Technical Contents

Engineering Guide: Premium Cnc Milling Machines For Automotive

Engineering Insight: Precision CNC Milling Machines for Automotive Applications

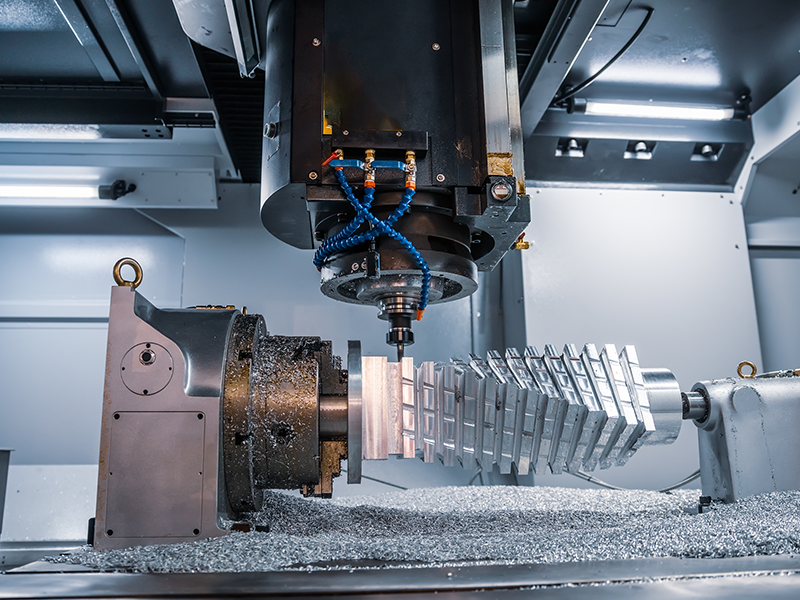

In the high-stakes world of automotive manufacturing, precision is not merely a performance metric—it is a foundational requirement. From engine blocks to transmission components, suspension systems to electric vehicle (EV) battery housings, the dimensional accuracy, surface finish, and repeatability of machined parts directly influence vehicle performance, safety, and longevity. Premium CNC milling machines designed for the automotive sector must therefore deliver micron-level consistency, robust thermal stability, and advanced control systems capable of sustaining high-volume production without compromising quality.

At Wuxi Lead Precision Machinery, we understand that automotive OEMs and Tier-1 suppliers demand more than just metal removal—they require predictable, traceable, and scalable precision. Our CNC milling solutions are engineered with rigid cast iron bases, linear guideways, and high-torque spindles to ensure minimal deflection and vibration during heavy cutting operations. These design elements, combined with real-time tool compensation and in-process probing, allow our machines to maintain tolerances within ±0.002 mm, a standard essential for critical drivetrain and safety components.

Precision, however, is not solely a function of machine hardware. It is the result of holistic engineering—integrating mechanical design, control algorithms, thermal management, and software intelligence. Our machines feature FANUC or Siemens CNC systems with adaptive control, enabling dynamic adjustments to cutting parameters based on load feedback. This ensures consistent tool wear, extended spindle life, and reduced scrap rates in continuous production environments.

Wuxi Lead Precision Machinery brings over 15 years of experience in delivering mission-critical machining solutions for industries where failure is not an option. Our engineering team has contributed to projects requiring Olympic-level precision in metrology standards and has supplied equipment meeting stringent military-grade specifications. This heritage of uncompromising accuracy directly informs our automotive CNC platform development, ensuring each machine meets the highest global benchmarks for performance and reliability.

As the automotive industry transitions toward electrification and lightweight materials, the demand for multi-axis milling capabilities and high-speed machining has intensified. Our premium CNC milling machines support 4-axis and 5-axis configurations, enabling complex geometries to be machined in a single setup—reducing cycle times and improving part integrity.

Below are key specifications of our flagship automotive-grade CNC milling machine series:

| Specification | Detail |

|---|---|

| Spindle Speed | 8,000 – 12,000 rpm (optional 18,000 rpm high-speed) |

| Table Size | 1,200 x 600 mm (custom up to 2,000 x 1,000 mm) |

| Axis Travel (X/Y/Z) | 1,200 / 600 / 550 mm |

| Repeatability | ±0.002 mm |

| Positioning Accuracy | ±0.005 mm |

| Control System | FANUC 31i-B5 or Siemens 840D sl |

| Tool Magazine | 24 to 60 tools (ATC) |

| Rapid Traverse Rate | 48 m/min (X/Y/Z) |

| Spindle Power | 15 – 22 kW |

| Cooling System | Centralized high-pressure (20 bar) through-spindle coolant |

Wuxi Lead Precision Machinery continues to set the standard for premium CNC milling in automotive manufacturing—where precision, durability, and innovation converge to drive the future of mobility.

