Technical Contents

Engineering Guide: Metals Stainless Steel

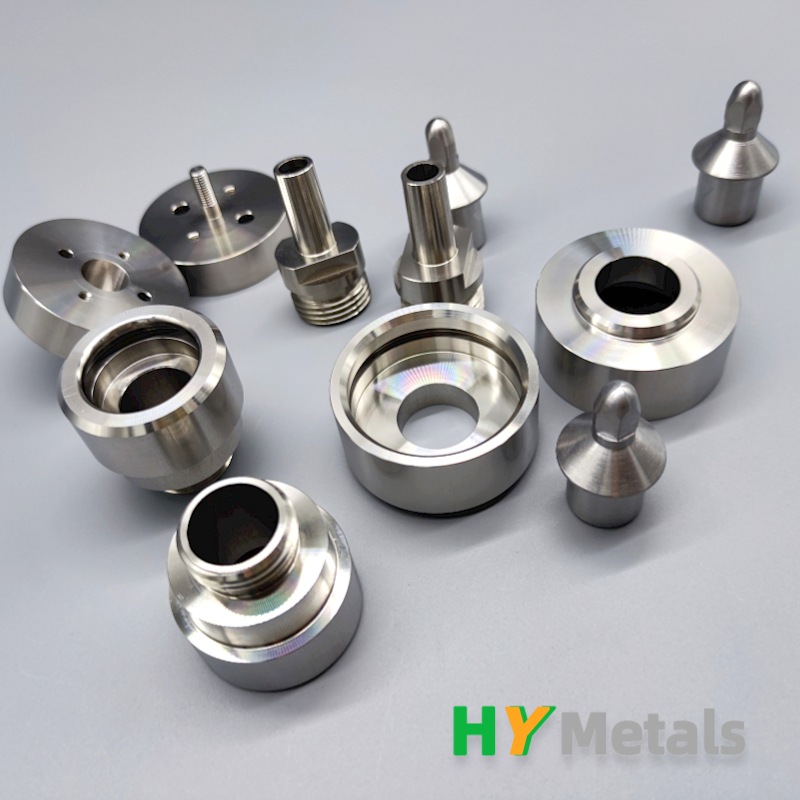

Engineering Insight: Stainless Steel in High-Precision Manufacturing

In the realm of advanced manufacturing, stainless steel remains a cornerstone material due to its exceptional strength, corrosion resistance, and thermal stability. However, its true performance potential is only fully realized when paired with precision engineering. At Wuxi Lead Precision Machinery, we understand that achieving micron-level tolerances in stainless steel components is not merely a technical challenge—it is a necessity for industries where failure is not an option.

Stainless steel, particularly grades such as 304, 316, and 17-4 PH, presents unique machining challenges. Its high work-hardening rate and low thermal conductivity demand carefully optimized cutting parameters, tool selection, and cooling strategies. Even minor deviations in tool path or feed rate can result in dimensional inaccuracies, surface defects, or premature tool wear. This is why precision is not just a metric—it is a philosophy that must be embedded throughout the entire manufacturing process, from design and material selection to CNC programming and post-processing inspection.

Our engineering team at Wuxi Lead has spent over a decade mastering the nuances of stainless steel machining. We have delivered mission-critical components for applications in aerospace, defense, and large-scale infrastructure, including parts used in Olympic-grade facilities and military-grade equipment. These projects demanded not only adherence to strict international standards such as ISO 2768 and ASME Y14.5 but also the ability to maintain consistency across high-mix, low-volume production runs.

