Technical Contents

Engineering Guide: Vacuum Plate For Machining

Engineering Insight: The Critical Role of Precision in Vacuum Plates for Machining

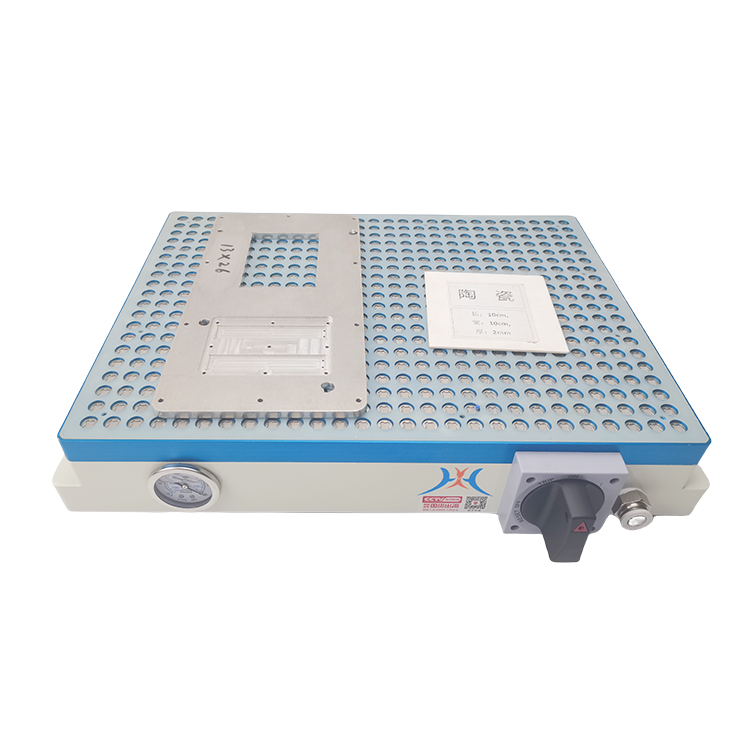

In high-precision metal manufacturing, the stability and accuracy of workholding solutions directly influence the final product’s dimensional integrity and surface quality. Among advanced workholding systems, the vacuum plate for machining stands out for its ability to secure delicate, thin-walled, or complex geometries without mechanical clamps that may induce distortion. At Wuxi Lead Precision Machinery, we recognize that the performance of a vacuum plate is not merely a function of suction strength, but of engineered precision at every level—from surface flatness to channel distribution and material integrity.

A vacuum plate must maintain consistent vacuum pressure across its entire surface while resisting deformation under cutting forces. This demands micron-level flatness, typically within ±0.005 mm over the full surface area, and a rigid base structure that prevents deflection during high-speed milling or grinding operations. Even minor deviations can result in workpiece shift, vibration, or incomplete vacuum seal—leading to scrapped components and costly downtime. Our engineering team applies finite element analysis (FEA) and computational fluid dynamics (CFD) to simulate vacuum flow and structural behavior, ensuring optimal channel layout and pressure distribution tailored to the client’s specific part geometry and machining parameters.

Material selection is equally critical. At Lead Precision, we primarily utilize high-grade cast iron (GG25/GG30) or aerospace-grade aluminum alloys, depending on thermal stability, weight, and application requirements. Each plate undergoes stress-relieving heat treatment and precision grinding on surface and sealing faces to achieve mirror-like finishes and long-term durability. All components are manufactured in-house using 5-axis CNC machining centers, guaranteeing tight control over tolerances and repeatability.

Our expertise is validated through mission-critical applications. Lead Precision has supplied custom vacuum workholding systems for components used in Olympic-standard sports equipment and precision subsystems in defense-grade unmanned platforms. These projects demanded not only extreme accuracy but also full traceability, rigorous testing, and compliance with international quality standards—benchmarks we meet routinely.

The following table outlines typical technical specifications for our custom vacuum plates:

| Specification | Standard Value | Customizable Range |

|---|---|---|

| Surface Flatness | ±0.005 mm | Up to ±0.001 mm |

| Surface Finish | Ra 0.8 µm | Down to Ra 0.2 µm |

| Vacuum Pressure | -85 kPa (typical) | -60 to -95 kPa |

| Base Material | GG25 Cast Iron, 6061-T6 Aluminum | Custom alloys available |

| Channel Pattern | Grid, Radial, or Custom | CAD-defined layouts |

| Sealing Method | O-ring + Surface Lapping | Laser-welded joints |

| Max Operating Temp | 150°C | Up to 300°C with ceramic coating |

At Wuxi Lead Precision Machinery, we treat every vacuum plate as a precision instrument—not just a fixture. Our integration of advanced materials, simulation-driven design, and military-grade quality control ensures that our clients achieve maximum yield, repeatability, and confidence in their machining processes.

