Technical Contents

Engineering Guide: Custom 3D Printing Service

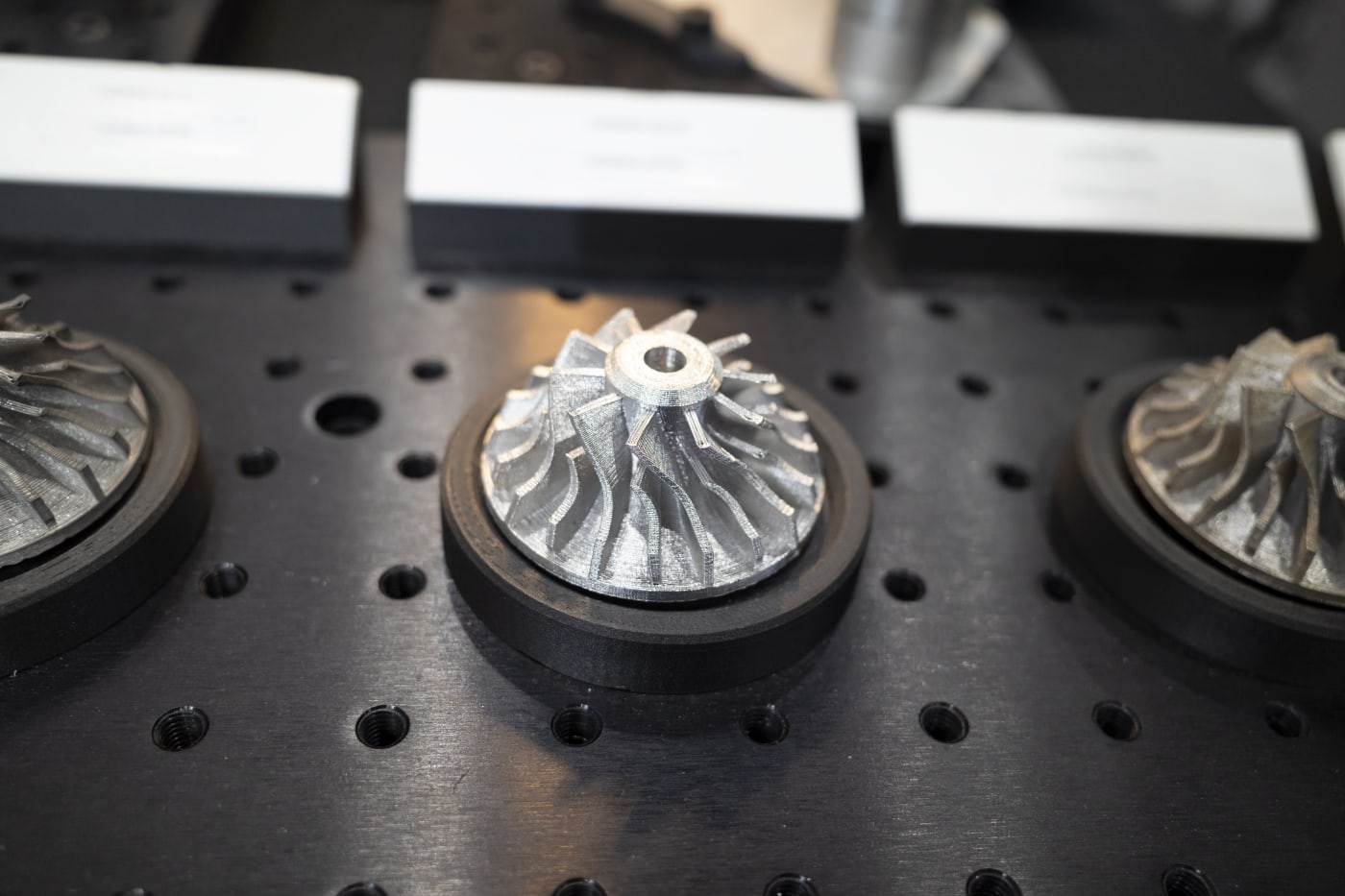

Engineering Insight Precision in Custom Metal 3D Printing

Precision is not merely a specification in high-stakes metal additive manufacturing; it is the foundational requirement determining functional integrity, safety, and longevity. In aerospace, medical implants, and advanced energy systems, micro-scale deviations propagate into catastrophic failures under operational stress. Custom 3D printing demands sub-50-micron geometric accuracy and consistent material properties layer-by-layer to meet stringent industry certifications. Achieving this requires far more than advanced hardware—it necessitates deep metallurgical expertise, rigorous in-process monitoring, and closed-loop quality systems calibrated to aerospace-grade standards. Tolerances below 0.1mm are non-negotiable for components interfacing with legacy assemblies, where thermal expansion mismatches or surface roughness exceeding Ra 3.2μm induce premature fatigue. At Wuxi Lead Precision Machinery, we treat precision as an engineering discipline, not a machine capability.

