Technical Contents

Engineering Guide: Large Part Injection Molding

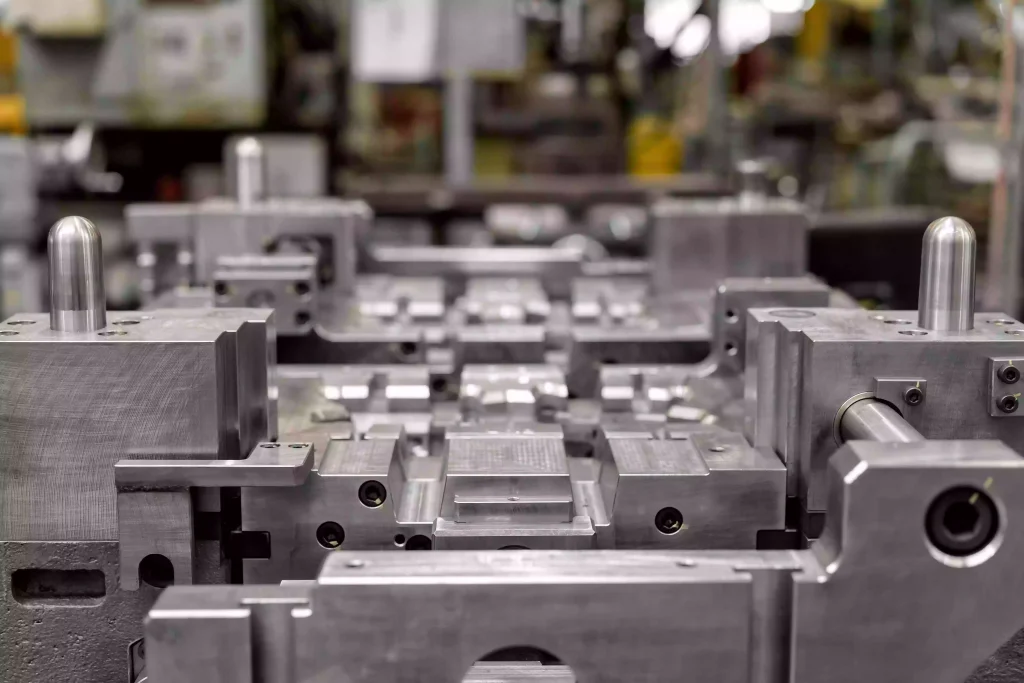

Engineering Insight: Precision in Large Part Injection Molding

In the realm of custom metal manufacturing, large part injection molding stands as a critical process for producing high-strength, dimensionally stable components used in aerospace, defense, energy, and large-scale industrial equipment. Unlike standard injection molding, this specialized technique demands an elevated level of engineering rigor, particularly when dealing with parts exceeding typical size thresholds—often measuring over 500 mm in any dimension and weighing several kilograms. At such scales, even minor deviations in tolerances can lead to catastrophic assembly failures, reduced operational lifespan, or non-compliance with stringent industry standards.

Precision is not merely a performance metric in large part injection molding—it is a foundational requirement. The interplay of material flow, thermal distribution, clamping force, and mold alignment becomes exponentially more complex as part dimensions increase. Non-uniform cooling rates, for instance, can induce internal stresses and warpage, while inconsistent pressure application may result in incomplete cavity filling or flash formation. These challenges necessitate a holistic approach to machine design, process control, and quality assurance.

Wuxi Lead Precision Machinery has spent over 15 years refining this balance of scale and accuracy. Our engineering team specializes in designing and manufacturing custom molding solutions tailored to the most demanding applications. This expertise has been validated through high-profile projects, including the production of structural components for Olympic-grade sports infrastructure and mission-critical housings for military-grade communication systems. In both cases, the success of the final assembly relied on micron-level tolerances maintained across meter-scale parts—a testament to our mastery of precision at scale.

