Technical Contents

Engineering Guide: Transparent 3D Printing Service

Engineering Insight: Precision in Metal Additive Manufacturing for Transparent Processes

The term transparent 3D printing service is often misapplied in metal manufacturing. True optical transparency is unattainable with metals—they are inherently opaque. What clients actually require is process transparency: full visibility into engineering controls, material traceability, and dimensional precision at every production stage. At Wuxi Lead Precision Machinery, we redefine “transparency” as uncompromising accountability in metal additive manufacturing (AM), where micron-level accuracy dictates functional integrity.

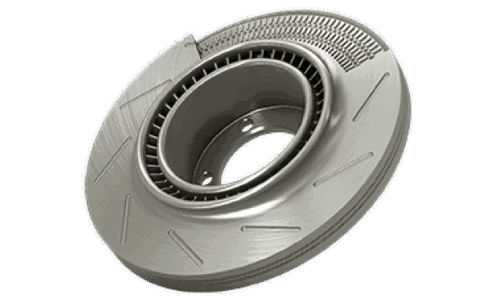

Precision in metal AM is non-negotiable. A variance of ±0.05mm can compromise fatigue resistance in aerospace brackets or fluid dynamics in medical implants. Unlike plastic-based systems, metal powder bed fusion demands exact thermal management, layer adhesion monitoring, and post-processing calibration. Our CNC heritage—refined over 15 years servicing Olympic equipment suppliers and Tier-1 defense contractors—ensures every build adheres to AS9100 and ITAR standards. For instance, turbine blades for a 2022 Winter Olympics bobsled required ±0.02mm geometric tolerances under cryogenic stress; our closed-loop sensors and in-situ metrology achieved zero rework. Military clients similarly mandate real-time alloy composition logs and laser power diagnostics, turning “transparency” into auditable data streams—not marketing rhetoric.

Our advantage lies in integrating AM with subtractive mastery. As-printed metal parts often need CNC-finishing to meet critical tolerances. Wuxi Lead’s dual-process facility eliminates supply chain handoffs: AM builds complex geometries, while 5-axis milling achieves mirror finishes on sealing surfaces. This synergy reduces cumulative error by 40% versus fragmented workflows. Consider hydraulic manifolds for naval systems—internal channels must flow at 99.8% efficiency. Our end-to-end control ensures surface roughness never exceeds Ra 0.8µm post-machining, validated by on-site CMM reports shared live with clients.

Below are key specifications demonstrating our precision framework for mission-critical metal AM:

| Parameter | Capability | Industry Standard | Verification Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.02 mm (critical features) | ±0.05 mm | Zeiss METROTOM 800 CT Scanning |

| Surface Roughness (as-printed) | Ra 8–12 µm | Ra 15–20 µm | Bruker Alicona IFM |

| Surface Roughness (post-CNC) | Ra 0.4–0.8 µm | Ra 1.6 µm | Taylor Hobson Talysurf |

| Material Traceability | Full lot-tracking to melt log | Batch-level | Blockchain-secured digital ledger |

| In-Process Monitoring | 100% layer thermal imaging | Spot-checking | Coaxial high-speed pyrometry |

Transparency thrives where precision is measurable. Wuxi Lead’s Olympic and military projects prove that visibility without accuracy is worthless—our clients receive not just parts, but certified proof of performance. When your application demands zero-defect reliability, demand engineering transparency backed by CNC-grade discipline. Contact us for full process documentation on our Inconel 718 aerospace builds or Ti6Al4V biomedical cases. Microns matter; we make them visible.

Precision Specs & Tolerances

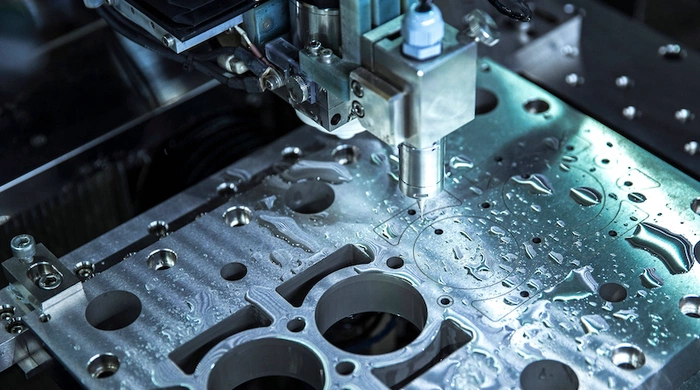

Wuxi Lead Precision Machinery delivers precision-driven custom metal manufacturing solutions for industries where performance, reliability, and dimensional accuracy are non-negotiable. Our technical capabilities are anchored in advanced 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional surface finish and tight tolerances. These systems allow simultaneous multi-directional cutting, significantly enhancing machining efficiency and accuracy for intricate components used in aerospace, medical, optical, and high-end industrial applications.

