Technical Contents

Engineering Guide: Small Run Injection Molding

Engineering Insight Precision Imperatives in Small Run Injection Molding

Small run injection molding presents unique precision challenges distinct from high-volume production. While mass manufacturing leverages process stabilization over thousands of cycles, low-volume batches demand immediate, consistent accuracy from the first shot. Minor deviations in mold geometry, material flow, or thermal management become critically amplified when producing only dozens or hundreds of parts. Tolerances that might be manageable in large runs translate directly into functional failure or assembly rejection in specialized applications. The cost of rework or scrap in small batches is disproportionately high, eroding margins and delaying time-sensitive projects. Achieving micron-level repeatability requires not just advanced machinery, but deep process understanding and rigorous real-time metrology – capabilities often overlooked by standard molding suppliers.

At Wuxi Lead Precision Machinery, we engineer small run molding solutions specifically for mission-critical metal components where precision is non-negotiable. Our approach integrates ultra-stable Swiss and German molding platforms with in-house tooling expertise and closed-loop quality control. Every process parameter – from barrel temperature profiles to injection velocity curves and cooling cycle dynamics – is meticulously modeled and validated before production commences. This eliminates the traditional “ramp-up” phase, ensuring Part #1 meets the same stringent specifications as Part #100. Our facility’s ISO 9001-certified environment and Class 10,000 cleanroom capabilities further guarantee dimensional stability and surface integrity, essential for aerospace, medical, and defense applications.

Our proven capability in extreme precision contexts underscores this commitment. We successfully manufactured hermetically sealed connectors for military communication systems requiring ±0.01mm tolerances under extreme vibration and thermal cycling. Similarly, we produced critical structural components for the Beijing Winter Olympics infrastructure, where thermal expansion coefficients had to be precisely controlled within 0.005mm across fluctuating alpine conditions. These projects demanded not only tight tolerances but absolute consistency across small batches – a standard we apply universally to every client’s small run requirement.

The table below outlines key precision specifications achievable for small run metal injection molding at Lead Precision:

| Specification Parameter | Standard Precision Range | High-Precision Capability (Olympic/Military Grade) |

|---|---|---|

| Dimensional Tolerance | ±0.025mm | ±0.005mm (Critical Features) |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Material Density Consistency | 98.5% | 99.8% |

| Batch-to-Batch Repeatability | CpK ≥ 1.33 | CpK ≥ 1.67 |

| Typical Lead Time (Tooling + 100 Parts) | 25-30 Days | 15-20 Days |

This level of control transforms small run molding from a necessary compromise into a strategic advantage. It enables rapid prototyping validation, low-risk production of legacy parts, and economical manufacturing of complex, high-value components without sacrificing reliability. For applications where failure is not an option, precision in small volumes is the foundation of performance. Contact our engineering team to discuss how our validated processes ensure your critical specifications are met, consistently, from the very first part.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in small run injection molding applications that demand precision, repeatability, and rapid turnaround. Our integrated production environment combines state-of-the-art 5-axis CNC machining with comprehensive quality control systems to ensure every component meets the exacting standards required by aerospace, medical, and high-performance industrial sectors.

At the core of our machining capability is a modern fleet of 5-axis CNC centers, enabling us to produce complex geometries with superior surface finish and dimensional accuracy. These machines allow simultaneous multi-axis movement, reducing setup times and minimizing cumulative tolerances associated with multiple operations. This is particularly critical in small batch production, where flexibility and precision are paramount. Our programming team utilizes advanced CAM software to optimize toolpaths, ensuring efficient material removal and maintaining tight tolerances across intricate features.

Every component produced undergoes a rigorous quality assurance process anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide full 3D metrology validation, capturing critical dimensions, geometric tolerances, and surface characteristics with micron-level resolution. This data is documented per customer requirements and available with each shipment, offering full traceability and compliance with ISO 9001 standards. In addition to CMM, we employ visual inspection, surface roughness testing, and first-article inspection protocols to guarantee consistency from prototype to final part.