Precision Specs & Tolerances

Advanced Vacuum Plate Machining Capabilities at Wuxi Lead Precision Machinery

Vacuum plates represent a critical enabling technology for high-precision, distortion-free machining of thin-walled, complex, or large-format metal components. At Wuxi Lead Precision Machinery, we specialize in the design and production of custom vacuum plates engineered to meet the exacting demands of aerospace, medical device, semiconductor, and optical industries. Our integrated manufacturing approach ensures these fixtures deliver exceptional holding force uniformity and thermal stability, directly translating to superior part accuracy and surface integrity during critical machining operations.

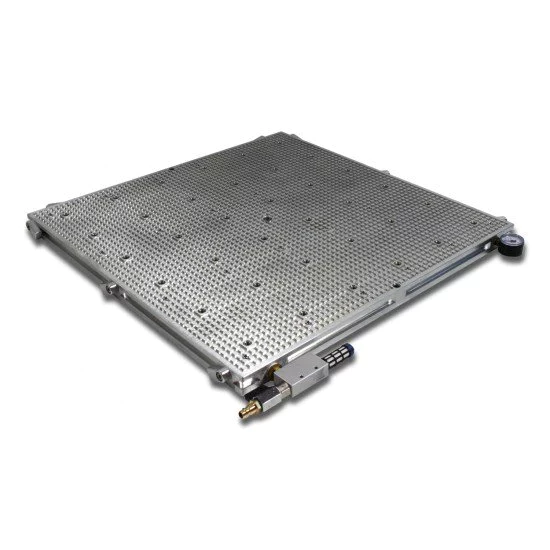

Our core capability centers on advanced 5-axis CNC milling and turning centers, specifically configured for the intricate geometries and stringent flatness requirements inherent in vacuum plate manufacturing. These machines feature high-rigidity cast iron structures, sub-micron linear scale feedback, and thermal compensation systems. This enables us to machine complex sealing channels, intricate vacuum port networks, and ultra-flat reference surfaces within a single setup, eliminating cumulative errors from multiple fixtures. We routinely machine plate sizes up to 1200mm x 800mm in materials including hardened tool steels, aluminum alloys, and specialized composites, achieving geometries impossible with conventional 3-axis methods. The elimination of mechanical clamps via the integrated vacuum system prevents part distortion, a critical factor for components requiring micron-level dimensional stability post-machining.

Rigorous quality control is non-negotiable for vacuum plate performance. Every plate undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM) equipped with high-precision probes and advanced metrology software. Our CMM protocols verify critical parameters across the entire surface, including absolute flatness, parallelism between mounting and sealing surfaces, positional accuracy of ports and channels, and surface roughness profiles. Full inspection reports, including deviation maps against CAD models, are provided with each shipment, ensuring complete traceability and compliance with ISO 9001 standards. This data-driven verification guarantees the vacuum plate will perform as an integral, reliable component of the client’s machining process, minimizing setup time and scrap rates.

The following table details the standard and premium tolerance capabilities achievable on vacuum plate features using our integrated 5-axis CNC and CMM inspection processes:

| Parameter | Standard Tolerance | Premium Tolerance |

|---|---|---|

| Overall Flatness (per 100mm) | ±0.005 mm | ±0.002 mm |

| Surface Parallelism | ±0.008 mm | ±0.003 mm |

| Port Positional Accuracy | ±0.010 mm | ±0.005 mm |

| Channel Depth Accuracy | ±0.020 mm | ±0.010 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Edge Break (Chamfer) | ±0.05 mm | ±0.02 mm |

Wuxi Lead Precision Machinery combines deep application engineering expertise with cutting-edge manufacturing and metrology to deliver vacuum plates that are not merely fixtures, but precision-engineered components essential for achieving the highest levels of machining productivity and part quality. We partner with clients from initial concept through final validation to ensure optimal integration into their specific production environment.

Material & Finish Options

Material Selection for Vacuum Plates in Precision Machining

Selecting the appropriate material for a vacuum plate is critical to ensuring performance, durability, and compatibility with high-precision machining environments. At Wuxi Lead Precision Machinery, we specialize in custom vacuum plates engineered to maintain flatness, thermal stability, and consistent vacuum integrity under demanding production conditions. The three primary materials used in vacuum plate manufacturing—aluminum, steel, and titanium—each offer distinct advantages depending on application requirements such as load capacity, weight, corrosion resistance, and thermal behavior.

