Technical Contents

Engineering Guide: Cnc Machining Services Birmingham

Engineering Insight: The Critical Role of Precision in CNC Machining Services in Birmingham

In the competitive landscape of advanced manufacturing, CNC machining services in Birmingham must meet exacting standards to support industries where failure is not an option. Whether serving aerospace, medical, defense, or high-performance automotive sectors, the margin for error is measured in microns. Precision is not merely a performance metric—it is the foundation of reliability, safety, and operational integrity. At Wuxi Lead Precision Machinery, we understand that world-class engineering demands more than advanced equipment; it requires a culture of uncompromising accuracy and proven expertise.

While Birmingham remains a historic hub for British manufacturing, global supply chains now allow companies to source precision components from international leaders without sacrificing quality or delivery timelines. Wuxi Lead Precision Machinery stands at the forefront of this evolution, delivering CNC machining services that meet and exceed the stringent requirements historically associated with domestic production. Our facility in China is equipped with state-of-the-art 3-, 4-, and 5-axis machining centers, coordinate measuring machines (CMM), and real-time inspection systems, ensuring every component adheres to tight tolerances and rigorous quality protocols.

Our engineering team brings over 15 years of experience in high-stakes manufacturing environments. This includes producing critical components for Olympic-standard sporting equipment, where material performance and dimensional accuracy directly influence athletic outcomes, and supplying mission-critical parts for military-grade applications, where environmental resilience and repeatability under stress are non-negotiable. These projects demand more than technical capability—they require a deep understanding of material behavior, thermal stability, and geometric complexity, all of which are embedded in our machining philosophy.

Precision begins at the design stage. Our engineers collaborate closely with clients to optimize part geometry, select appropriate alloys or composites, and implement efficient toolpaths that maintain integrity without compromising cycle time. From prototype to full-scale production, we apply statistical process control (SPC) and first-article inspection (FAI) to ensure consistency across batches. Our ISO 9001-certified quality management system supports traceability, documentation, and continuous improvement—key requirements for clients in regulated industries.

The following table outlines key capabilities that define our precision CNC machining services:

| Specification | Detail |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Axis Capabilities | 3-axis, 4-axis, 5-axis simultaneous |

| Materials Processed | Aluminum (7075, 6061), Stainless Steel (316L, 17-4 PH), Titanium (Grade 5), Inconel 718, PEEK, Delrin |

| Surface Finish | As low as Ra 0.2 µm (polished), standard Ra 1.6 µm |

| Tolerances Achieved | IT6 to IT7 per ISO 286 |

For engineering firms in Birmingham seeking reliable, high-precision CNC machining, global partnerships with specialists like Wuxi Lead offer a strategic advantage. By combining local design innovation with international manufacturing excellence, we enable faster time-to-market, reduced costs, and uncompromised quality. Precision is not location-dependent—it is process-driven. And at Wuxi Lead, it is our standard.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Birmingham Industry Demands

Wuxi Lead Precision Machinery delivers advanced CNC machining services engineered to meet the stringent requirements of Birmingham’s aerospace, medical, and high-value engineering sectors. Our core strength lies in mastering complex geometries and tight tolerances through state-of-the-art multi-axis technology and rigorous quality control, providing a reliable offshore solution that complements local UK capacity constraints.

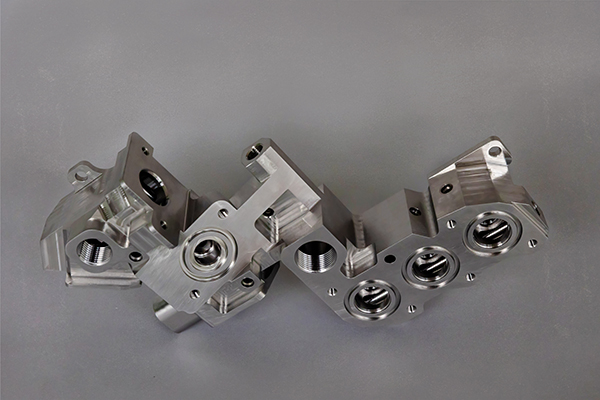

Our dedicated fleet of 5-axis CNC machining centers forms the backbone of complex part production. These Haas and DMG MORI systems enable true simultaneous 5-axis movement, eliminating the need for multiple setups and significantly reducing cumulative error. This capability is essential for producing intricate components such as turbine blades, surgical instrument housings, and bespoke automation fixtures common in Birmingham’s advanced manufacturing landscape. The elimination of re-fixturing ensures superior part accuracy, enhanced surface finish, and reduced lead times compared to traditional 3-axis methods, directly addressing the need for rapid prototyping and low-volume production runs demanded by Midlands innovators.

