Technical Contents

Engineering Guide: Molding Aluminum

Engineering Insight: Precision in Aluminum Molding for High-Performance Applications

In the realm of custom metal manufacturing, molding aluminum demands a balance of advanced engineering, material science, and uncompromising precision. Aluminum, prized for its strength-to-weight ratio, corrosion resistance, and thermal conductivity, is a preferred material across aerospace, defense, and high-performance industrial sectors. However, its successful application hinges not just on the alloy selected but on the accuracy and consistency of the molding process. At Wuxi Lead Precision Machinery, we understand that in mission-critical environments, even micrometer-level deviations can compromise structural integrity, performance, and safety.

Precision in aluminum molding begins with mold design. The geometry of the mold cavity, thermal expansion characteristics, and gating system must be engineered to account for aluminum’s behavior during solidification. Shrinkage, warpage, and internal stress development are inherent challenges that require predictive modeling and iterative refinement. Our engineering team employs finite element analysis (FEA) and computational fluid dynamics (CFD) to simulate fill patterns, cooling rates, and stress distribution, ensuring optimal mold performance before any metal is poured.

Material consistency is equally vital. We source aerospace-grade aluminum alloys—including 6061, 7075, and A356—subjected to stringent quality controls. Each batch undergoes spectrographic analysis and mechanical testing to verify composition and performance characteristics. This level of traceability is not merely procedural; it is a requirement for clients in military and Olympic-grade equipment manufacturing, where component failure is not an option.

Wuxi Lead Precision Machinery has supported projects demanding the highest standards of reliability and repeatability. Our involvement in supplying precision-molded components for Olympic athletic equipment underscores our commitment to performance under extreme conditions. Similarly, our work with defense contractors has required adherence to MIL-STD specifications, including rigorous non-destructive testing (NDT) protocols such as X-ray and ultrasonic inspection.

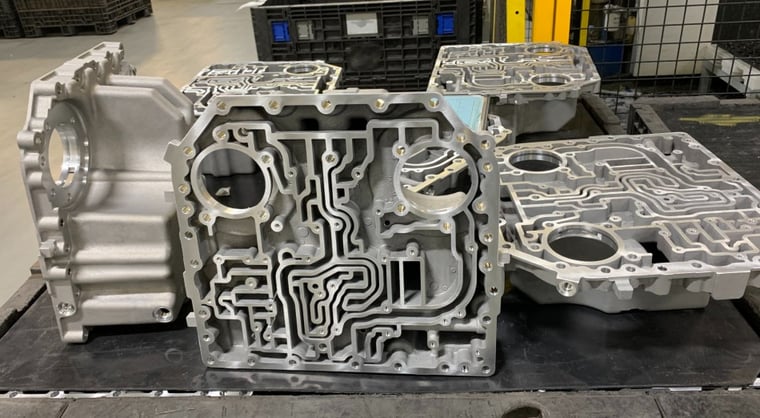

Our in-house capabilities span from mold design and CNC machining to die casting, low-pressure casting, and post-casting heat treatment. This vertical integration ensures full control over tolerances, surface finish, and dimensional stability. Whether producing lightweight structural housings or complex fluid manifolds, our process guarantees repeatability within ±0.02 mm, a benchmark that aligns with international precision standards.

The following table outlines key specifications and capabilities relevant to our aluminum molding processes:

| Parameter | Specification |

|---|---|

| Alloy Types | 6061, 7075, A356, ADC12 |

| Tolerance Range | ±0.02 mm to ±0.05 mm |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm (as-cast or machined) |

| Casting Processes | Die Casting, Low-Pressure Casting |

| Max Part Weight | 8 kg (Aluminum) |

| Post-Processing | T6 Heat Treatment, CNC Machining, Anodizing |

| Quality Standards | ISO 9001, MIL-STD-883, ASTM B26/B26M |

| Non-Destructive Testing | X-Ray, Ultrasonic, Dye Penetrant |

At Wuxi Lead Precision Machinery, precision is not a claim—it is engineered into every stage of production. For industries where performance is non-negotiable, our expertise in molding aluminum delivers components that meet the most exacting demands.