Aluminum is the most commonly selected material for vacuum plates due to its excellent strength-to-weight ratio, high thermal conductivity, and ease of machinability. It allows for rapid heat dissipation, which is essential in maintaining dimensional stability during prolonged machining cycles. 6061-T6 and 7075-T6 aluminum alloys are particularly favored for their structural integrity and resistance to warping. When combined with anodizing surface treatment, aluminum gains enhanced wear resistance and improved surface hardness, making it ideal for environments where particulate generation must be minimized.

Steel, particularly tool steel and stainless steel variants, is chosen when maximum rigidity and wear resistance are required. Steel vacuum plates exhibit superior longevity in high-cycle applications and provide excellent resistance to deformation under heavy loads. While heavier than aluminum, steel offers unmatched durability in industrial environments involving aggressive coolants or elevated mechanical stress. Stainless steel also provides inherent corrosion resistance, reducing the need for additional surface treatments in wet or chemically active environments.

Titanium is reserved for specialized applications where extreme corrosion resistance, high strength at elevated temperatures, and minimal thermal expansion are paramount. Though more costly and challenging to machine, titanium vacuum plates are used in aerospace and medical manufacturing where material purity and long-term stability are non-negotiable. Its biocompatibility and resistance to chloride-induced stress corrosion make it suitable for cleanroom and high-purity processing environments.

Surface finish plays a crucial role in vacuum performance and contamination control. Anodizing, especially hard anodizing (Type III), is widely applied to aluminum vacuum plates to increase surface hardness up to 60 HRC, improve abrasion resistance, and enhance dielectric properties. This finish also seals the surface porosity, minimizing outgassing in vacuum chambers and improving cleanliness.

The following table summarizes key material properties and performance characteristics for vacuum plate applications:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Common Finish | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 167 | Hard Anodizing (Type III) | General-purpose, electronics, automation |

| Steel (Tool/SS) | 7.8 | 900–1200 | 15–25 | Passivation, Nitriding | Heavy-duty, high-wear industrial use |

| Titanium Grade 5 | 4.5 | 900 | 6.7 | None or Passivated | Aerospace, medical, high-corrosion areas |

Material and finish selection must align with operational parameters including vacuum level, temperature range, and part geometry. Wuxi Lead Precision Machinery supports clients in evaluating these factors to deliver vacuum plates optimized for performance, longevity, and precision.

Manufacturing Process & QC

Precision Vacuum Plate Manufacturing: Zero Defects Process Flow

At Wuxi Lead Precision Machinery, our production of vacuum plates for high-precision machining adheres to a rigorously controlled three-phase methodology. This ensures absolute dimensional stability, optimal vacuum integrity, and flawless performance under demanding production conditions. Zero Defects is not a target but the foundational requirement embedded within every stage.

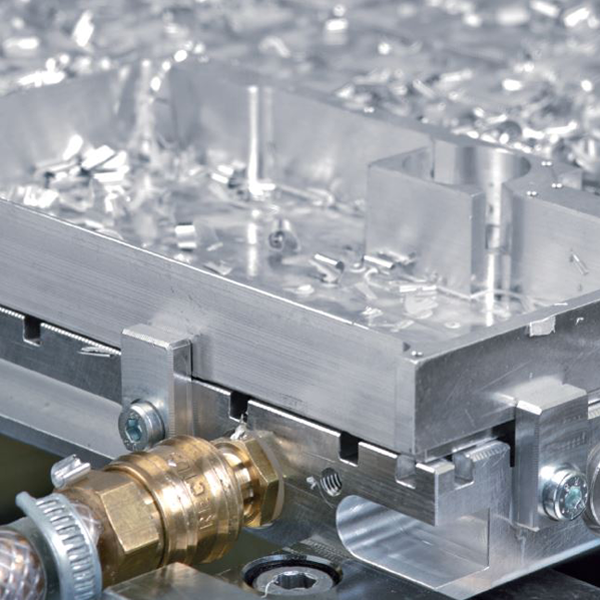

The Design phase begins with deep collaboration. Our engineering team works directly with the client to define exact application parameters: workpiece geometry, machining forces, coolant exposure, and machine tool interface. Advanced Finite Element Analysis (FEA) simulates thermal gradients, clamping stresses, and vacuum distribution across the plate surface. Material selection is critical; we specify aerospace-grade aluminum alloys like 6061-T6 or 7075-T6 based on required strength-to-weight ratio and thermal conductivity. Every port location, seal channel, and mounting feature is optimized for maximum hold force uniformity and minimal deflection during operation. Design validation includes computational fluid dynamics (CFD) to confirm vacuum flow efficiency before any metal is cut.

