Technical Contents

Engineering Guide: Injection Moulding Prototypes

Engineering Insight Precision in Injection Moulding Prototypes

Injection moulding prototypes are far more than preliminary models; they are critical validation tools that directly impact time-to-market, cost efficiency, and final product success. In high-stakes industries like aerospace, medical devices, and defense, the dimensional fidelity and material performance of a prototype are non-negotiable. A prototype failing to replicate the precision of the final production tool introduces significant risk—masking critical design flaws, invalidating material testing, and leading to costly iterations or, worse, field failures. Precision engineering at the prototype stage is not an optional luxury; it is the foundation for mitigating downstream risk and ensuring seamless transition to volume manufacturing.

The core challenge lies in achieving production-intent accuracy early. Prototype tools, often built faster and with different materials than hardened production moulds, must still deliver parts within tight tolerances to validate form, fit, and function accurately. Factors like thermal management, material flow dynamics, gate positioning, and ejection mechanics must be precisely simulated and executed. Even minor deviations in wall thickness consistency or critical feature location during prototyping can cascade into major issues during full-scale production, causing tolerance stack-up problems, assembly difficulties, or compromised structural integrity. This demands mould makers possess deep process understanding and advanced metrology capabilities from day one.

Wuxi Lead Precision Machinery leverages over 15 years of specialized expertise in high-precision metal fabrication to address this challenge. Our CNC engineering heritage, honed through supplying mission-critical components for Olympic venue infrastructure and certified military-grade applications, underpins our approach to prototype mould construction. We apply the same rigorous standards of geometric dimensioning and tolerancing (GD&T), material science knowledge, and in-process verification used in serial production to our prototype tools. This ensures dimensional stability, surface finish consistency, and material compatibility are validated under conditions mirroring true manufacturing, providing clients with actionable data, not just a physical sample. Our process stability, validated under ISO 13485 and AS9100 frameworks, guarantees that the prototype part is a true representative of what the production tool will deliver.

The tangible outcome is reduced development cycles and lower total project risk. Clients gain confidence that design validation is accurate, material choices are proven under realistic conditions, and first-article approval hurdles are minimized. This precision-driven prototyping strategy transforms a potential bottleneck into a strategic advantage.

Key prototype performance metrics achievable with Lead Precision’s engineering approach include:

| Parameter | Typical Requirement | Lead Precision Achievable Range |

|---|---|---|

| Dimensional Tolerance | ±0.10 mm | ±0.025 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm – 0.8 µm |

| Critical Feature Cpk | ≥1.33 | ≥1.67 |

| Material Consistency | Batch Verification | In-Process Spectro Analysis |

| First Article Pass Rate | Industry Avg 70% | >92% |

This level of control stems directly from our integrated CNC machining capabilities and disciplined quality management system, proven in the most demanding global projects. Precision prototyping is where robust manufacturing strategy begins.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specifically engineered to meet the rigorous demands of injection moulding prototype development. Our integrated production environment combines high-precision 5-axis CNC machining with comprehensive quality control systems, ensuring that every prototype meets exact design specifications and functional requirements. This level of precision is critical during the prototyping phase, where form, fit, and function must be validated before transitioning to full-scale production.

At the core of our manufacturing process is state-of-the-art 5-axis CNC machining technology. This advanced system enables multi-directional cutting with exceptional accuracy, allowing us to produce complex geometries and intricate features that are often required in injection moulding tools and prototype components. The simultaneous movement across five axes reduces setup time, minimizes human error, and ensures superior surface finishes—key factors in achieving repeatable, high-quality results. Materials such as hardened steels, aluminum alloys, and specialty tooling materials are machined with consistency and tight tolerance control, supporting both aesthetic and structural prototyping needs.

Quality assurance is embedded throughout our workflow, beginning with digital design validation and extending through final inspection. Every injection moulding prototype undergoes rigorous dimensional verification using a Coordinate Measuring Machine (CMM). This non-contact and contact-based metrology system provides micron-level accuracy in measuring critical features, ensuring compliance with engineering drawings and industry standards. Our CMM inspection process generates detailed reports that document conformance, supporting traceability and customer approval workflows.

