Technical Contents

Engineering Guide: 3D Molding

Engineering Insight: Precision as the Core of 3D Molding in Critical Metal Components

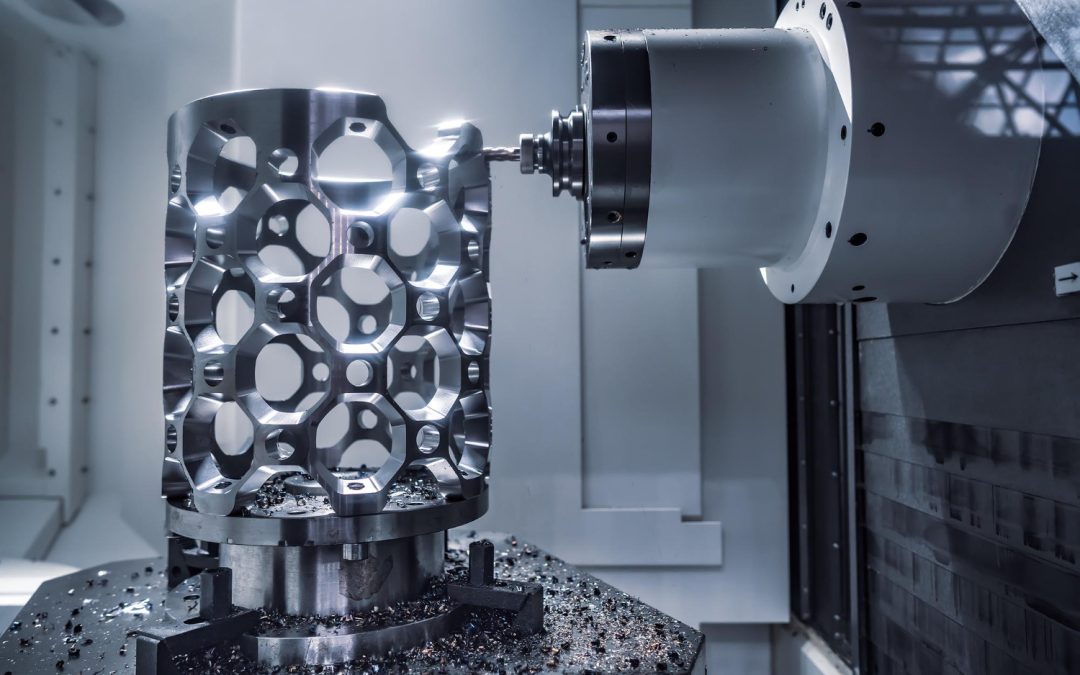

In the realm of advanced custom metal manufacturing, the term “3D molding” specifically refers to the high-precision, multi-axis CNC machining processes required to produce complex, three-dimensional geometries from solid metal stock. This is distinct from plastic injection molding and represents the pinnacle of subtractive manufacturing for mission-critical applications. At Wuxi Lead Precision Machinery, we define 3D molding by its uncompromising demand for micron-level accuracy across all spatial dimensions. The significance of this precision cannot be overstated; even minute deviations in critical features directly impact component functionality, structural integrity, assembly fit, and ultimately, the safety and performance of the final system. Dimensional instability cascades into premature wear, system failure, or catastrophic safety hazards, especially under extreme operational stresses encountered in aerospace, defense, and high-performance sporting equipment. Tolerances are not merely specifications on a drawing; they are the fundamental guarantee of reliability.

Achieving true 3D molding precision requires far more than advanced machinery. It demands an integrated mastery of material science, thermal dynamics, cutting tool technology, vibration control, and real-time process monitoring. Sub-micron thermal compensation systems, ultra-rigid machine structures, and adaptive control algorithms are non-negotiable elements in our manufacturing ecosystem. This level of control is precisely why Wuxi Lead Precision Machinery has been entrusted with components for Olympic-level competition equipment and stringent military/aerospace programs. These applications tolerate zero margin for error, where a variance of 0.005mm can mean the difference between victory and failure, or safety and risk. Our engineering team possesses deep, proven experience navigating the extreme tolerances and material challenges inherent in these sectors, translating theoretical precision into consistent, certified reality.

