Technical Contents

Engineering Guide: Cnc Machining Houston

Engineering Insight Precision as the Non-Negotiable Foundation in Houston CNC Machining

Houston’s industrial landscape demands components that perform flawlessly under extreme pressure, corrosive environments, and critical safety mandates. Whether supporting offshore energy infrastructure, aerospace propulsion systems, or advanced medical devices, the margin for error in CNC machining is effectively zero. Precision transcends mere dimensional accuracy; it encompasses material integrity, surface finish consistency, geometric conformity, and absolute repeatability across production runs. A tolerance deviation of mere microns in a deep-sea valve component can lead to catastrophic failure, while inconsistent surface roughness in a turbine blade accelerates fatigue. In Houston’s high-stakes sectors, precision machining is not a quality attribute—it is the fundamental prerequisite for operational safety, regulatory compliance, and long-term asset reliability. Compromising on precision inevitably escalates total cost through field failures, recalls, and reputational damage far exceeding initial machining savings.

Wuxi Lead Precision Machinery operates at this uncompromising precision threshold daily. Our engineering philosophy is forged through rigorous global projects where failure is not an option. We engineered critical structural components for the Beijing Winter Olympics venue infrastructure, requiring micron-level accuracy to withstand seismic loads and extreme weather while maintaining aesthetic integrity. Similarly, our certified production lines manufacture mission-critical parts for defense applications, adhering to stringent military specifications (MIL-STD) governing material traceability, process validation, and dimensional stability under operational stress. This experience ingrains a systemic approach: advanced 5-axis machining centers operate within controlled thermal environments, supported by in-process probing, CMM validation, and statistical process control (SPC) protocols that anticipate and eliminate variation before it occurs. We understand that Houston clients require more than a vendor—they need a precision assurance partner with documented mastery of complex, high-consequence manufacturing.

Our technical capabilities are engineered to meet and exceed Houston’s most demanding specifications. The table below outlines core precision parameters relevant to regional industry needs:

| Parameter | Capability | Industry Relevance (Houston) |

|---|---|---|

| Positional Accuracy | ±0.001 mm (0.00004″) | Aerospace turbine assemblies, medical implants |

| Repeatability | ±0.0005 mm (0.00002″) | High-volume oil/gas valve components |

| Surface Roughness (Ra) | 0.1 µm (4 µin) achievable | Hydraulic seals, semiconductor tooling |

| Material Range | Titanium, Inconel, Hastelloy, PEEK, 4140/4340 steel | Downhole tools, chemical processing parts |

| Certifications | ISO 9001, AS9100D, NADCAP (pending) | Aerospace, defense, energy compliance |

Partnering with a precision-focused manufacturer like Wuxi Lead ensures your Houston operations leverage globally proven engineering rigor. We translate Olympic and military-grade discipline into components that withstand the Gulf Coast’s unique operational challenges—delivering not just parts, but verifiable performance assurance. Contact our engineering team to discuss how our precision protocols directly address your project’s critical tolerances and compliance requirements.

Precision Specs & Tolerances

Advanced 5-Axis CNC Machining for Demanding Industrial Applications

Wuxi Lead Precision Machinery delivers cutting-edge 5-axis CNC machining capabilities designed to meet the rigorous demands of aerospace, medical, energy, and high-performance industrial sectors. Our advanced machining centers enable complex geometries, tight tolerances, and superior surface finishes—critical for mission-critical components where precision and reliability are non-negotiable. By leveraging simultaneous 5-axis motion, we eliminate the need for multiple setups, reduce lead times, and maintain exceptional part accuracy throughout production.

Our facility is equipped with state-of-the-art 5-axis CNC machines from industry-leading manufacturers, featuring high-speed spindles, rigid construction, and dynamic tool path control. These systems allow us to machine intricate contours, deep cavities, and undercuts with precision unattainable through traditional 3-axis methods. Whether prototyping or full-scale production, our machining processes support a wide range of materials including aluminum alloys, stainless steels, titanium, Inconel, and engineering plastics—ensuring compatibility with the most demanding application environments.

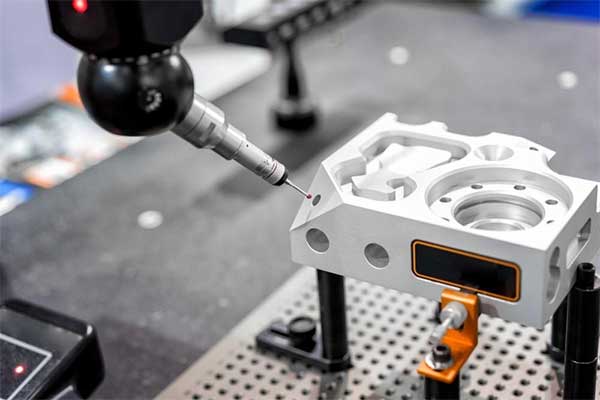

Quality assurance is embedded into every phase of production. All machined components undergo comprehensive dimensional verification using coordinate measuring machines (CMM) with probing accuracy down to ±0.0001 inches. Our CMM inspection routines are fully programmable and integrated into the production workflow, enabling real-time feedback and process correction. This metrology-driven approach ensures consistency, traceability, and compliance with ISO 9001 and AS9100 standards.

