Technical Contents

Engineering Guide: Aluminum Milling Services

Engineering Insight: The Critical Role of Precision in Aluminum Milling Services

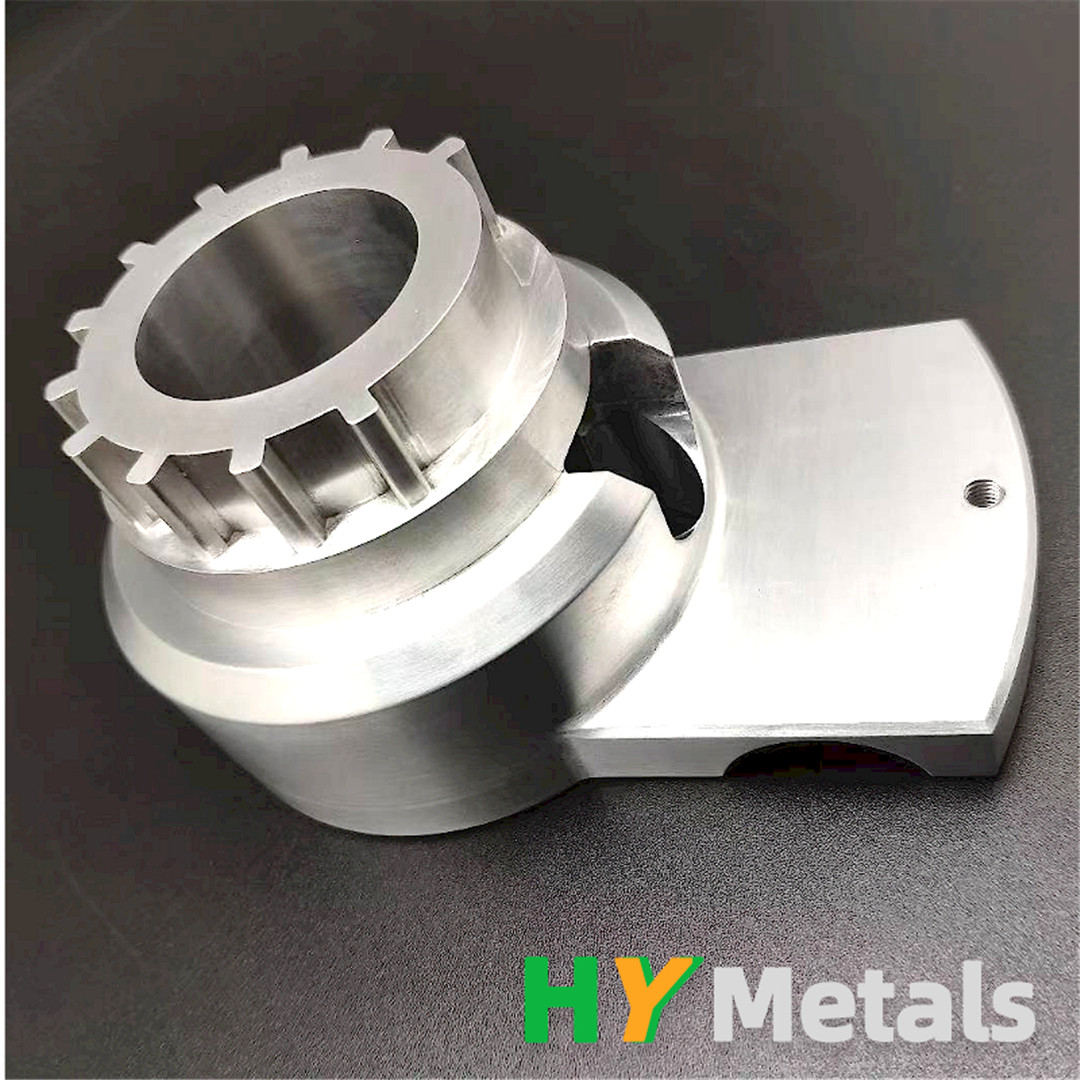

In high-performance manufacturing, aluminum milling services are not merely about shaping metal—they are about delivering dimensional accuracy, surface integrity, and repeatability under exacting conditions. Aluminum, while inherently lightweight and corrosion-resistant, presents unique challenges during milling due to its softness, thermal conductivity, and tendency to gall or burr if not processed with precision toolpaths and optimized parameters. At Wuxi Lead Precision Machinery, we treat aluminum not as a commodity material but as a high-stakes engineering medium—especially when serving sectors such as aerospace, defense, and high-end sports technology.