Quality assurance is non-negotiable. Every critical dimension undergoes verification using calibrated Zeiss CONTURA Coordinate Measuring Machines (CMMs). Our inspection process follows ISO 10360 standards, providing full first-article inspection reports (FAIRs) and comprehensive dimensional data packages traceable to NPL standards. This systematic approach, integrated within our ISO 9001:2015 certified quality management system, guarantees dimensional integrity from raw material to finished component, mitigating risk for our Birmingham clients operating in regulated industries.

The following table details the standard precision tolerances we consistently achieve across common engineering materials. These values represent our baseline capability; tighter tolerances are achievable through specialized processes and enhanced inspection protocols upon project consultation.

| Material Category | Dimensional Tolerance | Typical Surface Finish (Ra) |

|---|---|---|

| Aluminum Alloys (e.g., 6061, 7075) | ±0.005 mm | 0.8 µm (as-machined) |

| Stainless Steels (e.g., 304, 316, 17-4PH) | ±0.008 mm | 1.6 µm (as-machined) |

| Engineering Plastics (e.g., PEEK, Delrin) | ±0.010 mm | 3.2 µm (as-machined) |

| Titanium Alloys (e.g., Grade 5) | ±0.008 mm | 1.6 µm (as-machined) |

This technical foundation ensures Birmingham manufacturers receive components that fit, function, and perform as engineered. Our commitment extends beyond machining; we provide proactive engineering feedback during the design phase to optimize manufacturability and cost-effectiveness for UK-specific applications. Partnering with Wuxi Lead offers Birmingham businesses access to scalable precision capacity without compromising on the exacting standards required for critical components, delivering measurable value through reduced scrap, accelerated time-to-market, and unwavering quality consistency.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is a foundational decision in precision CNC machining, directly influencing performance, durability, and cost-efficiency. For industries in Birmingham and across the UK requiring high-tolerance components—such as aerospace, medical, and automotive—understanding the mechanical properties and machining behaviors of aluminum, steel, and titanium is essential. At Wuxi Lead Precision Machinery, we support global clients with expert material recommendations based on application demands and environmental conditions.

Aluminum remains one of the most widely used materials in CNC machining due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly favored for structural and mechanical components, offering good corrosion resistance and weldability. Its lower density makes it ideal for applications where weight reduction is critical, such as in aerospace enclosures or automotive heat sinks. Aluminum is also highly compatible with anodizing, a finish that enhances surface hardness and corrosion resistance while allowing for color customization.

Steel, particularly in alloy forms such as 4140 and 1018, delivers superior strength and wear resistance. These grades are commonly selected for high-stress mechanical parts, tooling, and industrial machinery components. While steel is more challenging to machine than aluminum due to increased tool wear and higher cutting forces, its durability under load and impact makes it indispensable in demanding environments. Post-machining treatments such as heat treating or plating are often applied to further enhance performance.

Titanium, specifically Grade 5 (Ti-6Al-4V), offers an exceptional balance of strength, corrosion resistance, and biocompatibility. It is widely used in aerospace and medical implant applications where performance under extreme conditions is non-negotiable. However, titanium’s low thermal conductivity and high chemical reactivity require specialized tooling and slower machining parameters. Despite higher material and processing costs, its long-term reliability justifies its use in mission-critical systems.

Surface Finish: Anodizing for Aluminum

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum, significantly improving surface hardness and corrosion resistance. Type II (sulfuric acid) anodizing is commonly used for general industrial applications, offering a durable, decorative finish with optional dyeing. Type III, or hard anodizing, provides even greater wear resistance and is suitable for components exposed to abrasion or high stress. At Wuxi Lead, we apply precision anodizing in accordance with international standards, ensuring consistent coating thickness and adhesion.