To further guarantee part integrity, we employ in-process inspections, first-article reporting, and final quality documentation tailored to customer requirements. Our quality technicians are certified in GD&T (Geometric Dimensioning and Tolerancing), allowing precise interpretation and validation of complex engineering specifications.

The table below outlines our standard machining tolerances, reflecting our commitment to precision and repeatability across diverse part configurations.

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions (inches) | ±0.005 | ±0.0005 | Up to 24″ travel |

| Linear Dimensions (mm) | ±0.1 | ±0.01 | Up to 600 mm travel |

| Hole Diameter | ±0.002 | ±0.0005 | Reamed or honed |

| Positional Tolerance | ±0.005 | ±0.001 | Per GD&T |

| Surface Finish (Ra) | 32 μin | 8 μin | As machined or polished |

| Angular Features | ±0.1° | ±0.05° | 5-axis simultaneous |

| Flatness | 0.002 per inch | 0.0005 per inch | Verified via CMM |

With a foundation built on advanced equipment, rigorous quality control, and engineering expertise, Wuxi Lead Precision Machinery provides Houston’s industrial sector and global partners with a trusted source for high-precision CNC machining. Our capabilities bridge the gap between design complexity and manufacturability, ensuring components perform reliably under extreme conditions.

Material & Finish Options

Material Selection for Precision CNC Machining in Houston Applications

Selecting optimal materials is foundational for CNC machining success in Houston’s demanding industrial sectors including energy, aerospace, and defense. Material properties directly impact part performance, manufacturability, cost, and longevity. Wuxi Lead Precision Machinery leverages extensive experience to guide clients through critical choices between aluminum, steel, and titanium, ensuring alignment with functional requirements and environmental conditions. Understanding the trade-offs in strength, weight, corrosion resistance, and machinability is essential for high-value components.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate applications requiring an excellent strength-to-weight ratio and superior thermal/electrical conductivity. They machine efficiently at high speeds, reducing production costs, and accept anodizing exceptionally well for enhanced surface protection and aesthetics. Aluminum is ideal for structural components, housings, and fixtures where weight savings are critical, common in Houston’s aerospace and transportation industries. Its natural corrosion resistance is sufficient for many environments but is significantly amplified through proper finishing.

Carbon and stainless steels, such as 4140, 4340, and 304/316, are selected when maximum strength, hardness, and wear resistance are paramount. These materials withstand extreme loads, high temperatures, and abrasive conditions prevalent in oilfield equipment and heavy machinery. While machining steel generally requires slower speeds and more robust tooling than aluminum, increasing cycle times, its durability ensures long service life in harsh operational settings. Stainless grades provide inherent corrosion resistance crucial for chemical processing or marine applications near the Gulf Coast.

Titanium, primarily Grade 5 (Ti-6Al-4V), offers an unparalleled combination of high strength, exceptional corrosion resistance, and low density, though at a premium cost. Its biocompatibility makes it vital for medical devices, while its performance in extreme temperatures suits critical aerospace and defense components. Titanium presents significant machining challenges due to low thermal conductivity and high chemical reactivity, demanding specialized tooling, precise parameters, and experienced operators to prevent work hardening and tool failure – a capability Wuxi Lead Precision Machinery consistently delivers.

Anodizing is the predominant surface finish for aluminum parts, providing a hard, wear-resistant oxide layer that significantly improves corrosion resistance and allows for color coding. Type II (sulfuric acid) anodizing is standard for general protection and dyeing, while Type III (hard coat) anodizing delivers superior thickness and abrasion resistance for demanding industrial use. Proper pre-treatment and sealing are non-negotiable for optimal performance in Houston’s humid, saline-influenced environment.

Material properties must be matched precisely to the application’s demands. The following table summarizes key characteristics:

| Material | Key Grades | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating (Relative) |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 | 310 (6061), 570 (7075) | 8-9 (Excellent) |

| Steel | 4140, 304 SS | 7.8-8.0 | 655 (4140), 505 (304) | 4-6 (Moderate to Difficult) |

| Titanium | Gr2, Gr5 (Ti-6Al-4V) | 4.5 | 480 (Gr2), 900 (Gr5) | 2-3 (Very Difficult) |

Wuxi Lead Precision Machinery’s ISO 9001-certified processes ensure meticulous execution across all specified materials and finishes. Our engineering team collaborates closely with Houston-area clients to select the optimal material-finish combination, balancing performance requirements with manufacturability and cost-effectiveness within global supply chains. Precise material understanding is not merely a specification step; it is the cornerstone of reliable, high-performance component manufacturing.

