Technical Contents

Engineering Guide: Injection Molding Process Training

Engineering Insight: Precision as the Non-Negotiable Core of Injection Molding Training

Achieving true excellence in injection molding transcends merely operating machinery; it demands an ingrained, systematic understanding of precision at every process stage. For high-value custom metal manufacturing, particularly in sectors where failure is not an option, tolerances measured in microns dictate success. Generic training often overlooks the critical interplay between machine capability, material science, thermal dynamics, and real-time process control. At Wuxi Lead Precision Machinery, our foundational training philosophy centers on this reality: precision isn’t a target, it’s the operational baseline. We instill in engineers and technicians that minute deviations in melt temperature, injection speed, packing pressure, or cooling rate propagate into significant part defects – warpage, sink marks, or compromised structural integrity – unacceptable in mission-critical applications.

Our training methodology is forged in the crucible of the most demanding specifications. Having supplied components meeting stringent Olympic-standard tolerances for precision sporting equipment and adhering to rigorous military-grade requirements for defense systems, we understand the absolute necessity of process repeatability and material consistency. This experience directly informs our curriculum, moving beyond theoretical concepts to practical mastery of achieving and verifying micron-level accuracy under production conditions. Trainees learn not just how to set parameters, but why specific values are critical for the material and geometry, utilizing advanced process monitoring systems to detect and correct micro-variations before they impact output. The consequence of imprecision in aerospace, medical, or defense components is catastrophic; our training eliminates ambiguity, ensuring every cycle meets the uncompromising standards demanded by these industries.

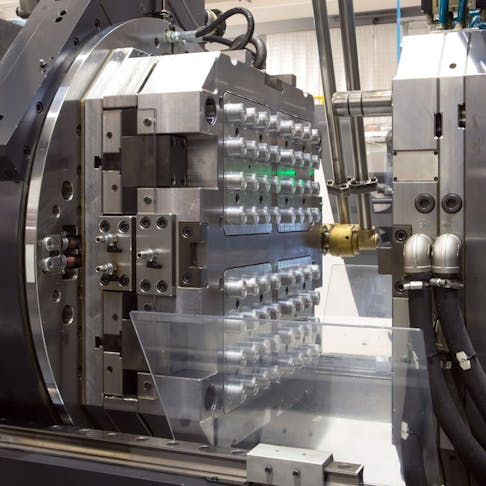

True precision engineering requires machinery engineered to sustain it. Our training emphasizes the direct correlation between machine specification and achievable part quality. Understanding the capabilities and limitations of the molding platform is paramount. The table below outlines key specifications inherent to Wuxi Lead’s high-precision molding systems, which form the practical foundation of our advanced training modules:

| Specification | Typical High-Precision Range | Critical Impact on Part Quality |

|---|---|---|

| Clamp Force | 500 – 2500 Tons | Prevents flash, ensures cavity integrity under pressure |

| Shot Weight (PS) | 500 – 5000 grams | Enables consistent filling of complex, high-precision geometries |

| Repeatability (Weight) | ±0.01% – ±0.03% | Directly correlates to dimensional stability and material consistency |

| Melt Temperature Control | ±1°C | Critical for material viscosity, flow, and final mechanical properties |

| Injection Rate Control | ±0.5% | Governs fill pattern, weld line strength, and internal stresses |

| Tool Steel (Standard) | H13 / Pre-hardened | Ensures thermal stability and longevity for micron-tolerance molds |

This technical rigor, combined with our proven experience delivering under the highest scrutiny, defines Wuxi Lead’s injection molding process training. We equip your engineering teams with the disciplined precision mindset and actionable skills required to transform complex designs into flawless, high-integrity metal components, consistently meeting the exacting demands of elite global manufacturing. Precision isn’t taught as a concept here; it’s engineered into every lesson and validated on the production floor.

Precision Specs & Tolerances

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the exacting demands of high-performance industries such as aerospace, medical devices, automotive, and industrial automation. As a leader in custom metal manufacturing, we integrate advanced 5-axis CNC machining with comprehensive quality assurance protocols to deliver components that adhere to the strictest dimensional and geometric tolerances. Our facility in Wuxi, China, operates with a focus on precision, repeatability, and process integrity, ensuring that every part produced meets international standards for performance and reliability.