Below is a comparative overview of key properties for common CNC machining materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications | Machinability |

|---|---|---|---|---|---|

| Aluminum | 310 | 2.7 | 6061-T6, 7075-T6 | Aerospace, Enclosures, Heat Sinks | Excellent |

| Steel | 655–1000 | 7.85 | 4140, 1018 | Tooling, Shafts, Industrial Parts | Moderate |

| Titanium | 900–950 | 4.5 | Ti-6Al-4V (Gr5) | Medical Implants, Aerospace | Challenging |

Understanding these material characteristics enables informed decisions that align with functional requirements and production efficiency. At Wuxi Lead Precision Machinery, we provide expert consultation and precision machining services to ensure optimal material and finish selection for every project.

Manufacturing Process & QC

Integrated Production Workflow for Precision CNC Machining

Our production process for Birmingham manufacturers follows a rigorously defined sequence from initial concept to finished component, engineered to deliver Zero Defects performance. This structured approach eliminates costly iterations and ensures seamless transition from design intent to high-volume output, directly addressing the stringent quality demands of UK aerospace, medical, and automotive sectors.

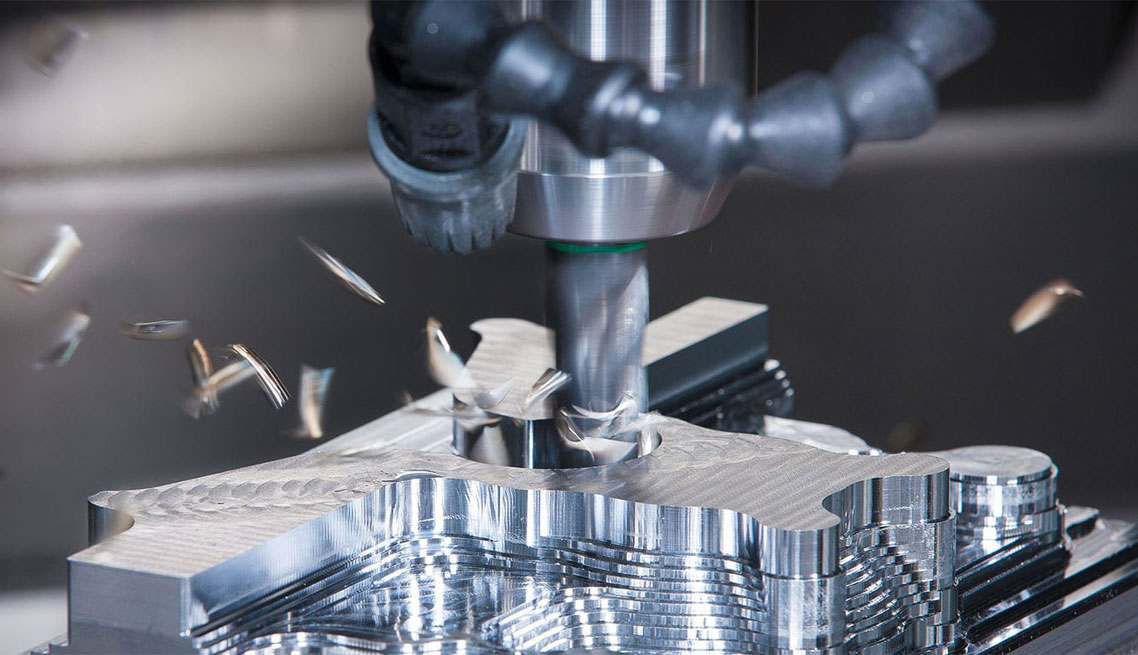

Design verification begins with comprehensive DFM analysis. Our engineering team collaborates closely with your designers, utilizing advanced CAD/CAM simulation to identify potential manufacturability issues, optimize toolpaths, and validate geometric dimensioning and tolerancing (GD&T) schemes against your technical drawings. This proactive step prevents downstream errors, ensuring the digital model is fully optimized for precision machining before any material is cut. Critical tolerances and surface finish requirements are explicitly defined and cross-referenced against material properties and machine capabilities during this phase.

Prototyping serves as the critical validation checkpoint. We produce functional prototypes using the identical CNC equipment, tooling, and materials designated for full production. Each prototype undergoes exhaustive metrology, including CMM inspection against the original CAD model and all specified GD&T callouts. Dimensional accuracy, surface integrity, and material properties are verified beyond standard requirements. Client feedback on these prototypes is incorporated immediately, with engineering changes documented and re-validated. This phase confirms process stability and component functionality, providing absolute confidence before committing to mass production tooling and scheduling.

