Technical Contents

Engineering Guide: Custom Metal Fabrications

Engineering Insight: The Critical Role of Precision in Custom Metal Fabrications

In the realm of advanced manufacturing, custom metal fabrications serve as the backbone of countless high-performance industries, from aerospace and defense to medical and energy systems. At Wuxi Lead Precision Machinery, we understand that the success of these applications hinges not only on material selection and design integrity but, most critically, on precision. The difference between functional reliability and catastrophic failure often lies in tolerances measured in microns.

Precision in sheet metal fabrication is not merely a quality benchmark—it is an engineering imperative. Components used in mission-critical environments must perform under extreme conditions, where thermal expansion, mechanical stress, and dimensional stability directly impact system performance. A deviation of even 0.05 mm can compromise fit, alignment, or sealing in high-pressure assemblies. At Lead Precision, our engineering protocols are built around maintaining tolerances down to ±0.02 mm across complex geometries, ensuring that every fabricated part meets exacting design specifications.

Our commitment to precision is rooted in decades of experience serving some of the most demanding sectors. We have contributed to infrastructure projects linked to Olympic facilities, where architectural metalwork required both aesthetic perfection and structural resilience. Equally, our components have been integrated into military-grade systems, where reliability under operational stress is non-negotiable. These projects demand not only technical excellence but also rigorous documentation, traceability, and compliance with international standards such as ISO 9001 and AS9100.

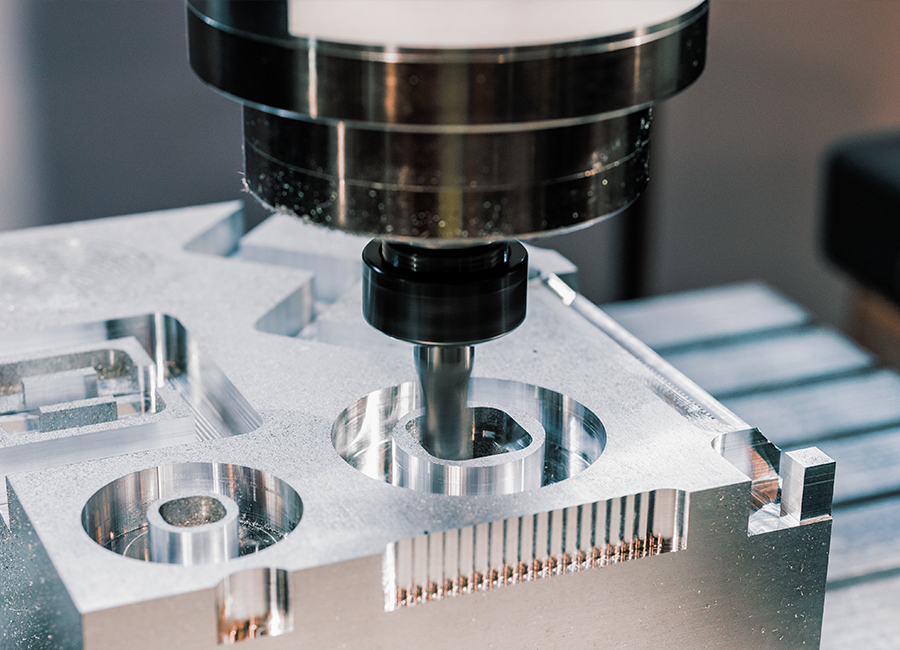

Achieving this level of accuracy begins with advanced CNC-controlled machinery, including laser cutting, precision bending, and automated welding systems. Our facility in Wuxi integrates real-time monitoring and in-process inspection to maintain consistency across production runs. Finite element analysis (FEA) and 3D metrology are employed during prototyping to validate designs before full-scale manufacturing, minimizing rework and ensuring first-time-right outcomes.

Beyond equipment, precision is sustained through engineering expertise. Our team of veteran fabricators and design engineers collaborates closely with clients to optimize manufacturability, addressing potential issues such as material spring-back, weld distortion, and thermal deformation at the design stage. This proactive approach reduces lead times and enhances end-product performance.

The following table outlines key precision capabilities at Wuxi Lead Precision Machinery:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Cutting Tolerance | ±0.02 mm |

| Bending Tolerance | ±0.1° angular, ±0.05 mm linear |

| Welding Standards | ISO 15614, AWS D1.1 |

| Surface Roughness (Ra) | As low as 0.8 µm |

| Dimensional Inspection | CMM, Laser Tracker, 3D Scanning |

| Production Capacity | Up to 500 tons/month |

Precision in custom metal fabrication is not an isolated process—it is a holistic discipline that spans design, material science, and production execution. At Wuxi Lead Precision Machinery, we bring proven expertise from high-stakes applications to every custom project, ensuring that precision is not just achieved, but guaranteed.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery executes complex custom metal fabrications through integrated 5-axis CNC machining centers, enabling single-setup production of intricate geometries unattainable with conventional 3-axis systems. Our DMG MORI and MAZAK platforms achieve micron-level accuracy across titanium, aluminum alloys, stainless steel, and exotic materials, eliminating secondary operations for critical aerospace, medical, and semiconductor components. Advanced toolpath optimization reduces cycle times by 35% while maintaining ±0.005mm positional tolerances on multi-faceted features. Full digital twin simulation validates part integrity prior to cutting, ensuring first-article success for low-volume high-mix production runs up to 500mm³ work envelopes.