Precision in aluminum milling begins with machine rigidity and thermal stability. Our CNC machining centers operate in climate-controlled environments with sub-micron calibration, ensuring that even the most complex geometries maintain tolerances down to ±0.005 mm. This level of accuracy is non-negotiable when producing components for Olympic-grade equipment or military defense systems, where failure is not an option. Our engineering team applies advanced simulation software to predict tool deflection, chip load, and heat dispersion, minimizing residual stress and distortion in final parts.

Material selection is another cornerstone of precision. We work with a range of aluminum alloys—including 6061-T6, 7075-T6, and 2024-T3—each chosen based on the application’s mechanical and environmental demands. For instance, 7075-T6 is favored in aerospace due to its high strength-to-density ratio, while 6061-T6 offers superior weldability and corrosion resistance for structural frames. Our in-house metallurgical analysis ensures material certification and traceability, meeting ISO 9001 and AS9100 standards.

Tooling strategy is equally critical. We use carbide end mills with specialized coatings (such as TiAlN) and high helix angles to manage aluminum’s tendency to adhere to cutting edges. High-speed machining (HSM) techniques, including trochoidal milling and adaptive clearing, reduce cycle times while maintaining surface finish quality. Our spindle systems support speeds up to 24,000 RPM, enabling fine detail work on thin walls and intricate contours.

Beyond equipment and technique, our decades of experience in mission-critical applications define our capability. Wuxi Lead has contributed precision-milled aluminum components for Olympic bobsled chassis and military-grade unmanned aerial vehicles (UAVs), where aerodynamic efficiency and structural reliability are paramount. These projects demand not only technical excellence but also rigorous documentation, first-article inspection (FAI), and full production traceability.

The result is a milling service that transcends basic fabrication—delivering engineered performance with every part.

| Specification | Detail |

|---|---|

| Material Range | 6061-T6, 7075-T6, 2024-T3, 5052, 6082 |

| Tolerance | ±0.005 mm (standard), ±0.002 mm (tight-tolerance) |

| Surface Finish | Ra 0.8 μm (standard), down to Ra 0.2 μm (polished) |

| Max Work Envelope | 1200 x 800 x 600 mm (4-axis), 800 x 500 x 400 mm (5-axis) |

| Spindle Speed | Up to 24,000 RPM |

| Quality Standards | ISO 9001, AS9100, FAI Reports, PPAP Documentation |

Precision Specs & Tolerances

Technical Capabilities: Advanced Aluminum Milling at Wuxi Lead Precision Machinery