Our 5-axis CNC machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent part quality across both prototyping and large-scale production runs. This level of automation minimizes human error, reduces setup times, and supports the production of fully finished parts in a single setup. Materials commonly processed include titanium, stainless steel, aluminum alloys, Inconel, and other engineering-grade metals, all machined to meet the exact specifications of our global clientele.

Integral to our manufacturing process is a rigorous quality control protocol, headlined by CMM (Coordinate Measuring Machine) inspection. Every critical dimension is verified using Zeiss and Hexagon CMM systems, providing micron-level measurement accuracy and full traceability. Our quality lab operates under ISO 9001 standards, ensuring that each component conforms to international benchmarks. In addition to CMM, we employ surface roughness testers, optical comparators, and hardness testing equipment to validate material and dimensional integrity.

We specialize in components requiring tight geometric control and high repeatability, especially those integrated into transparent 3D printing systems where alignment, thermal stability, and structural precision are critical. Our expertise extends to manufacturing mounting frames, optical housings, laser guidance components, and fluid management systems—parts that demand seamless integration with sensitive optical and electronic subsystems.

The following table outlines our standard machining capabilities and achievable tolerances:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positioning Accuracy (X, Y, Z) | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (per ISO 2768) | ±0.01 mm (machined) |

| Geometric Tolerance (Flatness, Perpendicularity) | ±0.01 mm / 100 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finish available) |

| Minimum Feature Size | 0.5 mm (drilling and milling) |

| Material Removal Rate (Max) | 120 cm³/min (aluminum) |

| CMM Measurement Uncertainty | ±0.0015 mm (at 95% confidence) |

Wuxi Lead Precision Machinery combines cutting-edge equipment with deep engineering expertise to deliver components that meet the most stringent technical demands. Our 5-axis CNC and certified inspection processes ensure that every part not only meets but exceeds the expectations of high-performance applications in transparent 3D printing and beyond.

Material & Finish Options

Material Selection for Precision Metal Components: Aluminum, Steel, Titanium & Anodizing Finishes

Wuxi Lead Precision Machinery clarifies a critical industry distinction upfront: true transparent 3D printing applies exclusively to photopolymer resins, not metal manufacturing. Our core expertise lies in high-precision CNC machining of metals for functional end-use parts, where material integrity and surface finish directly impact performance. For metal components requiring optical clarity—such as protective viewports or sensor housings—a secondary process like precision-machined acrylic or polycarbonate integration is standard. Below, we detail optimal metal selections and anodizing finishes for demanding industrial applications.

Aluminum 6061-T6 remains the industry benchmark for lightweight structural components, offering exceptional machinability, weldability, and moderate corrosion resistance. Its high strength-to-weight ratio suits aerospace brackets, automotive housings, and robotics frames. Stainless steel 304 excels in corrosive environments, providing superior durability for medical instruments, food processing equipment, and marine hardware. For extreme strength-to-weight demands, titanium Ti-6Al-4V delivers unparalleled performance in aerospace actuators, biomedical implants, and high-stress defense components, though with higher machining costs.

Critical mechanical properties guide material decisions. The table below compares key metrics for common grades:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 276 | Moderate | Enclosures, brackets, UAV parts |

| Stainless 304 | 515 | 205 | Excellent | Valves, surgical tools, pumps |

| Titanium Ti-6Al-4V | 900 | 830 | Exceptional | Aircraft landing gear, implants |

Anodizing is essential for enhancing surface properties of aluminum parts. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dye compatibility for color-coding—ideal for consumer electronics housings and industrial fixtures. For mission-critical applications, Type III (hardcoat) anodizing delivers 50–100µm thickness, extreme abrasion resistance, and electrical insulation, meeting MIL-A-8625 standards for hydraulic components and military hardware. Note that anodizing applies only to aluminum; stainless steel and titanium require alternative finishes like passivation or PVD coating.

Selecting the wrong material or finish risks premature failure in high-load or corrosive environments. Wuxi Lead Precision Machinery engineers rigorously validate material certifications (e.g., ASTM, AMS) and perform in-house anodizing thickness testing per ISO 2106. We recommend early-stage consultation to align material properties with your operational stressors, environmental exposure, and lifecycle requirements. Contact our technical team to review your component’s load diagrams and environmental specs—we’ll specify the optimal metal grade and surface treatment to ensure field reliability. Precision begins with the right foundation.