To further demonstrate our precision capabilities, the following table outlines the standard tolerance specifications achievable across various feature types during prototype manufacturing. These values reflect our typical performance under controlled conditions and can be tightened based on specific application requirements.

| Feature Type | Standard Tolerance | Typical Surface Finish (Ra) | Material Compatibility |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | 0.8 – 1.6 µm | Tool Steel, Stainless Steel, Aluminum |

| Bore & Pin Holes | H7 (±0.010 mm) | 0.4 – 0.8 µm | Pre-hardened Steel, Brass, Titanium |

| Flatness | 0.008 mm per 100 mm | 0.8 – 1.2 µm | All machinable metals |

| Profile Accuracy | ±0.01 mm | 1.2 – 2.0 µm | P20, H13, S136, NAK80 |

| Inter-axis Angles (5-axis) | ±0.005° | 1.0 – 1.6 µm | High-alloy and wear-resistant steels |

Our technical capabilities are designed to support rapid iteration, design validation, and functional testing for injection moulding applications across industries such as automotive, medical devices, and consumer electronics. By combining 5-axis CNC precision with systematic CMM-based quality control, Wuxi Lead Precision Machinery ensures that every prototype not only meets but exceeds expectations in performance and reliability.

Material & Finish Options

Strategic Material Selection for Injection Moulding Prototypes

Selecting the optimal base material for injection moulding prototypes is a critical engineering decision impacting prototype fidelity, iteration speed, and path to production. At Wuxi Lead Precision Machinery, our CNC expertise ensures material choices align precisely with your functional requirements and project timeline. Aluminum, steel, and titanium each offer distinct advantages for the prototyping phase, where balancing cost, lead time, and performance is paramount. Understanding their core properties prevents costly mismatches between prototype behavior and final production tooling expectations.

Aluminum alloys, particularly 7075-T6, are the preferred choice for rapid functional prototyping. Its high thermal conductivity accelerates cooling cycles, enabling faster part validation and design iterations. While softer than tool steels, aluminum provides sufficient durability for hundreds to low thousands of shots, especially with abrasive-filled resins. This makes it ideal for validating part geometry, ejection, and initial material flow before committing to hardened steel. Lead times are significantly shorter than steel due to easier machinability, accelerating your development schedule. Steel, specifically pre-hardened grades like H13, becomes essential when prototypes must replicate the exact wear resistance, surface finish, and longevity of production tools. Its superior hardness and thermal fatigue resistance withstand high-volume prototype runs (thousands to tens of thousands of shots) and aggressive materials like glass-filled polymers. While machining lead times are longer and costs higher than aluminum, steel prototypes provide the most accurate representation of final part quality and mold maintenance needs. Titanium alloys, primarily Grade 5 (Ti-6Al-4V), serve highly specialized prototyping needs where extreme corrosion resistance to specific chemicals or very high strength-to-weight ratios are non-negotiable. Its use is niche due to significantly higher material and machining costs, coupled with challenging workability. Titanium prototypes are justified only when aluminum or steel demonstrably fail under the specific corrosive or mechanical demands of the intended application.

Anodizing is a vital surface treatment exclusively for aluminum prototype molds. Type II (Sulfuric Acid) anodizing enhances corrosion resistance and provides a good base for subsequent coloring. For functional molds, Type III (Hardcoat) anodizing is critical, creating a dense, wear-resistant ceramic layer that dramatically improves surface hardness and extends mold life, particularly against abrasive resins. This treatment is indispensable for achieving production-intent surface finishes and part release characteristics during the aluminum prototyping phase.

Material properties directly dictate prototype performance. The following table summarizes key specifications for informed selection:

| Material | Typical Grade | Hardness (HRC) | Corrosion Resistance | Typical Mold Application |

|---|---|---|---|---|

| Aluminum | 7075-T6 | 15-20 | Moderate | Rapid functional prototypes (100s-1k shots) |

| Tool Steel | H13 (Pre-Hard) | 40-44 | Good | High-fidelity prototypes (1k-50k+ shots) |

| Titanium | Grade 5 | 30-36 (as-mach) | Excellent | Specialized corrosive/chemical apps |

Wuxi Lead Precision Machinery leverages deep material science knowledge and advanced CNC capabilities to match your prototype goals with the optimal material and finish. Our engineers collaborate closely to ensure your prototype mold delivers actionable data, minimizing risk and accelerating your path from concept to validated production. Contact us to discuss your specific application requirements.