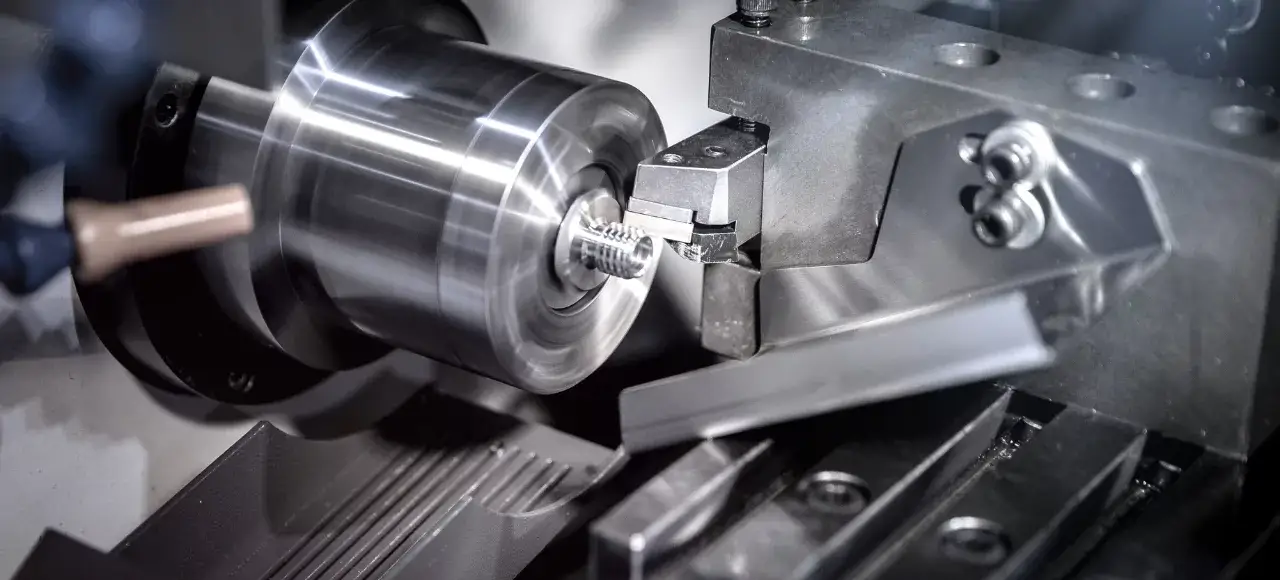

Our CNC machining centers operate under tightly controlled environmental conditions, ensuring thermal stability and minimizing dimensional drift. We employ multi-axis simultaneous machining, in-process probing, and real-time tool wear compensation to maintain tolerances as tight as ±0.002 mm. Every component undergoes rigorous metrology using coordinate measuring machines (CMM) and optical inspection systems, ensuring full traceability and compliance with customer specifications.

The result is a level of precision that transforms stainless steel from a robust material into a high-performance solution. Whether it’s a turbine blade for a naval propulsion system or a structural joint for a stadium roof, the integrity of the final product hinges on the accuracy of its manufacture.

Typical Stainless Steel Machining Specifications at Wuxi Lead Precision Machinery

| Parameter | Specification |

|---|---|

| Material Grades | 304, 316, 316L, 17-4 PH, 440C |

| Tolerance Range | ±0.002 mm to ±0.025 mm |

| Surface Finish (Ra) | 0.4 µm to 3.2 µm |

| Maximum Part Size | 1200 mm × 800 mm × 600 mm |

| CNC Equipment | 3-axis, 4-axis, 5-axis milling, turning |

| Quality Standards | ISO 9001, ISO 13485, AS9100 (in process) |

| Inspection Tools | CMM, optical comparators, roughness testers |

Precision in stainless steel manufacturing is not an added feature—it is the foundation of reliability, safety, and performance. At Wuxi Lead, we bring proven expertise and uncompromising standards to every project, ensuring that our clients receive components engineered to excel in the most demanding environments.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Stainless Steel Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision in custom stainless steel components, leveraging deep material science expertise and cutting-edge technology. Our specialization in austenitic (304, 316/L), martensitic (410, 420), and duplex (2205) stainless steel grades ensures optimal process parameters for challenging alloys. We understand the critical balance between maintaining corrosion resistance, achieving tight tolerances, and managing work hardening inherent in stainless steel machining. Our integrated approach spans from initial material certification review through final dimensional validation, guaranteeing parts meet the rigorous demands of aerospace, medical, and semiconductor applications where failure is not an option.

Our core manufacturing capability centers on state-of-the-art 5-axis simultaneous CNC machining centers. These platforms enable the production of highly complex geometries—including contoured impellers, intricate valve bodies, and monolithic structural components—in a single setup. This eliminates cumulative errors from multiple fixtures, significantly reducing lead times while enhancing geometric accuracy and surface integrity. High-speed spindles with rigid tapping and advanced coolant delivery systems are optimized specifically for stainless steel, minimizing thermal distortion and ensuring superior surface finishes essential for critical sealing surfaces and fatigue-critical parts. Complex features such as deep cavities, undercuts, and precise angular intersections are executed with exceptional repeatability.

Quality assurance is non-negotiable. Every critical stainless steel component undergoes comprehensive verification using Zeiss and Hexagon Coordinate Measuring Machines (CMMs). Our CMM inspection protocols, developed per AS9100 and ISO 13485 standards, provide full GD&T validation against CAD models. This includes rigorous analysis of form, position, profile, and runout tolerances on features like concentric bores, datum references, and complex freeform surfaces. Real-time SPC data from machining processes is correlated with final CMM reports, enabling proactive process refinement and ensuring statistical confidence in every shipment. Material traceability from certified mill test reports through final inspection is meticulously maintained.