Our large part injection molding systems integrate advanced hydraulic and electric drive technologies, real-time process monitoring, and closed-loop control systems to ensure repeatability and consistency. Mold bases are fabricated from high-grade tool steels with precision-ground surfaces and optimized cooling channels to minimize thermal gradients. Each machine is calibrated and tested under simulated production loads to verify performance before deployment.

Below are key specifications representative of our large part injection molding platforms:

| Parameter | Specification |

|---|---|

| Maximum Shot Weight (PS) | Up to 5,000 g |

| Clamping Force | 2,500 to 6,000 kN |

| Screw Diameter | 80 – 150 mm |

| Injection Pressure | Up to 2,200 bar |

| Platen Size | Up to 2,000 x 2,000 mm |

| Tie-Bar Spacing | 1,300 x 1,300 mm (min) to 1,800 x 1,800 mm (max) |

| Control System | Siemens S7-1500 with HMI touch interface |

| Repeatability (Weight) | ±0.3% |

| Positioning Accuracy (Screw) | ±0.1 mm |

These technical capabilities, combined with our deep application knowledge, enable Wuxi Lead Precision Machinery to deliver solutions where reliability, precision, and scalability converge. In large part injection molding, success is measured not just in output volume, but in the fidelity of every manufactured component. We engineer for both.

Precision Specs & Tolerances

Technical Capabilities for Large Part Injection Molding

Manufacturing precision-molded large components presents unique engineering challenges, including thermal distortion management, material stability across expansive surfaces, and maintaining micron-level accuracy at scale. At Wuxi Lead Precision Machinery, we specialize in overcoming these obstacles through integrated advanced machining and rigorous quality control systems. Our facility deploys industrial-grade 5-axis CNC machining centers with extended travel ranges (X: 3,200 mm / Y: 1,800 mm / Z: 1,200 mm) and high-torque spindles capable of handling workpieces up to 8,000 kg. This enables single-setup machining of complex mold bases, cavity inserts, and structural frames exceeding 2 meters in critical dimensions, eliminating cumulative errors from multi-stage processing. Advanced adaptive control systems dynamically adjust feed rates and toolpaths to counteract material deflection during deep cavity milling or thin-wall contouring, ensuring dimensional integrity across the entire component envelope.

Quality assurance is non-negotiable for large-scale tooling where deviations compound exponentially. Every mold undergoes comprehensive metrology via our dual-arm Coordinate Measuring Machine (CMM) with a 4,500 mm × 2,500 mm × 1,500 mm measurement volume, calibrated to ISO 10360-2 standards. Temperature-stabilized inspection cells (20 ± 0.5°C) mitigate thermal drift during extended measurement cycles. We implement full-surface 3D scanning for warp analysis on substrates over 1.5 meters, generating deviation maps that feed directly into corrective machining loops. This closed-loop process, combined with real-time in-process gauging during CNC operations, guarantees that geometric tolerances are consistently achieved before final assembly. Our protocols exceed automotive and aerospace requirements for mold durability and part repeatability, directly impacting client production yield and lifecycle costs.

The following table details achievable tolerance specifications for large-part injection molds:

| Parameter | Standard Capability | Precision Capability | Measurement Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.08 mm | ±0.03 mm | CMM / Laser Tracker |

| Flatness (per m²) | 0.10 mm | 0.05 mm | Optical Flat / CMM |

| Concentricity | Ø 0.05 mm | Ø 0.02 mm | CMM |

| Surface Finish (Cavity) | Ra 0.8 μm | Ra 0.4 μm | Profilometer |

These capabilities are validated through our AS9100-certified quality management system, with full traceability from raw material certification to final mold validation reports. Wuxi Lead’s engineering team collaborates with clients during DFM analysis to optimize part geometry for manufacturability, ensuring that large-scale molds meet injection molding machine requirements while minimizing cycle time and part defects. This technical rigor positions us as the strategic partner for mission-critical large-part molding applications in energy, transportation, and industrial equipment sectors.

