Technical Contents

Engineering Guide: Moldable Materials

Engineering Insight: Precision as the Non-Negotiable Foundation for Moldable Material Performance

In high-stakes custom metal manufacturing, the selection of moldable materials is intrinsically linked to the achievable precision of the final component. Material properties dictate not only the functional capabilities of the part but also the stringent tolerances and surface finishes attainable during CNC machining, casting, or forming processes. Compromising on precision during material selection or processing invites catastrophic failure in demanding applications – from micro-movements in aerospace actuators to thermal stress fractures in power generation systems. The true cost of imprecision manifests not in initial machining time, but in field failures, warranty claims, and reputational damage. At Wuxi Lead Precision Machinery, we treat dimensional accuracy and material integrity as inseparable; our engineering protocols begin with deep material science analysis to ensure the chosen alloy can consistently meet micron-level tolerances under operational stress.

Our extensive experience manufacturing mission-critical components for Olympic timing systems and military-grade equipment underscores this philosophy. These projects demanded absolute zero-failure performance, where material consistency and micron-precision machining were non-negotiable. Olympic components required sub-5-micron tolerances to ensure flawless split-second accuracy under dynamic loads, while military applications mandated materials maintaining structural integrity across extreme temperature ranges (-55°C to +200°C) and high-vibration environments. This level of reliability is only achievable through rigorous control of material grain structure, thermal treatment, and CNC process parameters – a capability forged through decades of solving the most complex precision challenges.

Selecting the optimal moldable material requires evaluating a precise interplay of properties against the application’s specific demands. The table below outlines key characteristics for common high-performance alloys we routinely machine to exacting standards:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Machinability Rating | Key Applications |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 2.81 | 572 | 130 | Fair (60%) | Aerospace frames, high-stress fittings |

| Titanium 6Al-4V | 4.43 | 930 | 6.7 | Poor (30%) | Military aircraft, medical implants |

| Inconel 718 | 8.19 | 1240 | 11.4 | Very Poor (20%) | Jet engine components, rocket systems |

| Stainless 17-4PH | 7.75 | 1310 | 16.2 | Moderate (45%) | Defense actuators, marine hardware |

Material choice directly impacts manufacturability and ultimate performance. For instance, while Inconel 718 offers exceptional strength at high temperatures, its low thermal conductivity and work-hardening tendency demand specialized tooling and ultra-stable CNC processes to prevent micro-cracking during machining – a challenge our Olympic and military programs have repeatedly overcome. Conversely, Aluminum 7075-T6 provides excellent strength-to-weight ratio but requires precise coolant control to avoid thermal distortion during high-speed milling.

Precision in moldable materials transcends mere dimensional compliance; it is the cornerstone of functional reliability and lifecycle cost. Wuxi Lead Precision Machinery integrates material science expertise with advanced CNC capabilities to transform demanding specifications into flawless components. We partner with clients from the initial material selection phase, ensuring the chosen alloy’s properties align perfectly with both the functional requirements and the achievable precision of our manufacturing processes. This holistic approach, proven in the world’s most rigorous applications, delivers components where every micron contributes to mission success.

Precision Specs & Tolerances

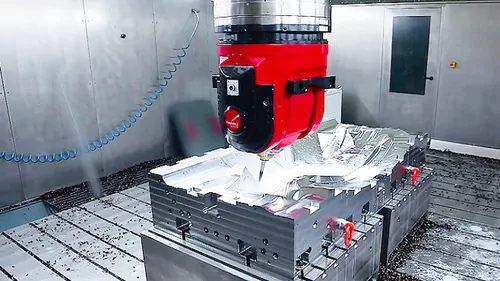

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the exacting demands of high-performance industries such as aerospace, medical devices, automotive, and industrial automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex, organic, and highly precise metal components from moldable materials including aluminum alloys, stainless steels, titanium, and high-temperature superalloys. Our 5-axis technology provides simultaneous multi-directional cutting, minimizing setup cycles and ensuring superior surface finish, geometric accuracy, and part consistency. This capability is essential for manufacturing components with undercuts, compound angles, and intricate contours that cannot be achieved with conventional 3-axis systems.

All machining operations are supported by in-house engineering expertise, utilizing industry-leading CAD/CAM software for precision toolpath generation and simulation. This digital workflow ensures optimal material removal rates, tool life, and part integrity, particularly when working with moldable metals that require controlled thermal and mechanical input. Our facility maintains strict environmental and operational controls to ensure machine stability and repeatability across long production runs.

Quality assurance is embedded throughout the manufacturing process. Every critical dimension is verified using a state-of-the-art Coordinate Measuring Machine (CMM) with tactile probing and high-resolution scanning capabilities. The CMM system is calibrated to international standards and operates within a temperature-controlled metrology lab to eliminate measurement drift. This allows for full first-article inspection reports (FAIR) and production lot certification, meeting AS9100, ISO 13485, and other industry-specific compliance requirements. Our inspection protocols support both GD&T (Geometric Dimensioning and Tolerancing) validation and surface roughness analysis, ensuring that every component conforms to the most stringent design specifications.