Our commitment to precision is quantifiable across our core 3D molding capabilities. The following table outlines the critical performance specifications achievable on our dedicated high-precision machining platforms:

| Specification Category | Performance Level | Key Technology Enablers |

|---|---|---|

| Geometric Tolerance (GD&T) | ±0.005 mm (±0.0002″) | 5-Axis Simultaneous Machining, Laser Calibration, In-Process Probing |

| Surface Finish (Ra) | 0.4 µm (16 µin) | Precision Spindles (≤ 1µm runout), Optimized Toolpaths, Vibration Dampening |

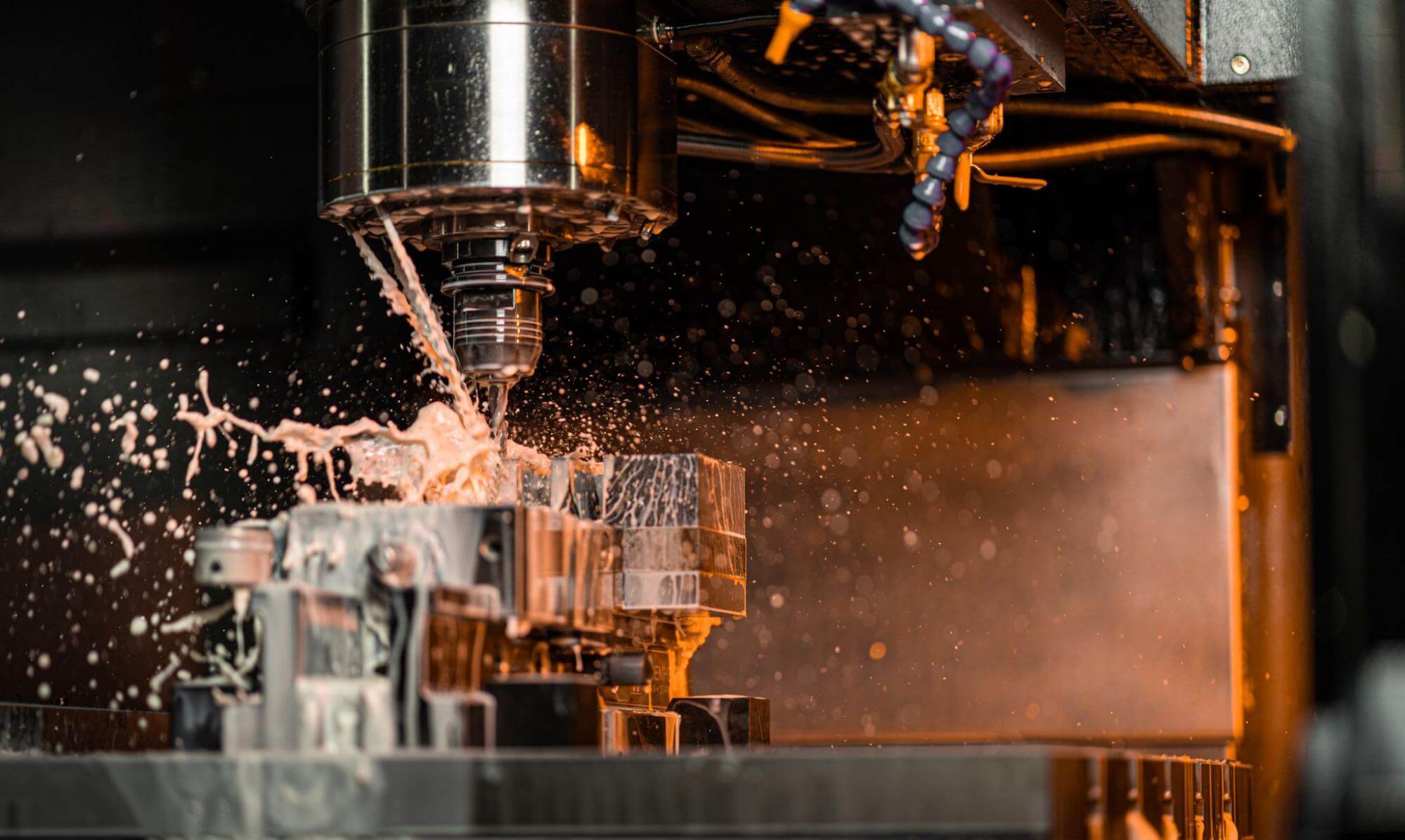

| Material Range | Titanium Alloys, Inconel, High-Strength Steels, Aluminum Alloys | Application-Specific Tooling, Coolant Strategies, Thermal Management |