Our small run injection molding support extends beyond mold fabrication to include precision machining of inserts, cores, and cavities in hardened and pre-hardened tool steels, aluminum, and specialty alloys. We understand that even in low-volume production, mold longevity and part consistency are essential. By combining high-speed 5-axis machining with precision electrode EDM preparation, we ensure optimal mold performance and reduced cycle times.

The table below outlines the typical tolerances achievable across our machining and inspection processes.

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Geometric Tolerances (GD&T) | ±0.012 mm | ±0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Angular Tolerances | ±0.05° | ±0.02° |

| Hole Diameter (Drilled) | ±0.01 mm | ±0.005 mm (Reamed) |

| Positional Accuracy | ±0.01 mm | ±0.003 mm |

| CMM Measurement Uncertainty | ≤ 0.0025 mm (k=2) | N/A |

These capabilities are supported by a skilled engineering team with over 15 years of experience in precision tooling and custom metalwork. At Wuxi Lead Precision Machinery, we treat every small run as a high-integrity project, applying the same rigor to prototype batches as we do to full-scale production. This commitment ensures our clients receive injection molding solutions that are not only precise but also scalable and reliable.

Material & Finish Options

Material Selection Fundamentals for Precision Injection Molds

Selecting optimal materials for small-run injection molding tooling directly impacts part quality, mold longevity, and project economics. At Wuxi Lead Precision Machinery, we prioritize metals balancing machinability, thermal performance, and durability for low-volume production. Aluminum offers rapid machining and excellent thermal conductivity, ideal for prototype molds or short production cycles under 10,000 shots. Steel provides superior hardness and wear resistance for medium-run applications exceeding 50,000 cycles, particularly with abrasive resins. Titanium delivers exceptional strength-to-weight ratio and corrosion resistance for highly corrosive polymers or weight-sensitive aerospace applications, though its machining complexity requires specialized expertise. Material choice must align with resin type, part geometry, and expected cycle count to avoid premature mold failure or excessive costs.

Key mechanical properties guide critical decisions. The following table compares standard grades we machine for mold construction:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Relative Cost |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Moderate | Excellent (A1) | Low |

| Steel 4140 | 7.85 | 655 | Low | Good (B) | Medium |

| Titanium Ti-6Al-4V | 4.43 | 900 | Excellent | Fair (C) | High |

Anodizing for Performance Enhancement

Surface finishing is non-negotiable for mold performance in small runs. Anodizing aluminum molds significantly increases surface hardness and wear resistance while improving release properties. Type II (sulfuric acid) anodizing provides a standard protective layer up to 25µm thick, suitable for most commodity resins. For engineering plastics like nylon or PVC requiring extreme corrosion resistance, Type III (hardcoat) anodizing delivers 50µm+ coatings with 600+ HV hardness. This process minimizes galling during ejection and extends mold life by 30-50% in demanding applications. Note that steel molds typically require nitriding or PVD coatings instead, while titanium benefits from specialized passivation treatments.

Strategic Implementation

Material and finish selection must be integrated with CNC machining strategy from day one. Aluminum’s softness allows aggressive cutting parameters, reducing lead times by 40% versus steel for equivalent molds. Titanium demands slower feeds and specialized toolpaths to prevent work hardening—a capability our 5-axis mills excel at. For small runs, we recommend aluminum with Type III anodizing as the optimal balance of speed, cost, and durability for 5,000–25,000 shots. When resin abrasiveness or cycle requirements exceed this threshold, pre-hardened steel becomes economically justified. Wuxi Lead’s engineering team provides material validation reports with every quote, ensuring your mold’s metallurgical properties align with empirical production data. Contact us to discuss resin-specific material certifications and accelerated anodizing schedules for urgent projects.