Material & Finish Options

Material Selection for Large Part Injection Molding in Precision Metal Manufacturing

Selecting the appropriate material for large part injection molding is critical to ensuring structural integrity, production efficiency, and long-term performance. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to high-demand industrial applications. Our expertise includes the use of premium-grade aluminum, steel, and titanium—each offering distinct mechanical properties, weight characteristics, and cost considerations suitable for large-scale molding tooling and end-use components.

Aluminum is widely favored in large part injection molding due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. It enables faster cycle times by facilitating efficient heat dissipation during the molding process. This makes aluminum ideal for prototyping and medium-volume production runs where tooling longevity is balanced with cost efficiency. Commonly used alloys such as 7075 and 6061 offer high fatigue resistance and weldability, making them suitable for complex mold designs.

Steel, particularly tool steel variants like P20, H13, and S136, provides superior hardness, wear resistance, and dimensional stability under continuous operation. These properties make steel the preferred choice for high-volume production molds subjected to elevated pressures and temperatures. While heavier and more costly to machine than aluminum, steel molds offer extended service life, reducing long-term maintenance and replacement costs in large-scale manufacturing environments.

Titanium stands out for its exceptional strength-to-density ratio and corrosion resistance, particularly in aggressive environments. Though less common in standard mold tooling due to higher material and machining costs, titanium is increasingly used in specialized aerospace and medical applications where weight reduction and extreme durability are paramount. Its biocompatibility and resistance to oxidation further support use in critical high-performance sectors.

Surface finishing plays a vital role in enhancing material performance and part quality. Anodizing, especially for aluminum components, significantly improves surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with the latter offering thicker, more durable oxide layers suitable for heavy-duty applications. Anodized finishes also allow for color coding and improved aesthetic consistency without compromising dimensional accuracy.

The following table outlines key mechanical and thermal properties of the primary materials used in large part injection molding applications:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Thermal Conductivity (W/m·K) | Hardness (HB) | Common Applications |

|---|---|---|---|---|---|

| Aluminum 7075 | 570 | 2.81 | 130 | 150 | Prototyping, medium-volume molds |

| Steel P20 | 950 | 7.85 | 30 | 290 | High-volume production molds |

| Steel H13 | 1700 | 7.80 | 35 | 450 | Hot-runner molds, high-temp use |

| Titanium Gr5 | 900 | 4.43 | 7.2 | 360 | Aerospace, medical components |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production volume, environmental exposure, and performance requirements. Our engineering team ensures optimal material pairing with advanced manufacturing techniques to deliver robust, precision-engineered solutions for large part injection molding.

Manufacturing Process & QC

Large Part Injection Molding: Precision Execution from Concept to Zero-Defect Production

Achieving flawless large part injection molding demands a rigorously controlled process, far exceeding standard manufacturing tolerances. At Wuxi Lead Precision Machinery, we integrate advanced engineering with meticulous production oversight to eliminate defects inherent in scaling complex geometries. Our methodology ensures dimensional stability, structural integrity, and surface perfection for components exceeding 500mm in critical dimensions, where thermal gradients and material flow present significant challenges.

The process commences with collaborative Design for Manufacturing (DFM) analysis. Our engineering team dissects CAD models, simulating melt flow, cooling dynamics, and potential warpage specific to large-scale production. We identify sink marks, weld lines, or venting issues early, optimizing gate placement, wall thickness transitions, and cooling channel layouts. This phase is non-negotiable; it transforms theoretical designs into manufacturable realities, preventing costly errors downstream. Material selection is critically evaluated against mechanical requirements, environmental exposure, and processing stability under extended cycle times.

Prototyping validates the refined design under real-world conditions. Utilizing high-precision steel molds machined on our multi-axis CNC centers, we produce functional prototypes mirroring mass production tooling. This stage is not merely a shape check. We conduct rigorous dimensional inspection using CMMs against all critical tolerances, perform structural load testing, and assess surface finish quality under controlled parameters. Any deviation triggers immediate root cause analysis and mold adjustment. This iterative validation ensures the process window is fully understood and locked before committing to high-volume runs, directly contributing to our zero-defect mandate.