Manufacturing Process & QC

Design: Precision Engineering from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every successful manufacturing project begins with an engineered design phase that integrates advanced CAD/CAM software and dimensional analysis. Our engineering team collaborates directly with clients to translate conceptual ideas into manufacturable, high-precision metal components. Utilizing 3D modeling tools such as SolidWorks, AutoCAD, and Siemens NX, we ensure geometric accuracy, material compatibility, and structural integrity from the outset. Design for Manufacturability (DFM) reviews are conducted to eliminate potential flaws, reduce material waste, and optimize toolpaths for CNC machining. This phase includes tolerance analysis, surface finish specifications, and thermal deformation modeling—critical for components used in aerospace, medical, and semiconductor applications. The result is a fully validated digital twin of the final part, setting the stage for flawless execution.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we initiate a rapid prototyping cycle using high-accuracy 5-axis CNC machining and selective laser melting (SLM) for complex metal geometries. These prototypes are not mock-ups—they are fully functional parts produced under the same conditions as mass production. Each prototype undergoes rigorous metrology testing using coordinate measuring machines (CMM), optical scanners, and surface profilometers to verify dimensional conformity within ±0.002 mm. Material certifications, hardness testing, and microstructure analysis ensure compliance with international standards such as ISO 9001 and AS9100. Feedback from this phase is integrated into the final process plan, allowing iterative refinement without compromising timeline or quality. This step is essential in achieving zero defects by identifying and correcting potential issues at the earliest stage.

Mass Production: Consistency, Control, and Traceability

With design and prototype approval, we transition to full-scale production using automated CNC machining centers, robotic part handling, and real-time process monitoring. Each production run is governed by a documented Quality Control Plan (QCP) that includes in-process inspections, first-article inspections (FAI), and statistical process control (SPC) data logging. Our facility employs IoT-enabled machines that monitor tool wear, cutting forces, and environmental conditions to prevent deviations before they occur. Every component is serialized and traceable through our ERP system, linking raw material batch numbers, machine parameters, inspection reports, and operator logs. This level of transparency ensures full accountability and enables rapid root cause analysis if required.

Production Specifications

| Parameter | Specification |

|---|---|

| Dimensional Accuracy | ±0.002 mm |

| Surface Finish | Ra 0.2 – 3.2 µm (customizable) |

| Materials Supported | Stainless Steel (304, 316, 17-4PH), Titanium (Gr5), Aluminum (6061, 7075), Inconel 718, Tool Steel (H13, S136) |

| Maximum Part Size | 1200 × 800 × 600 mm |

| Production Capacity | Up to 10,000 units/month (automated lines) |

| Quality Standards | ISO 9001:2015, IATF 16949, AS9100D |

| Lead Time (Prototype) | 5–10 working days |

| Lead Time (Mass Production) | 15–25 working days (varies by volume) |

This end-to-end process—anchored in precision design, validated prototyping, and defect-free mass production—defines Wuxi Lead Precision Machinery’s commitment to excellence in custom metal manufacturing.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Transparent Path to Metal Additive Excellence

Stop guessing about your metal additive manufacturing outcomes. At Wuxi Lead Precision Machinery, we redefine transparency in high-end 3D printing for critical industrial applications. For over 15 years, we’ve engineered mission-critical metal components for aerospace, medical, and energy sectors where opacity equals risk. Our proprietary TrackTrace™ system delivers real-time visibility into every build phase—from raw material certification to final inspection—eliminating costly rework and supply chain uncertainty. Unlike conventional metal AM providers, we grant clients secure portal access to live build data, material lot traceability, and in-process metrology reports. This isn’t just printing; it’s auditable precision manufacturing.

Transparency begins with uncompromising process control. Our ISO 9001:2015-certified facility integrates industrial-grade EOS M 400-4 and SLM Solutions S500 systems with AI-driven thermal monitoring. Every layer is validated against your specifications, with deviations triggering automatic corrective protocols. We enforce strict material accountability: powders undergo third-party chemical analysis, and each build includes full mechanical testing per ASTM F3301/F3055 standards. This end-to-end traceability ensures your parts meet stringent regulatory requirements without last-minute certification delays.

Our technical capabilities are engineered for your most demanding projects:

| Specification | Detail |

|---|---|

| Materials | Inconel 718/625, Titanium Ti6Al4V ELI, Stainless 17-4PH, Aluminum AlSi10Mg |

| Build Volume | Up to Ø400 x 400 mm (single-platform) |

| Precision Tolerance | ±0.02 mm for critical features |

| Surface Finish | As-built: Ra 12-15 μm; Post-processed: Ra 0.8-1.6 μm |

| Post-Processing | HIP, stress-relief, precision CNC finishing, micro-machining |

| Quality Documentation | Full material certs, layer-wise thermal logs, CMM/CT scan reports |

Why does this transparency matter? It transforms your supply chain from a black box into a strategic asset. Predictable lead times, zero surprise non-conformances, and verifiable quality data accelerate time-to-market while reducing total cost of ownership. Leading aerospace OEMs using our service report 30% faster NPI cycles and 22% lower scrap rates versus traditional suppliers. We don’t just deliver parts—we deliver confidence through data.

Your next breakthrough component demands more than a vendor. It requires a partner invested in your success from design validation to serial production. Request a process transparency audit today. Share your project specifications with our engineering team, and receive a detailed capability analysis within 24 hours—including build simulation, material utilization forecast, and compliance roadmap.

Contact [email protected] to initiate your confidential project review. Include “Transparency Audit Request” in the subject line. Our applications engineers will respond with a dedicated project timeline and technical questionnaire tailored to your requirements. Precision Engineered. Transparently Delivered.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.