Technical Contents

Engineering Guide: Second Hand Injection Moulding Machine

Engineering Insight: Precision Imperatives in Second Hand Injection Moulding Machines

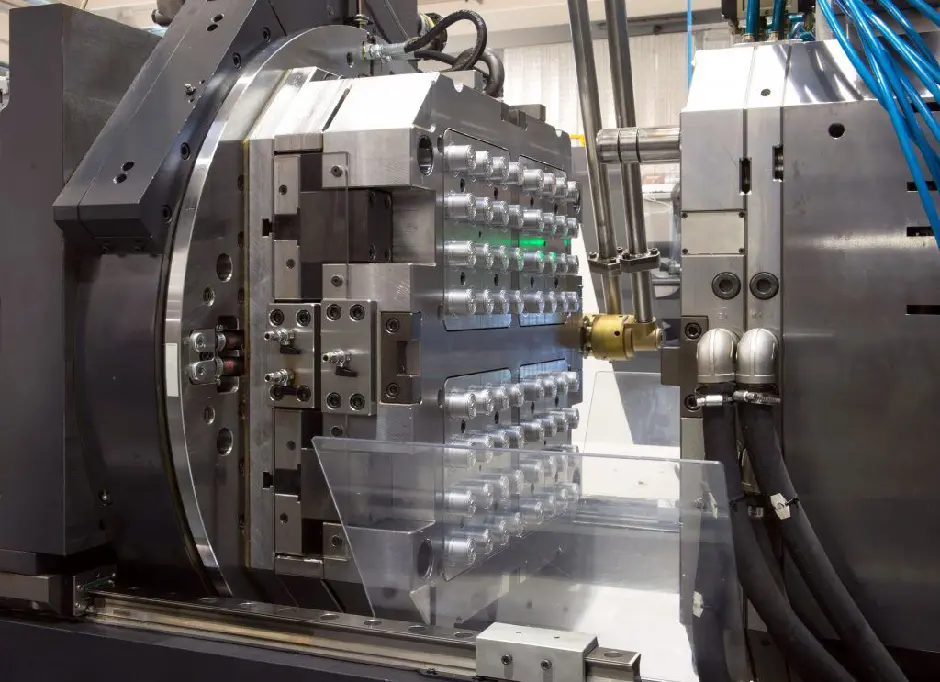

In the demanding realm of custom metal manufacturing, the performance of auxiliary processes like plastic injection moulding directly impacts final product integrity and assembly efficiency. When integrating second hand injection moulding machines into production workflows, dimensional precision and process repeatability are non-negotiable factors, not mere technical specifications. Sub-micron variations in clamp force consistency, platen parallelism, or injection velocity control translate directly into part warpage, flash, or critical dimension drift. These defects cascade into downstream metal fabrication stages, causing costly rework, assembly failures, or compromised component lifespans. For high-tolerance metal assemblies requiring seamless integration with plastic counterparts – such as aerospace housings, medical device frames, or precision instrumentation – the machine’s inherent stability becomes as critical as the metal part’s own tolerances. Selecting a refurbished machine demands rigorous validation against these precision benchmarks, far beyond basic operational functionality.

Wuxi Lead Precision Machinery applies this exacting standard honed through decades of mission-critical production. Our engineering protocols for evaluating and refurbishing second hand injection moulding equipment are derived directly from projects demanding zero-defect outcomes. This includes supplying components for Olympic-standard timing systems requiring nanosecond synchronization and manufacturing parts for defense applications where environmental resilience is paramount. We understand that precision is systemic; it requires not just machine capability but validated process control. Our refurbishment process transcends cosmetic renewal. We conduct metrology-grade assessments of all critical axes, hydraulic/pneumatic circuits, and control systems, recalibrating to original OEM specifications or tighter tolerances where feasible. This ensures the machine delivers the consistent shot-to-shot repeatability essential for producing plastic components that interface flawlessly with precision metal parts.