Rigorous quality assurance is enforced through Zeiss CONTURA G2 metrology-grade CMM systems operating in ISO Class 7 cleanrooms. Each component undergoes 100% first-article inspection per AS9102 standards, with real-time SPC data tracking dimensional drift during production. Our certified technicians perform GD&T analysis on critical datums, surface finishes, and hole patterns, generating traceable inspection reports compliant with NADCAP and ISO 17025 requirements. In-process verification at 50% and 90% production stages prevents batch non-conformities, while material certificates and heat-treat documentation accompany every shipment.

Tolerance performance is systematically controlled across material types as demonstrated below:

| Material Category | Standard Dimensional Tolerance | Critical Feature Tolerance | Surface Roughness (Ra) |

|---|---|---|---|

| Carbon Steel | ±0.05 mm | ±0.005 mm | 0.8 µm |

| Aluminum Alloys | ±0.05 mm | ±0.005 mm | 0.4 µm |

| Stainless Steel | ±0.08 mm | ±0.01 mm | 1.6 µm |

| Exotic Alloys | ±0.10 mm | ±0.02 mm | 3.2 µm |

This capability framework supports mission-critical applications including fuel system manifolds requiring leak-tight integrity, surgical robotics end-effectors with sub-10µm motion control, and semiconductor chamber components demanding particle-free surfaces. Our engineering team collaborates during DFM stages to optimize part geometry for manufacturability, reducing cost drivers while meeting IPC-6012 Class 3 and AMS 2750 E compliance. All processes adhere to ISO 9001:2015 and IATF 16949 standards, with full supply chain transparency from raw material sourcing to final packaging. Wuxi Lead Precision Machinery delivers certified precision for industries where failure is not an option, backed by 15 years of Tier 1 aerospace and defense manufacturing expertise. Contact our applications engineers for technical consultation on your most demanding fabrication challenges.

Material & Finish Options

Material Selection for High-Precision Custom Metal Fabrications

Selecting the appropriate material is a critical step in the development of custom sheet metal fabrications, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-engineered solutions using premium-grade aluminum, steel, and titanium—each offering distinct mechanical and chemical properties suited to specific industrial applications. Understanding the strengths and limitations of these materials ensures optimal performance across aerospace, automotive, medical, and industrial equipment sectors.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is particularly common in structural and enclosure applications due to its weldability and moderate strength. It is ideal for lightweight components where thermal and electrical conductivity are beneficial. However, aluminum’s lower hardness compared to steel makes it more prone to wear under abrasive conditions.

Steel remains the backbone of industrial fabrication, with carbon steel (such as Q235 and Q345) providing high tensile strength and structural integrity. It is well-suited for heavy-duty applications, including frames, enclosures, and machinery guards. While inherently more susceptible to corrosion than aluminum or titanium, steel can be protected through various finishing processes, including powder coating and galvanization. Stainless steel (e.g., 304 and 316) offers superior corrosion resistance and aesthetic appeal, making it ideal for food processing, medical devices, and marine environments.

Titanium, although more costly, delivers exceptional performance in extreme conditions. Its high strength-to-density ratio, resistance to oxidation, and ability to perform under elevated temperatures make it indispensable in aerospace and defense applications. Grade 5 (Ti-6Al-4V) is the most commonly used titanium alloy in precision fabrication, offering excellent fatigue resistance and biocompatibility for medical implants.

Surface finishing plays a pivotal role in enhancing both functionality and appearance. Anodizing, particularly for aluminum, is a key process offered at Wuxi Lead. This electrochemical treatment increases surface hardness, improves wear resistance, and allows for color customization through dye integration. Type II (sulfuric acid) anodizing is standard for decorative and moderate protective needs, while Type III (hardcoat anodizing) provides a thicker, more durable layer suitable for high-wear environments.

The following table summarizes key mechanical and chemical properties of commonly used materials:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 276 | 2.7 | High | Enclosures, aerospace components |

| Carbon Steel Q235 | 370–500 | 235 | 7.85 | Low (without coating) | Structural frames, brackets |

| Stainless Steel 304 | 515 | 205 | 8.0 | Very High | Medical devices, food equipment |

| Titanium Ti-6Al-4V | 900 | 830 | 4.43 | Excellent | Aerospace, defense, implants |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on application requirements, environmental exposure, and lifecycle expectations. Our expertise ensures every custom fabrication meets exacting standards in performance and reliability.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Zero-Defect Production Process for Custom Metal Fabrications

At Wuxi Lead Precision Machinery, our custom metal fabrication process is engineered for uncompromising quality from initial concept to final delivery. We integrate advanced engineering rigor with precision manufacturing to ensure zero defects, critical for aerospace, medical, and industrial clients demanding absolute reliability.

