead Precision Machinery delivers the foundation for zero-defect production.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the rigorous demands of high-precision industries such as automotive, aerospace, medical, and industrial automation. At the core of our production infrastructure is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly reducing setup times and part handling while maintaining superior dimensional consistency. This capability is particularly critical when addressing injection moulding defects such as warpage, sink marks, or dimensional instability—issues often rooted in imprecise tooling or inconsistent component geometry.

Our machining processes are supported by a disciplined quality control framework anchored in CMM (Coordinate Measuring Machine) inspection. Every component undergoes rigorous metrological validation to ensure compliance with design specifications and international standards. The CMM system provides high-resolution 3D measurement data, enabling real-time verification of critical features such as radii, flatness, positional tolerances, and contour accuracy. This level of inspection is essential for identifying and correcting deviations that could contribute to moulding defects during the production lifecycle.

Precision is not an outcome but a designed parameter at Wuxi Lead. Our manufacturing tolerances are engineered to align with the tightest industry requirements, ensuring that every machined part contributes to the overall reliability and performance of the final mould assembly. By maintaining strict control over material removal rates, tool path optimization, and thermal stability during machining, we minimize variability and enhance repeatability across production runs.

The integration of 5-axis CNC technology with systematic CMM-based quality assurance enables us to proactively address root causes of injection moulding defects. For instance, precise cavity and core fabrication reduces the risk of uneven cooling—a common cause of warpage—while exact ejection system machining prevents drag marks or part deformation. Similarly, tight control over venting features and gating interfaces supports consistent melt flow, reducing the incidence of short shots or gas traps.

All processes are documented and traceable, with full inspection reports available upon delivery. Our technical team works closely with clients during the design-for-manufacturability (DFM) phase to anticipate potential issues and optimize part geometry for both manufacturability and performance.

The following table outlines our standard machining tolerances, reflecting the precision achievable through our integrated manufacturing and inspection systems.

| Feature | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Hole Diameter | ±0.015 mm | ±0.008 mm |

| Positional Tolerance | ±0.02 mm | ±0.01 mm |

| Flatness | 0.02 mm per 100 mm | 0.008 mm per 100 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm |

| Angular Tolerance | ±0.1° | ±0.05° |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner in resolving injection moulding defects through precision engineering and data-driven manufacturing excellence.

Material & Finish Options

Material Selection for Injection Moulding Defect Mitigation

Selecting optimal materials for injection mould tooling directly impacts defect prevention and production efficiency. At Wuxi Lead Precision Machinery, our empirical evidence confirms that mismatched material properties exacerbate common defects like sink marks, flash, warpage, and surface blemishes. Precision-engineered moulds require substrates balancing thermal management, wear resistance, and dimensional stability under cyclic stress. Below we detail critical material considerations for high-volume applications.

Aluminum alloys, particularly 7075-T6, offer superior thermal conductivity (130 W/m·K), accelerating cycle times by 30–50% compared to steel. This rapid heat dissipation minimizes sink marks and internal stresses in thick-walled parts. However, aluminum’s lower hardness (150 HB) limits use in abrasive polymers or high-cavity-count moulds where flash may occur at parting lines. We reserve aluminum for prototyping and medium-run production of engineering plastics like ABS or PP, where thermal efficiency outweighs wear concerns.

Tool steels such as H13 dominate high-volume production due to exceptional hardness (48–52 HRC) and thermal fatigue resistance. H13 maintains dimensional stability at 600°C, preventing flash formation even after 500,000+ cycles. Its moderate thermal conductivity (28 W/m·K) requires strategic cooling channel design to avoid warpage in semi-crystalline resins like nylon. For glass-filled polymers or LSR moulding, we specify pre-hardened P20 steel (28–32 HRC) as a cost-effective alternative with balanced machinability and polishability.

Titanium Ti-6Al-4V addresses extreme corrosion challenges in medical or chemical applications. Its near-zero thermal expansion coefficient (8.6 µm/m·°C) eliminates warpage in precision optics moulding, while corrosion resistance prevents surface pitting defects when processing PVC or flame-retardant additives. Though costly, titanium’s 36 HRC hardness and 7 W/m·K conductivity suit low-thermal-demand scenarios where part integrity is non-negotiable.

Anodizing Finishes for Defect Prevention

Hard anodizing (Type III) transforms aluminum mould surfaces into 50–75 µm thick ceramic layers (60–70 HRC), eliminating galling in high-polish cavities and reducing part ejection defects by 40%. For steel moulds, PVD coatings like TiN (2,400 HV) prevent sticking in sticky polymers (e.g., TPE), while electroless nickel plating provides uniform corrosion resistance for titanium without compromising dimensional tolerances.