The following table outlines the standard precision tolerances achievable through our 5-axis CNC and inspection processes:

| Feature Type | Standard Tolerance | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Geometric Tolerances (GD&T) | ±0.02 mm | ±0.008 mm | CMM with GD&T Analysis |

| Hole Diameter | ±0.01 mm | ±0.003 mm | Air Gauges, CMM |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | Surface Roughness Tester |

| Positional Accuracy | ±0.015 mm | ±0.005 mm | CMM, Optical Alignment |

| Angular Features | ±0.05° | ±0.01° | CMM, Precision Probes |

These capabilities are reinforced by a continuous improvement framework, where process data is monitored and refined using statistical process control (SPC) methodologies. Wuxi Lead Precision Machinery is committed to delivering not only precision but also reliability, traceability, and scalability for every custom metal manufacturing project involving moldable materials.

Material & Finish Options

Material Selection for Precision Metal Components

Selecting the optimal material is foundational to achieving performance, durability, and cost efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we prioritize materials that balance machinability, mechanical properties, and environmental resilience. Aluminum, steel, and titanium dominate high-end applications, each serving distinct operational demands. Aluminum 6061-T6 remains the industry benchmark for lightweight structural parts, offering excellent corrosion resistance and weldability while maintaining high strength-to-weight ratios. Its superior thermal conductivity and ease of CNC machining reduce production lead times significantly. For applications requiring extreme hardness and wear resistance, alloy steel 4140 delivers exceptional tensile strength and fatigue performance, particularly in high-stress environments like aerospace actuators or heavy machinery components. Titanium 6Al-4V excels where weight reduction and corrosion immunity are non-negotiable—think medical implants or marine hardware—though its abrasive nature demands specialized tooling and slower machining parameters.

Critical material properties must align with functional requirements. The table below summarizes key specifications for common grades we machine to tight tolerances:

| Material Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Machinability Rating | Primary Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 276 | 95 | Excellent (65%) | Enclosures, brackets, heat sinks |

| Steel 4140 | 655 | 415 | 197 | Good (62%) | Shafts, gears, landing gear |

| Titanium 6Al-4V | 900 | 830 | 334 | Fair (30%) | Biomedical implants, aerospace fittings |

Surface finishing, particularly anodizing, critically enhances part longevity and functionality. Type II (sulfuric acid) anodizing provides robust corrosion protection and dye receptivity for aluminum, ideal for consumer-facing components requiring color coding or branding. For mission-critical industrial parts, Type III (hardcoat) anodizing delivers wear resistance up to 60 HRC, doubling surface durability in abrasive environments like hydraulic systems. We strictly control electrolyte temperature, voltage, and immersion time to ensure uniform coating thickness within ±5μm—preventing dimensional drift that compromises precision fits. Note that anodizing titanium requires specialized processes like plasma electrolytic oxidation (PEO) to achieve comparable hardness without hydrogen embrittlement risks.

Material and finish selection directly impacts manufacturability and lifecycle costs. Aluminum 6061-T6 with Type II anodizing suits high-volume consumer electronics housings, balancing speed and aesthetics. Steel 4140 paired with precision grinding meets aerospace fatigue specs but incurs higher machining costs. Titanium 6Al-4V necessitates slower CNC cycles yet justifies its expense in saltwater-exposed marine valves through decades of service life. Always validate material-chemistry compatibility with operational environments—chloride exposure, for instance, mandates titanium over aluminum despite cost premiums. At Wuxi Lead, our engineering team collaborates early to model these trade-offs, ensuring your design achieves peak performance without over-engineering. Contact us to optimize your material strategy for yield, tolerance, and total cost.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process for moldable materials is engineered to deliver precision, repeatability, and zero-defect performance across every production phase. We specialize in high-tolerance metal components used in aerospace, medical devices, automotive systems, and industrial automation, where material integrity and dimensional accuracy are non-negotiable. Our end-to-end workflow integrates Design, Prototyping, and Mass Production into a seamless pipeline, governed by strict quality control and advanced CNC technologies.

The process begins with Design, where our engineering team collaborates closely with clients to translate conceptual requirements into manufacturable designs. Using advanced CAD/CAM software, we analyze material behavior under stress, thermal conditions, and forming dynamics to optimize geometry, wall thickness, and tooling paths. Finite element analysis (FEA) ensures that moldable materials—such as aluminum alloys, stainless steel, and titanium—are formed within elastic and plastic deformation limits, minimizing warping and residual stress. Design for manufacturability (DFM) reviews are conducted to eliminate costly revisions and ensure seamless transition to prototyping.