Our validation extends beyond laboratory metrics to real-world mission-critical environments. We engineered titanium lattice structures for Beijing Winter Olympics snowmaking nozzles operating at -40°C, where dimensional drift under cryogenic cycling would disrupt ice formation physics. Similarly, our Inconel 718 turbine components for military drone propulsion systems underwent 1,200+ hours of accelerated life testing under supersonic vibration profiles—zero failures recorded. This pedigree stems from 18 years of CNC machining heritage directly informing our additive protocols. Every build incorporates thermal distortion compensation algorithms refined through 9,000+ military-specification machining runs, ensuring first-article conformance without iterative correction. Our engineers prioritize predictable precision: material density exceeding 99.95%, residual stress below 50 MPa, and microstructure homogeneity validated via ASTM E8 metallography.

The following table outlines core capabilities enabling this precision regime for production-scale custom 3D printing services:

| Parameter | Specification | Industry Relevance |

|---|---|---|

| Layer Thickness | 20–50 μm | Critical for thin-wall aerospace ducts |

| Build Volume | 250 x 250 x 325 mm | Accommodates complex assemblies |

| Dimensional Accuracy | ±0.05 mm over 100 mm | Ensures fit with legacy CNC components |

| Surface Roughness (As-Built) | Ra 12–25 μm | Optimized for minimal post-processing |

| Surface Roughness (Post-Processed) | Ra ≤2.5 μm | Meets medical implant requirements |

| Material Density | >99.95% | Eliminates fatigue initiation points |

| Key Alloys | Ti6Al4V, Inconel 718, 316L, AlSi10Mg | Validated for aerospace/medical use |

Precision engineering translates directly to client ROI. Reduced scrap rates, elimination of secondary alignment processes, and extended component service life deliver 22–37% lifecycle cost savings versus conventional manufacturing for our Tier-1 aerospace clients. When tolerances define success, Wuxi Lead’s Olympic-proven process control ensures your design intent becomes physical reality—without compromise. We don’t just print parts; we deliver certified performance.