Precision Specs & Tolerances

Technical Capabilities for Automotive Precision Machining

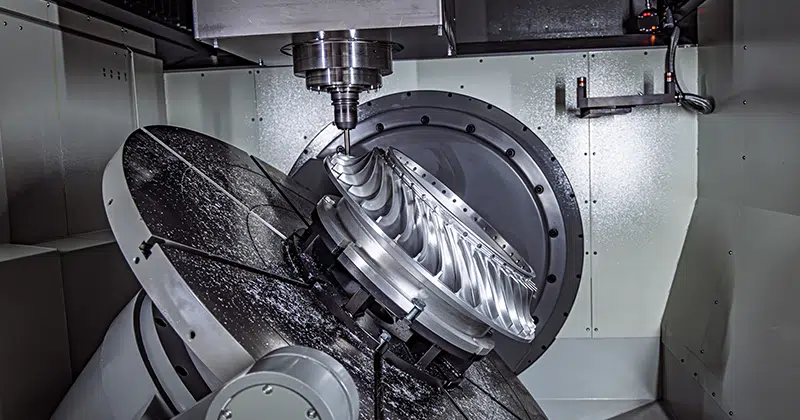

Wuxi Lead Precision Machinery delivers uncompromising precision engineered specifically for the demanding requirements of the global automotive sector. Our core strength lies in advanced 5-axis CNC milling technology, enabling the production of complex, high-integrity components essential for modern powertrains, chassis systems, and safety-critical assemblies. Unlike conventional 3-axis systems, our 5-axis machining centers simultaneously manipulate the workpiece across five distinct planes. This capability is fundamental for automotive applications, allowing complete machining of intricate geometries—such as cylinder heads, transmission cases, differential housings, and structural brackets—in a single setup. The elimination of multiple fixturing operations drastically reduces cumulative error, ensures superior part-to-part consistency, and significantly cuts overall production cycle times. This translates directly to enhanced throughput and reduced cost-per-part for our automotive clients without sacrificing dimensional integrity.

Achieving the stringent tolerances mandated by automotive OEMs and tier suppliers requires more than advanced machinery; it demands a holistic precision ecosystem. Our facility operates under strict environmental controls to minimize thermal drift, a critical factor for maintaining micron-level accuracy during extended production runs. Machine tools undergo rigorous, scheduled calibration using laser interferometers and ballbar systems, verifying positioning accuracy, repeatability, and contouring performance against ISO 230-2 and ISO 230-4 standards. This proactive maintenance ensures machines consistently perform at their specified capability limits, providing the foundation for reliable high-volume output.

Quality verification is non-negotiable in automotive manufacturing. Every critical component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMMs), including multi-sensor platforms capable of high-speed tactile probing and optical scanning. Our CMMs are calibrated to national standards and integrated with advanced metrology software for GD&T analysis, surface texture measurement, and full first-article inspection reports compliant with PPAP requirements. This robust QC process provides traceable, objective evidence that every part meets the exacting specifications demanded by automotive quality management systems like IATF 16949.

The following table details the typical geometric and dimensional tolerances achievable across common automotive materials (aluminum alloys, cast iron, steel, titanium) using our optimized 5-axis machining and inspection processes:

| Tolerance Characteristic | Typical Capability | Critical Application Example |

|---|---|---|

| Positional Accuracy | ±0.005 mm | Bolt hole patterns on engine blocks |

| Profile of a Surface | 0.010 mm | Sealing surfaces for cylinder heads |

| Flatness | 0.008 mm / 100 mm | Transmission case mating surfaces |

| Concentricity | 0.015 mm | Bearing bores in differential carriers |

| Surface Roughness (Ra) | 0.4 – 0.8 µm | Hydraulic valve spool bores |

These capabilities are not theoretical benchmarks but proven production standards maintained daily. Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology, rigorous process control, and metrology-grade inspection to deliver the dimensional perfection and reliability the automotive industry requires. Partner with us to transform complex automotive designs into flawlessly machined reality.

