Technical Contents

Engineering Guide: Machining Companies

Precision Engineering: The Non-Negotiable Foundation of Modern Manufacturing

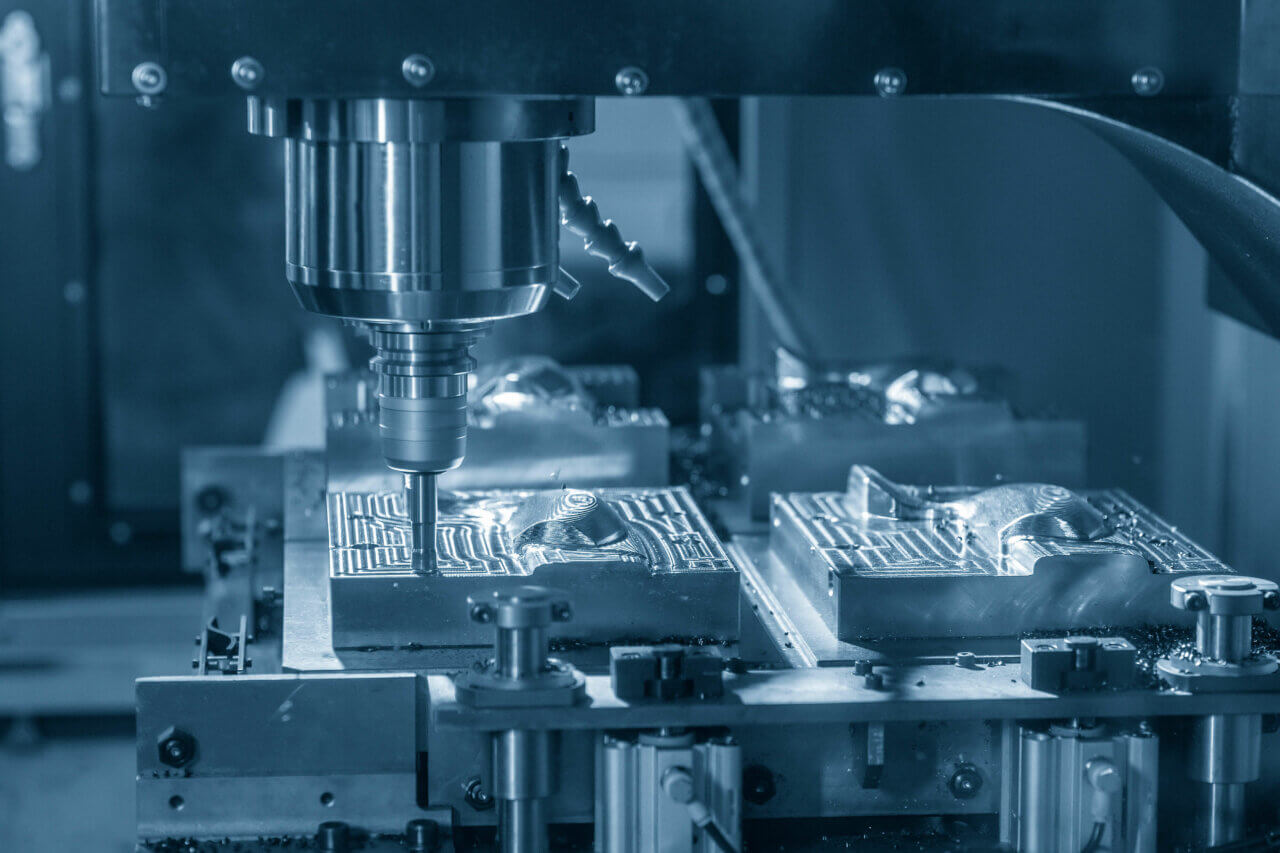

In the demanding landscape of custom metal manufacturing, precision transcends mere specification; it is the absolute cornerstone of component functionality, system reliability, and ultimate product success. For machining companies serving advanced sectors like aerospace, medical technology, and high-performance industrial equipment, achieving micron-level tolerances and exceptional surface integrity is not an option—it is a fundamental requirement dictated by the physics of operation and the relentless pursuit of efficiency. Modern engineering designs push materials to their limits, demanding parts that fit perfectly, perform predictably under extreme conditions, and contribute to the overall longevity of complex assemblies. Compromising on precision inevitably leads to premature failure, costly field repairs, and reputational damage that far outweighs any initial production savings. The ability to consistently deliver this level of accuracy requires far more than advanced machinery; it demands a deeply ingrained engineering culture, rigorous process control, and unwavering commitment to metrology throughout the entire manufacturing workflow.