| Critical Feature Repeatability (CpK) | ≥ 1.67 | Statistical Process Control (SPC), Real-Time Monitoring, Closed-Loop Feedback |

| Max Work Envelope (5-Axis) | Ø 800 mm x 600 mm H | High-Torque Rotary Tables, Rigorous Machine Foundation |

This capability set is not theoretical; it is the operational standard applied daily to meet the exacting demands of our most discerning clients. The investment in metrology – including coordinate measuring machines (CMMs) with nanometer resolution and optical comparators – ensures every component leaving our facility meets or exceeds the specified precision envelope. For engineers specifying complex metal components, understanding that true 3D molding capability resides in the consistent execution of these tolerances, across diverse materials and geometries, is paramount. Wuxi Lead Precision Machinery provides not just machining services, but guaranteed dimensional integrity for applications where performance is non-negotiable. Contact our engineering team to discuss how our precision 3D molding expertise solves your most challenging manufacturing requirements.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the rigorous demands of high-precision industries such as aerospace, medical devices, and advanced automation. At the core of our production infrastructure is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to execute complex 3D molding operations with exceptional accuracy and surface integrity. These multi-axis systems provide simultaneous motion across all five axes, allowing for intricate geometries, deep cavities, and organic contours that are unattainable with conventional 3-axis methods. Our machining platforms support a broad range of metals, including aluminum alloys, stainless steel, titanium, and high-performance superalloys, ensuring material compatibility across diverse application environments.

Precision is non-negotiable in high-end manufacturing, which is why every component undergoes comprehensive quality verification using coordinate measuring machine (CMM) inspection. Our CMM systems are integrated into the production workflow to provide real-time dimensional analysis, ensuring compliance with tight tolerances and geometric specifications. Each inspection report is fully documented and traceable, meeting ISO 9001 and IATF 16949 quality standards. This end-to-end inspection protocol guarantees consistency across batches and supports full regulatory compliance for mission-critical components.

Our 5-axis CNC technology eliminates the need for multiple setups, reducing cumulative error and improving throughput. The ability to approach a workpiece from nearly any angle ensures superior surface finish and reduced tool wear, contributing to longer tool life and lower production costs over time. Advanced CAM software enables optimized toolpaths, minimizing cycle times while maintaining micron-level accuracy. This capability is particularly valuable in 3D molding applications where complex curvature, undercuts, and thin-walled structures are common.

Wuxi Lead Precision Machinery maintains strict environmental controls within its machining cells to minimize thermal drift and vibration, further enhancing dimensional stability. All operators are certified in high-precision machining protocols and supported by in-house engineering teams who specialize in design for manufacturability (DFM) analysis. This collaborative approach ensures that every part is not only manufacturable but optimized for performance, cost, and scalability.

The following table outlines the standard tolerance specifications achievable through our 5-axis CNC and inspection systems:

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Geometric Tolerance (GD&T) | ±0.02 mm | ±0.01 mm |

| Repeatability (Cp/Cpk ≥1.67) | ±0.01 mm | ±0.005 mm |

These capabilities reflect our commitment to delivering precision-engineered metal components that meet the highest standards of form, fit, and function in advanced 3D molding applications.

Material & Finish Options

Material Selection for Precision 3D Molding Applications

Material choice fundamentally dictates the performance, longevity, and cost-effectiveness of components produced via precision 3D molding processes. At Wuxi Lead Precision Machinery, we emphasize selecting the optimal metal alloy in conjunction with the appropriate surface finish to meet stringent functional requirements and environmental exposure. Aluminum, steel, and titanium represent the core material families for demanding industrial applications, each offering distinct advantages.