Prototyping follows design finalization, serving as both a functional validation and process rehearsal. We employ high-precision CNC milling, turning, and progressive die forming to produce initial samples from the actual production-grade materials. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify conformance to tolerances as tight as ±0.005 mm. Any deviations trigger immediate design or process adjustments. This iterative verification ensures that the final product meets all mechanical, thermal, and aesthetic specifications before scaling to mass production.

Mass Production leverages fully automated CNC cells, robotic material handling, and real-time in-process monitoring to maintain consistency across thousands of units. Our production lines are configured for flexible batch sizing, supporting both low-volume specialty runs and high-volume OEM demands. Statistical process control (SPC) systems continuously track critical dimensions and surface finishes, with automatic alerts for any parameter drift. Every component is traceable through our digital manufacturing execution system (MES), enabling full auditability from raw material to final shipment.

Our zero-defect philosophy is enforced through ISO 9001-certified workflows, multi-stage inspection protocols, and a closed-loop corrective action system. By integrating precision engineering with intelligent manufacturing, Wuxi Lead ensures that every part meets the highest standards of reliability and performance.

Typical Material & Process Specifications

| Material Type | Tolerance Range | Surface Finish (Ra) | Max Part Size (mm) | Production Speed (Parts/Hour) |

|---|---|---|---|---|

| Aluminum 6061-T6 | ±0.005 – ±0.01 mm | 0.4 – 1.6 µm | 500 x 300 x 200 | 120 |

| Stainless Steel 316L | ±0.01 – ±0.02 mm | 0.8 – 2.0 µm | 400 x 250 x 180 | 80 |

| Titanium Grade 5 | ±0.01 mm | 0.6 – 1.2 µm | 350 x 200 x 150 | 50 |

| Brass C3604 | ±0.005 mm | 0.4 µm | 300 x 150 x 100 | 150 |

This structured approach ensures that from initial concept to final delivery, Wuxi Lead Precision Machinery delivers defect-free, high-performance metal components tailored to the most demanding industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Manufacturing Excellence

In the demanding realm of high-precision metal components for moldable material applications, tolerances are non-negotiable. Sub-micron deviations directly impact performance, longevity, and yield in injection molding, die casting, and advanced composite tooling. Generic manufacturing partners often lack the metallurgical expertise and process control to consistently deliver parts that meet aerospace, medical, or semiconductor industry standards. At Wuxi Lead Precision Machinery, we engineer solutions where material science converges with micron-level precision. Our integrated approach spans material selection, thermal treatment, and multi-axis CNC fabrication to ensure your mold cores, cavities, and electrodes perform under extreme thermal cycling and mechanical stress.

We specialize in transforming challenging alloys into mission-critical components through proprietary process protocols. Our AS9100-certified facility leverages 5-axis milling, wire EDM, and laser texturing capabilities to achieve geometric complexities unattainable through conventional molding alone. This precision extends to surface integrity—critical for preventing material adhesion and ensuring uniform part release. The table below outlines our validated capabilities for key moldable material substrates:

| Material Category | Common Alloys | Typical Applications | Precision Capability | Surface Finish (Ra) |

|---|---|---|---|---|

| Tool Steels | H13, S7, A2 | Injection molds, die casting dies | ±0.002 mm | 0.05–0.4 μm |

| Stainless Steels | 17-4PH, 440C | Corrosive environment tooling | ±0.003 mm | 0.1–0.8 μm |

| Aluminum Alloys | 7075-T6, 6061 | Rapid prototype molds | ±0.005 mm | 0.2–1.6 μm |

| Titanium Alloys | Ti-6Al-4V | High-temperature composite molds | ±0.004 mm | 0.1–0.6 μm |

| Copper Alloys | C18200, C17200 | Heat dissipation inserts | ±0.003 mm | 0.05–0.4 μm |

Beyond technical execution, we function as your strategic extension. Our engineering team collaborates from DFM stage through production ramp-up, optimizing material utilization and cycle times while mitigating porosity or distortion risks inherent in moldable material processes. Real-time SPC monitoring and in-process CMM verification ensure lot-to-lot consistency, directly reducing your scrap rates and validation costs. For global supply chains, our JIT logistics framework guarantees on-time delivery without compromising traceability—every component ships with full material certs and inspection reports.

The true measure of a manufacturing partner lies in their ability to anticipate failures before they occur. With Wuxi Lead, you gain proactive metallurgical consultation, rapid iteration cycles for complex geometries, and unwavering accountability for performance-critical outputs. We do not merely fulfill orders; we safeguard your reputation through engineered reliability.

Initiate a precision partnership that elevates your moldable material applications. Contact our engineering team directly at [email protected] to discuss material specifications, tolerance requirements, or confidential project reviews. Include your target alloy, critical dimensions, and production volume for a tailored capability assessment within 24 business hours. Let us demonstrate why global leaders trust Wuxi Lead Precision Machinery for zero-defect metal manufacturing where precision defines success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.