Wuxi Lead Precision Machinery operates at this critical intersection of capability and expectation. Our engineering team possesses extensive, proven experience in delivering components where failure is not an option. This includes manufacturing mission-critical parts for Chinese military platforms, adhering strictly to demanding MIL-STD specifications where dimensional stability and material integrity under stress are paramount. Similarly, we contributed precision-engineered components for timing and structural systems utilized during the Beijing Olympic Games, meeting the exacting standards required for global-scale event reliability and safety. These high-stakes projects exemplify our systematic approach: integrating cutting-edge multi-axis CNC machining centers with in-process probing, environmental controls, and a closed-loop quality system validated by state-certified metrology labs. Every process, from material certification through final inspection, is engineered to eliminate variables and ensure repeatability.

The tangible output of this precision-focused methodology is reflected in our measurable capabilities. The following table outlines core performance metrics achievable across our production environment for critical client applications.

| Parameter | Capability Range | Application Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm to ±0.005 mm | Aerospace actuators, medical implants, optical mounts |

| Surface Roughness (Ra) | 0.1 μm to 0.8 μm | Hydraulic seals, bearing surfaces, fluid dynamics |

| Geometric Accuracy | < 0.002 mm (True Position) | Multi-part assemblies, high-speed rotating components |

| Material Range | Titanium, Inconel, Stainless Steels, Aluminum Alloys, High-Strength Steels | Defense, energy, semiconductor manufacturing |

| Critical Feature Repeatability | CpK > 1.67 (Sustained) | High-volume production of safety-critical parts |

Achieving such performance consistently requires viewing precision as an end-to-end engineering discipline, not merely a machining outcome. It involves proactive collaboration during the Design for Manufacturability (DFM) phase, selecting optimal toolpaths and cutting strategies to minimize thermal distortion, implementing rigorous in-process verification, and employing advanced metrology like CMM and optical comparators for final validation. For machining companies seeking partners capable of handling the most stringent requirements, the proven ability to deliver certified precision under real-world project constraints is the ultimate differentiator. Wuxi Lead Precision Machinery stands ready to apply its deep engineering expertise and disciplined processes to ensure your most demanding metal components meet and exceed the highest global standards.

Precision Specs & Tolerances

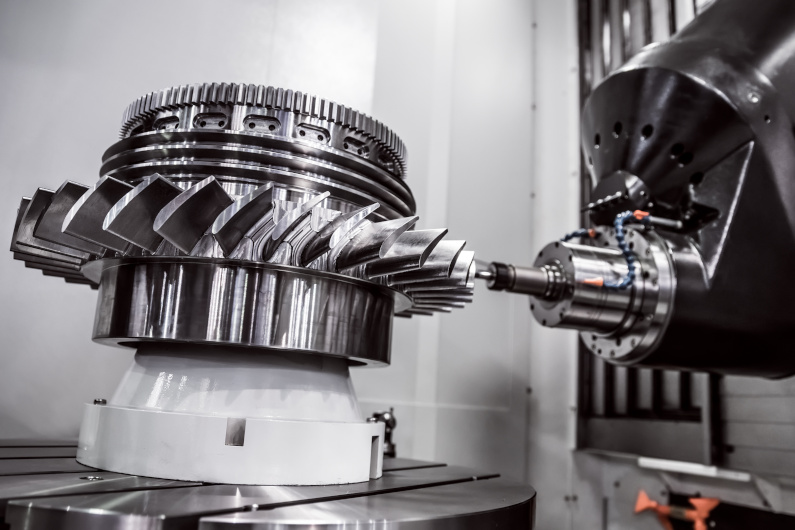

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the exacting demands of high-performance industries such as aerospace, medical, energy, and precision automation. At the core of our production infrastructure is a comprehensive suite of 5-axis CNC machining centers, enabling us to execute complex geometries with superior accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing tool access and reducing setup cycles. This capability is critical for producing intricate components with tight tolerances and organic contours that would be unachievable with conventional 3-axis methods.

Our 5-axis machining platforms are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems to ensure consistent performance and minimal thermal drift. Materials commonly processed include titanium alloys, Inconel, stainless steel, aluminum alloys, and specialty engineering metals, all machined under controlled environmental conditions to maintain dimensional stability. The integration of advanced CAM software enables optimized toolpaths, efficient material removal, and reduced cycle times—delivering both precision and cost-effectiveness for low-to-medium volume production runs.

Quality control is embedded throughout our manufacturing process, with a dedicated Coordinate Measuring Machine (CMM) inspection station forming the backbone of our metrology assurance. Utilizing a Zeiss CONTURA CMM with a VAST XT sensor, we perform full first-article inspections and batch sampling to validate geometric dimensions and tolerances per ISO 1101 standards. The CMM system supports both tactile and optical probing, allowing for comprehensive evaluation of internal features, thread forms, positional tolerances, and surface profiles. All inspection data is documented in detailed quality reports, traceable to individual work orders and customer specifications.