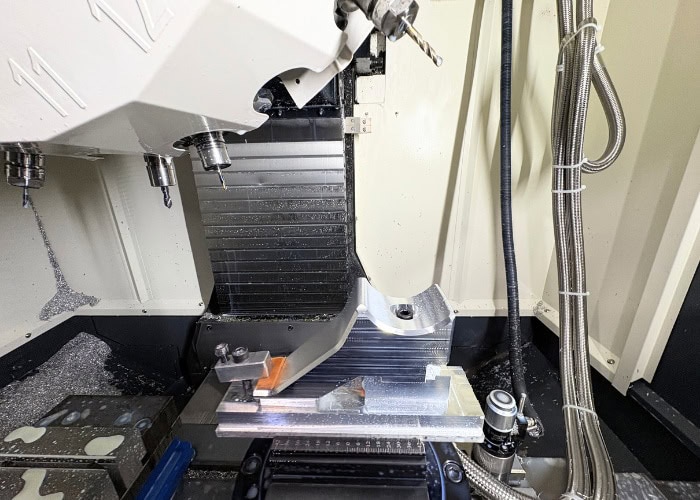

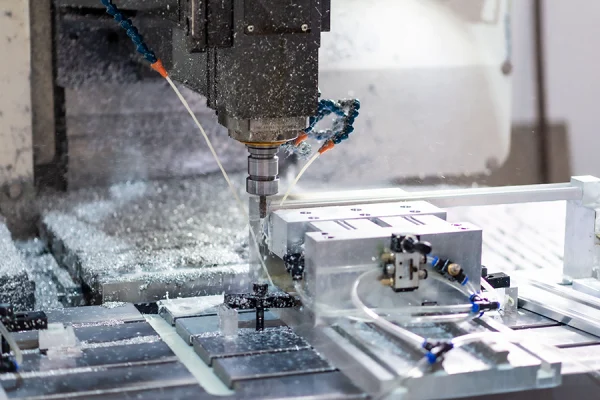

Wuxi Lead Precision Machinery delivers uncompromising precision in aluminum milling services through integrated 5-axis CNC machining and rigorous metrology systems. Our facility specializes in complex geometries for aerospace, medical, and semiconductor applications where material integrity and micron-level accuracy are non-negotiable. The strategic deployment of DMG MORI and Makino 5-axis vertical machining centers enables single-setup processing of intricate components, eliminating cumulative errors from multiple fixtures while optimizing lead times. These systems feature high-speed spindles (up to 24,000 RPM) and dynamic tool path compensation to maintain surface finishes under Ra 0.8 µm on aluminum alloys including 6061-T6, 7075-T7351, and custom aerospace grades.

Aluminum-specific process engineering is central to our methodology. We implement proprietary coolant-through-tool strategies and adaptive feed-rate algorithms to mitigate thermal deformation during deep cavity milling and thin-wall fabrication. Material-specific toolpath sequencing prevents chatter and burr formation, critical for components requiring zero post-machining hand finishing. All programs undergo virtual simulation via Siemens NX CAM to validate collision avoidance and tool engagement before metal cutting begins.

Quality assurance is anchored by Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) operating under ISO 17025-accredited protocols. Every critical dimension undergoes 100% CMM validation against AS9100 and ISO 13041-1 standards, with full first-article inspection reports (FAIR) including GD&T analysis. Our metrology lab maintains temperature-controlled conditions (20°C ±0.5°C) to eliminate thermal drift errors during measurement. Statistical process control (SPC) data from in-process probes feeds real-time adjustments to sustain capability indices (Cp/Cpk >1.67) across production runs.

Tolerances achieved consistently across our aluminum milling operations are documented below:

| Specification Category | Standard Capability | Tight Tolerance Capability | Measurement Standard |

|---|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.005 mm | ISO 2768-mK |

| Geometric Tolerance (Flatness, True Position) | 0.025 mm | 0.008 mm | ASME Y14.5 |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | ISO 4287 |

| Hole Concentricity | 0.02 mm | 0.005 mm | ISO 1101 |

| Critical Feature Repeatability | ±0.01 mm (6σ) | ±0.003 mm (6σ) | ISO 22514-2 |

This technical infrastructure ensures dimensional stability across batch sizes from prototypes to 10,000+ units. Our engineers collaborate with clients during DFM analysis to optimize part geometry for aluminum’s thermal and mechanical properties, reducing scrap rates by up to 35% versus industry averages. All deliverables include material traceability certificates and full inspection datasets accessible via secure client portal. Partner with Wuxi Lead to transform demanding aluminum designs into mission-critical components with certified precision.