Design Phase Integration

Our process begins with collaborative Design for Manufacturability (DFM) analysis. Engineers utilize Siemens NX and SolidWorks to scrutinize CAD models for material efficiency, weld accessibility, and geometric feasibility. We identify potential stress points, tolerance stack-ups, or tooling conflicts early, reducing downstream rework. Every design undergoes thermal and structural simulation to validate performance under operational loads, ensuring manufacturability aligns with functional requirements before physical production commences.

Prototyping: Validation Before Scale

Prototyping is not a formality but a critical validation checkpoint. Using our fiber laser cutters (±0.05mm accuracy) and CNC press brakes (repeatability ±0.1°), we produce first-article prototypes for rigorous testing. Dimensional reports per AS9102 standards, material certification traceability, and functional fit checks are mandatory. Clients receive detailed inspection data—including CMM reports and weld penetration analysis—enabling design refinement with zero assumptions. This phase de-risks mass production by confirming process stability and component integrity.

Mass Production: Statistical Process Control

Full-scale production leverages our automated production cells under real-time Statistical Process Control (SPC). Each operation—from laser cutting to robotic welding and precision bending—is monitored via integrated sensors tracking force, angle, and dimensional drift. In-process inspections occur at defined intervals using vision systems and calibrated hand tools, with data logged to our centralized quality management system. Any parameter deviation beyond CpK 1.67 triggers immediate line stoppage and root-cause analysis. Final assemblies undergo 100% functional testing and first-article revalidation per batch, ensuring every unit meets print specifications without exception.

Key Production Capabilities & Quality Metrics

| Parameter | Capability | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.025mm (machined) | CMM, Optical Comparator |

| Weld Integrity | 100% Penetration (GTAW/Laser) | Dye Penetrant, X-Ray, Macro Etch |

| Material Traceability | Full Mill Cert to Serial No. | Blockchain-Linked Digital Ledger |

| Process Stability | CpK ≥ 1.67 (All Critical Ops) | Real-Time SPC Dashboard |

| Surface Finish | Ra 0.4µm (Machined) | Profilometer, Visual Standard |

Zero Defects: An Engineered Outcome

Wuxi Lead’s process eliminates defects through embedded quality controls, not end-of-line checks. By fusing predictive design, validated prototyping, and closed-loop production monitoring, we deliver custom fabrications that perform flawlessly in mission-critical applications. Partner with us for metal components where failure is never an option.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Expertise in Custom Metal Fabrications

When your project demands precision, consistency, and engineering excellence in sheet metal fabrication, partnering with Wuxi Lead Precision Machinery ensures a competitive advantage. Based in Wuxi, China, we specialize in high-end custom metal fabrications for global industries including aerospace, medical equipment, automation, and advanced industrial machinery. Our commitment to quality, technical innovation, and responsive service makes us the preferred manufacturing partner for OEMs and engineering firms worldwide.

At Lead Precision, we understand that every custom fabrication project begins with a unique challenge. Our engineering team collaborates closely with clients from design inception through final production, offering Design for Manufacturability (DFM) analysis, rapid prototyping, and scalable production runs. With over 15 years of experience and a fully integrated facility equipped with advanced CNC punching, bending, laser cutting, and robotic welding systems, we deliver complex sheet metal components with tolerances as tight as ±0.05 mm.

Our ISO 9001-certified manufacturing processes are designed to meet the highest international standards. From material sourcing to final inspection, every stage is monitored for consistency, traceability, and performance. We work with a broad range of materials, including stainless steel, aluminum, carbon steel, copper, and specialty alloys, supporting both low-volume prototypes and high-volume production with equal precision.

We recognize that lead time and communication are critical in global supply chains. That’s why we maintain a dedicated project management team to provide real-time updates, comprehensive documentation, and agile response to engineering changes. Our clients benefit from reduced time-to-market, minimized production risk, and long-term cost efficiency.

Whether you require a single custom enclosure or a complete subsystem assembly, Lead Precision delivers engineered solutions that meet exact functional and dimensional requirements. Our facility supports secondary operations such as surface finishing, powder coating, precision tapping, and hardware insertion—ensuring your parts arrive production-ready.

Below are key capabilities that define our sheet metal fabrication services

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Max Working Size | 3000 mm × 1500 mm |

| Tolerance Accuracy | ±0.05 mm |

| Laser Cutting Power | Up to 12 kW Fiber |

| CNC Turret & Punching | Amada & Trumpf Systems |

| Bending Capacity | Up to 200 tons, 4-axis back gauge |

| Welding Processes | MIG, TIG, Spot, Robotic Pulsed Arc |

| Surface Finishes | Brushing, Anodizing, Powder Coating, Passivation |

| Quality Standards | ISO 9001:2015, ISO 14001, RoHS Compliant |

Partnering with Lead Precision means aligning with a manufacturer that values precision as much as you do. Let us help you transform your designs into high-performance metal components with confidence and speed.

Contact us today at [email protected] to discuss your next project. Our engineering team is ready to provide a detailed quotation, DFM feedback, and sample support within 24 hours.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.