Technical Contents

Engineering Guide: Rubber For Molds

Engineering Insight: Rubber Selection for Precision Mold Applications

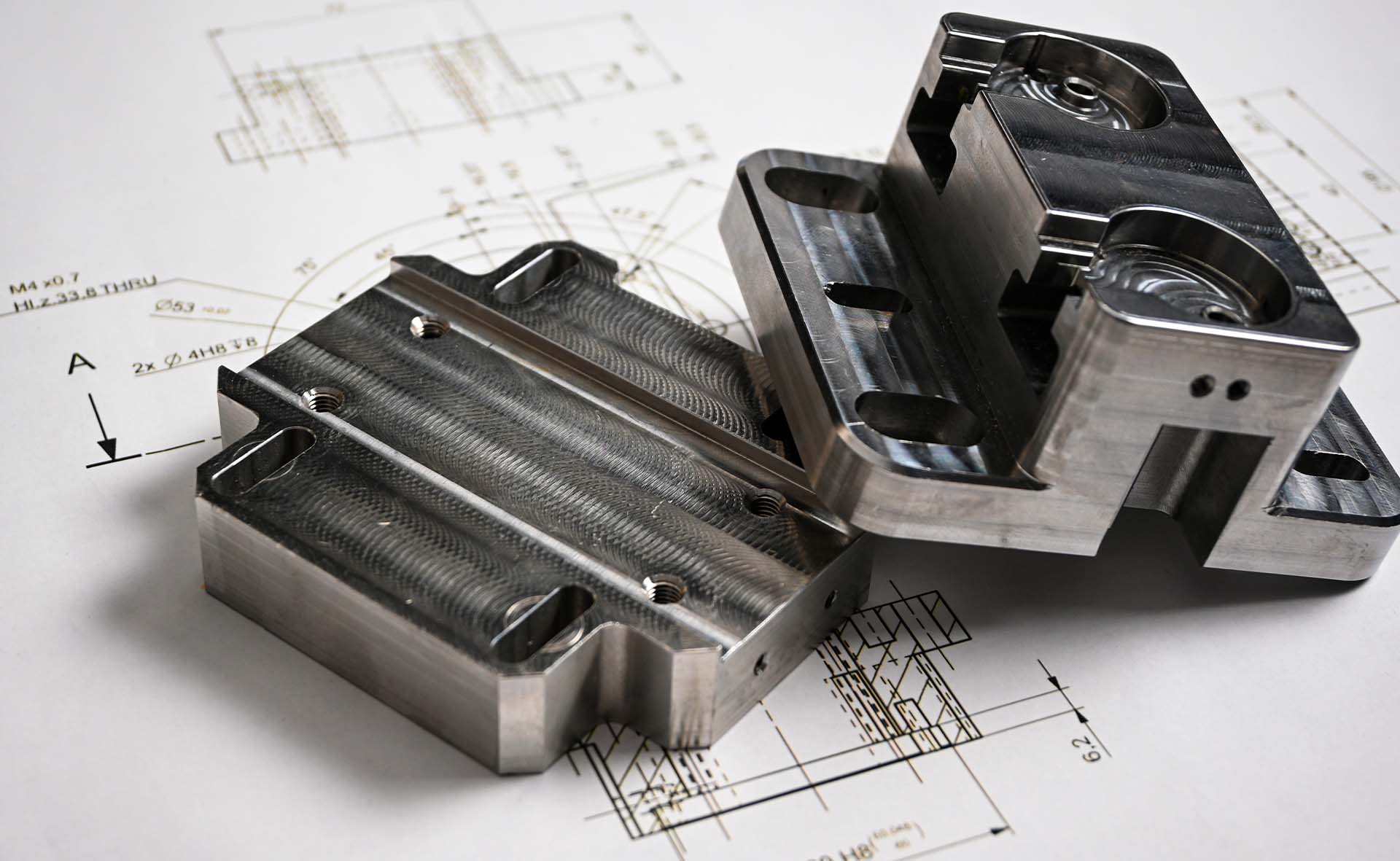

In high-tolerance metal manufacturing, the elastomer selected for mold tooling is not merely a consumable component; it is a critical engineering variable directly impacting final part quality, production yield, and dimensional repeatability. At Wuxi Lead Precision Machinery, our decades of experience machining complex aerospace, medical, and defense components underscore that rubber performance specifications must be treated with the same rigor as the metal substrate itself. Precision molding demands elastomers capable of maintaining exact cavity geometry under repeated thermal cycling and mechanical stress, resisting degradation from release agents, and providing consistent part ejection without distortion. Compromising on rubber quality inevitably leads to flash, incomplete fills, surface defects, and accelerated tool wear – failures unacceptable in mission-critical applications where we operate.

