Technical Contents

Engineering Guide: Plastic Molding Material

Engineering Insight: Precision in Plastic Molding Material Selection and Application

In high-end custom metal manufacturing, the integration of plastic molding materials is no longer a secondary consideration—it is a critical engineering decision that directly impacts the performance, durability, and precision of the final product. At Wuxi Lead Precision Machinery, we understand that material behavior under thermal, mechanical, and environmental stress must be anticipated with exacting accuracy. This is especially vital when producing components for sectors such as aerospace, defense, and high-performance industrial systems—fields where our work has supported Olympic-standard equipment and military-grade applications.

Precision in plastic molding begins with material selection. Not all polymers respond equally to injection molding processes, and dimensional stability, shrinkage rates, and thermal expansion coefficients must align with tight tolerance requirements. For instance, semi-crystalline materials like PEEK or PPS offer superior mechanical strength and chemical resistance but demand precise control over mold temperature and cooling cycles to avoid warping. Amorphous resins such as polycarbonate or ABS, while easier to process, may exhibit higher creep under sustained load, necessitating design compensation. Our engineering team leverages decades of experience to match material properties with functional demands, ensuring that every molded component meets micron-level specifications.

Beyond material science, the synergy between mold design and process control determines the outcome. At Lead Precision, we employ advanced simulation software to model flow dynamics, predict shrinkage, and optimize gate locations before a single pellet is melted. This predictive capability, combined with in-house tooling expertise, allows us to produce molds with tolerances as tight as ±0.002 mm—essential when plastic components interface with high-precision metal assemblies.

Our track record in mission-critical projects underscores this commitment. Components we’ve developed have operated in extreme environments—from sub-zero arctic conditions to high-vibration defense systems—proving that precision molding is not just about accuracy, but reliability under duress.

The following table outlines key plastic molding materials we commonly engineer for, along with their critical performance characteristics:

| Material | Tensile Strength (MPa) | Heat Deflection Temp (°C) | Shrinkage Rate (%) | Typical Applications |

|---|---|---|---|---|

| PEEK | 90–100 | 143–160 | 0.1–0.2 | Aerospace, Medical, Defense |

| PPS | 65–80 | 110–120 | 0.2–0.4 | Automotive sensors, Electrical housings |

| Polycarbonate | 55–75 | 115–135 | 0.6–0.8 | Optical components, Safety enclosures |

| ABS | 35–45 | 95–105 | 0.4–0.7 | Industrial controls, Consumer devices |

| Nylon 66 | 75–85 | 80–85 | 0.7–1.0 | Gears, Bearings, Structural parts |

At Wuxi Lead Precision Machinery, we treat plastic molding not as a standalone process, but as an integrated discipline within precision manufacturing. Our experience with demanding clients—ranging from national defense contractors to Olympic technology partners—has refined our ability to deliver materials and components that perform flawlessly, every time.