Material & Finish Options

Material Selection for Premium CNC Milling in Automotive Applications

Selecting the right material for CNC milled automotive components is critical to achieving performance, durability, and weight efficiency. At Wuxi Lead Precision Machinery, we specialize in high-precision CNC milling of advanced materials tailored to the demanding requirements of modern automotive engineering. Three primary materials dominate this space: aluminum, steel, and titanium. Each offers distinct mechanical properties and is suited to specific applications within powertrain systems, chassis components, and performance-critical assemblies.

Aluminum alloys, particularly 6061 and 7075, are widely used due to their excellent strength-to-weight ratio and machinability. These alloys are ideal for suspension arms, engine blocks, and transmission housings where weight reduction is paramount without sacrificing structural integrity. Aluminum also responds well to anodizing, a common surface finish that enhances corrosion resistance and wear performance while allowing for aesthetic customization through coloration.

Steel, especially alloy grades like 4140 and 4340, provides superior tensile strength and fatigue resistance. It is the preferred choice for drivetrain components such as shafts, gears, and high-load fasteners. While heavier than aluminum, steel’s durability under high stress and elevated temperatures makes it indispensable in performance and heavy-duty automotive systems. Our CNC milling processes ensure tight tolerances and fine surface finishes, critical for mating surfaces and dynamic load environments.

Titanium alloys, such as Ti-6Al-4V, offer an exceptional combination of strength, low density, and corrosion resistance. Though more challenging to machine due to their low thermal conductivity and tendency to work-harden, titanium is increasingly used in high-performance and motorsport applications—including connecting rods, valve trains, and aerospace-derived structural elements. At Wuxi Lead, our advanced tooling strategies and cooling techniques ensure efficient titanium machining with minimal tool wear and optimal surface quality.

Surface finishing plays a vital role in component longevity and performance. Anodizing, particularly Type II (sulfuric acid) and Type III (hardcoat), is a key post-processing step for aluminum parts. It creates a durable, non-conductive oxide layer that improves wear resistance and protects against environmental degradation. Hard anodizing can achieve coating thicknesses up to 50–75 µm with hardness values exceeding 60 HRC, making it suitable for high-friction applications.

The following table summarizes key material properties and machining characteristics relevant to automotive CNC milling:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Automotive Use | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Brackets, housings | Yes |

| Aluminum | 7075-T6 | 570 | 2.8 | Suspension, aerospace | Yes (Type II/III) |

| Steel | 4140 | 850–1000 | 7.85 | Shafts, gears | No |

| Steel | 4340 | 900–1200 | 7.85 | High-stress components | No |

| Titanium | Ti-6Al-4V | 900–1000 | 4.43 | Valves, rods, fasteners | No |

Material and finish selection must align with functional requirements, environmental exposure, and lifecycle expectations. Wuxi Lead Precision Machinery supports automotive manufacturers with expert consultation and precision machining to ensure optimal material utilization and part performance.

Manufacturing Process & QC

Precision Production Process for Automotive CNC Milling Excellence

Precision begins at the design phase, where Wuxi Lead integrates deep automotive application knowledge with advanced CAD/CAM simulation. Our engineers collaborate directly with client design teams to optimize part geometry for manufacturability, ensuring critical features like transmission housings or suspension components meet stringent GD&T requirements while minimizing cycle times. Finite Element Analysis (FEA) validates structural integrity under operational loads, and virtual machine simulation eliminates potential collisions or toolpath errors before metal is cut. This proactive approach prevents costly redesigns and establishes the foundation for zero defects.

Prototyping transitions seamlessly from validated digital models to physical verification. Utilizing our premium 5-axis milling centers, we produce initial components in the exact production material—be it aerospace-grade aluminum, high-strength steel, or specialized alloys. Each prototype undergoes rigorous metrology using calibrated CMMs and optical scanners, comparing every critical dimension against the master CAD model. Crucially, we perform functional testing under simulated automotive operating conditions, such as thermal cycling or load-bearing assessments. This phase isn’t merely about part validation; it’s a stress test for the entire manufacturing process, identifying micro-vibrations, thermal drift, or tool wear patterns that could compromise future production runs. Only when dimensional accuracy, surface finish, and material properties consistently exceed automotive OEM specifications do we approve the process for scale-up.