Material selection hinges on precise alignment with the specific metal being formed, the required surface finish, and the operational environment. Standard silicone rubbers often lack the thermal stability and mechanical resilience needed for high-volume production of intricate geometries. High-performance liquid silicone rubber (LSR) or specialized fluorosilicones become essential when processing temperatures exceed 180°C or when chemical resistance to aggressive metalworking fluids is paramount. Shore hardness must be meticulously calibrated; too soft, and the mold cavity deforms under pressure, sacrificing detail replication; too hard, and the rubber fails to absorb minor substrate imperfections or causes part damage during demolding. Our CNC-machined mold bases, validated in extreme conditions including Olympic winter sports equipment production and sensitive military hardware, demand elastomers engineered for micron-level consistency across thousands of cycles.

The consequences of imprecise rubber specification are quantifiable in scrap rates and downtime. Below are critical elastomer properties requiring stringent control for precision metal molding applications:

| Property | Standard Silicone Range | Precision Application Requirement | Impact of Deviation |

|---|---|---|---|

| Shore A Hardness | 30 – 70 | Tightly controlled ±2 points | Dimensional instability, poor ejection |

| Thermal Stability (°C) | 150 – 200 | Sustained 220+ | Cavity distortion, reduced tool life |

| Tear Strength (kN/m) | 10 – 20 | Minimum 25+ | Premature wear, flash generation |

| Compression Set (%) | 20 – 40 | < 10 after 24h @ 200°C | Loss of sealing integrity, part defects |

| Coefficient of Friction | 0.8 – 1.2 | Optimized for specific metal | Part sticking or surface marring |

Wuxi Lead Precision Machinery integrates elastomer science with ultra-precision CNC machining. Our engineering team collaborates with clients to specify and validate rubber compounds meeting exact thermal, mechanical, and chemical profiles for each unique metal forming challenge. This holistic approach – where the rubber is engineered as precisely as the steel cavity it supports – is why our molds deliver exceptional repeatability in applications demanding the utmost reliability, from Beijing Winter Olympics infrastructure components to classified defense systems. Precision in molding begins with the fundamental properties of every material in the tool assembly; we ensure none are left to chance.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions tailored for high-performance applications in mold-making, particularly where rubber for molds demands precision-engineered metal components. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface finish. These systems allow simultaneous multi-axis movement, ensuring optimal tool positioning and reduced setup times, which translates into faster lead times without compromising on quality. This is especially critical when manufacturing mold bases, cavities, and cores that interface with rubber compounds, where dimensional stability and repeatability directly influence the final product’s integrity.

Our machining centers are operated by skilled technicians with deep expertise in materials commonly used in rubber molding applications, including tool steels, stainless steels, aluminum alloys, and hardened pre-treated materials. We support both low-volume prototyping and high-volume production runs, maintaining consistent tolerances across batches. The integration of high-speed machining strategies ensures minimal thermal deformation and superior edge definition—key factors when producing fine details such as venting channels, parting lines, and ejection pin bores that interact directly with rubber during the molding process.

Quality control is embedded into every stage of production. All critical dimensions are verified using a Coordinate Measuring Machine (CMM), providing full traceability and compliance with international standards. Our CMM inspection routines are programmed to match the geometric dimensioning and tolerancing (GD&T) requirements specified by clients, ensuring that each component meets exact functional criteria. In addition to dimensional accuracy, we perform surface roughness testing and visual inspections under controlled lighting to detect any imperfections that could affect mold performance or rubber release characteristics.