Manufacturing Process & QC

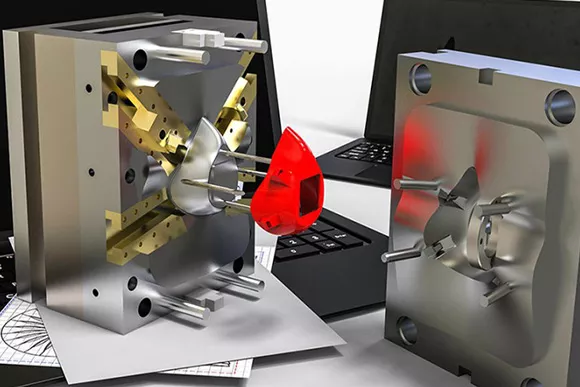

Design: Engineering Precision from the First Sketch

At Wuxi Lead Precision Machinery, the foundation of successful small run injection molding begins with precision-driven design. Our engineering team collaborates closely with clients to transform conceptual sketches into manufacturable, high-integrity metal components. Utilizing advanced CAD/CAM software and DFMA (Design for Manufacturing and Assembly) principles, we ensure every geometry, tolerance, and surface finish is optimized for both performance and process efficiency. Thermal flow analysis and mold stress simulations are conducted during this phase to anticipate potential defects such as warping, sink marks, or incomplete fills. This proactive approach eliminates costly revisions later and ensures that the design is fully aligned with the capabilities of our precision molding systems.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using high-precision CNC-machined molds or soft tooling, depending on complexity and material requirements. This stage is critical for functional testing, dimensional verification, and client approval. Prototypes are produced under actual molding conditions to simulate real-world performance. Every prototype undergoes rigorous inspection using CMM (Coordinate Measuring Machines), optical comparators, and metallurgical analysis to confirm compliance with specified tolerances and material properties. Feedback from this stage is integrated into final mold adjustments, ensuring that any micro-defects are identified and corrected before mass production begins. Our zero-defect philosophy is enforced through documented traceability and SPC (Statistical Process Control) monitoring at every checkpoint.

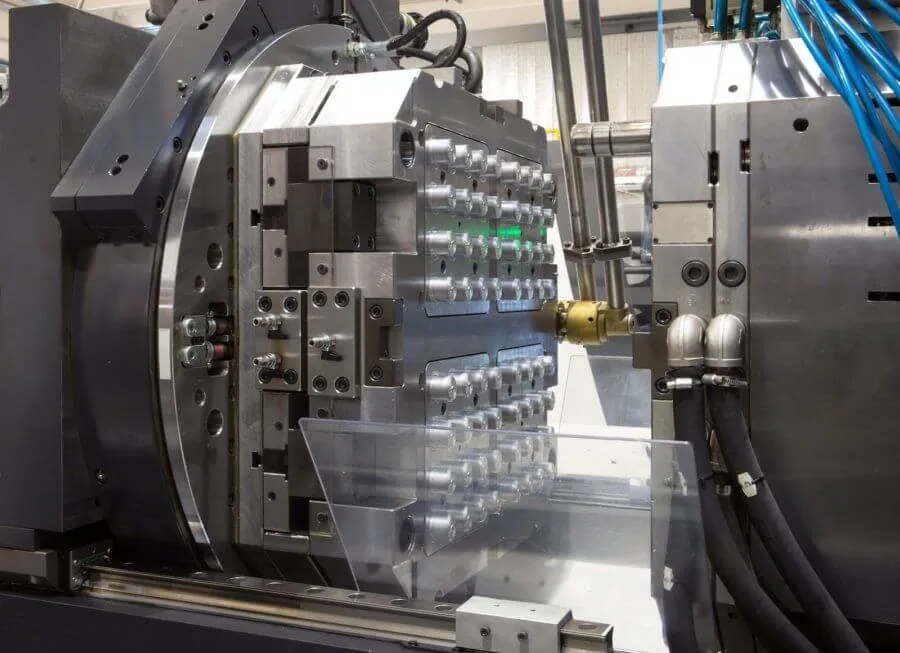

Mass Production: Consistency, Control, and Quality Assurance

With design and prototyping validated, we transition to small-batch production using state-of-the-art electric and hybrid injection molding presses. These systems provide exceptional repeatability, critical for maintaining tight tolerances—down to ±0.005 mm—across limited production runs. Each mold is monitored in real time for pressure, temperature, and cycle consistency. Automated vision systems and in-process gauging detect deviations instantly, triggering corrective actions before defective parts are produced. Every batch is accompanied by full material certifications, first-article inspection reports, and process validation data. Our cleanroom-compliant facilities and ISO 9001-certified workflows ensure that quality is not inspected in but built into every stage.