Aluminum alloys, particularly 6061 and 7075, are preferred for applications demanding a high strength-to-weight ratio, excellent thermal conductivity, and good machinability. They are cost-effective for complex geometries and respond exceptionally well to anodizing, significantly enhancing surface hardness and corrosion resistance. Aluminum is ideal for aerospace components, automotive heat sinks, and portable electronic enclosures where weight savings are critical.

Steel, encompassing both stainless grades (304, 316) and alloy steels (4140, 4340), provides superior strength, wear resistance, and structural integrity under heavy loads or high temperatures. Stainless variants offer inherent corrosion resistance suitable for medical, marine, and chemical processing environments. Alloy steels, often requiring post-machining heat treatment, deliver maximum hardness for tooling, shafts, and high-stress mechanical parts. Steel selection balances ultimate strength needs against weight considerations and corrosion exposure.

Titanium, primarily Grade 5 (Ti-6Al-4V), is the solution for extreme environments demanding unparalleled strength-to-weight ratio, exceptional corrosion resistance (including seawater and chlorides), and biocompatibility. Its high cost is justified in critical aerospace, defense, and medical implant applications where failure is not an option. Titanium’s low thermal conductivity presents machining challenges that require specialized CNC strategies and tooling expertise.

The following table summarizes key properties for common precision molding alloys:

| Material | Key Alloys | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 2.7 | 310 (6061), 570 (7075) | Good (Excellent w/ Anodizing) | Aerospace brackets, heat sinks, enclosures |

| Steel | 304, 316, 4140 | 7.8-8.0 | 515 (304), 655 (4140) | Excellent (SS), Moderate (Alloy) | Medical instruments, marine fittings, tooling |

| Titanium | Grade 5 (Ti-6Al-4V) | 4.4 | 900 | Exceptional | Aircraft structural parts, surgical implants |

Anodizing is the predominant surface finish for aluminum components in precision 3D molding. This electrochemical process creates a durable, wear-resistant oxide layer integral to the base metal. Type II (sulfuric acid) anodizing offers good corrosion protection and dye acceptance for decorative or identification purposes. Type III (hardcoat) anodizing produces significantly thicker, harder coatings essential for parts subjected to abrasion, sliding contact, or severe environmental exposure. Proper anodizing parameters are critical; excessive thickness can compromise tight tolerances on precision-molded features. Wuxi Lead engineers collaborate closely with clients to specify the exact anodizing type, thickness, and sealing process aligned with the component’s functional demands and dimensional constraints, ensuring optimal performance and service life. Material and finish selection is never generic; it is a precise engineering decision central to the success of your application.

Manufacturing Process & QC

The 3D molding production process at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect outcomes in custom metal manufacturing. Our integrated workflow spans design, prototyping, and mass production, ensuring every component meets exacting industrial standards.

Design begins with a collaborative engineering review, where our team analyzes 3D CAD models, material specifications, and functional requirements. Finite element analysis (FEA) and mold flow simulations are applied to predict structural integrity and molding behavior, minimizing risk before physical production. This phase emphasizes manufacturability, optimizing wall thickness, draft angles, and parting lines to ensure dimensional stability and surface quality in the final metal component. All designs are validated against international tolerancing standards, including ISO 2768 and GD&T protocols.

