Technical Contents

Engineering Guide: Thick Molding

Engineering Insight: Precision Imperatives in Thick-Section Metal Manufacturing

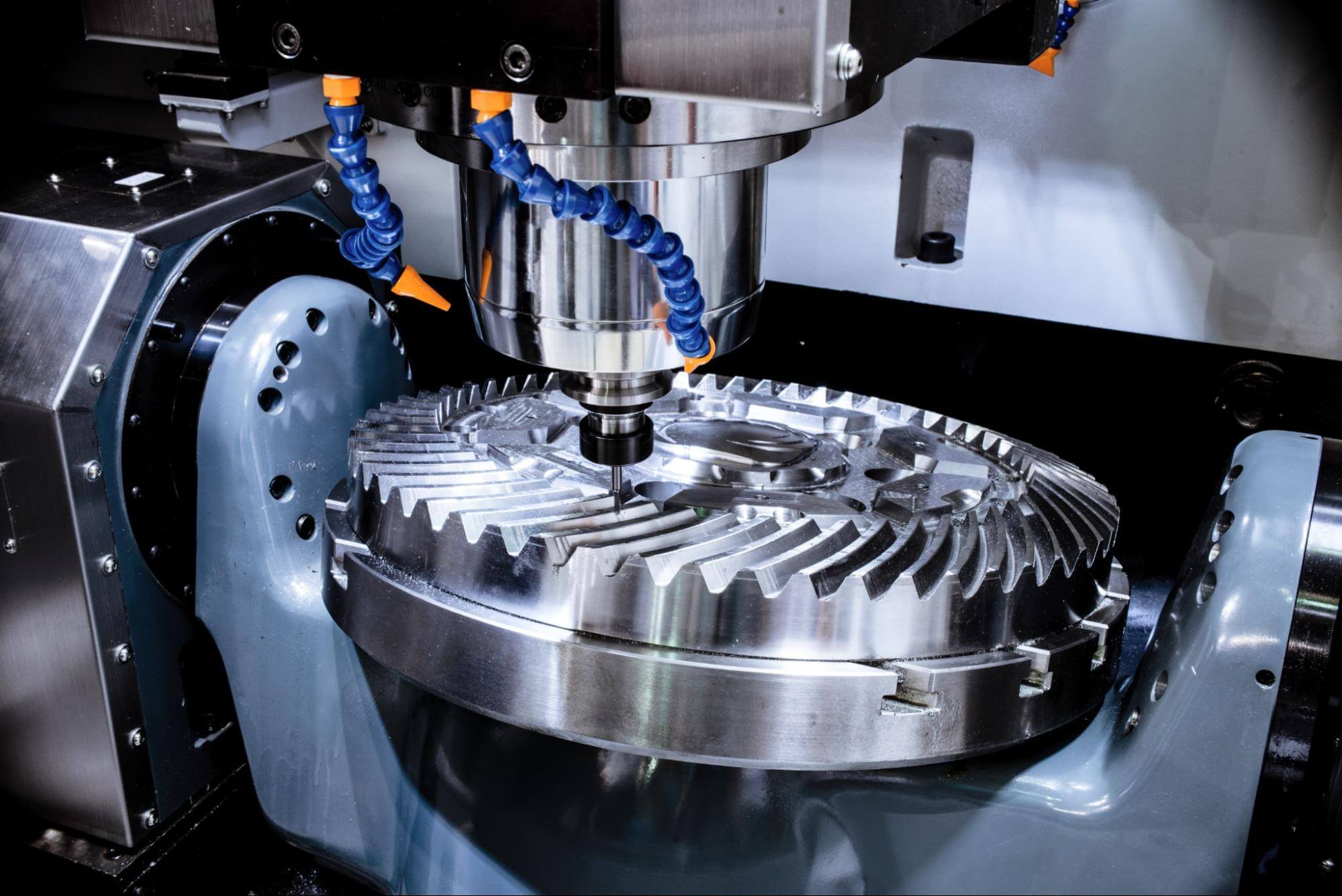

Thick-section metal components present unique engineering challenges where precision transcends mere specification adherence; it becomes the critical factor determining structural integrity, performance longevity, and operational safety. In applications demanding walls exceeding 100mm or complex geometries within substantial material volumes, conventional machining approaches often fail. Thermal distortion during processing, residual stress management, and maintaining micron-level tolerances across vast surfaces are not optional refinements but fundamental requirements. A deviation of mere hundredths of a millimeter in a thick-walled hydraulic manifold or massive gear housing can propagate catastrophic failure under cyclic load, leading to unplanned downtime, safety hazards, and significant financial loss far exceeding the initial component cost. Precision here directly dictates the total cost of ownership.

The core difficulty lies in controlling material behavior. Thick sections retain heat unevenly during machining, inducing internal stresses that manifest as warpage long after processing concludes. Achieving uniform metallurgical properties throughout the cross-section requires meticulous thermal management during both forming and machining stages. Furthermore, maintaining geometric accuracy—flatness, concentricity, critical bore alignments—demands machine rigidity, advanced toolpath strategies, and real-time process monitoring far beyond standard capabilities. Sub-optimal precision compromises load distribution, accelerates wear in mating components, and ultimately undermines the entire assembly’s reliability. For mission-critical infrastructure, energy systems, or heavy machinery, this level of accuracy is non-negotiable.