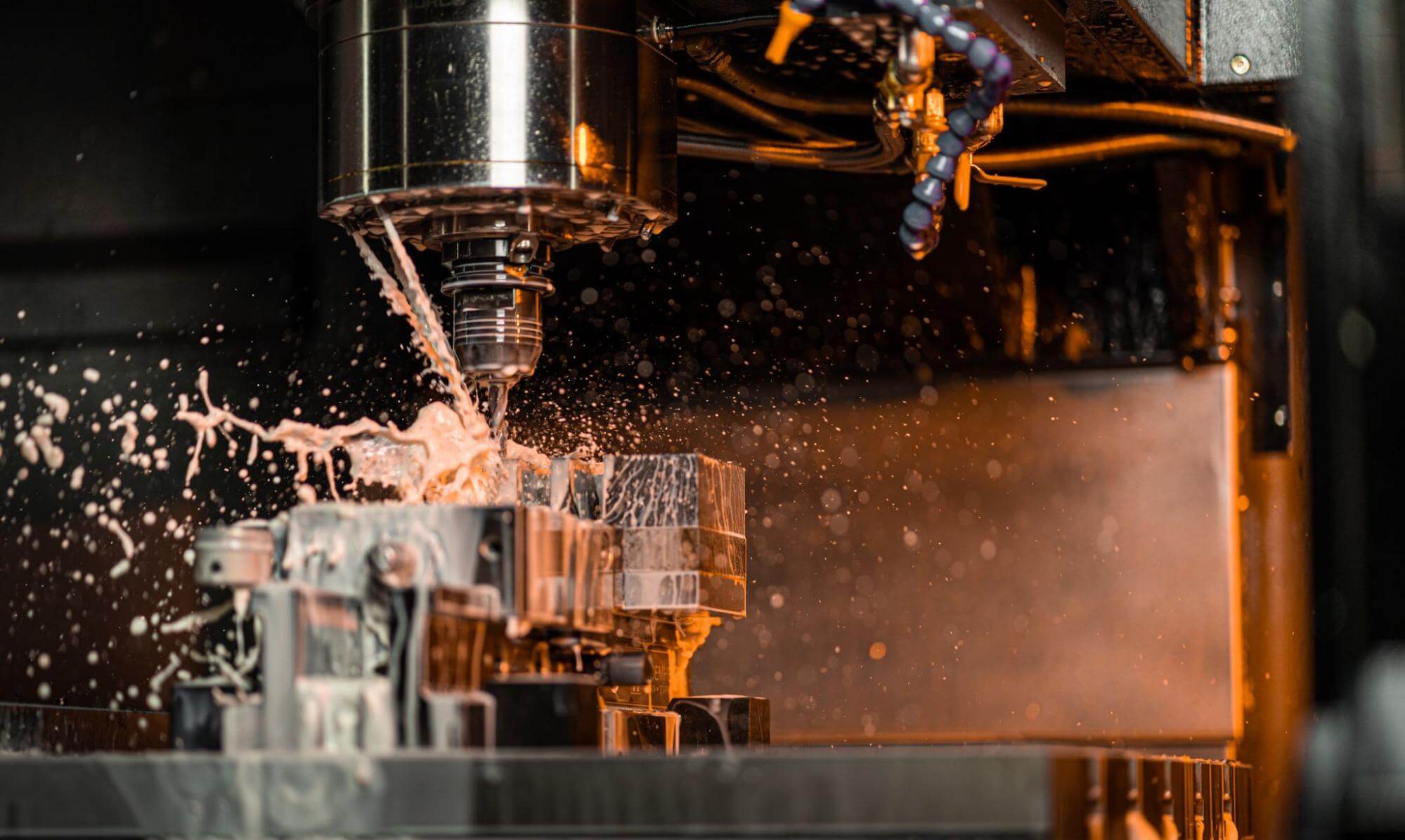

Our 5-axis CNC machining centers provide full simultaneous motion across all five axes, enabling the production of complex geometries with minimal setup and reduced cycle times. This advanced capability allows for intricate contouring, deep cavity milling, and multi-face machining in a single setup, significantly improving accuracy and surface finish. We work with a wide range of engineering-grade metals, including aluminum alloys, stainless steels, titanium, and high-temperature superalloys, ensuring material compatibility with demanding operational environments.

To maintain the highest level of quality, every component undergoes rigorous inspection using state-of-the-art Coordinate Measuring Machine (CMM) technology. Our CMM systems are calibrated to ISO 17025 standards and operated by certified metrology technicians. These systems provide full 3D measurement validation, ensuring compliance with GD&T (Geometric Dimensioning and Tolerancing) requirements and generating detailed inspection reports traceable to each production batch. In addition to CMM, we utilize optical comparators, surface roughness testers, and hardness gauges to verify both dimensional and material properties.

Our process control extends beyond equipment and inspection. We implement real-time tool wear monitoring, in-process probing, and thermal compensation systems within our CNC machines to maintain stability across long production runs. This integrated approach to precision manufacturing ensures minimal variation and maximum consistency, even for low-volume, high-mix production scenarios.