Mass production execution leverages the validated process parameters. Our facility employs a multi-stage in-process quality control system. Raw material certification is verified upon receipt. During machining, automated tool length and diameter compensation, coupled with in-cycle probing on critical features, ensures dimensional consistency. Every component undergoes 100% first-article inspection and statistically significant in-process checks per AS9102 or ISO 13485 standards as required. Final inspection utilizes calibrated CMMs, optical comparators, and surface roughness testers against the complete specification. Non-conforming parts are immediately quarantined; root cause analysis triggers corrective actions within our closed-loop quality management system. This systematic enforcement of Zero Defects methodology minimizes scrap, guarantees batch-to-batch repeatability, and safeguards your supply chain continuity.

Key Production Capabilities for Birmingham Partners

| Parameter | Specification | Relevance for UK Manufacturing |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | Meets aerospace hydraulic & medical implant standards |

| Surface Roughness (Ra) | As low as 0.2 µm (8 µin) | Critical for fluid dynamics & biocompatibility |

| Max Work Envelope | 1200 x 800 x 650 mm | Accommodates complex structural components |

| Primary Materials | Aerospace Al, Ti-6Al-4V, Inconel, Medical SS, Engineering Plastics | Supports diverse sector requirements |

| Core Equipment | 5-Axis Milling (DMG MORI), Swiss Lathes (Citizen), Grinding (Makino) | Ensures complex geometry capability & tight tolerance control |

| Quality Certification | ISO 9001:2015, IATF 16949, AS9100D | Mandatory for automotive & aerospace supply chains |

This disciplined workflow, underpinned by advanced metrology and our Zero Defects culture, transforms design specifications into flawless physical components. We eliminate the hidden costs of rework and delays, providing Birmingham engineers with a predictable, high-integrity manufacturing partner for mission-critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

When sourcing high-precision CNC machining services for demanding industrial applications, global manufacturers trust Wuxi Lead Precision Machinery to deliver superior quality, tight tolerances, and on-time delivery—no matter the complexity. While Birmingham continues to grow as a hub for advanced engineering and aerospace innovation, many UK-based firms are discovering strategic advantages in partnering with offshore leaders who combine cutting-edge technology with cost efficiency. At Wuxi Lead, we bridge that gap with seamless integration, ISO-certified processes, and a customer-centric approach tailored to the exacting standards of European and North American industries.

Our facility in Wuxi, China, spans over 10,000 square meters and is equipped with a full suite of 3-, 4-, and 5-axis CNC machining centers, Swiss-type lathes, and multi-tasking machines capable of handling both prototyping and high-volume production. We specialize in precision components for aerospace, medical devices, automation, and energy sectors—where tolerances often reach ±0.002 mm and surface finishes demand micron-level consistency. Every part is manufactured under strict quality control, with full traceability, first-article inspection reports (FAIR), and PPAP documentation available upon request.

What sets Wuxi Lead apart is not just our technical capability, but our commitment to partnership. We assign a dedicated project manager to every client, ensuring clear communication, real-time updates, and rapid response to engineering feedback. Our team is fluent in English and operates in alignment with Western business hours for seamless collaboration. Whether you’re based in Birmingham, London, or beyond, you’ll experience the reliability of local service with the scalability and cost benefits of offshore manufacturing.

We understand that trust is earned through performance. That’s why we encourage engineering teams to send us your most challenging designs—complex geometries, tight tolerance requirements, or multi-material assemblies. Our in-house engineering support will conduct a detailed Design for Manufacturability (DFM) analysis and provide actionable feedback to optimize cost, lead time, and performance before production begins.

Below are key capabilities that define our CNC machining services:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, turning, mill-turn, Swiss machining |

| Tolerances | As tight as ±0.002 mm |

| Materials | Aluminum, stainless steel, titanium, brass, PEEK, Delrin, and exotic alloys |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), up to Ø320 mm for turning |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by volume) |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), RoHS compliant |

| Finishes | As-machined, anodizing, passivation, polishing, powder coating |

Partnering with Wuxi Lead Precision Machinery means gaining a reliable extension of your manufacturing team—one that prioritizes precision, transparency, and long-term collaboration. If you’re seeking CNC machining services that combine world-class accuracy with competitive pricing, contact us today. Send your RFQ or 3D CAD file to [email protected] and discover how we can support your next project from concept to delivery.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.