Wuxi Lead Precision Machinery specializes in conquering these thick-section complexities. Our engineering protocols integrate multi-axis CNC machining centers with exceptional thermal stability and dynamic stiffness, specifically configured for high-mass material removal. We employ proprietary stress-relief cycles and in-process metrology, utilizing coordinate measuring machines (CMM) capable of verifying tolerances on components weighing multiple tons. This systematic approach ensures dimensional stability under operational thermal loads and mechanical stress, delivering components that perform reliably for decades. Our commitment to precision is validated through stringent adherence to international standards and proven in the most demanding environments.

Our capability to deliver uncompromising precision in thick-section manufacturing is demonstrated by the rigorous demands of our clientele. We have successfully produced critical structural components for major international sporting venues, including Olympic-class facilities, where architectural integrity and public safety are paramount. Furthermore, we supply precision-machined elements for national defense systems, meeting exacting military specifications where failure is not an option. This experience underscores our mastery of the thermal, mechanical, and geometric challenges inherent in thick-section work.

The following table outlines key capabilities for thick-section metal manufacturing at Wuxi Lead Precision Machinery:

| Parameter | Capability Range | Precision Standard |

|---|---|---|

| Maximum Material Thickness | Up to 350 mm | N/A |

| Typical Material Types | Carbon Steel, Stainless Steel, Alloy Steel, Cast Iron | N/A |

| Dimensional Tolerance | ±0.02 mm (localized features) | ISO 2768-mK / Custom |

| Geometric Tolerance | Flatness: 0.05 mm/m²; True Position: ±0.03 mm | ASME Y14.5 GD&T |

| Surface Finish (Machined) | Ra 0.8 µm to 3.2 µm | ISO 1302 |

| In-Process Verification | On-machine probing; CMM validation up to 3m x 2m x 1.5m | Calibration to ISO 17025 |

Precision in thick-section manufacturing is not an incremental advantage; it is the foundational requirement for functional, safe, and economically viable components. Wuxi Lead Precision Machinery applies decades of specialized engineering rigor, advanced technology, and proven success in Olympic and defense applications to ensure your most demanding thick-metal projects achieve absolute dimensional integrity. Trust in precision engineered for consequence.