Precision Specs & Tolerances

Technical Capabilities: Precision Aluminum Molding at Wuxi Lead Precision Machinery

Aluminum molding for demanding industrial applications requires exceptional precision, material expertise, and rigorous quality control. At Wuxi Lead Precision Machinery, we specialize in transforming complex aluminum designs into high-integrity components through advanced manufacturing processes. Our core strength lies in integrating state-of-the-art multi-axis machining with stringent metrology, ensuring every part meets the exacting standards of aerospace, medical, and high-performance automotive sectors. Aluminum’s favorable strength-to-weight ratio and thermal properties present unique machining challenges; our dedicated processes are engineered to manage thermal expansion, chip evacuation, and surface finish requirements inherent to this versatile material.

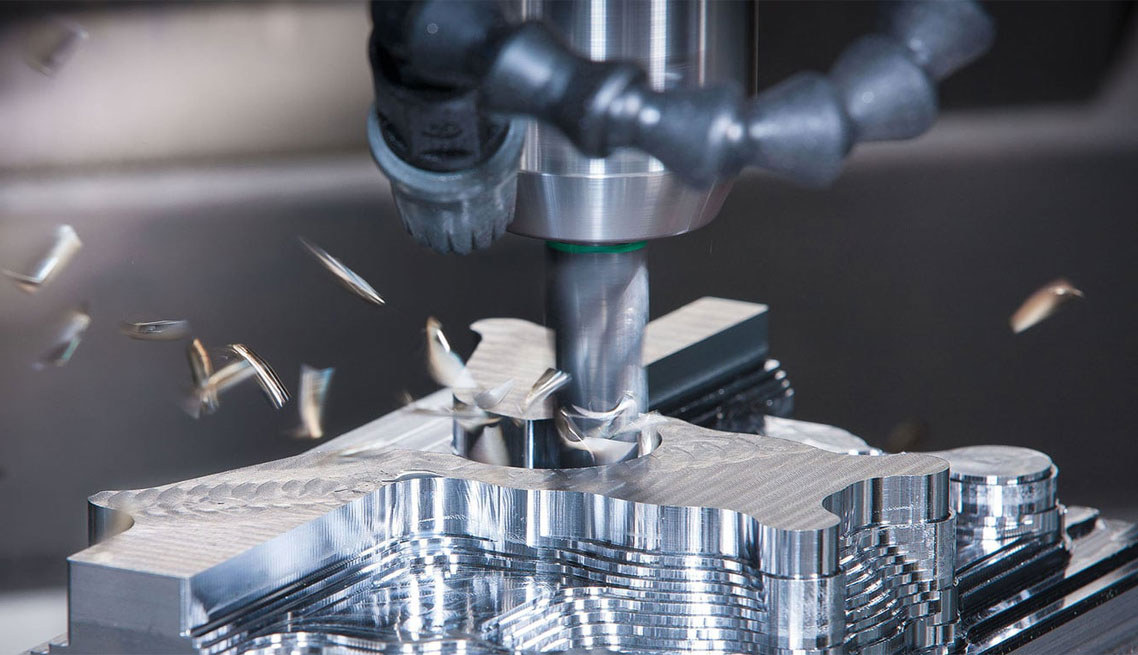

Central to our capability is a modern fleet of 5-axis CNC machining centers, including HAAS UMC and DMG MORI models. These systems enable simultaneous multi-axis motion, allowing us to machine intricate geometries, deep cavities, and complex undercuts in a single setup. This eliminates cumulative error from multiple fixtures, significantly improving positional accuracy and reducing lead times. Our programming leverages Mastercam and Siemens NX CAM for optimized toolpaths, minimizing cycle times while maximizing surface integrity and dimensional stability. Dedicated aluminum machining protocols, including high-speed spindles, specialized cutting tools, and optimized coolant strategies, ensure burr-free finishes and prevent material deformation during production.

Quality assurance is non-negotiable. Every critical dimension undergoes verification using our Zeiss CONTURA and Hexagon GLOBAL S-Class Coordinate Measuring Machines (CMMs). These systems provide sub-micron repeatability for comprehensive dimensional analysis, including GD&T verification, contour scanning, and first-article inspection reports compliant with AS9102 and PPAP requirements. Our CMM process is integrated into the manufacturing workflow, enabling real-time process control and immediate corrective action if deviations occur. This closed-loop system guarantees consistency across production runs, from prototype to high-volume orders.