The following table outlines the standard tolerances we consistently achieve across our machining operations:

| Feature Type | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 500 mm length |

| Geometric Tolerances | ±0.02 mm (GD&T) | ±0.01 mm | Includes flatness, roundness, runout |

| Hole Diameter | ±0.01 mm | ±0.005 mm | Reamed or honed features |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Relative to datum |

| Surface Roughness (Ra) | 3.2 µm | 0.4 µm | Machined finish; polishing available |

| Angular Features | ±0.05° | ±0.01° | Verified via CMM and optical methods |

These capabilities are supported by a robust quality management system compliant with ISO 9001:2015 standards. At Wuxi Lead Precision Machinery, we do not simply manufacture parts—we engineer precision solutions backed by data, traceability, and technical excellence.

Material & Finish Options

Material Selection for Precision Injection Molds: Aluminum, Steel, and Titanium

Material selection is a foundational engineering decision directly impacting injection mold performance, longevity, and part quality. At Wuxi Lead Precision Machinery, our engineering teams prioritize matching material properties to specific production demands, balancing cycle time, part complexity, volume, and cost. Understanding the core characteristics of Aluminum, Tool Steel, and Titanium is critical for optimizing your molding process.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer significant advantages for prototyping and low-to-medium volume production. Their high thermal conductivity accelerates cooling cycles, directly reducing part cycle times. This property, combined with excellent machinability, allows for faster mold fabrication and intricate cavity details. While ultimate hardness is lower than steel, properly heat-treated aluminum provides sufficient wear resistance for many applications, especially when enhanced with surface treatments. Aluminum molds are cost-effective for initial production runs and design validation.

Tool steels, including P20, H13, and S136, remain the industry standard for high-volume production. Their superior hardness and wear resistance ensure dimensional stability over millions of cycles, maintaining tight tolerances critical for complex geometries. Steels offer excellent polishability for optical or cosmetic surfaces and withstand higher injection pressures. The trade-off is slower thermal conductivity compared to aluminum, requiring optimized cooling channel design. Proper selection of the specific steel grade is paramount; corrosion-resistant grades like S136 are essential for PVC or flame-retardant materials, while H13 excels in high-temperature applications.

Titanium alloys, primarily Ti-6Al-4V, present a specialized solution for extreme conditions. Their exceptional strength-to-weight ratio, outstanding corrosion resistance against aggressive resins and chemicals, and biocompatibility make them ideal for medical, aerospace, and highly corrosive environments. While significantly more expensive and challenging to machine than steel, titanium’s non-galling properties and thermal stability justify its use where other materials fail prematurely. Its application is typically reserved for critical, high-value components demanding maximum mold life under harsh conditions.

Surface finishing, particularly anodizing, is integral to aluminum mold performance. Type II (sulfuric acid) anodizing creates a hard, wear-resistant oxide layer significantly improving surface durability and release properties. This treatment mitigates aluminum’s susceptibility to wear and galling during ejection, extending mold life in production scenarios. Anodizing also enhances corrosion resistance, crucial when processing certain additives or in humid environments. The specific anodizing process parameters must be precisely controlled to achieve the required coating thickness and hardness without compromising dimensional accuracy.

The optimal material choice requires a detailed analysis of your specific application. Below is a comparative overview of key properties:

| Material | Density (g/cm³) | Hardness (HB) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Mold Applications |

|---|---|---|---|---|---|

| Aluminum 7075 | 2.81 | 150 | 130 | Moderate (Raw) | Prototypes, Low/Med Volume |

| High (Anodized) | Rapid Production Tools | ||||

| Tool Steel H13 | 7.80 | 229 | 36 | Moderate | High Temp, High Pressure, Med/Large Volume |

| Tool Steel S136 | 7.80 | 215 | 28 | High | Corrosive Resins, Optical, Medical |

| Titanium Ti-6Al-4V | 4.43 | 363 | 7.2 | Exceptional | Extreme Corrosion, Medical, Aerospace |

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to guide clients through this critical selection process. We ensure the chosen material and finish align precisely with your production goals, maximizing ROI through enhanced mold performance and longevity. Contact our engineering team for a tailored material assessment for your next mold project.