Precision Specs & Tolerances

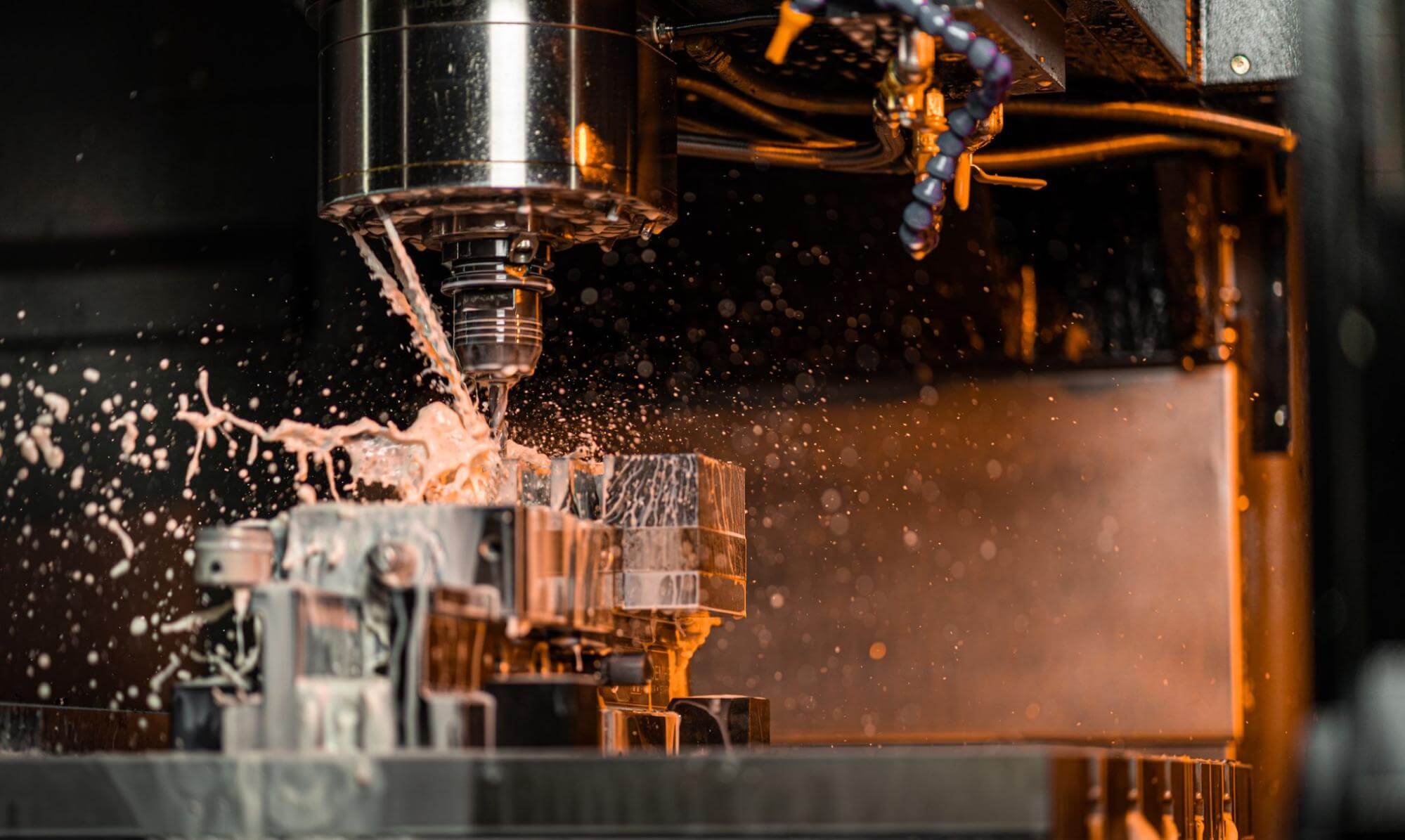

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered for precision-critical industries such as aerospace, energy, medical, and high-performance automotive. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometries with superior accuracy and surface integrity. Our facility utilizes state-of-the-art multi-axis CNC centers equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems. This allows for uninterrupted, high-efficiency machining of thick molding components—parts characterized by deep cavities, heavy wall sections, and intricate 3D profiles—without compromising dimensional stability or surface finish.

Our 5-axis technology supports simultaneous five-axis motion, eliminating the need for multiple setups and minimizing cumulative alignment errors. This capability is particularly critical in thick molding applications where internal features and undercuts are common. With a work envelope accommodating parts up to 2,000 mm in length and a maximum load capacity of 5,000 kg, we are equipped to handle large-scale, high-mass components typical in industrial tooling and mold manufacturing. Materials processed include hardened steels, stainless alloys, titanium, aluminum, and specialty high-temperature alloys, all machined under controlled thermal and vibration-dampened environments to ensure repeatability.