Manufacturing Process & QC

From Concept to Consistency: The Injection Moulding Prototype Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer precision into every phase of custom metal manufacturing, especially when delivering injection moulding prototypes for high-performance industrial applications. Our structured workflow—Design, Prototyping, and Mass Production—is built on decades of expertise and a Zero Defects philosophy. This ensures that every component meets exacting functional, dimensional, and material specifications before scaling to full production.

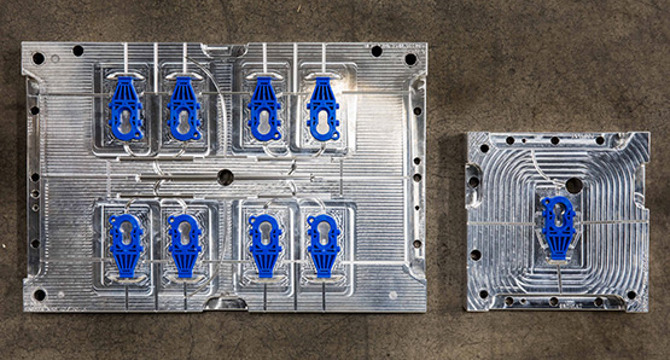

The process begins with collaborative design engineering. Our team works closely with clients to analyze CAD models, assess manufacturability, and optimize part geometry for both performance and tooling longevity. Finite Element Analysis (FEA) and Moldflow simulations are employed to predict material behavior, identify potential stress points, and refine gate locations and cooling channels. This proactive approach eliminates costly design flaws early and ensures the prototype will accurately represent final production behavior.

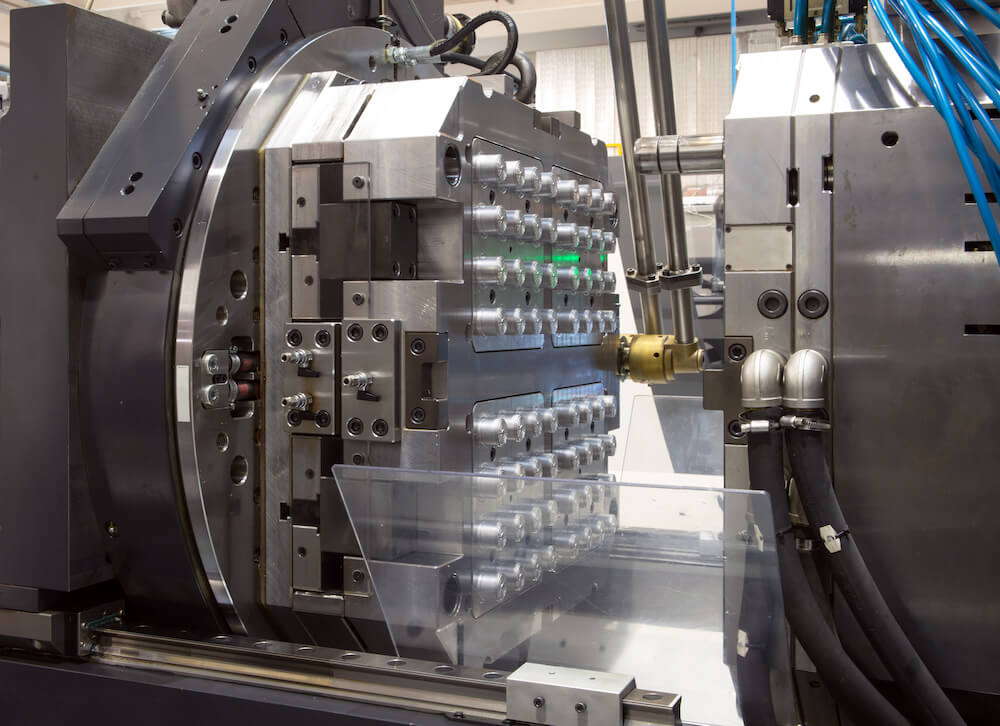

Once the design is validated, we proceed to prototyping using high-precision CNC-machined steel or aluminum moulds. These prototype tools replicate the exact cavity and core configurations of production tools, enabling functional testing under real-world conditions. Prototypes are produced on the same class of electric or hybrid injection machines used in mass production, ensuring consistency in pressure, temperature, and cycle time. Materials are carefully matched to production intent—whether PEEK, PPS, or reinforced engineering thermoplastics—so that mechanical, thermal, and chemical performance can be rigorously evaluated.