Precision Specs & Tolerances

Technical Capabilities for Precision Plastic Molding Tooling

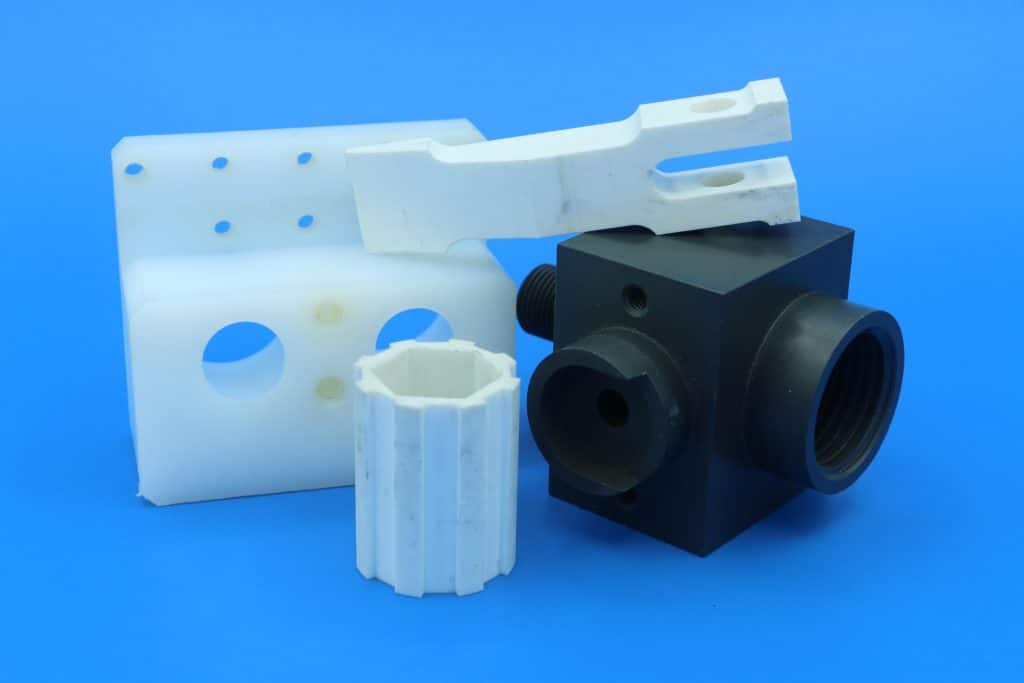

At Wuxi Lead Precision Machinery, our core competency lies in producing mission-critical metal components for advanced plastic injection molding applications. We specialize in manufacturing mold cores, cavities, inserts, and structural components where dimensional stability, surface integrity, and thermal management directly determine the quality and longevity of molded plastic parts. Our integrated approach ensures that every metal component meets the rigorous demands of high-volume, high-precision plastic production environments.