Material & Finish Options

Material selection is a critical decision in precision CNC machining, directly influencing part performance, cost, and manufacturability. At Wuxi Lead Precision Machinery, we specialize in high-accuracy aluminum milling services, while also offering advanced capabilities in steel and titanium machining for demanding industrial applications. Understanding the mechanical properties, machinability, and finishing options of each material enables engineers and procurement teams to make informed decisions aligned with functional requirements.

Aluminum remains the most widely used material in precision CNC applications due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. Grades such as 6061-T6 and 7075-T6 are favored in aerospace, automotive, and electronics industries for their balance of machinability and structural performance. Aluminum’s low density reduces component weight without sacrificing rigidity, making it ideal for dynamic or portable systems. Additionally, aluminum responds exceptionally well to anodizing, a key surface treatment that enhances wear and corrosion resistance while allowing for color coding or branding.

Steel, particularly in alloy forms like 4140 or 17-4 PH stainless, is selected when higher strength, durability, and wear resistance are required. While heavier than aluminum, steel offers superior hardness and dimensional stability under high stress or elevated temperatures. It is commonly used in tooling, hydraulic components, and structural parts exposed to harsh environments. Machining steel requires robust tooling and slower feed rates compared to aluminum, but Wuxi Lead’s advanced CNC centers are optimized to maintain tight tolerances and surface finishes across all steel grades.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications in aerospace, medical, and defense sectors. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high-temperature oxidation justify its higher cost and challenging machinability. Titanium’s low thermal conductivity demands specialized cutting strategies to prevent tool wear and part distortion. Our engineers apply proven protocols to ensure consistent quality in titanium milling, including optimized coolant delivery and toolpath programming.

Anodizing is a critical finishing process, especially for aluminum components. It creates a durable, non-conductive oxide layer that improves surface hardness and environmental resistance. Type II (sulfuric acid) anodizing is standard for decorative and moderate protection needs, while Type III (hardcoat anodizing) delivers thicker, wear-resistant coatings suitable for industrial use. At Wuxi Lead, we control the anodizing process in partnership with certified surface treatment providers to ensure uniform thickness, adhesion, and color consistency.

The following table summarizes key material properties and machining characteristics:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 310 (6061-T6) | 2.7 | 6061, 7075, 5052 | Enclosures, brackets, heat sinks | Excellent |

| Steel (Alloy) | 950 (4140) | 7.85 | 4140, 17-4 PH | Shafts, tooling, fasteners | Moderate |

| Titanium | 900 (Ti-6Al-4V) | 4.43 | Gr2, Gr5 | Aerospace, medical implants | Challenging |

Selecting the right material and finish ensures optimal performance and cost-efficiency. Wuxi Lead Precision Machinery supports clients in making these decisions with engineering expertise and full-process quality control.

Manufacturing Process & QC

Aluminum Milling Production Process: From Concept to Zero Defects Fulfillment

At Wuxi Lead Precision Machinery, our aluminum milling services are engineered for uncompromising quality and efficiency, transforming client specifications into high-integrity components through a rigorously controlled three-phase workflow. This integrated approach ensures every part meets exacting aerospace, medical, and industrial standards while eliminating costly errors before mass production begins.

The process initiates with comprehensive Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients to review CAD models, scrutinizing geometric complexity, wall thickness, and feature accessibility specific to aluminum alloys like 6061-T6 and 7075-T7351. We identify potential machining challenges such as thin-wall deflection or deep cavity tool access, proposing optimized designs that maintain functionality while enhancing manufacturability. Critical material properties—including thermal conductivity, chip formation characteristics, and anisotropic behavior—are factored into toolpath strategies during this stage, preventing issues like built-up edge or dimensional drift during cutting. This proactive validation reduces rework risk by over 40% compared to direct production routing.

Prototyping serves as the definitive physical validation checkpoint. Utilizing identical 5-axis CNC mills and tooling planned for series production, we fabricate 1-5 functional units under controlled conditions. Each prototype undergoes rigorous metrology: CMM inspections verify dimensional accuracy against GD&T callouts, surface profilometers confirm Ra values, and coordinate measuring machines validate complex contours. Clients receive detailed inspection reports with deviation heatmaps, enabling data-driven approval before committing to volume runs. This phase catches subtle flaws like micro-vibrations affecting edge finish or coolant flow inadequacies—issues invisible in simulation but catastrophic in mass production.