Mass production executes with uncompromising process discipline. We deploy closed-loop monitoring systems tracking injection pressure, temperature profiles, cooling rates, and clamp force in real-time across every cycle. Statistical Process Control (SPC) charts continuously verify parameters remain within the validated window. Automated vision systems inspect 100% of critical surfaces for micro-defects invisible to the naked eye. In-process metrology stations randomly sample parts for full dimensional validation against the original CAD model. Crucially, our operators are trained engineers empowered to halt production at the first sign of parameter drift, ensuring only conforming parts advance. This integrated system of predictive control and immediate corrective action is the foundation of our zero-defect guarantee for large components.

Our technical capabilities for large part injection molding are defined by stringent specifications:

| Parameter | Specification Range | Capability Highlight |

|---|---|---|

| Max Part Dimension | 1200 x 800 x 600 mm | Optimized for structural components |

| Dimensional Tolerance | ±0.05 mm per 100 mm | Critical for assembly interfaces |

| Material Range | Engineering Thermoplastics (PP, ABS, PC, POM, PBT, Nylon GF), LCP | High-flow, low-warpage grades prioritized |

| Mold Steel | H13, S136, 2738HH | Hardened for >500k cycles |

| Max Injection Pressure | 2200 bar | Ensures cavity fill for thick walls |

| Process Control | Real-time SPC, Cavity Pressure | Zero-defect process window lock |

This systematic progression—from engineered design through validated prototyping to intelligently monitored production—ensures Wuxi Lead delivers large injection molded parts meeting the most demanding aerospace, automotive, and industrial equipment specifications, consistently achieving zero defects.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Large Part Injection Molding

When precision, scale, and reliability define your manufacturing needs, partnering with Wuxi Lead Precision Machinery ensures you’re backed by engineering excellence and decades of focused expertise in custom metal manufacturing. Specializing in large part injection molding, we deliver end-to-end solutions tailored to the most demanding industrial applications. From aerospace components to heavy-duty automotive systems and large-scale consumer goods, our capabilities are engineered to exceed expectations.

At Lead Precision, we understand that large part injection molding is not simply an extension of standard processes—it demands specialized tooling, reinforced clamping forces, advanced material handling, and meticulous process control. Our facility in Wuxi, China, is equipped with state-of-the-art hydraulic and hybrid molding machines capable of handling molds up to 2,500 metric tons, ensuring dimensional accuracy and structural integrity even for the most complex geometries. Every project is supported by in-house mold design, finite element analysis (FEA), and real-time process monitoring to guarantee repeatable quality across high-volume production runs.

We serve global OEMs and Tier-1 suppliers who require more than just a vendor—they need a technical partner. That’s why our engineering team collaborates closely with clients from concept through to validation, offering design for manufacturability (DFM) reviews, rapid prototyping, and full-scale production planning. Our ISO 9001-certified quality management system ensures compliance with international standards, while our agile supply chain enables on-time delivery to North America, Europe, and Asia.

Whether you’re developing a single large component or launching a full product line, Lead Precision provides the technical depth, production scalability, and responsive support to bring your vision to life. Our commitment to innovation is matched only by our dedication to customer success.

Explore how our large part injection molding solutions can elevate your manufacturing strategy. Contact us today to speak with one of our application engineers and discover the Lead Precision difference.

| Specification | Detail |

|---|---|

| Maximum Clamping Force | 2,500 metric tons |

| Maximum Mold Size | 2,200 mm × 2,000 mm |

| Shot Weight Capacity | Up to 5,800 grams (PS) |

| Material Compatibility | Engineering plastics (PC, POM, PA6/66, PBT), reinforced polymers (GF/CF), high-temperature resins |

| Tolerance Capability | ±0.05 mm for critical dimensions |

| Production Capacity | High-volume runs with cycle time optimization |

| Quality Standards | ISO 9001:2015 certified, full traceability, SPC monitoring |

| Secondary Operations | In-house assembly, ultrasonic welding, labeling, packaging |

For project inquiries, technical consultations, or to request a quote, email us at [email protected]. Let Lead Precision be your trusted partner in large part injection molding.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.