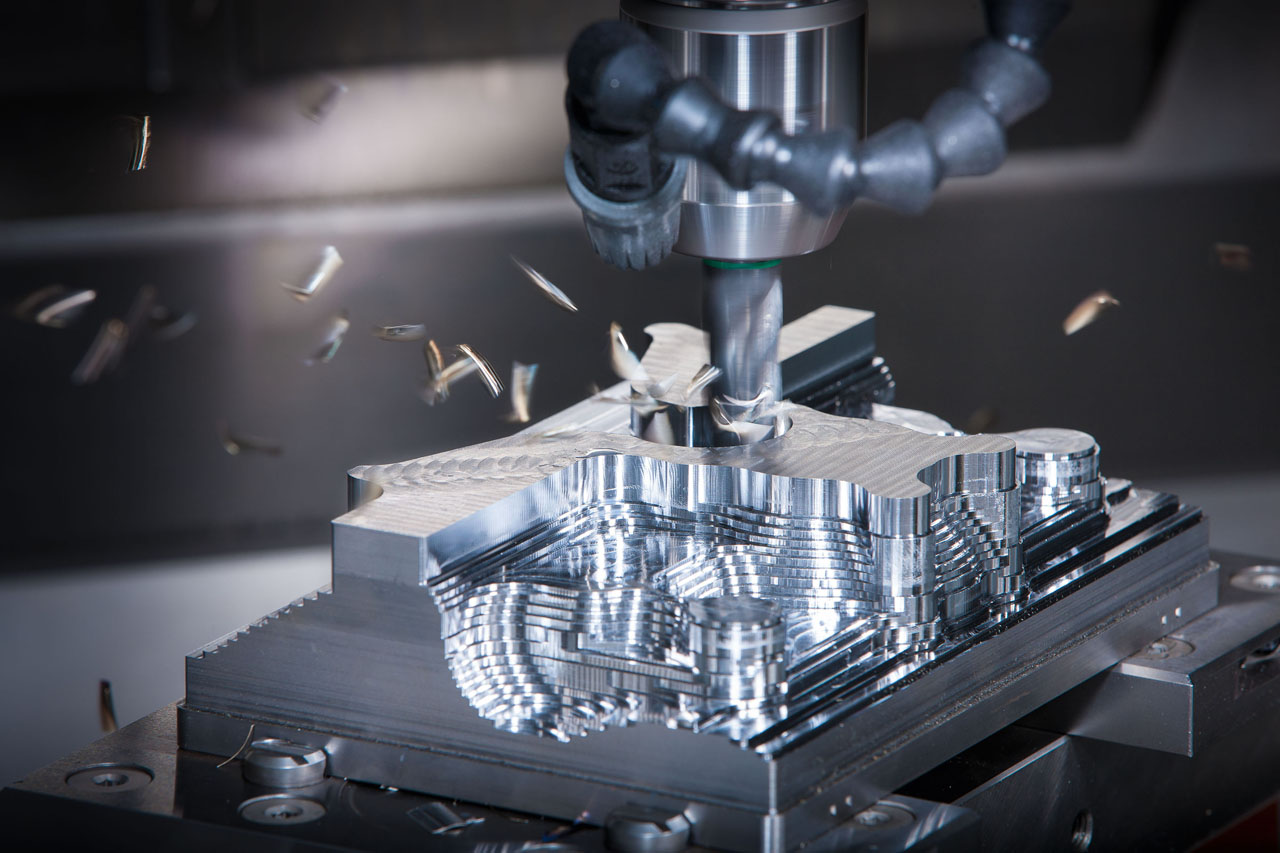

Central to our capability is a dedicated fleet of state-of-the-art 5-axis CNC machining centers, primarily DMG MORI and Makino platforms. This technology enables us to machine complex geometries—such as deep ribs, undercuts, and organic cooling channels—in a single setup. Eliminating multiple fixturing steps drastically reduces cumulative error while achieving superior surface finishes down to Ra 0.4 µm. For plastic molding applications, this precision translates directly into reduced part warpage, minimized flash, consistent wall thickness, and extended mold life. Our programmers leverage Siemens NX CAM to optimize toolpaths for hardened tool steels (e.g., H13, S136) and pre-hardened alloys, ensuring optimal material removal rates without compromising edge integrity critical for part ejection.

Quality control is non-negotiable. Every component undergoes rigorous inspection via Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMM), operating within an ISO 17025-accredited metrology lab maintained at 20±0.5°C. We perform full 3D geometric dimensioning and tolerancing (GD&T) verification against CAD models, with emphasis on critical features like parting line alignment, gate geometry, and cooling channel positioning. Surface roughness, flatness, and profile deviations are measured empirically to validate performance against molding simulation data. This closed-loop process ensures components arrive ready for assembly, eliminating costly trial-and-error during mold commissioning.

Our machining tolerances are engineered specifically for the thermal and pressure dynamics of plastic molding. Standard capabilities exceed typical industry benchmarks, while critical features are held to tighter internal standards proven in high-cavity production molds:

| Feature | Standard Tolerance | Critical Tolerance |

|---|---|---|

| Linear Dimensions | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) |

| Hole Diameter | +0.010/-0.000 mm | +0.005/-0.000 mm |

| Flatness | 0.015 mm/m | 0.005 mm/m |

| Profile of Surface | ±0.015 mm | ±0.008 mm |

| Parting Line Alignment | ≤ 0.020 mm | ≤ 0.010 mm |

These specifications are not theoretical; they are validated across thousands of production hours in automotive, medical, and consumer electronics molding. By controlling metal component precision at this level, we directly enable our clients to achieve superior plastic part consistency, reduce scrap rates, and accelerate time-to-market. Wuxi Lead delivers not just parts, but the foundational accuracy that makes high-performance plastic molding possible. Partner with us to transform your tooling requirements into a competitive manufacturing advantage.

Material & Finish Options

Material Selection for High-Performance Plastic Molding Tools

Selecting the appropriate metal for plastic molding tools is critical to ensuring durability, precision, and cost-efficiency in high-volume manufacturing. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for injection molds, extrusion dies, and precision tooling. Our engineering team evaluates material properties such as hardness, thermal conductivity, corrosion resistance, and machinability to match the optimal metal to your application.