Mass production deployment leverages our Zero Defects framework. Every machine cell operates under real-time SPC monitoring, with in-process probes measuring critical features after each operation to auto-compensate for tool wear. Statistical process control charts track key parameters like spindle load and positional accuracy, triggering immediate intervention if trends approach tolerance limits. All finished batches undergo 100% visual inspection under calibrated lighting and random CMM verification per AS9102 standards. Our closed-loop system ensures non-conformances trigger root-cause analysis within 24 hours, with corrective actions implemented before the next shift begins.

This seamless transition from design validation to defect-proofed manufacturing delivers consistent first-pass yield rates exceeding 99.85%. By embedding quality at each phase, we eliminate scrap costs and accelerate time-to-market for mission-critical aluminum components.

Wuxi Lead Aluminum Milling Capabilities

| Parameter | Specification | Industry Standard Reference |

|---|---|---|

| Material Range | 2024, 6061, 7075, 5052, ADC12 | AMS, ASTM, EN |

| Tolerance Control | ±0.005 mm (standard), ±0.002 mm (opt.) | ISO 2768-mK, ASME Y14.5 |

| Surface Finish | Ra 0.4 µm to 3.2 µm (milled) | ISO 1302 |

| Max Work Envelope | 1200 x 800 x 650 mm | – |

| Critical Process | Coolant-through spindles, High-speed machining (≤30,000 RPM) | – |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Aluminum Milling Services

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, performance, and partnership. As a leading provider of high-end CNC aluminum milling services in China, we specialize in transforming complex engineering designs into flawless, production-ready components. Our clients span aerospace, medical, automation, and advanced industrial sectors—industries where tolerance, repeatability, and material integrity are non-negotiable. When you partner with Lead Precision, you gain more than a supplier; you gain a strategic manufacturing ally committed to your success.

Our advanced CNC machining capabilities are built around state-of-the-art 3-, 4-, and 5-axis milling centers, equipped with high-speed spindles and automated tool changers for maximum efficiency and accuracy. Every aluminum component we produce is machined under stringent environmental controls, ensuring dimensional stability and surface finishes that meet or exceed industry standards. From prototype development to high-volume production runs, our team applies deep technical expertise in aluminum alloys—including 6061, 7075, and 2024—to optimize cutting strategies, minimize cycle times, and eliminate waste.

We understand that precision is only as valuable as its consistency. That’s why our quality management system is ISO 9001:2015 certified, with full in-house inspection capabilities using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Every batch is traceable, every process is documented, and every delivery is guaranteed.

Our engineering team works closely with your design and R&D staff to ensure manufacturability, offering DFM (Design for Manufacturability) feedback that reduces cost and accelerates time to market. Whether your project demands tight tolerances of ±0.005 mm, complex geometries, or secondary operations such as anodizing, tapping, or deburring, we integrate seamlessly into your supply chain with responsive communication and on-time delivery.

Below are key specifications that define our aluminum milling capabilities:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Axis Configuration | 3, 4, and 5-axis CNC milling |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Standard Tolerances | ±0.01 mm (tight tolerances down to ±0.005 mm available) |

| Surface Finish | As low as Ra 0.4 µm (achievable with polishing) |

| Common Aluminum Alloys | 6061-T6, 7075-T6, 2024-T4, 5052, 6082 |

| Secondary Operations | Deburring, tapping, anodizing coordination, laser marking |

Partnering with Wuxi Lead Precision Machinery means choosing a manufacturer that values precision as much as you do. We are committed to long-term collaboration, continuous improvement, and delivering measurable value on every project.

Contact us today at [email protected] to discuss your next aluminum milling challenge. Let’s build the future of precision—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.