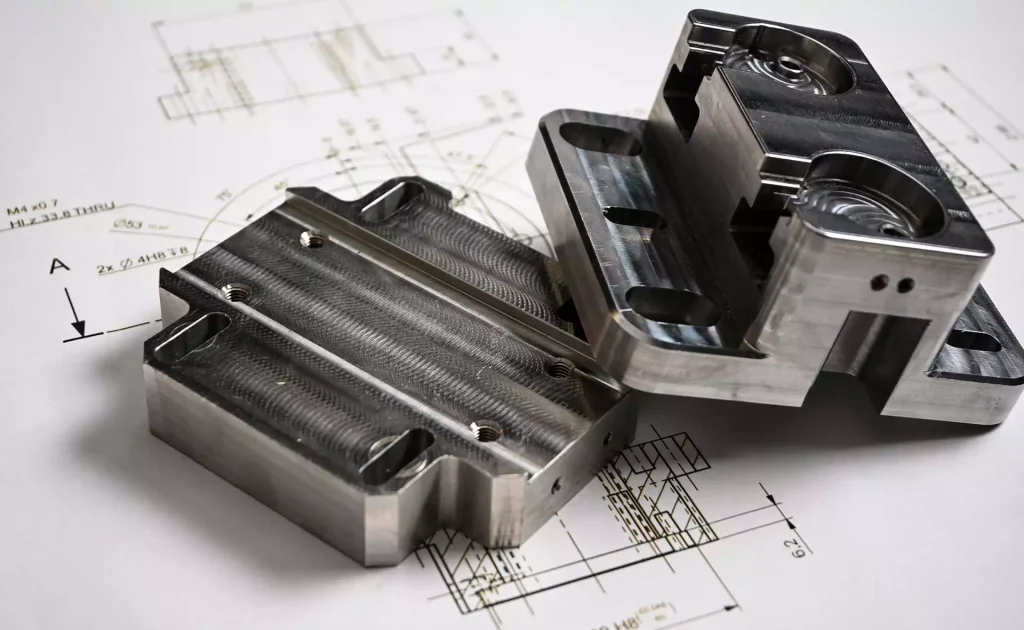

Quality assurance is maintained through a rigorous inspection protocol anchored by a certified Coordinate Measuring Machine (CMM) laboratory. Every thick molding component undergoes full 3D dimensional validation using a Hexagon GLOBAL S 15.30.10 CMM with PC-DMIS software, enabling micron-level verification of critical datums, profile tolerances, and geometric form. In addition to CMM inspection, we employ on-machine probing for in-process verification and implement SPC (Statistical Process Control) methodologies to monitor process capability and ensure long-term consistency.

All manufacturing and inspection data are documented and traceable, meeting ISO 9001:2015 and customer-specific AS9100 or NADCAP requirements. Our engineering team collaborates directly with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce lead times, and ensure compliance with functional performance standards.

The following table outlines our standard and achievable tolerance capabilities for thick molding components:

| Feature Type | Standard Tolerance | Achievable Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Geometric Tolerances | ±0.03 mm (GD&T) | ±0.01 mm | CMM, Optical Comparator |

| Surface Finish (Ra) | 3.2 µm | 0.4 µm | Surface Roughness Tester |

| Hole Diameter | ±0.02 mm | ±0.008 mm | CMM, Air Gauges |

| Positional Accuracy | ±0.03 mm | ±0.01 mm | CMM |

| Angular Features | ±0.05° | ±0.01° | CMM, Precision Protractors |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with metrology-grade quality control to deliver thick molding components that meet the most stringent industrial requirements.