Process Specifications

| Parameter | Capability |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Material Compatibility | Stainless Steel, Titanium, Tool Steels, Superalloys |

| Mold Tooling | Hardened Steel, PCD Inserts, Multi-Cavity |

| Production Volume | 100 – 10,000 units per run |

| Lead Time (Prototype) | 10–15 days |

| Lead Time (Production) | 20–30 days |

| Quality Standards | ISO 9001, PPAP, FAIR, SPC, 100% Inspection |

| Surface Finish | Ra 0.2 – 1.6 µm (polished, textured, coated) |

At Wuxi Lead Precision Machinery, small run injection molding is not a compromise—it is a precision commitment. From design through delivery, our integrated process ensures zero-defect output, on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Small Run Injection Molding

In the demanding landscape of precision engineering, securing a manufacturing partner capable of delivering exceptional quality for low-volume, high-complexity metal components is critical. Standard mass-production approaches fail to address the unique challenges of prototyping, bridge tooling, and specialized small-batch production. Wuxi Lead Precision Machinery exists to solve this precise gap. We specialize in providing engineered solutions where tolerances are non-negotiable, material integrity is paramount, and project timelines are inflexible. Our commitment extends beyond mere component fabrication; we integrate deeply with your engineering team as a strategic extension of your R&D and production capabilities. This collaborative partnership ensures your small-run injection molding projects achieve the exacting standards required for aerospace, medical devices, and advanced industrial applications, mitigating risk and accelerating time-to-market.

Our dedicated small-run injection molding service leverages advanced German and Japanese machinery within a climate-controlled ISO 9001:2015 certified facility. We master the intricate balance between rapid tooling deployment and uncompromised part fidelity, utilizing hardened steel molds designed specifically for low-cycle durability without sacrificing dimensional stability. This focus on precision engineering for limited quantities ensures every component meets your stringent specifications, batch after batch. The table below details our core technical capabilities for small-run metal injection molding projects.

| Specification Category | Capability |

|---|---|

| Material Range | 17-4 PH Stainless Steel, 316L Stainless Steel, Inconel 718, Custom Alloys |

| Tolerance Capability | ±0.005 mm (±0.0002″) on critical features |

| Max Part Size | 300 mm x 300 mm x 250 mm (12″ x 12″ x 10″) |

| Surface Finish | Ra 0.8 µm standard; Ra 0.4 µm achievable |

| Secondary Operations | CNC Milling, Turning, Laser Marking, Precision Cleaning, Vacuum Sintering |

| Typical Lead Time | 15-25 days from approved design to first article |

Choosing Lead Precision means selecting a partner invested in your project’s technical success from inception. Our engineering team engages proactively during the design phase, providing critical DFM insights to optimize part geometry for the MIM process, prevent costly iterations, and ensure manufacturability. We understand that small runs often represent high-value, mission-critical components; therefore, our quality control protocols exceed industry norms with 100% critical feature inspection using CMM, optical comparators, and metallurgical analysis. This rigorous approach guarantees consistency and traceability, providing the documentation and confidence essential for regulated industries.

Do not let the complexities of low-volume precision manufacturing impede your innovation or production schedule. Partner with an organization engineered to deliver where others cannot. Contact our technical sales engineering team directly to initiate a confidential consultation. Email [email protected] with your project specifications and requirements. Our engineers will respond within 24 business hours to discuss material selection, tolerance strategies, and a precise timeline for your unique small-run injection molding challenge. Let Lead Precision be the foundation for your next precision component success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.