Precision Specs & Tolerances

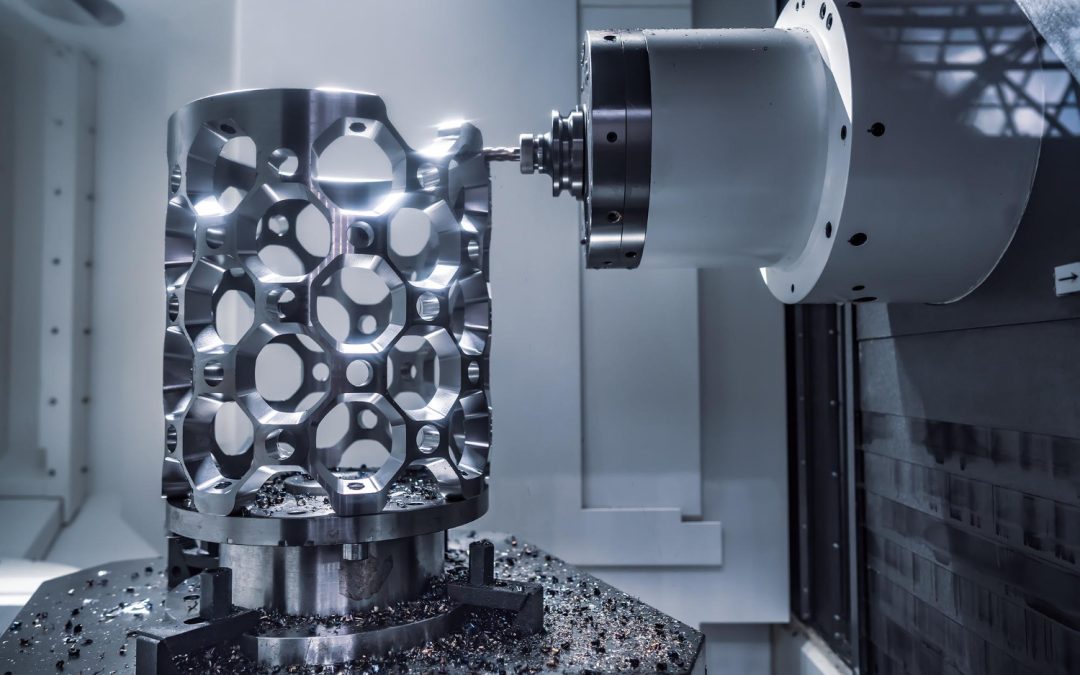

Wuxi Lead Precision Machinery delivers advanced custom 3D printing services tailored for high-performance industrial applications, integrating additive manufacturing with precision post-processing to meet the most demanding engineering requirements. Our technical capabilities are built around a hybrid manufacturing model, combining metal additive processes with 5-axis CNC machining and comprehensive quality assurance protocols. This integrated approach ensures that every component not only achieves complex geometries but also meets strict dimensional accuracy, surface finish, and material performance standards.

Our facility is equipped with state-of-the-art metal 3D printing systems capable of processing a wide range of engineering alloys, including stainless steels, titanium (Ti6Al4V), Inconel 718, aluminum alloys, and tool steels. These systems utilize laser powder bed fusion (LPBF) technology to build parts layer by layer with fine resolution and excellent mechanical properties. However, we recognize that as-printed components often require precision machining to achieve functional tolerances and interface compatibility. This is where our 5-axis CNC machining centers play a critical role. These multi-axis systems allow for simultaneous machining from multiple angles, enabling tight-tolerance features, precision holes, and smooth surface finishes on complex 3D printed geometries that would be unattainable with conventional 3-axis methods.

To ensure every part conforms to design specifications, we implement a rigorous quality control process centered on Coordinate Measuring Machine (CMM) inspection. Our CMM systems perform full dimensional validation using tactile probing and high-accuracy scanning, generating detailed inspection reports traceable to international standards. Each component undergoes first-article inspection for production runs and random sampling for batch consistency, with full data archiving for traceability.

Our technical expertise extends beyond equipment to process optimization. Our engineering team collaborates with clients during design for additive manufacturing (DfAM) to enhance part functionality, reduce weight, consolidate assemblies, and minimize post-processing requirements. We support both prototyping and low-to-mid volume production, with rapid turnaround times and full documentation packages including inspection reports, material certifications, and as-built CAD comparisons.

The following table outlines our standard technical specifications and achievable tolerances:

| Parameter | Capability |

|---|---|

| 3D Printing Process | Laser Powder Bed Fusion (LPBF) |

| Materials | Stainless Steel 316L, 17-4PH, Inconel 718, Ti6Al4V, AlSi10Mg, Tool Steel H13 |

| Build Envelope (max) | 250 x 250 x 300 mm |

| Layer Thickness | 20–50 µm |

| As-Printed Surface Roughness | Ra 10–15 µm |

| Post-Machined Surface Finish | Ra 0.8–1.6 µm (CNC finished) |

| Dimensional Tolerance (CNC) | ±0.005 mm (for critical features) |

| Feature Tolerance (as-built) | ±0.1 mm (typical, geometry-dependent) |

| Positional Accuracy (CMM) | ±0.003 mm |

| Inspection Standard | ISO 10360, ASME Y14.5 |

Wuxi Lead Precision Machinery is committed to delivering custom 3D printed components that meet the highest standards of precision, reliability, and repeatability for aerospace, medical, energy, and advanced industrial sectors.

Material & Finish Options

Material Selection for Precision Metal Additive Manufacturing

Selecting the optimal material for custom metal 3D printing is a critical engineering decision directly impacting part performance, longevity, and cost-effectiveness. At Wuxi Lead Precision Machinery, our expertise in metal additive manufacturing ensures clients leverage the intrinsic properties of Aluminum, Steel, and Titanium alloys to meet demanding application requirements. Understanding the core characteristics and limitations of each material family is essential for successful project execution.