Aluminum is often the preferred choice for prototype molds and low-to-medium production runs. Its high thermal conductivity allows for faster cooling cycles, reducing part cycle time. Aluminum is also lightweight and easier to machine, which shortens lead times and lowers machining costs. However, its lower hardness compared to steel limits its use in high-wear applications or with abrasive plastics.

Steel, particularly pre-hardened and tool-grade steels like P20, H13, and S136, offers superior durability and wear resistance. These steels are ideal for high-volume production where mold longevity is paramount. Stainless tool steels also provide excellent corrosion resistance, making them suitable for molding aggressive or halogenated resins. While steel molds require longer machining and heat treatment processes, their extended service life often justifies the initial investment.

Titanium alloys are used in specialized applications where extreme strength-to-density ratios and corrosion resistance are required. Though not common in standard mold bases, titanium may be integrated into core components or inserts exposed to high stress or corrosive environments. Its high cost and challenging machinability limit broad adoption, but for mission-critical tooling, titanium delivers unmatched performance under demanding conditions.

Surface finishing, particularly anodizing, plays a vital role in enhancing mold performance. Anodizing increases surface hardness and wear resistance, especially for aluminum molds. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied based on required thickness and functionality. Hard anodizing can produce a ceramic-like surface layer up to 100 µm thick, significantly extending mold life and reducing galling in sliding components. Anodized surfaces also improve release properties, minimizing the need for mold release agents and reducing part contamination.

Our team at Wuxi Lead Precision Machinery works closely with clients to evaluate production volume, resin type, part geometry, and environmental factors when recommending materials and finishes. We combine advanced CNC machining with rigorous quality control to deliver molds that meet international standards for dimensional accuracy and surface integrity.

Below is a comparative overview of key materials used in plastic molding tooling:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Low to Moderate | Prototypes, low-volume production |

| P20 Steel | 28–32 | 30 | Moderate | Medium to high-volume molds |

| H13 Steel | 48–52 | 35 | Good | Hot-runner molds, high stress |

| S136 Stainless | 50–54 | 25 | Excellent | Corrosive resins, cleanroom |

| Titanium Ti-6Al-4V | 36–40 | 7 | Exceptional | Specialized inserts, aerospace |

Manufacturing Process & QC

Precision Metal Tooling for Plastic Molding: Achieving Zero Defects

Wuxi Lead Precision Machinery engineers deliver flawless plastic components through an integrated metal tooling process. Our expertise lies in crafting the high-precision metal molds and dies essential for demanding plastic molding applications. This rigorous methodology spans design, prototyping, and mass production, ensuring zero defects from concept to final part. We transform client specifications into reality using advanced metallurgy and manufacturing science, focusing exclusively on the critical metal tooling that dictates plastic part quality.

The process initiates with collaborative design engineering. Our team conducts thorough Design for Manufacturability (DFM) analysis, scrutinizing part geometry, material flow, cooling requirements, and ejection strategies. We utilize advanced simulation software to model resin behavior within the proposed metal cavity, identifying potential weaknesses like weld lines, sink marks, or warpage before metal is cut. This phase optimizes the mold core, cavity, and ancillary systems for structural integrity, thermal management, and longevity under high-cycle production. Client feedback is integrated iteratively, ensuring the metal tool design aligns perfectly with functional and aesthetic requirements while minimizing inherent plastic molding risks.

Prototyping validates the metal tool design under real-world conditions. We fabricate a fully functional prototype mold using the same premium tool steels and hardening processes intended for production. This prototype undergoes rigorous testing with the client’s specified resin at controlled parameters. We measure critical dimensions, surface finish, gate vestige, and mechanical properties against stringent acceptance criteria. Cavity pressure and temperature data are meticulously recorded. Any deviations trigger immediate design refinement—adjusting cooling channels, venting, or gating—before committing to full-scale production tooling. This step is non-negotiable for eliminating defects at the source.