The following table details our standard and achievable tolerance capabilities for critical features in precision aluminum molding. Actual tolerances are geometry-dependent and confirmed during engineering review.

| Feature | Standard Tolerance | Tight Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.05 | ±0.0125 | Up to 150mm length |

| Hole Diameter (mm) | ±0.025 | ±0.005 | Reamed/bored features |

| Positional Tolerance | ±0.05 | ±0.025 | Relative to datum system |

| Flatness (mm) | 0.05/100mm | 0.025/100mm | Critical sealing surfaces |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Machined finishes |

| Angularity (deg) | ±0.1 | ±0.05 | Relative to primary datum |

Our technical team collaborates closely with clients during the design phase to optimize manufacturability, ensuring tolerances are achievable without unnecessary cost. By combining 5-axis flexibility, material-specific process knowledge, and CMM-validated quality, Wuxi Lead delivers aluminum molding solutions that consistently exceed performance expectations. We transform complex engineering requirements into reliable, high-precision components ready for mission-critical assembly.

Material & Finish Options

Material Selection for High-Precision Aluminum Molding

In high-end custom metal manufacturing, material selection directly influences performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision molding of aluminum, steel, and titanium—each offering distinct advantages depending on the application. Aluminum remains the preferred choice for industries requiring lightweight strength, thermal conductivity, and corrosion resistance, such as aerospace, automotive, and consumer electronics.

Aluminum alloys, particularly 6061 and 7075, are widely used in molding processes due to their excellent machinability and structural integrity. 6061 aluminum provides good weldability and moderate strength, making it ideal for structural components and enclosures. In contrast, 7075 aluminum offers higher tensile strength, suited for high-stress applications like aerospace fittings and military hardware. Its lower corrosion resistance compared to 6061 is often mitigated through surface treatments such as anodizing.

Steel, particularly stainless steel grades like 304 and 17-4 PH, delivers superior hardness, wear resistance, and temperature tolerance. It is commonly selected for tooling, molds, and components exposed to harsh environments. While heavier than aluminum, steel ensures long service life under repetitive stress and elevated temperatures. Titanium, though more expensive and challenging to machine, provides an exceptional strength-to-density ratio and outstanding resistance to corrosion, especially in marine and biomedical applications.

Surface finishing plays a critical role in enhancing both functionality and aesthetics. Anodizing is the most prevalent finish for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving wear and corrosion resistance. It also allows for color customization through dye integration, beneficial for branding or identification in complex assemblies. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) delivers thicker, harder coatings for engineering applications requiring enhanced durability.

At Wuxi Lead, we integrate material science with precision CNC molding to deliver components that meet exact mechanical and environmental demands. Our engineering team collaborates with clients to select the optimal alloy and finish based on load requirements, operating conditions, and lifecycle expectations.

The following table summarizes key mechanical properties and applications of common materials used in precision molding:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications | Suitable Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | High | Enclosures, brackets, frames | Anodizing, powder coating |

| Aluminum 7075 | 572 | 2.8 | Moderate | Aerospace, military components | Hard anodizing, Alodine |

| Stainless Steel 304 | 505 | 8.0 | Very High | Medical devices, food processing | Passivation, polishing |

| Titanium Grade 5 | 900 | 4.5 | Excellent | Aerospace, implants, marine | Anodizing, thermal spray |

Material and finish selection is not a one-size-fits-all decision. At Wuxi Lead Precision Machinery, we apply decades of manufacturing expertise to guide clients toward optimal solutions—ensuring performance, reliability, and value in every molded component.

Manufacturing Process & QC

Wuxi Lead Precision Machinery executes precision aluminum molding through a rigorously controlled three-phase workflow, ensuring zero-defect outcomes for demanding industrial applications. Our integrated process eliminates traditional quality gaps between design intent and serial production.

Design phase begins with comprehensive digital analysis. We employ advanced simulation software to model thermal dynamics, material flow, and solidification behavior specific to aluminum alloys like A356 and 6061. This virtual prototyping identifies potential porosity, shrinkage, or distortion risks before tooling commences. Critical factors including optimal gating design, cooling channel placement, and thermal compensation algorithms are finalized. Our engineering team collaborates directly with client CAD data to implement Design for Manufacturing (DFM) refinements, ensuring geometric complexity aligns with molding physics and achieves specified tolerances down to ±0.02mm.

Prototyping transitions validated designs into physical validation. We utilize rapid tooling methods alongside direct metal laser sintering (DMLS) for initial cavities where justified. Each prototype undergoes full metrological inspection on 5-axis CMMs and CT scanning to verify internal integrity against simulation predictions. Dimensional reports, mechanical property testing (tensile strength, elongation), and surface finish analysis (Ra ≤ 0.8µm) are provided. This phase is iterative; any deviation triggers immediate process parameter adjustment or tooling modification, not design compromise.