Each prototype undergoes comprehensive inspection using CMM (Coordinate Measuring Machine), optical comparators, and metrology-grade 3D scanning. Dimensional accuracy, surface finish, and structural integrity are verified against GD&T specifications. Any deviations trigger immediate root cause analysis and design or process adjustments. This closed-loop validation ensures that only fully qualified prototypes advance to the next stage.

With prototype approval, we transition seamlessly into mass production. Production-grade hardened steel moulds are manufactured in-house with tight tolerances and integrated hot runner systems for maximum repeatability. Our automated production cells run under real-time process monitoring, with SPC (Statistical Process Control) tracking critical parameters such as injection pressure, cooling time, and clamp force. Every batch is subject to first-article inspection and ongoing quality audits, maintaining our Zero Defects standard across thousands of cycles.

Our integrated approach eliminates guesswork and minimizes time-to-market. By aligning design, prototyping, and production under one quality-controlled environment, Wuxi Lead ensures that what works in prototype performs flawlessly in volume.

| Specification | Detail |

|---|---|

| Prototype Tooling Materials | P20, 718H, H13, Aluminum 7075 |

| Production Tooling Materials | 1.2344, 1.2379, S136, 420SS |

| Tolerance Range | ±0.005 mm to ±0.02 mm (depending on part size) |

| Surface Finish Options | SPI-SPE, VDI 3400, Textured, Mirror Polish |

| Supported Plastics | ABS, PC, POM, PA6/66, PBT, PPS, PEEK, LCP |

| Machine Capacity | 50–2000 Ton Clamping Force |

| Quality Standards | ISO 9001:2015, IATF 16949, PPAP Level 3 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Moulding Prototypes That Accelerate Your Time-to-Market

In high-stakes product development, the quality and speed of your injection moulding prototype directly impact downstream success. Substandard prototypes lead to costly design iterations, delayed validation, and compromised final production tooling. Wuxi Lead Precision Machinery eliminates these risks through an integrated approach combining advanced CNC manufacturing, rigorous quality control, and deep materials expertise. We are not merely a supplier; we are your strategic partner in transforming concept into precision-engineered reality, ensuring your prototype accurately reflects production intent and withstands rigorous testing.

Our dedicated prototype division leverages German-engineered CNC machining centers and Swiss precision measurement systems to produce mould bases, cavities, and cores meeting the most demanding tolerance-critical specifications. Unlike conventional rapid prototyping services, we utilize the exact hardened tool steels (such as H13, S136, and 2738HH) and surface treatments employed in full-scale production tooling. This critical distinction guarantees thermal stability, wear resistance, and dimensional accuracy during prototype validation runs, providing reliable data for your engineering team. Our engineers collaborate closely with your design staff from day one, offering DFM insights to optimize part geometry for manufacturability and longevity before metal is cut, preventing costly rework later.

The technical superiority of our process is quantifiable. We consistently achieve tolerances unattainable with standard rapid methods, ensuring your prototype performs identically to the final production part under real-world conditions. This precision minimizes validation surprises and accelerates the path to mass production.

| Capability | Specification | Benefit for Your Prototype |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (0.0002″) | Ensures fit, function, and assembly accuracy |

| Surface Roughness (Cavity) | Ra 0.2 µm (8 µin) standard | Validates cosmetic requirements and ejection |

| Material Options | H13, S136, 2738HH, 1.2344, P20+ | Matches production tool steel properties |

| Lead Time (Complex Cavity) | As fast as 72 hours machining | Dramatically reduces design iteration cycles |

| Quality Verification | Full CMM report + 3D scan overlay | Provides objective data for engineering sign-off |

Choosing Lead Precision means gaining a partner invested in your product’s ultimate success. We understand that a prototype is not just a physical model—it is the foundation for your production strategy. Our commitment to transparency, technical excellence, and on-time delivery ensures you receive a functional, reliable prototype that builds confidence in your design and streamlines the transition to volume manufacturing. Avoid the pitfalls of generic prototyping services that compromise on materials or precision. Contact our engineering team today to discuss how we can deliver a prototype that meets your exact performance criteria and accelerates your development timeline. Send your project details and CAD files to [email protected]. Let us provide the precision foundation your innovation requires.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.