The difference between a standard used machine and a precision-refurbished asset is quantifiable. Key performance indicators must be rigorously measured and certified:

| Critical Specification | Typical Used Machine Tolerance | Lead Precision Refurbished Standard |

|---|---|---|

| Clamp Force Deviation | ±5% | ±1.5% |

| Platen Parallelism (Full Stroke) | 0.05 mm | ≤0.01 mm |

| Injection Velocity Repeatability | ±3.0% | ±0.8% |

| Melt Temperature Stability | ±5.0°C | ±1.5°C |

| Dry Cycle Time Repeatability | ±0.20 sec | ±0.05 sec |

| Positional Accuracy (Screw) | ±0.15 mm | ±0.03 mm |

This level of precision assurance is why global manufacturers trust Lead Precision for critical production lines. Our expertise ensures your second hand injection moulding machine isn’t merely operational; it becomes a predictable, high-yield asset within your integrated metal and plastic manufacturing ecosystem. We provide full traceable calibration reports and performance validation data, mitigating the hidden risks of used equipment acquisition. For applications where component synergy is vital, investing in verified precision through our engineering-led refurbishment delivers immediate ROI through reduced scrap, accelerated qualification, and seamless production integration. Contact our engineering team to discuss how our precision validation protocols can secure your next used machine investment.

Precision Specs & Tolerances

Technical Capabilities in Precision Metal Manufacturing

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the exacting demands of high-performance industries such as aerospace, medical, automotive, and advanced automation. As a leader in custom metal manufacturing, we integrate advanced machinery, rigorous quality assurance protocols, and decades of engineering expertise to deliver components that consistently meet or exceed client specifications. Central to our production workflow is the deployment of 5-axis CNC machining centers, which enable us to produce highly complex geometries with exceptional accuracy and surface finish.

Our 5-axis CNC systems provide simultaneous movement across all five axes, allowing for multi-faceted cutting in a single setup. This capability significantly reduces cycle times, minimizes human error, and ensures superior part consistency. The technology supports a wide range of metals, including aluminum alloys, stainless steel, titanium, and high-temperature superalloys. By eliminating the need for multiple fixturing stages, we achieve tighter tolerances and improved structural integrity, particularly in intricate components used in mission-critical applications.

To validate every manufactured part, we employ a comprehensive quality control system anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide micron-level measurement accuracy, ensuring full dimensional compliance with CAD models and engineering drawings. Each component undergoes a full inspection protocol, including first-article inspection (FAI) and in-process checks, with detailed inspection reports available upon request. This data-driven approach to quality assurance ensures traceability, repeatability, and compliance with international standards such as ISO 9001.

All machining and inspection processes are supported by a climate-controlled production environment, minimizing thermal variance and ensuring measurement stability. Our engineering team works closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and tolerancing, reducing lead times and production costs without compromising performance.

The following table outlines our standard machining capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Maximum Working Volume (5-axis) | 1200 mm × 800 mm × 750 mm |

| Spindle Speed | Up to 24,000 rpm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (per ISO 2768-m) | ±0.05 mm |

| Angular Tolerance | ±0.05° |

| Surface Roughness (Ra) | As low as 0.4 μm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

These technical capabilities, combined with our commitment to precision and customer collaboration, position Wuxi Lead Precision Machinery as a trusted partner for high-end custom metal components. Whether supporting prototyping or high-mix, low-volume production, we deliver engineered solutions with uncompromising quality.

Material & Finish Options

Material Selection for Second-Hand Injection Moulding Machine Components

Selecting appropriate materials for critical components in pre-owned injection moulding machines is paramount for maximizing operational lifespan and return on investment. Material integrity directly influences thermal stability, wear resistance, and dimensional accuracy under repeated cyclic stresses. This guide focuses on core structural and mould materials relevant to refurbished systems: Aluminum, Steel, and Titanium, alongside essential surface finishing considerations.

Aluminum alloys, particularly 7075-T6 and 6061-T6, are frequently encountered in older machine platens, ejector plates, and non-critical mould bases due to their high strength-to-weight ratio and excellent machinability. However, their lower hardness and thermal conductivity compared to steel make them susceptible to galling and deformation under high tonnage or prolonged thermal cycling. Refurbished machines with aluminum structural components require rigorous inspection for micro-cracking and surface wear, especially in clamping units. Aluminum remains cost-effective for low-volume or prototype applications but demands careful operational parameter validation during recommissioning.