The table below details our standard achievable tolerance capabilities for machined stainless steel components. Note that specific project requirements may allow for tighter control through process optimization.

| Dimension Type | Tolerance Range | Material Grade Applicability |

|---|---|---|

| Linear Dimensions | ±0.005 mm | 304, 316/L, 2205, 410, 420 |

| Geometric Position | Ø0.010 mm | 304, 316/L, 2205 |

| Concentricity | Ø0.008 mm | 316/L, 2205 |

| Surface Roughness Ra | 0.4 – 0.8 µm | All grades (as machined) |

| Angular Features | ±0° 05′ | 304, 316/L |

Wuxi Lead’s technical foundation combines advanced 5-axis machining mastery with metrology-grade inspection discipline. We transform challenging stainless steel alloys into mission-critical components where dimensional perfection directly impacts system performance and longevity. Partner with us for custom manufacturing where capability meets certified precision.

Material & Finish Options

Material Selection for High-Precision Custom Metal Manufacturing

Selecting the appropriate material is a critical step in custom metal manufacturing, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision components for aerospace, automotive, medical, and industrial automation sectors, where material integrity is non-negotiable. Our expertise spans aluminum, stainless steel, and titanium—each offering distinct mechanical and environmental advantages.

Aluminum is favored for applications requiring a high strength-to-weight ratio and excellent thermal and electrical conductivity. It is particularly suitable for lightweight structural components, heat sinks, and housings in electronics. While inherently less wear-resistant than steel, aluminum responds exceptionally well to anodizing—a surface treatment that enhances corrosion resistance, surface hardness, and aesthetic consistency. Type II and Type III (hard coat) anodizing are commonly applied, with the latter providing a wear-resistant layer up to 50–100 µm thick, ideal for high-stress environments.

Stainless steel remains the standard for applications demanding corrosion resistance, mechanical strength, and sterilizability. Grades such as 304 and 316 are widely used in medical devices, food processing equipment, and marine environments due to their chromium and nickel content, which forms a passive oxide layer protecting against oxidation and chemical exposure. Unlike aluminum, stainless steel does not undergo anodizing; instead, surface finishes include passivation, electropolishing, and precision polishing to enhance corrosion resistance and surface integrity.

Titanium, particularly Grade 5 (Ti-6Al-4V), offers an unmatched combination of high tensile strength, low density, and exceptional resistance to extreme temperatures and corrosive media. It is the material of choice in aerospace, defense, and implantable medical devices. While more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s longevity in harsh environments justifies its use in mission-critical applications.

Below is a comparative overview of key mechanical and physical properties for common grades in each material category.

| Material | Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Finishes |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 276 | 2.7 | Moderate | Anodizing, Bead Blast |

| Stainless Steel | 304 | 515 | 205 | 8.0 | High | Passivation, Polishing |

| Stainless Steel | 316 | 570 | 275 | 8.0 | Very High | Electropolishing, Passivation |

| Titanium | Ti-6Al-4V | 950 | 880 | 4.4 | Exceptional | Laser Etching, Polishing |

At Wuxi Lead, our engineering team collaborates closely with clients to match material and finish specifications to operational demands. Whether optimizing for weight reduction, sterilization cycles, or saltwater exposure, the right material choice forms the foundation of precision performance.

Manufacturing Process & QC

Precision Stainless Steel Manufacturing: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, our stainless steel manufacturing process for demanding aerospace, medical, and semiconductor applications is engineered for absolute reliability. We integrate rigorous engineering with advanced CNC technology to transform your specifications into zero-defect components, ensuring performance in the most critical environments. This commitment begins at the earliest design phase and permeates every subsequent stage.

Our process initiates with comprehensive collaborative design engineering. Our team works directly with your CAD models, performing detailed manufacturability analysis specific to stainless steel grades like 304, 316L, and 17-4PH. We identify potential stress points, thermal distortion risks, and optimal fixture strategies before metal is cut. Utilizing advanced CAM simulation software, we validate toolpaths for complex geometries, ensuring minimal residual stress and precise dimensional control inherent to high-grade stainless alloys. This proactive engineering eliminates costly iterations and establishes the foundation for defect prevention.