Aluminum alloys, particularly AlSi10Mg and 7075, dominate applications requiring an exceptional strength-to-weight ratio and thermal conductivity. AlSi10Mg offers good castability, weldability, and moderate strength, making it ideal for complex aerospace brackets, fluid manifolds, and lightweight automotive components. High-strength 7075 aluminum provides mechanical properties approaching some steels, suitable for highly stressed structural parts where weight savings are paramount. Aluminum parts inherently possess good corrosion resistance but typically require post-processing like anodizing for enhanced surface hardness and wear resistance in critical interfaces.

Stainless steel variants, especially 316L and 17-4 PH, deliver superior strength, hardness, and excellent corrosion resistance across diverse environments. 316L stainless steel is the benchmark for biocompatibility and chemical resistance, widely specified for medical implants, surgical instruments, and marine applications. 17-4 PH stainless steel offers precipitation-hardening capabilities, achieving very high strength levels after heat treatment, making it suitable for demanding aerospace actuators, valve components, and high-wear tooling. Steel parts generally exhibit excellent as-built surface integrity but may undergo machining or polishing for tight tolerances.

Titanium alloys, primarily Ti6Al4V (Grade 5), are indispensable for applications demanding the highest strength-to-weight ratio combined with outstanding biocompatibility and exceptional corrosion resistance, particularly in saline or chemically aggressive environments. This makes titanium the material of choice for critical aerospace structural components, high-performance racing parts, and permanent medical implants like hip stems and dental fixtures. Titanium’s biocompatibility eliminates adverse tissue reactions, while its fatigue strength ensures long service life under cyclic loads.

The following table summarizes key properties of common metal 3D printing alloys:

| Material Family | Key Alloys | Yield Strength (MPa) | Density (g/cm³) | Primary Applications |

|---|---|---|---|---|

| Aluminum | AlSi10Mg, 7075 | 200-500 | 2.68-2.81 | Aerospace brackets, lightweight structures, heat exchangers |

| Stainless Steel | 316L, 17-4 PH | 400-1300 | 7.8-7.9 | Medical implants, marine components, high-strength tooling |

| Titanium | Ti6Al4V (Gr5) | 880-1100 | 4.43 | Aerospace structures, medical implants, high-performance racing |

Anodizing is a vital post-processing step exclusively for aluminum components produced via additive manufacturing. This electrochemical process significantly enhances surface hardness, wear resistance, and corrosion protection. Type II (Sulfuric Acid) anodizing provides a standard decorative and protective layer, while Type III (Hardcoat) anodizing delivers a much thicker, harder ceramic-like surface essential for high-wear applications like hydraulic fittings or mating surfaces. Wuxi Lead Precision Machinery integrates precise anodizing parameters to ensure consistent, high-integrity finishes that meet aerospace and medical standards without compromising dimensional accuracy. Material selection, coupled with appropriate finishing like anodizing, forms the foundation for achieving optimal performance and value in your custom metal additive manufacturing project.

Manufacturing Process & QC

Design Phase: Precision Engineering from Concept to CAD

At Wuxi Lead Precision Machinery, the custom 3D printing process begins with a comprehensive design phase that integrates client specifications with advanced engineering analysis. Our team of CNC engineers and design specialists work closely with clients to translate initial concepts into detailed 3D CAD models. This stage includes dimensional validation, material compatibility analysis, and structural simulation using finite element analysis (FEA) to ensure mechanical integrity under operational loads. We support STEP, IGES, and native SolidWorks file formats and provide design for additive manufacturing (DfAM) feedback to optimize part geometry for laser powder bed fusion. All designs undergo rigorous internal review to eliminate stress concentrations, reduce residual deformation, and ensure manufacturability—laying the foundation for zero-defect production.

Prototyping: Functional Validation and Iterative Refinement

Once the design is finalized, we proceed to produce high-fidelity metal prototypes using our industrial-grade 3D printing systems. Prototyping serves not only as a physical validation of form and fit but as a critical testbed for function and performance. Parts are built in the intended production material—typically stainless steel 316L, titanium Ti6Al4V, or Inconel 718—enabling accurate assessment of thermal, chemical, and mechanical behavior. Each prototype undergoes full metrology inspection via coordinate measuring machines (CMM) and 3D laser scanning to verify dimensional accuracy within ±0.02 mm. Clients receive detailed inspection reports and are invited to participate in design reviews for any necessary refinements. This iterative loop ensures complete alignment before transitioning to mass production, minimizing downstream risk and cost.