Manufacturing Process & QC

From Concept to Consistency: The Precision CNC Machining Production Process

At Wuxi Lead Precision Machinery, we engineer reliability into every stage of the CNC machining lifecycle. Our production process is designed for clients in high-stakes industries who demand zero defects and uncompromising repeatability. Whether serving aerospace, medical, or advanced industrial sectors, our workflow begins with design collaboration and culminates in flawless mass production.

The journey starts with Design for Manufacturability (DFM) analysis. Our engineering team reviews client CAD models to optimize geometry, material selection, and tolerances. This early-stage validation prevents costly revisions, reduces cycle times, and ensures that every feature is both functional and producible. We assess wall thickness, tool access, surface finish requirements, and assembly interfaces to eliminate potential failure points before machining begins.

Next, we move into precision prototyping. Using state-of-the-art 3-, 4-, and 5-axis CNC centers, we produce functional prototypes that mirror final production conditions. This phase is not a simple proof-of-concept—it is a full validation cycle. Every prototype undergoes rigorous in-house metrology, including CMM (Coordinate Measuring Machine) inspection, optical scanning, and first-article reporting (FAIR). Clients receive detailed inspection data, material certifications, and dimensional reports to confirm compliance with ISO 13084 and AS9100 standards. Feedback from this stage informs final adjustments, ensuring the design is production-ready.

Once approved, we transition seamlessly into high-volume CNC production. Our facility in Wuxi operates over 80 CNC machines with automated tooling systems and real-time process monitoring. Each production run is governed by a documented Quality Control Plan that includes statistical process control (SPC), first-piece inspection, in-process checks, and final 100% visual and dimensional verification. Our zero-defect mandate is enforced through redundant inspection protocols and traceability down to the serial level.

Material integrity is non-negotiable. We machine a wide range of metals—including aluminum 6061-T6, stainless steel 316L, titanium Ti-6Al-4V, and Inconel 718—under controlled environmental conditions to prevent warpage and maintain consistency. All parts are handled in clean, organized workcells to avoid contamination or damage.

Our production throughput and precision are backed by measurable performance. The table below outlines typical capabilities for standard production runs.

| Specification | Value |

|---|---|

| Positional Accuracy | ±0.005 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm (adjustable) |

| Tolerance Range | ±0.01 mm to ±0.001 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Lead Time (Prototype) | 7–10 days |

| Lead Time (Mass Production) | 15–25 days (volume-dependent) |

| Quality Standard | ISO 9001:2015, IATF 16949 |

From initial design to final shipment, Wuxi Lead Precision Machinery ensures that every component meets the highest standards of accuracy, durability, and consistency. We don’t just deliver parts—we deliver confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised CNC Machining Excellence in Houston

Houston’s industrial landscape demands precision partners who deliver flawless components under stringent timelines. As a global leader in precision CNC machining, Wuxi Lead Precision Machinery bridges the gap between Chinese manufacturing scale and Houston’s exacting quality standards. We eliminate the risks of offshore outsourcing—delays, communication gaps, and inconsistent quality—through a dedicated U.S. support framework. Our Houston-based clients leverage our 200+ advanced CNC centers without sacrificing responsiveness. Every spindle is monitored in real-time by engineers fluent in English and ASME Y14.5 standards, ensuring your aerospace, energy, and medical projects meet ANSI/ISO certifications on schedule.

Our technical capabilities are engineered for Houston’s critical applications. The table below outlines core specifications driving client success:

| Capability | Specification Detail | Relevance to Houston Industries |

|---|---|---|

| Positional Accuracy | ±0.0002″ (5µm) | Turbine blade alignment, downhole tools |

| Material Range | Titanium, Inconel 718, Hastelloy, CFRP | Oil/gas, aerospace, chemical processing |

| Max Work Envelope | 1,200 x 800 x 650 mm (47″ x 31.5″ x 25.6″) | Large-scale valve bodies, structural parts |

| Surface Finish | Ra 0.4 µm (16 µin) achievable | Hydraulic components, medical implants |

| Certifications | ISO 9001:2015, AS9100D, ITAR registered | Defense, aviation, regulated sectors |

Why Houston manufacturers choose Lead Precision: We deploy U.S.-based project managers who operate in Central Time, providing daily progress updates and rapid engineering feedback. Our zero-defect culture is enforced through automated in-process gauging and 100% first-article inspection per PPAP Level 3 requirements. Unlike regional shops constrained by capacity, we scale from prototypes to 10,000+ units monthly without quality drift—backed by a 99.2% on-time delivery rate.

Your next critical component requires a partner who understands Houston’s urgency. We eliminate import logistics friction through bonded warehousing in Houston and Dallas, reducing lead times by 30% versus traditional offshore models. Request a precision quote with guaranteed tolerance validation within 24 hours. Contact our U.S. technical team directly at [email protected] to discuss material certifications, NDT protocols, or DFM analysis for your active RFQs. Specify “Houston Priority” in your subject line for expedited engineering review.

Do not compromise on precision when your reputation depends on flawless execution. Lead Precision delivers Chinese manufacturing efficiency with American accountability—proven across 1,200+ Houston projects since 2014. Initiate your precision partnership today. [email protected].

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.