Material and finish selection must align with resin chemistry, part geometry, and volume requirements. Wuxi Lead’s engineering team conducts thermal-mechanical simulations during mould design to preempt defect risks—ensuring your tooling investment delivers zero-defect output from day one.

| Material | Hardness | Thermal Conductivity (W/m·K) | Key Defects Mitigated | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075-T6 | 150 HB | 130 | Sink marks, internal stress | Prototypes, medium runs |

| Steel H13 | 48–52 HRC | 28 | Flash, thermal fatigue | High-volume engineering plastics |

| Steel P20 | 28–32 HRC | 30 | Warpage, surface drag | Glass-filled polymers |

| Titanium Ti-6Al-4V | 36 HRC | 7 | Corrosion pitting, warpage | Medical, chemical moulding |

Manufacturing Process & QC

Design: The Foundation of Zero Defects in Injection Moulding

At Wuxi Lead Precision Machinery, precision begins at the design stage. Our engineering team utilizes advanced CAD/CAM software and simulation tools to model every aspect of the injection moulding process before any metal is cut. This virtual prototyping ensures optimal gate placement, cooling channel layout, and material flow analysis, directly addressing potential defects such as warpage, sink marks, and short shots. By conducting thorough Design for Manufacturability (DFM) reviews, we identify and resolve structural or dimensional risks early, aligning client specifications with production realities. Finite Element Analysis (FEA) validates stress points and thermal distribution, ensuring the mould design supports consistent, high-integrity part formation across thousands of cycles.