Mass production leverages lessons from prototyping within a closed-loop quality system. Production cells feature real-time monitoring of melt temperature, injection speed, and clamp pressure. Statistical Process Control (SPC) charts track critical dimensions on every 10th part. Automated vision systems scan for surface defects, while in-line spectrometry verifies alloy composition per batch. Our zero-defect mandate is enforced through poka-yoke fixtures and mandatory first-article inspections per AS9102. All processes adhere strictly to ISO 9001:2015 and IATF 16949 standards, with full traceability from raw ingot to finished component.

The following table details critical process parameters maintained during high-integrity aluminum molding:

| Parameter | Standard Range | Control Method | Defect Prevention Target |

|---|---|---|---|

| Melt Temperature | 660°C – 720°C | Dual thermocouple monitoring | Minimize oxide formation |

| Injection Speed | 3 – 5 m/s | Servo-hydraulic closed-loop | Eliminate air entrapment |

| Shot Pressure | 80 – 120 MPa | Real-time pressure transducers | Prevent cold shuts |

| Mold Temperature | 180°C – 220°C | Integrated thermal cartridges | Control solidification rate |

| Cooling Time | 15 – 45 seconds | Flow meter & temp sensors | Reduce warpage & shrinkage |

| Dimensional Tolerance | ±0.02mm – ±0.05mm | Automated CMM verification | Zero out-of-spec parts |

This disciplined progression from simulation-validated design through physically proven prototyping to SPC-governed mass production forms the cornerstone of Wuxi Lead’s zero-defect guarantee. We transform complex aluminum molding challenges into consistently flawless industrial components.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Aluminum Molding Solutions

When it comes to high-performance aluminum molding in precision manufacturing, Wuxi Lead Precision Machinery stands at the forefront of innovation, quality, and engineering excellence. As a trusted leader in custom metal manufacturing, we specialize in delivering tailored aluminum molding solutions that meet the rigorous demands of aerospace, automotive, electronics, and industrial equipment sectors. Our advanced capabilities, combined with decades of technical expertise, ensure that every component we produce adheres to the highest standards of dimensional accuracy, surface finish, and structural integrity.

Aluminum molding requires more than just machinery—it demands a deep understanding of material behavior, thermal dynamics, and precision tooling. At Lead Precision, we integrate state-of-the-art CNC-controlled molding systems with proprietary process optimization techniques to deliver consistent, high-yield production. Whether you require low-volume prototypes or high-volume serial manufacturing, our team collaborates closely with clients to develop solutions that enhance performance, reduce weight, and streamline assembly.

Our facility in Wuxi, China, is equipped with fully automated molding lines, real-time quality monitoring, and in-house metallurgical analysis to ensure complete process control. We work with a wide range of aluminum alloys—including 6061, 7075, and A380—tailoring material selection and process parameters to your application’s mechanical and environmental requirements. From mold design and simulation to final inspection and surface treatment, every stage is executed with precision and documented for full traceability.

We understand that in today’s competitive market, speed-to-market and reliability are critical. That’s why we offer rapid prototyping, agile production scaling, and full project lifecycle support. Our engineering team provides DFM (Design for Manufacturability) analysis early in the development phase, minimizing risks and reducing time-to-production. With ISO 9001 and IATF 16949 certifications, we guarantee compliance with international quality standards across all deliverables.

Choose a partner who combines technical mastery with operational excellence. At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer performance.

Key Technical Capabilities

| Specification | Detail |

|---|---|

| Maximum Molding Force | 2,500 Tons |

| Part Weight Range | 50 g – 25 kg |

| Dimensional Accuracy | ±0.02 mm |

| Surface Finish | Ra 0.4 – 3.2 µm (customizable) |

| Aluminum Alloys Supported | 6061, 6082, 7075, A356, A380 |

| Production Capacity | Up to 5 million units/year |

| Secondary Operations | CNC Machining, Heat Treatment, Anodizing, Powder Coating |

| Quality Standards | ISO 9001, IATF 16949, RoHS Compliant |

Contact us today to discuss your next aluminum molding project. Our engineering team is ready to support you with technical consultation, material selection, and rapid quoting. Reach out to [email protected] and discover how Wuxi Lead Precision Machinery can elevate your manufacturing performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.