Mass Production: Scalable Precision with Zero-Defect Assurance

Our mass production phase leverages a fully integrated digital manufacturing ecosystem, combining automated build preparation, real-time process monitoring, and post-processing traceability. Each build is executed on certified EOS or SLM Solutions platforms under controlled atmosphere conditions to ensure batch consistency. In-situ layer monitoring and melt pool analytics detect anomalies during printing, enabling immediate corrective action. After build completion, parts undergo stress relief, support removal, heat treatment, and surface finishing tailored to application requirements. Every component is subject to non-destructive testing (NDT), including X-ray and penetrant inspection, followed by final dimensional certification. Our quality management system is ISO 9001:2015 certified, with full lot traceability and documented process validation for every order.

Typical Material and Process Specifications

| Parameter | Specification |

|---|---|

| Supported Materials | Stainless Steel 316L, Titanium Ti6Al4V, Inconel 718, Aluminum AlSi10Mg, Tool Steel MS1 |

| Layer Thickness | 20–60 μm |

| Build Envelope (Max) | 275 x 275 x 350 mm |

| Dimensional Accuracy | ±0.02 mm |

| Surface Roughness (As-Built) | Ra 8–12 μm (can be reduced to Ra 1–2 μm with polishing) |

| Post-Processing Options | Heat Treatment, HIP, CNC Machining, Polishing, Passivation |

| Quality Standards | ISO 9001:2015, Full Inspection Report, Material Certificates, NDT Documentation |

Through seamless integration of design, prototyping, and production, Wuxi Lead ensures every custom 3D printed component meets the highest standards of precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Elevate Your Production Capabilities Through Strategic Partnership

In today’s competitive industrial landscape, securing a manufacturing partner that consistently delivers uncompromising precision, material integrity, and technical agility is non-negotiable. Wuxi Lead Precision Machinery transcends conventional vendor relationships by integrating deeply into your engineering and production workflows. We specialize in custom metal additive manufacturing for mission-critical sectors including aerospace, medical implant systems, and energy infrastructure, where failure is not an option. Our ISO 9001:2015 and AS9100D certified facility in Wuxi operates under stringent process controls, ensuring every component meets or exceeds aerospace-grade tolerances and material specifications. Unlike generic service bureaus, our engineering team collaborates from initial design validation through post-processing and final inspection, eliminating costly iterations and accelerating time-to-market.

Our technical infrastructure supports the most demanding applications, leveraging industrial-grade metal 3D printing platforms with multi-laser systems and inert atmosphere processing. The table below details core capabilities enabling complex, high-value part production.

| Parameter | Specification | Application Impact |

|---|---|---|

| Build Volume | 500 x 500 x 500 mm | Monolithic production of large structural components |

| Material Range | Titanium Ti6Al4V, Inconel 718, 316L, AlSi10Mg | Compatibility with extreme thermal/corrosive environments |

| Dimensional Accuracy | ±0.02 mm per 100 mm | Eliminates secondary machining for critical interfaces |

| Surface Finish | As-built Ra ≤ 12.5 μm (achievable to Ra ≤ 1.6 μm post-processed) | Meets stringent biocompatibility and fluid dynamics requirements |

| Certification | Full material traceability, in-process NDT, final CMM reports | Compliance with FAA, FDA, and PED directives |

This technical foundation is augmented by our proactive engineering engagement model. We conduct Design for Additive Manufacturing (DfAM) reviews to optimize topology, minimize support structures, and ensure printability—reducing material waste by up to 40% while enhancing part performance. Our quality management system includes real-time melt pool monitoring and layer-wise thermal imaging, providing auditable data for every build. Crucially, we maintain strict IP protection protocols through encrypted data transfer and signed NDAs, recognizing that your designs are strategic assets.

Initiate your precision manufacturing workflow today by contacting our engineering team directly. Email [email protected] with your project specifications, including 3D models, material requirements, and target volumes. Our specialists will respond within 24 business hours to discuss feasibility, lead times, and a tailored production strategy. For urgent RFQs, include “Priority Engineering Review” in the subject line to expedite assessment. Wuxi Lead Precision Machinery operates as your dedicated extension—not merely a service provider but a committed partner invested in the success of your most challenging metal components. Trust in our technical rigor, transparency, and unwavering commitment to quality to transform your design vision into certified reality. Your next breakthrough component begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.