Prototyping transforms the validated digital model into a physical benchmark. Utilizing our 5-axis CNC milling centers with sub-micron positioning accuracy, the first article is machined under strict environmental controls. This prototype undergoes exhaustive metrology: full-surface flatness mapping on a Zeiss CONTURA CMM, vacuum decay testing under simulated machining loads, and verification of port alignment tolerances. Crucially, the prototype is subjected to client-specified machining trials. Any deviation in hold force stability or surface distortion triggers immediate design refinement. Only after achieving perfect functional performance in real-world conditions does the design lock for production.

Mass Production leverages our certified ISO 9001:2015 quality management system. Each plate is manufactured on dedicated, temperature-stabilized machining cells. Process controls include in-process laser scanning for critical datums and real-time Statistical Process Control (SPC) monitoring of key parameters like surface finish and flatness. 100% final inspection is non-negotiable: every plate undergoes full CMM verification against the approved design, comprehensive vacuum integrity testing at multiple pressure points, and visual inspection for surface defects under calibrated lighting. Traceability is maintained from raw material batch to finished part. This integrated approach guarantees consistent delivery of vacuum plates meeting the most stringent aerospace and semiconductor manufacturing standards.

Critical Vacuum Plate Specifications Achieved

| Parameter | Standard Tolerance | Precision Option | Measurement Method |

|---|---|---|---|

| Surface Flatness | ≤ 0.015 mm | ≤ 0.005 mm | Zeiss CMM (per ISO 1101) |

| Surface Roughness (Ra) | ≤ 0.8 µm | ≤ 0.4 µm | Profilometer (per ISO 4287) |

| Vacuum Hold Force | ≥ 8 N/cm² | ≥ 12 N/cm² | Calibrated Force Gauge |

| Port Position Accuracy | ± 0.02 mm | ± 0.01 mm | CMM |

| Vacuum Decay Rate | ≤ 5% in 5 minutes | ≤ 2% in 5 min | Precision Pressure Decay Test |

This disciplined progression from collaborative design through validated prototyping to tightly controlled mass production is how Wuxi Lead delivers vacuum plates that eliminate workholding failures and maximize client machine uptime. Contact our engineering team to specify your exact requirements.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced Vacuum Plate Solutions in High-Precision Machining

In the competitive landscape of custom metal manufacturing, achieving repeatable accuracy, superior workholding stability, and efficient production cycles is non-negotiable. At Wuxi Lead Precision Machinery, we specialize in engineering vacuum plates tailored to the exacting demands of high-end machining applications. Our vacuum clamping systems provide a secure, distortion-free method of holding thin-walled components, complex geometries, and large surface-area parts—common challenges in aerospace, automotive, medical device, and precision mold manufacturing.

Our vacuum plates are not off-the-shelf solutions. Each system is developed through a collaborative engineering process, ensuring compatibility with your CNC machine platform, material type, and production volume. Whether you are machining aluminum aerospace panels, titanium medical implants, or composite molds, our vacuum technology eliminates mechanical clamps that obstruct tool paths and induce stress deformation. The result is uninterrupted machining access, improved surface finishes, and enhanced throughput.

We integrate precision-machined sealing zones, optimized vacuum channel networks, and high-flow suction systems to deliver uniform holding force across the entire work surface. Our plates are manufactured from high-grade aluminum alloys or stainless steel, depending on application requirements, and are rigorously tested for leak integrity and performance under full load. Surface flatness is maintained within ±0.005 mm over the entire area, ensuring consistent part alignment and dimensional accuracy.

Below are key technical specifications representative of our standard and custom vacuum plate offerings:

| Specification | Detail |

|---|---|

| Material Options | 6061-T6, 7075-T6 Aluminum, 304/316 Stainless Steel |

| Surface Flatness | ±0.005 mm over full surface |

| Vacuum Pressure | Up to -85 kPa (adjustable via regulator) |

| Sealing Method | Laser-cut elastomer gaskets, multi-zone isolation |

| Port Configuration | Custom NPT or G-threaded ports, centralized or distributed |

| Compatible Machines | FANUC, DMG MORI, MAZAK, HAAS, OKUMA, and more |

| Control Interface | Optional digital vacuum monitoring with alarm feedback |

| Lead Time | 4–8 weeks, based on complexity and customization level |

Partnering with Wuxi Lead Precision Machinery means gaining access to over 15 years of advanced workholding expertise. Our engineering team works directly with your design and production staff to validate fixturing concepts, simulate vacuum distribution, and deliver a solution that integrates seamlessly into your workflow. We support global clients with technical documentation, installation guidance, and after-sales service.

For a consultation on how our vacuum plates can elevate your machining precision and productivity, contact us today. Send your project details to [email protected] and receive a tailored proposal within 48 hours. Let Wuxi Lead Precision Machinery be your trusted partner in precision manufacturing innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.