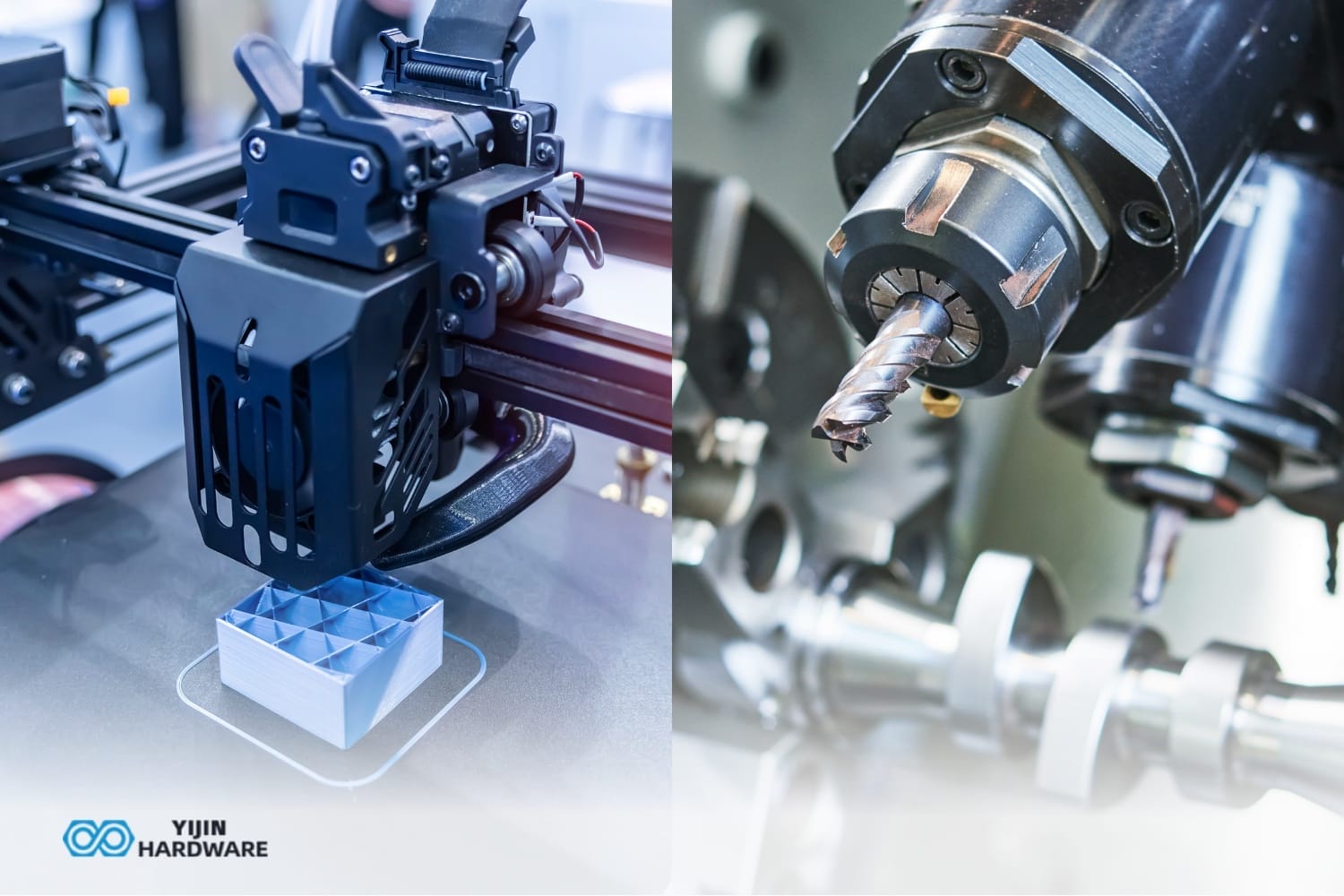

Prototyping follows design validation using high-precision CNC-machined molds or additive-manufactured tooling, depending on complexity and volume requirements. Each prototype is subjected to rigorous metrological inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify conformity to design intent. Functional testing, including thermal cycling and load simulation, is performed to assess real-world performance. Feedback from this stage is incorporated into final mold adjustments, ensuring process readiness for scale. Our closed-loop prototyping cycle reduces time-to-production while eliminating potential flaws before mass manufacturing begins.

Mass production leverages automated 3D molding cells equipped with real-time monitoring systems. Each molding press operates under tightly controlled parameters—temperature, pressure, cycle time—with data logged for full traceability. In-process quality checks occur at defined intervals, supported by automated vision systems and statistical process control (SPC). Every batch is accompanied by a material certification and first-article inspection report. Our zero-defect philosophy is enforced through preventive maintenance schedules, operator training, and a non-conformance management system that triggers immediate root-cause analysis for any deviation.