Tool steels dominate critical wear surfaces in second-hand machines. AISI P20 (1.2311) offers balanced toughness and polishability for general-purpose mould cavities and cores in pre-owned systems. For high-wear applications like hot-runner manifolds or gates in refurbished machines, H13 (1.2344) is preferred due to superior thermal fatigue resistance and hardness retention at elevated temperatures. Pre-hardened steels simplify re-machining during refurbishment but necessitate verification of prior heat treatment integrity. Always inspect used steel components for signs of decarburization, pitting, or residual stress fractures before reintegration.

Titanium alloys (e.g., Ti-6Al-4V) are exceptionally rare in standard injection moulding machine structures due to cost but may appear in specialized corrosion-resistant nozzles or sensor housings within high-end pre-owned units. Its exceptional strength-to-weight ratio and inertness justify use in aggressive chemical processing environments, though machinability challenges limit widespread adoption. Verify material certification and prior service history rigorously when encountered.

Surface finishing, particularly anodizing, is critical for aluminum components in refurbished machines. Hard anodizing (Type III per MIL-A-8625) forms a dense, wear-resistant oxide layer (50-100 µm thickness) significantly enhancing surface hardness (up to 600 HV) and corrosion resistance. Standard anodizing (Type II) offers basic protection but is insufficient for high-stress interfaces. Inspect anodized surfaces on second-hand parts for coating adhesion, uniformity, and micro-cracks; compromised layers accelerate wear in moving assemblies. Avoid chromate conversion coatings on reused parts due to environmental compliance risks.

Material properties must align with the machine’s intended duty cycle post-refurbishment. The following table summarizes key mechanical characteristics for informed assessment of used components:

| Material | Typical Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Key Refurbishment Inspection Focus |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 (HB) | 503-572 | 130 | Micro-cracks, surface galling, coating integrity |

| Steel P20 | 28-32 | 950-1100 | 28-36 | Decarburization, pitting, prior heat treatment |

| Steel H13 | 44-52 | 1300-1800 | 24-29 | Thermal fatigue cracks, edge chipping |

| Titanium Ti-6Al-4V | 36-41 | 900-1000 | 7.2 | Surface contamination, certification validity |

Prioritize material verification through hardness testing and metallurgical analysis during pre-purchase evaluation of second-hand machines. Matching component materials to the specific application demands ensures reliable performance and extends the viable service life of your refurbished asset. Wuxi Lead Precision Machinery provides comprehensive material certification and NDT services for all evaluated pre-owned systems.

Manufacturing Process & QC

Design: Precision Engineering at the Core

At Wuxi Lead Precision Machinery, the production process for second hand injection moulding machines begins with an advanced design phase rooted in precision engineering and client-specific requirements. Our engineering team conducts a comprehensive analysis of machine specifications, including clamping force, shot size, injection pressure, and energy efficiency, ensuring compatibility with the intended application in custom metal manufacturing. Utilizing 3D CAD modeling and finite element analysis (FEA), we simulate operational stress points and performance thresholds to optimize structural integrity and longevity. Every design is validated against international standards such as ISO 9001 and CE, guaranteeing compliance and operational safety. This data-driven approach ensures that reconditioned machines meet the exacting demands of high-performance industrial environments.

Prototyping: Validating Performance Before Scale

Following design finalization, we initiate the prototyping stage—where selected second hand injection moulding machines are fully disassembled, inspected, and rebuilt using OEM-grade components. This phase is not about creating a physical prototype from scratch, but rather reconstructing the machine to like-new condition under controlled conditions. Critical subsystems—including the hydraulic unit, control panel, and screw barrel—are tested individually before integration. We conduct trial runs under variable load conditions to assess repeatability, response time, and thermal stability. Real-time data acquisition systems monitor over 20 performance parameters, enabling us to identify and correct micro-deviations before progression. This rigorous validation ensures that each machine performs within ±0.5% of nominal specifications, forming the foundation of our zero-defect philosophy.