To ensure consistency and transparency, the following table outlines our standard machining tolerances based on material, feature type, and production method. These values represent our typical capability under stable process control; tighter tolerances are achievable upon engineering review and process validation.

| Feature Type | Standard Tolerance | Material Range | Process Method |

|---|---|---|---|

| Linear Dimensions (machined) | ±0.005 mm | Steel, Stainless, Ti, Al | 5-Axis CNC |

| Hole Diameter (drilled) | ±0.01 mm | Steel, Aluminum | CNC Drilling |

| Hole Diameter (reamed) | ±0.005 mm | All | CNC Reaming |

| Positional Tolerance | ±0.01 mm | All | 5-Axis CNC + CMM |

| Flatness | 0.01 mm per 100 mm | Steel, Stainless, Ti | Precision Milling |

| Surface Roughness (Ra) | 0.8 µm (typical) | All | Finish Machining |

| Angular Features | ±0.05° | All | 5-Axis Simultaneous |

All processes are supported by full documentation, process capability studies (Cp/Cpk), and non-conformance management in accordance with ISO 9001:2015 standards. Wuxi Lead Precision Machinery combines cutting-edge equipment with rigorous quality assurance to deliver custom metal components that meet the highest benchmarks in dimensional accuracy and repeatability.

Material & Finish Options

Strategic Material Selection for Precision Machined Components

Choosing optimal materials is foundational to achieving performance, cost efficiency, and longevity in custom metal manufacturing. At Wuxi Lead Precision Machinery, we guide clients through critical trade-offs between aluminum, steel, and titanium based on application demands, environmental exposure, and production economics. An incorrect selection directly impacts tool life, cycle time, secondary processing costs, and final part reliability. Understanding core material properties ensures your design intent translates into a manufacturable, high-value component.

The following table summarizes key characteristics for common high-performance alloys we machine to tight tolerances:

| Material Grade | Tensile Strength (MPa) | Machinability Rating | Primary Applications |

|---|---|---|---|

| Aluminum 6061-T6 | 310 | Excellent (65) | Aerospace brackets, hydraulic manifolds, enclosures |

| Stainless Steel 304 | 515 | Fair (41) | Medical instruments, food processing, chemical valves |

| Titanium Ti-6Al-4V | 900 | Poor (36) | Aircraft landing gear, biomedical implants, marine hardware |

Aluminum 6061-T6 remains the industry benchmark for cost-sensitive, high-volume applications requiring good strength-to-weight ratio and excellent machinability. Its thermal conductivity facilitates rapid heat dissipation during milling, reducing tool wear and enabling aggressive feed rates. This alloy accepts standard anodizing processes effectively, providing durable, corrosion-resistant finishes in various colors essential for both functional and aesthetic requirements. Avoid aluminum for high-temperature or extreme wear scenarios exceeding 150°C.

Stainless steel 304 delivers superior corrosion resistance and mechanical strength for demanding environments. While harder to machine than aluminum, generating more heat and requiring rigid setups, its non-magnetic properties and FDA compliance make it indispensable for medical and food-grade components. Note that standard anodizing is ineffective on steel; alternative finishes like passivation, electropolishing, or specialized coatings are necessary for enhanced corrosion protection.

Titanium Ti-6Al-4V offers exceptional strength-to-weight ratio and biocompatibility but presents significant machining challenges. Its low thermal conductivity causes heat concentration at the cutting edge, accelerating tool degradation and demanding specialized toolpaths and coolant strategies. Titanium cannot be anodized using standard aluminum processes; alternative surface treatments like plasma electrolytic oxidation (PEO) are required for wear resistance. Reserve titanium for mission-critical aerospace or medical applications where its premium cost is justified by performance.

Anodizing remains the dominant finish for aluminum parts, creating a hard, porous oxide layer that enhances corrosion resistance and accepts dyes. Type II (sulfuric acid) offers standard protection and coloration, while Type III (hardcoat) provides superior abrasion resistance for high-wear components. Crucially, anodizing specifications must be defined early in design, as the process adds dimensional tolerance considerations and requires proper racking points.

Material selection directly dictates manufacturability and total cost of ownership. Partner with Wuxi Lead Precision Machinery during the design phase to evaluate material suitability against your functional requirements, environmental factors, and production volume. Our engineering team provides detailed DFM analysis to prevent costly material-related rework and ensure optimal finish integration. Contact us for a technical consultation on your next precision machining project.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, we have engineered a seamless, high-precision production process that transforms conceptual designs into flawless, mass-produced metal components. Our methodology is built on three core stages—Design, Prototyping, and Mass Production—each governed by strict quality control protocols to achieve zero defects in every deliverable.

The process begins with Design, where our engineering team collaborates closely with clients to interpret technical drawings, 3D CAD models, and performance requirements. Utilizing advanced simulation software, we analyze structural integrity, material behavior, and manufacturability to optimize part geometry and ensure compliance with industry standards. This stage is critical for identifying potential issues before physical production begins, significantly reducing risk and rework.