Wuxi Lead Precision Machinery maintains strict compliance with ISO 9001 and IATF 16949 standards across all production stages. Our facility supports a wide range of metals, including aluminum alloys, stainless steel, and titanium, processed via advanced techniques such as high-pressure die casting, metal injection molding (MIM), and precision forging adapted for 3D molding geometries.

Key production specifications are outlined below:

| Parameter | Specification |

|---|---|

| Dimensional Accuracy | ±0.02 mm |

| Surface Finish | Ra 0.4–1.6 µm (polished to mirror grade) |

| Material Options | Al 6061, Al 7075, SS 316L, Ti-6Al-4V, Inconel |

| Maximum Part Weight | 2.5 kg |

| Minimum Wall Thickness | 0.5 mm |

| Production Tolerance Class | ISO 2768-mK, DIN 1688-3 |

| Lead Time (Prototype) | 10–15 days |

| Lead Time (Mass Production) | 25–35 days (10,000+ units) |

| Quality Standard | Zero-defect target, 100% inspection sampling |

From concept to completion, Wuxi Lead Precision Machinery delivers 3D molded metal components with uncompromising quality, enabling clients in aerospace, medical, and high-performance automotive sectors to achieve engineering excellence.

Why Choose Wuxi Lead Precision

Elevate Your Metal Fabrication with Precision Engineering Partnerships

In today’s competitive advanced manufacturing landscape, the convergence of 3D modeling and precision metal forming demands more than standard production capabilities. True innovation emerges when engineering expertise aligns with cutting-edge machinery to transform complex digital designs into mission-critical physical components. Wuxi Lead Precision Machinery specializes in this exact synergy, delivering custom 3D molding solutions for aerospace, medical, and energy sectors where tolerances below ±0.005mm and material integrity are non-negotiable. We bridge the gap between ambitious design intent and flawless execution, ensuring your prototypes and production runs meet the highest global standards without compromise.

Our integrated approach combines multi-axis CNC milling, precision stamping, and additive-subtractive hybrid processes within a single workflow. This eliminates traditional handoffs that introduce errors and delays, directly translating 3D CAD models into certified components with repeatable accuracy. Unlike conventional suppliers, we prioritize material science understanding—optimizing grain structure and stress distribution for titanium, Inconel, and high-strength alloys to prevent post-forming failures. Every project undergoes rigorous in-process metrology using Zeiss CMM systems, guaranteeing conformance to AS9100 and ISO 13485 specifications before shipment.

Technical Capabilities at a Glance

| Parameter | Specification | Industry Relevance |

|---|---|---|

| Material Range | Titanium, Inconel, Stainless Steel 17-4PH, Tool Steels | Critical for high-temp/corrosive environments |

| Geometric Tolerance | ±0.005 mm (±0.0002″) | Meets aerospace hydraulic component standards |

| Max Work Envelope | 1200 x 800 x 600 mm | Accommodates large structural assemblies |

| Surface Finish | Ra 0.4 µm (16 µin) achievable | Essential for medical implant biocompatibility |

| Lead Time (Prototype) | 15–22 days from CAD approval | Accelerates R&D validation cycles |

Partnering with Lead Precision means embedding our engineers into your development cycle from day one. We conduct Design for Manufacturability (DFM) reviews to identify potential forming challenges early—reducing scrap rates by up to 37% compared to industry averages. Our Wuxi facility operates under strict ITAR-compliant protocols, with dedicated cleanrooms for medical device production and real-time SPC data sharing portals for client transparency. When your project requires zero-defect delivery under tight regulatory scrutiny, our 98.2% first-pass yield rate becomes your strategic advantage.

Do not let manufacturing limitations constrain your next breakthrough. Contact our engineering team directly at [email protected] to initiate a technical consultation. Specify your component’s critical features, material requirements, and target volume in your inquiry. Within 24 business hours, you will receive a feasibility assessment with actionable recommendations—not a generic sales pitch. For urgent RFQs, include “Priority Engineering Review” in the subject line to trigger expedited analysis by our senior process engineers. Your designs deserve partners who speak the language of GD&T fluently and deliver precision as a baseline expectation. Reach out today to secure capacity for your high-complexity metal fabrication program.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.