Prototyping is not merely a sample stage; it is a critical validation checkpoint. We deploy multi-axis CNC milling and turning centers with sub-micron positioning accuracy to produce functional prototypes from your approved material batch. Every prototype undergoes stringent first-article inspection using coordinate measuring machines (CMM) and surface profilometers, verifying conformity to GD&T callouts and surface finish requirements down to Ra 0.8µm. Material certification and full traceability from the mill are provided, confirming chemical composition and mechanical properties. Client sign-off on this validated prototype is mandatory before proceeding, guaranteeing the process is locked and proven.

Mass production leverages the validated process under our Zero Defects Management System. High-speed CNC cells operate with automated tool compensation and in-process probing, continuously monitoring critical dimensions. Statistical Process Control (SPC) charts track key parameters like cutting force and thermal drift in real-time, triggering immediate corrective action if trends approach tolerance limits. 100% automated optical inspection (AOI) or CMM spot checks are implemented for high-risk features, while batch traceability links every component to its specific material heat number, machine parameters, and inspection data. Final inspection includes full dimensional reports, surface roughness verification, and mandatory material test reports (MTRs), delivering only components meeting the most stringent international standards.

This integrated approach ensures consistent output of mission-critical stainless steel parts. The table below outlines key capabilities for common grades:

| Stainless Steel Grade | Typical Applications | Max Tensile Strength (MPa) | Key Process Focus Areas | Achievable Surface Finish (Ra µm) |

|---|---|---|---|---|

| 304 / 304L | Food Processing, Chemical | 515 | Weldability, Corrosion Resistance Control | 0.8 – 1.6 |

| 316L | Medical Implants, Marine | 485 | Pitting Resistance, Ultra-Clean Finishing | 0.4 – 0.8 |

| 17-4PH (Precipitation Hardening) | Aerospace Actuators, Valves | 1310 | Heat Treatment Control, Dimensional Stability | 0.8 – 1.6 |

Wuxi Lead transforms stainless steel design intent into flawless reality through this disciplined, data-driven sequence. Partner with us to secure manufacturing excellence where failure is never an option.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Stainless Steel Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, custom metal manufacturing solutions tailored to the exacting demands of global industries. With stainless steel forming the backbone of modern industrial applications—from medical devices and aerospace systems to semiconductor equipment and food processing machinery—our engineering-driven approach ensures every component meets the highest standards of quality, durability, and performance.

Our advanced manufacturing capabilities are built on decades of metallurgical expertise and a commitment to innovation. We understand that stainless steel is not a one-size-fits-all material. Each grade presents unique challenges in machinability, corrosion resistance, and structural integrity. That’s why we combine precision CNC machining, automated fabrication, and rigorous quality control processes to transform your designs into flawless, production-ready parts. Whether you require small-batch prototypes or high-volume production runs, our facility in Wuxi, China, is equipped to deliver consistency and repeatability across every order.

We work closely with design engineers, procurement managers, and OEMs to optimize part geometry, material selection, and manufacturability—reducing lead times and minimizing total cost of ownership. Our team supports international standards including ISO 9001, ASME, and RoHS, ensuring compliance across regulated sectors. From initial concept review to final inspection and global logistics, we act as an extension of your engineering team, providing full transparency and technical collaboration at every stage.

Below are key technical specifications that define our stainless steel manufacturing capabilities:

| Specification | Capability |

|---|---|

| Material Grades | 303, 304, 304L, 316, 316L, 410, 420, 430, 17-4 PH, and custom alloys |

| Tolerance | ±0.005 mm (±0.0002″) for critical dimensions |

| Surface Finish | Ra 0.2 to 3.2 μm (Ra 8 to 125 μin), including mirror polishing and passivation |

| Machining Processes | 3-axis to 5-axis CNC milling, CNC turning, Swiss machining, EDM |

| Secondary Operations | Welding (TIG, MIG, laser), heat treatment, shot peening, coating |

| Quality Assurance | CMM inspection, optical comparators, material traceability, full FAI reports |

| Production Volume | Prototype to high-volume serial production |

| Lead Times | As fast as 7 days for prototypes, scalable for mass production |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a strategic manufacturing ally. We are committed to technical excellence, on-time delivery, and responsive customer support, ensuring your projects move from design to deployment without compromise.

Contact us today to discuss your stainless steel manufacturing requirements. Send your drawings, specifications, or inquiries to [email protected] and let our engineering team provide a fast, detailed quotation and manufacturability analysis. Let Lead Precision be the foundation of your next high-performance metal component.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.