Following design validation, we proceed to Prototyping. Using CNC milling, turning, and multi-axis machining centers, we produce functional prototypes from the same materials intended for final production. These prototypes undergo rigorous testing, including dimensional inspection via coordinate measuring machines (CMM), surface finish analysis, and in-application performance evaluation. Feedback from this phase is integrated into final design refinements, ensuring that every detail meets or exceeds client specifications.

Once the prototype is approved, we transition to Mass Production. Our 20,000 m² facility in Wuxi is equipped with over 120 automated CNC machines, robotic material handling systems, and real-time process monitoring. This enables consistent output at volumes ranging from hundreds to hundreds of thousands of parts annually. Throughout production, statistical process control (SPC) systems track key parameters such as tool wear, temperature variance, and dimensional drift, allowing immediate corrective action to maintain tolerance integrity.

To guarantee zero defects, we implement a multi-layered quality assurance framework. Every component undergoes 100% visual inspection and batch-based metrology checks. Our quality management system is ISO 9001:2015 certified, and we adhere to IATF 16949 standards for automotive applications. With full traceability from raw material to finished part, we ensure complete accountability across the supply chain.

The following table outlines key capabilities across our production process:

| Parameter | Specification |

|---|---|

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, Carbon Steel, Alloy Steel |

| Tolerances Achieved | ±0.005 mm |

| Surface Finish | Ra 0.2 – 3.2 µm (customizable) |

| Max Part Dimensions | 800 × 600 × 500 mm |

| Production Capacity | Up to 500,000 units/year |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Mass Production) | 15–30 days (volume-dependent) |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS, REACH |

From initial concept to final delivery, Wuxi Lead Precision Machinery ensures precision, repeatability, and uncompromising quality. Our integrated process eliminates variability, reduces time-to-market, and delivers custom metal components that perform reliably in the most demanding industrial environments.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Component Excellence

In the demanding landscape of precision manufacturing, selecting a partner capable of transforming complex engineering specifications into flawless metal components is critical. Wuxi Lead Precision Machinery stands as your definitive solution for high-mix, low-volume custom metal manufacturing where tolerances are non-negotiable and material integrity is paramount. We specialize in bridging the gap between intricate design intent and physical reality for aerospace, medical device, semiconductor, and advanced industrial clients who require zero-defect delivery. Our integrated approach combines German-engineered CNC technology with rigorous process control, ensuring every component meets or exceeds AS9100 and ISO 13485 standards. This is not contract manufacturing; it is precision engineering executed as a collaborative partnership.

Our technical capabilities are engineered for the most challenging applications. We deploy a monitored fleet of multi-axis milling and turning centers with sub-micron repeatability, supported by in-house metrology labs featuring CMMs, optical comparators, and surface roughness testers. Material expertise spans aerospace-grade aluminum alloys, medical titanium, hardened stainless steels, and exotic superalloys, all processed under controlled environmental conditions. The table below summarizes our core production parameters for immediate reference:

| Parameter | Capability Range |

|---|---|

| Tolerance Control | ±0.005 mm (±0.0002″) |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24″) |

| Surface Finish (Ra) | 0.2 – 1.6 μm (8 – 63 μin) |

| Materials Processed | Aluminum, Titanium, Stainless Steel, Inconel, Brass, Plastics |

| Certifications | ISO 9001, ISO 13485, AS9100 Rev D |

This technical foundation is augmented by our engineering-first engagement model. We initiate every project with a Design for Manufacturability (DFM) review, identifying potential production risks before machining begins. Our CNC programmers and tooling specialists collaborate directly with your design team to optimize part geometry, reduce cycle times, and eliminate secondary operations—translating to faster time-to-market and lower total cost of ownership. Real-time production data is shared via secure client portals, providing full traceability from raw material certification to final inspection reports. For mission-critical components, we implement First Article Inspection (FAI) protocols per AS9102 standards without additional cost.

The true differentiator lies in our commitment to becoming an extension of your engineering department. We understand that precision manufacturing is not merely about hitting dimensions; it is about solving unspoken challenges in thermal stability, microstructure integrity, and long-term component performance. Our engineers proactively suggest material substitutions or process adjustments that enhance functionality while maintaining compliance with stringent industry regulations. This consultative approach has reduced scrap rates by up to 37% for clients in regulated sectors over the past 18 months.

When component failure is not an option, partner with an organization where precision is the baseline, not the aspiration. Contact our engineering team directly to initiate a technical assessment of your most complex manufacturing challenge. Submit your CAD files and specifications to [email protected] for a detailed capability analysis within 24 business hours. Let us demonstrate how Wuxi Lead Precision Machinery delivers not just parts, but provable engineering value through every machining cycle. Your next breakthrough component begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.