Manufacturing Process & QC

Design: Engineering Precision from Concept to CAD

The foundation of a flawless injection molding process begins with precision engineering during the design phase. At Wuxi Lead Precision Machinery, our design engineers utilize advanced 3D CAD software to translate client specifications into manufacturable, high-tolerance metal components. Every geometry, draft angle, and wall thickness is optimized to ensure moldability, structural integrity, and long-term performance. Finite Element Analysis (FEA) is applied to simulate stress, thermal behavior, and flow dynamics, minimizing the risk of defects such as warping or sink marks. Design for Manufacturing (DFM) reviews are conducted collaboratively with clients to refine part geometry, select optimal materials, and ensure alignment with production goals. This proactive approach eliminates costly revisions and accelerates time-to-market.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using high-precision CNC machining and soft tooling methods. This stage is critical for physical validation of form, fit, and function. Prototypes are subjected to rigorous testing, including dimensional inspection via Coordinate Measuring Machines (CMM), material property verification, and functional performance under simulated operating conditions. Any deviations are analyzed and corrected digitally before tooling release. Our closed-loop feedback system ensures that prototype data directly informs final mold design, guaranteeing that the transition to mass production is seamless and defect-free. This iterative validation process is central to our Zero Defects philosophy.

Mass Production: Consistency Through Automation and Control

With design and prototyping successfully completed, we initiate high-volume injection molding using custom-engineered molds crafted from premium-grade tool steels. Our production lines integrate fully automated molding machines with real-time process monitoring systems. Parameters such as melt temperature, injection pressure, cooling time, and clamp force are continuously logged and controlled within tight tolerances. In-line vision systems and automated metrology ensure 100% inspection of critical dimensions, while statistical process control (SPC) enables predictive maintenance and immediate corrective action. Each batch is traceable through our ERP system, supporting full documentation for quality audits and compliance.

Process Specifications

| Parameter | Specification Range |

|---|---|

| Material Options | Stainless Steel, Aluminum Alloys, Tool Steels, Copper Alloys |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (polished to as-machined) |

| Mold Lifespan | 500,000+ cycles (P20/H13 steel, treated) |

| Production Capacity | 1,000 – 500,000 units/month |

| Quality Standard | ISO 9001:2015, PPAP, FAI, 8D Reporting |

| Lead Time (Design to Ship) | 4–8 weeks (varies by complexity) |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery ensures zero-defect delivery for mission-critical metal components in aerospace, medical, and industrial automation sectors.

Why Choose Wuxi Lead Precision

Elevate Your Injection Molding Capabilities Through Strategic Partnership

Wuxi Lead Precision Machinery stands as your definitive partner for advanced injection molding process training, engineered specifically for high-stakes industrial applications. Our programs transcend theoretical instruction, delivering hands-on mastery within a real-world production environment. We address critical pain points—material waste, cycle time inefficiencies, and dimensional instability—by embedding proven methodologies directly into your operational workflow. This approach ensures immediate ROI through reduced scrap rates and accelerated time-to-market for precision metal components. As a vertically integrated Chinese manufacturer with ISO 9001 and IATF 16949 certifications, we combine rigorous quality control with strategic cost advantages, eliminating the compromise between excellence and affordability.

Our training leverages cutting-edge infrastructure designed for complex metal injection molding (MIM) and high-tolerance polymer applications. Participants gain exclusive access to our production floor, operating machinery calibrated to aerospace and medical device standards. The following specifications reflect the industrial-grade equipment central to your curriculum:

| Parameter | Specification Detail | Industrial Relevance |

|---|---|---|

| Machine Tonnage Range | 50–2000 tons | Supports micro-components to large structural parts |

| Positioning Accuracy | ±0.002 mm | Ensures repeatable precision for critical tolerances |

| Material Compatibility | Engineering polymers, MIM feedstocks, LSR | Covers 95% of industrial material requirements |

| Process Monitoring | Real-time cavity pressure sensors | Enables data-driven defect root-cause analysis |

| Custom Tooling Support | In-house EDM and hard milling | Guarantees seamless transition from training to production |

This technical foundation allows us to tailor curricula to your exact challenges—whether optimizing gate design for zero-flash molding, mastering multi-component overmolding, or implementing statistical process control for batch consistency. Our engineers, with 15+ years in Tier 1 automotive and medical device manufacturing, translate complex principles into actionable protocols. You receive not just training, but a documented process validation framework compliant with AS9100 and ISO 13485 requirements.

Initiate your transformation with a no-obligation technical consultation. Contact our Applications Engineering Team at [email protected] to schedule a facility tour or request a customized training proposal. Specify your component material, volume requirements, and current yield challenges to receive a competency roadmap within 48 hours. Wuxi Lead Precision Machinery operates on a transparent engagement model—no hidden fees, no generic templates. We measure success by your production line’s performance uplift, cementing partnerships that drive measurable competitive advantage in global markets. Partner with us to convert injection molding from a production step into your strategic quality differentiator.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.