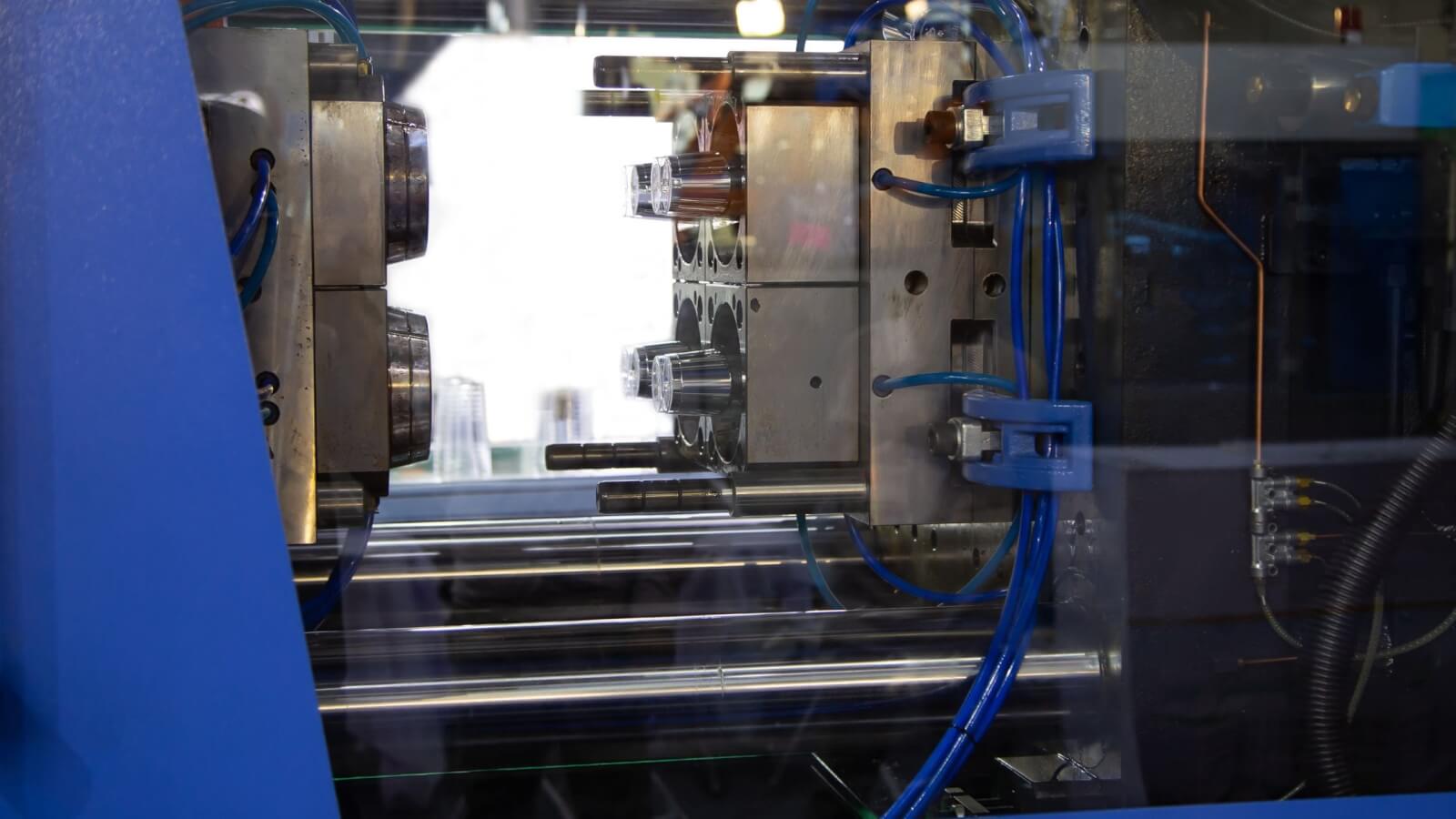

Prototyping: Validating Performance Under Real Conditions

Once the design is finalized, we proceed to prototype tooling using high-precision CNC machining and EDM processes. These soft or pre-hardened steel tools replicate the final production environment, allowing for functional testing of both the mould and the injection parameters. At this stage, we conduct rigorous trial runs on our state-of-the-art hydraulic and electric injection moulding machines, monitoring critical variables such as melt temperature, injection pressure, and cooling time. Each prototype part undergoes dimensional inspection via coordinate measuring machines (CMM) and surface finish analysis, ensuring conformity to ±0.005 mm tolerances. Any detected defects—such as flash, flow lines, or dimensional drift—are traced back to root causes, and corrective adjustments are implemented before advancing to full-scale production. This iterative validation process is essential for achieving zero defects in mass output.

Mass Production: Precision, Consistency, and Continuous Monitoring

With a fully validated mould, we transition to high-volume manufacturing using hardened steel tools built for durability and repeatability. Our production cells are equipped with automated monitoring systems that log real-time data on cycle times, pressure curves, and part weight, enabling immediate detection of process deviations. In-line vision systems and statistical process control (SPC) ensure every component meets exacting quality standards. Preventive maintenance schedules and automated lubrication systems extend mould life and minimize unplanned downtime. At Wuxi Lead, zero defects is not a goal—it is a standard enforced through integrated quality systems, operator training, and full traceability from raw material to finished part.

Key Production Specifications

| Parameter | Specification | Notes |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Achieved via CMM verification |

| Surface Roughness (Ra) | 0.1 – 0.8 µm | Adjustable per customer requirement |

| Mould Material | P20, 718H, H13, S136 | Selected based on part complexity and volume |

| Machine Tonnage Range | 50 – 2000 tons | Supports small to large part production |

| Production Monitoring | Real-time SPC & IoT integration | Enables predictive defect correction |

| Lead Time (Prototype) | 2–4 weeks | Depends on complexity |

| Lead Time (Mass Production) | 4–8 weeks | After prototype approval |

Why Choose Wuxi Lead Precision

Eliminate Injection Moulding Defects at the Source: Partner with Lead Precision

Persistent injection moulding defects like sink marks, warpage, or flash represent costly failures in production efficiency and part quality. These issues often stem not from the plastic process alone, but from underlying limitations in the mould tooling itself – dimensional instability, inadequate cooling, or insufficient structural rigidity in critical metal components. At Wuxi Lead Precision Machinery, we engineer the foundational metal solutions that directly prevent these defects before they occur. Our expertise lies in manufacturing the ultra-precise, high-performance mould bases, cavities, cores, inserts, and critical wear components that form the backbone of reliable, high-yield injection moulding. We move beyond standard fabrication to deliver metal parts engineered for micron-level repeatability and extended service life under demanding production cycles.

Our integrated approach combines advanced CNC machining capabilities with deep metallurgical understanding. We utilize premium tool steels and alloys, processed through stringent quality-controlled workflows, ensuring every component meets the exact thermal, mechanical, and dimensional requirements dictated by your specific application and resin. This precision directly translates to consistent cavity pressure, uniform cooling rates, and perfect part ejection – eliminating the root causes of common surface and structural defects. Partnering with Lead Precision means accessing a single-source solution for the most challenging metal elements within your mould system, backed by rigorous in-house metrology and material certification.

The technical foundation of our defect-prevention capability is demonstrated in our core manufacturing specifications:

| Specification Category | Capability | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | ISO 2768-mK |

| Surface Roughness (Ra) | 0.05 µm | ISO 1302 |

| Material Options | P20, H13, S136, 420SS, Maraging Steel | ASTM/EN Standards |

| Max Work Envelope | 1200 x 800 x 600 mm | |

| Critical Feature Repeatability | Cpk ≥ 1.67 | Statistical Process Control |

Beyond component supply, our value is embedded in proactive engineering collaboration. Our technical team works alongside your design and process engineers during the mould development phase. We identify potential defect risks related to metal part performance early, offering optimized material selections, heat treatment protocols, and geometric refinements proven to enhance mould stability and longevity. This collaborative engineering phase is critical for preventing costly mould modifications and production delays downstream. We understand that your success is measured in uptime, part consistency, and reduced scrap rates – metrics directly influenced by the precision and durability of the metal components we deliver.

Do not let substandard metal tooling compromise your injection moulding output. Wuxi Lead Precision Machinery provides the engineered metal foundation for defect-free production. Contact our engineering team today at [email protected]. Share your specific defect challenges or mould requirements, and receive a targeted assessment on how our precision metal components and collaborative approach can eliminate root causes,提升 your yield, and secure your competitive advantage in high-value manufacturing. Let us prove the Lead Precision difference in your next critical mould project.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.