Mass production leverages the perfected metal tooling within our climate-controlled facility. Each mold is monitored continuously using cavity pressure sensors, thermal imaging, and automated vision systems. Real-time data feeds into our Statistical Process Control (SPC) framework, enabling micro-adjustments to maintain dimensional stability within microns. Every production run undergoes First Article Inspection (FAI) and in-process checks against the approved prototype. Our zero-defect mandate is enforced through 100% traceability of tool steel batches, processing parameters, and final part certifications. The result is consistent, high-integrity plastic components meeting aerospace, medical, and automotive standards.

Critical process parameters distinguishing prototyping from production tooling are summarized below:

| Parameter | Prototyping Tooling | Mass Production Tooling |

|---|---|---|

| Tool Steel | Pre-hardened P20 | Hardened H13 / S136 Superior |

| Tolerance | ±0.05 mm | ±0.005 mm |

| Surface Finish | SPI-A2 (600 Grit) | SPI-A1 (Polished Mirror) |

| Lead Time | 2-4 Weeks | 8-12 Weeks |

| Validation | 50-100 Shots, Manual Checks | SPC, Cavity Pressure Monitoring, 100% Automated Inspection |

| Expected Life | 10,000 – 50,000 Cycles | 500,000+ Cycles |

Wuxi Lead’s integrated approach ensures the metal foundation of your plastic molding process is engineered for perfection. We eliminate defects by perfecting the tool—not merely inspecting the output. Partner with us to convert design intent into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing for Plastic Molding Applications

At Wuxi Lead Precision Machinery, we understand that the success of your plastic molding operations hinges on the precision, durability, and performance of your core components. As a leading provider of custom metal manufacturing solutions in China, we specialize in delivering high-performance mold bases, inserts, cavities, and precision-machined components tailored to the exacting demands of the plastic molding industry. Our engineering team combines decades of experience with advanced CNC machining, EDM, and surface treatment technologies to ensure every part meets the highest standards of quality and consistency.

Choosing the right material for plastic molding is critical—whether you’re working with P20, 718H, S136, H13, or custom alloy steels, our material selection and heat treatment processes are optimized to enhance wear resistance, corrosion protection, and thermal stability. We work closely with global OEMs, mold makers, and tier-one suppliers to develop components that deliver extended service life, reduced downtime, and superior surface finish on molded parts. From prototyping to high-volume production, our facility in Wuxi is equipped with ISO 9001-certified quality systems, in-process inspections, and full traceability to meet the most stringent industry requirements.

Our commitment to precision is reflected in every stage of production. We utilize 4-axis and 5-axis CNC centers, high-accuracy wire-cut and sinker EDM machines, and automated polishing systems to achieve tolerances down to ±0.002 mm. Surface finishes range from mirror-polished (SPI A1) to textured or coated variants, depending on your application needs. Whether your project involves large-scale mold frames or intricate core pins, we ensure dimensional accuracy, thermal efficiency, and seamless integration into your existing systems.

Below are key technical specifications we support in our custom manufacturing process:

| Specification | Capability |

|---|---|

| Material Types | P20, 718H, S136, H13, NAK80, 2344, Custom Alloy Steels |

| Tolerance | ±0.002 mm |

| Surface Finish | SPI A1 to B3, VDI 3400 up to #20, Custom Textures |

| Max Machining Size | 1200 x 800 x 600 mm |

| Heat Treatment | Pre-hardened, Through Hardening, Nitriding, Vacuum Hardening |

| Machining Equipment | 5-Axis CNC, Wire EDM, Sinker EDM, High-Speed Milling |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Reports, Material Certifications |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a technical ally committed to your long-term success. Our engineering team provides DFM analysis, mold flow support, and material optimization guidance to ensure your designs translate into reliable, high-yield production. We pride ourselves on on-time delivery, competitive pricing, and responsive communication in English and technical Mandarin.

Contact us today at [email protected] to discuss your next plastic molding material project. Let Lead Precision be the foundation of your manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.