Material & Finish Options

Material Selection for High-Intensity Thick-Section Metal Components

While the term “thick molding” often applies to polymers, in precision metal manufacturing for structural applications—such as heavy machinery frames, aerospace bulkheads, or defense hardware—we address thick-section fabrication where material integrity under extreme loads is non-negotiable. At Wuxi Lead Precision Machinery, we prioritize materials that maintain mechanical stability, resist deformation, and endure cyclic stress in sections exceeding 25mm. Aluminum, steel, and titanium each serve distinct high-performance niches, with finish selection further optimizing longevity.

Aluminum alloys like 6061-T6 and 7075-T6 dominate weight-sensitive applications requiring robust strength-to-weight ratios. 6061-T6 offers excellent weldability and moderate corrosion resistance for marine or transport infrastructure, while 7075-T6 delivers aerospace-grade strength for landing gear components. Anodizing is critical here: Type II sulfuric acid anodizing provides economical corrosion resistance and dye acceptance for visible parts, whereas Type III hardcoat anodizing (per MIL-A-8625) forms a 25–50µm ceramic layer, drastically improving surface hardness (500+ HV) and wear resistance for hydraulic pistons or rail couplings.

Carbon and alloy steels—including 4140 and 304 stainless—excel where raw strength and fatigue resistance are paramount. 4140, heat-treated to 250–300 HB, withstands high-impact loads in mining equipment shafts, while 304 stainless offers inherent corrosion resistance for chemical processing vessels. Unlike aluminum, steel requires alternative finishes: zinc-nickel plating or powder coating for corrosion barriers, and nitriding for surface hardening. Titanium Grade 5 (Ti-6Al-4V) is reserved for extreme environments—such as jet engine mounts or subsea housings—where its exceptional strength-to-weight ratio, 600°C+ thermal stability, and immunity to saltwater corrosion justify its premium cost. Titanium demands specialized CNC machining due to low thermal conductivity but achieves superior performance with abrasive blasting or plasma spray coatings for adhesion.

Material performance in thick sections hinges on predictable homogeneity. Below is a comparative overview of key properties for critical decision-making:

| Material | Typical Yield Strength (MPa) | Density (g/cm³) | Max Continuous Use Temp (°C) | Key Thick-Section Application |

|---|---|---|---|---|

| Aluminum 7075-T6 | 503 | 2.81 | 125 | Aircraft wing spars, missile fittings |

| Steel 4140 (HT) | 655 | 7.85 | 480 | Heavy-duty axles, forging dies |

| Titanium Ti-6Al-4V | 880 | 4.43 | 600 | Jet turbine blades, prosthetic implants |

Selecting the optimal material requires balancing operational stressors, environmental exposure, and lifecycle costs. Anodizing aluminum components is not merely cosmetic—it is a functional necessity for wear-prone surfaces. For steel or titanium, mismatched finishes can undermine material advantages. Wuxi Lead’s engineering team collaborates with clients to model material behavior in thick geometries, ensuring your design leverages the full potential of these metals. Consult us early in the specification phase to avoid costly revisions and maximize component service life. Our CNC centers are calibrated for the exacting tolerances these advanced materials demand.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the thick molding production process begins with a rigorous design phase rooted in advanced engineering principles. Our in-house team of mechanical and materials engineers collaborates closely with clients to translate conceptual requirements into technically viable designs. Using high-fidelity CAD software and finite element analysis (FEA), we simulate structural integrity, thermal behavior, and load distribution under operational conditions. This ensures that every component is optimized for performance, durability, and manufacturability. Special attention is given to wall thickness uniformity, material flow dynamics, and stress concentration zones—critical factors in thick molding applications where internal voids or warpage can compromise integrity. Design validation includes tolerance stack-up analysis and mold flow simulation, ensuring dimensional accuracy and process stability before any physical prototype is created.

Prototyping: Validating Performance Before Scale

Once the digital design is finalized, we move to precision prototyping using CNC-machined or 3D-printed molds, depending on material and complexity. These prototypes are produced under near-production conditions to accurately reflect final part behavior. Each prototype undergoes comprehensive metrological inspection using coordinate measuring machines (CMM) and 3D scanning to verify dimensional compliance. Functional testing includes pressure cycling, thermal aging, and mechanical load testing to validate performance in real-world environments. Any deviations are traced back to root causes through our closed-loop feedback system, and design or process adjustments are implemented immediately. This iterative validation ensures that the transition to mass production is seamless, with all risks mitigated prior to tooling finalization.