Mass production leverages the perfected process with unwavering discipline. Our premium CNC milling machines operate within climate-controlled environments, minimizing thermal variables. Real-time process monitoring systems track spindle load, vibration, and tool condition, automatically compensating for deviations or triggering tool changes before out-of-tolerance conditions occur. Statistical Process Control (SPC) is embedded at every station, with data fed continuously into our quality management system. Each component undergoes 100% critical feature inspection via automated in-process gauging, while final audit stations perform comprehensive checks. This closed-loop system, combined with operator expertise trained to Six Sigma standards, ensures batch-to-batch consistency and absolute adherence to zero-defect protocols demanded by automotive safety-critical applications.

Wuxi Lead Premium CNC Milling Machine Specifications for Automotive Production

| Critical Parameter | Performance Standard | Relevance to Automotive Zero-Defect Production |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ≤ ±1.5 µm (ISO 230-2) | Ensures precise bore alignment in engine blocks and transmission cases |

| Repeatability (X/Y/Z) | ≤ ±0.8 µm (ISO 230-2) | Guarantees consistent feature placement across high-volume runs |

| Thermal Growth Compensation | ≤ 2 µm over 8-hour shift | Maintains dimensional stability during extended production cycles |

| Vibration Level | < 0.5 mm/s RMS (ISO 10816) | Achieves mirror finishes on hydraulic components and critical sealing surfaces |

| In-Process Probing Accuracy | ±1.0 µm repeatability | Enables real-time correction of tool wear and thermal drift effects |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Milling Excellence in Automotive Manufacturing

In the fast-paced world of automotive production, precision, speed, and reliability are not just advantages—they are requirements. At Wuxi Lead Precision Machinery, we understand the demands of high-volume, high-tolerance manufacturing. Our premium CNC milling machines are engineered specifically for the automotive industry, delivering the repeatability, rigidity, and advanced control systems needed to produce complex engine components, transmission parts, chassis elements, and prototype systems with absolute consistency.

When you choose to partner with Lead Precision, you are not just purchasing machinery—you are gaining access to a full-scale engineering alliance. Our team of CNC specialists works closely with automotive OEMs, Tier 1 suppliers, and contract manufacturers to design, validate, and deploy milling solutions that integrate seamlessly into your production workflow. Whether you’re scaling up production lines or optimizing for next-generation electric vehicle components, our machines are built to adapt and excel.

Our premium CNC milling platforms combine high-speed spindles, thermally stable cast iron beds, and FANUC or Siemens controls to ensure micron-level accuracy across thousands of cycles. With rapid tool change systems, automated pallet changers, and real-time monitoring capabilities, our machines maximize uptime and minimize operator intervention—critical factors in maintaining lean, efficient automotive manufacturing operations.

We pride ourselves on delivering more than equipment. We deliver performance assurance. Every machine undergoes rigorous in-factory testing, including trial runs with customer-specified materials and cutting parameters. Our global service network ensures rapid deployment, on-site installation, and continuous technical support, so your operations face minimal downtime from day one.

Below are key specifications from our flagship CNC milling series tailored for automotive applications:

| Model | Travel (X/Y/Z) | Spindle Speed | Rapid Traverse | Positioning Accuracy | Control System | Tool Capacity |

|---|---|---|---|---|---|---|

| LP-MV850 | 850 x 500 x 500 mm | 8,000 rpm | 48 m/min | ±0.006 mm | FANUC 31i | 24 tools |

| LP-MV1060 | 1,000 x 600 x 600 mm | 6,000 rpm | 42 m/min | ±0.008 mm | Siemens 840D | 30 tools |

| LP-HMC1200 | 1,200 x 800 x 700 mm | 10,000 rpm | 50 m/min | ±0.005 mm | FANUC 31i | 40 tools (with pallet system) |

These machines are designed for durability under continuous operation and are compatible with advanced coolant delivery, chip management, and Industry 4.0 integration for full digital factory connectivity.

Partnering with Wuxi Lead Precision Machinery means investing in long-term manufacturing superiority. We are committed to supporting your growth with scalable, precision-engineered solutions backed by technical expertise and responsive service.

For detailed application support, custom configuration options, or to schedule a virtual demonstration, contact us today at [email protected]. Let us help you elevate your automotive machining performance—precision, power, and partnership, delivered.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.