Mass Production: Consistency Through Systematic Reconditioning

Once prototype validation is complete, we transition to mass reconditioning of the second hand injection moulding machines. Each unit follows a standardized workflow encompassing cleaning, non-destructive testing (NDT), component replacement, reassembly, and calibration. Our production floor operates under a documented quality management system with traceability for every part and process step. Automated diagnostic software verifies machine functionality, while final inspection includes a 72-hour endurance test simulating real-world production cycles. Only units passing 100% of test criteria are certified for delivery. This disciplined approach ensures batch-to-batch consistency and operational reliability, critical for clients in aerospace, automotive, and precision metal components manufacturing.

Technical Specifications of Reconditioned Machines

| Parameter | Standard Range | Tolerance / Accuracy |

|---|---|---|

| Clamping Force | 500–3000 kN | ±1% of rated value |

| Injection Pressure | 180–220 MPa | ±2 MPa |

| Screw Diameter | 40–80 mm | OEM specification |

| Shot Weight (PS) | 200–1200 g | ±0.3 g repeatability |

| Positioning Accuracy | 0.01–0.03 mm | ±0.005 mm |

| Repeatability (Weight) | Up to 0.1% CV | Verified over 100 cycles |

| Control System | PLC with Touch HMI | Siemens/Allen-Bradley |

| Energy Consumption | 30–90 kWh/cycle | Optimized via servo drives |

Our end-to-end process ensures that every reconditioned machine delivers original equipment performance with full traceability, documentation, and a 12-month warranty—proving that quality, precision, and zero defects are achievable in the second hand injection moulding machine market.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Engineered Second-Hand Injection Molding Solutions

At Wuxi Lead Precision Machinery, we understand the critical balance between operational cost efficiency and uncompromised manufacturing integrity. Sourcing a second-hand injection moulding machine is not merely a procurement decision; it is a strategic investment in process stability and long-term production capability. For over 15 years, we have specialized in the rigorous remanufacturing and certification of pre-owned machinery specifically for demanding metal-integrated and high-tolerance applications. Our engineering-led approach ensures every machine delivered meets the stringent requirements of precision metal manufacturing environments, eliminating the traditional risks associated with used equipment.

Our comprehensive remanufacturing process begins with a full metallurgical and dimensional assessment of core structural components. We disassemble each machine down to its base platens, inspecting for fatigue, wear, and alignment integrity. Critical systems undergo complete refurbishment: hydraulic units are rebuilt to NAS 7 cleanliness standards, electrical cabinets are updated with modern PLCs and safety circuits compliant with CE directives, and tie bars are stress-relieved and re-machined to ISO 2768-mK tolerances. This meticulous attention to foundational engineering guarantees that the machine’s core performance—clamping force accuracy, platen parallelism, and thermal stability—exceeds original OEM specifications for metal insert moulding and overmoulding processes. Every unit undergoes a 72-hour continuous production validation test using materials representative of your actual application, ensuring real-world readiness.

The performance specifications we achieve through this process are quantifiable and essential for precision metal manufacturing. Key validated parameters include:

| Critical Performance Parameter | Remanufactured Standard | Typical Industry Used Machine Range |

|---|---|---|

| Platen Parallelism Tolerance | ≤ 0.02 mm | 0.05 – 0.15 mm |

| Clamping Force Repeatability | ± 0.5% | ± 2.0 – 5.0% |

| Hydraulic System Cleanliness | NAS 7 | NAS 10 – 12 |

| Thermal Stability (Barrel) | ± 1.0°C | ± 3.0 – 5.0°C |

| Positioning Repeatability | ± 0.01 mm | ± 0.05 mm |

Choosing Lead Precision means selecting a partner accountable for your machine’s entire lifecycle performance, not just a transactional sale. We provide full technical documentation, including as-built dimensional reports, material certifications for rebuilt components, and a comprehensive 12-month warranty covering all remanufactured systems. Our engineering team remains accessible for process optimization support, ensuring seamless integration into your existing production workflow for metal-ceramic or metal-polymer composite manufacturing.

Do not compromise your production quality or throughput on unverified used equipment. Request a detailed technical assessment and remanufacturing proposal for your specific application requirements. Contact our engineering sales team directly at [email protected] to initiate a precision-focused consultation. Provide your target material, part geometry complexity, and annual volume, and we will deliver a validated machine solution engineered for your operational success. Partner with Lead Precision—where legacy machinery meets future-ready manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.