Mass Production: Zero-Defect Manufacturing Execution

With design and prototype approval, we initiate mass production using high-tonnage hydraulic presses and custom-engineered steel molds with integrated cooling and monitoring systems. Our thick molding process leverages controlled injection parameters, extended curing cycles, and real-time process monitoring to eliminate porosity, sink marks, and residual stress. Each production run is governed by Statistical Process Control (SPC), with automated data logging of temperature, pressure, and cycle time. Every component undergoes 100% visual inspection and selective destructive and non-destructive testing (NDT), including ultrasonic scanning and X-ray imaging for internal defect detection. Our quality management system is ISO 9001 certified, and we enforce a zero-defect protocol through traceability tagging, batch serialization, and continuous operator training.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material Compatibility | Thermoset resins, reinforced polymers, LSR |

| Wall Thickness Range | 8 mm to 50 mm |

| Tolerance Control | ±0.1 mm (standard), ±0.05 mm (tight-tolerance) |

| Production Capacity | Up to 50,000 units/month per mold |

| Tooling Material | H13, P20, or 420 stainless steel (hardened) |

| Quality Standards | ISO 9001, IATF 16949, RoHS compliant |

| Lead Time (Design to MP) | 6–10 weeks (depending on complexity) |

Through integrated design, validated prototyping, and disciplined mass production, Wuxi Lead Precision Machinery delivers thick molded metal and composite components with uncompromised quality and repeatability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Thick Molding Excellence

At Wuxi Lead Precision Machinery, we engineer solutions where standard manufacturing processes reach their limits. Thick molding demands exceptional control over thermal dynamics, material stress distribution, and dimensional stability—factors that directly impact part integrity, longevity, and performance in critical applications. Our dedicated thick molding division operates at the convergence of advanced CNC technology, metallurgical expertise, and rigorous process validation. We do not merely produce components; we resolve the technical constraints inherent in transforming dense, high-mass materials into precision-engineered assets for aerospace, energy, and heavy industrial systems.

Thick molding success hinges on equipment capability and process intelligence. Generic manufacturers often struggle with warpage, inconsistent grain structure, or tolerance drift in sections exceeding 100mm. Our integrated approach leverages proprietary thermal management protocols and real-time in-process metrology to maintain uniform material properties and micron-level accuracy throughout the entire cross-section. This eliminates costly rework and ensures your components perform reliably under extreme operational loads.

Our technical capacity is engineered for the most demanding specifications. The following parameters reflect our baseline capabilities for thick-section metal molding:

| Specification | Capability Range |

|---|---|

| Maximum Material Thickness | 150 mm (6 inches) |

| Tolerance Capability | ±0.005 mm per 100 mm |

| Surface Finish Range | Ra 0.4 μm to 3.2 μm |

| Max Part Weight | 8,500 kg (18,700 lbs) |

| Lead Time for Validation | 12-18 weeks (complex builds) |

These figures represent proven production standards, not theoretical ideals. Each parameter is validated through our ISO 13485-certified quality management system, with full traceability from raw material certification to final inspection. We prioritize material science collaboration, working with your team to select optimal alloys and heat treatment sequences that balance strength, machinability, and lifecycle cost.

Partnering with Lead Precision means embedding our engineering rigor into your supply chain. Our project managers and CNC specialists operate as extensions of your R&D and production teams, providing transparent progress updates and data-driven insights at every phase. We mitigate risk through pre-production FEA analysis and iterative prototyping, ensuring first-article approval aligns with your operational requirements. This collaborative model reduces time-to-market while guaranteeing that every component meets the uncompromising standards your industry demands.

Initiate your precision manufacturing consultation today. Contact our engineering team directly at [email protected] to discuss thermal management strategies, material selection, or process validation for your next thick molding project. Include your target specifications and application environment for a tailored capability assessment within 24 business hours. Wuxi Lead Precision Machinery: Where material integrity meets dimensional certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.