We understand that precision in mold manufacturing directly impacts the consistency, durability, and performance of rubber-molded parts. That is why our processes are designed to achieve tight tolerances consistently, even in the most intricate features. From initial design review to final inspection, we apply a disciplined approach to process validation, including first-article inspection reports (FAIR) and production part approval protocols (PPAP) when required.

The following table outlines typical machining tolerances achievable across common feature types:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, High-Precision Micrometers |

| Hole Diameter | ±0.01 mm | ±0.003 mm | Air Gauges, CMM |

| Positional Tolerance | ±0.02 mm | ±0.008 mm | CMM with GD&T Analysis |

| Flatness | 0.02 mm | 0.005 mm | CMM, Surface Plate + Dial Indicator |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Surface Roughness Tester |

| Angular Features | ±0.05° | ±0.01° | Optical Comparator, CMM |

All tolerances are achievable on parts up to 800 mm × 600 mm × 500 mm in size, depending on material and complexity. At Wuxi Lead Precision Machinery, we combine advanced equipment, rigorous quality assurance, and engineering expertise to deliver mold components that meet the highest standards in the rubber molding industry.

Material & Finish Options

Material Selection for Precision Metal Molds in Rubber Production

Selecting the optimal base material for custom metal molds is critical when producing high-integrity rubber components. At Wuxi Lead Precision Machinery, we engineer molds from aluminum, steel, and titanium alloys, each offering distinct performance characteristics essential for demanding rubber molding processes like injection, compression, and transfer molding. The mold material directly impacts thermal management, dimensional stability, part quality, and overall production economics. While rubber compounds form the final product, the precision metal mold dictates repeatability, surface finish, and cycle times. Choosing incorrectly risks premature wear, inconsistent parts, and costly downtime.

Material properties must align with your specific rubber application’s temperature, pressure, volume, and part complexity requirements. Below is a comparative overview of key mold materials we utilize:

| Material Type | Hardness Range (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Applications | Cost Factor |

|---|---|---|---|---|

| Aluminum Alloys (e.g., 7075-T6) | 15-50 | 120-180 | Low-volume prototyping, low-temp rubber, rapid tooling | Low |

| Tool Steels (e.g., H13, P20) | 40-52 | 25-35 | High-volume production, aggressive rubbers, high-temp processes | Medium |

| Titanium Alloys (e.g., Ti-6Al-4V) | 30-40 | 6-7 | Extreme corrosion resistance, aerospace seals, specialized medical | High |

Aluminum excels in prototyping and low-volume runs due to its superior thermal conductivity, enabling faster cooling cycles for thermoset rubbers. Its machinability allows complex geometries but limits longevity under high abrasive or high-temperature rubber formulations. Tool steels like H13 are the industry standard for production molds, offering exceptional wear resistance and stability at elevated temperatures encountered with silicone or EPDM. They withstand high clamp forces and maintain precision over millions of cycles. Titanium, while less common, is indispensable for highly corrosive rubber compounds or ultra-clean medical applications where steel passivation fails; its biocompatibility and inertness justify the premium cost in niche scenarios.

Surface finishing, particularly hard anodizing for aluminum molds, significantly enhances performance. Anodizing creates a dense, wear-resistant ceramic layer (up to 70 HRC) that improves release properties, reduces galling with rubber, and extends mold life in abrasive applications. For steel molds, nitriding or specialized PVD coatings are often preferred for extreme wear resistance, though anodizing remains vital for aluminum-based tooling where thermal management is paramount.

At Wuxi Lead Precision Machinery, our CNC expertise ensures precise material selection and finishing integration. We analyze your rubber compound, production volume, and part tolerances to recommend the optimal metal substrate and surface treatment. This engineered approach minimizes cycle times, maximizes mold service life, and guarantees the dimensional accuracy your rubber components require. Partner with us to transform material science into manufacturing advantage.

Manufacturing Process & QC

The production process for manufacturing rubber molds at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure precision, repeatability, and zero defects. This structured approach spans three core phases: Design, Prototyping, and Mass Production. Each stage is engineered to meet the exacting standards demanded by high-end industrial applications, where performance and reliability are non-negotiable.

Design begins with a comprehensive analysis of the client’s functional requirements, environmental conditions, and dimensional constraints. Our engineering team utilizes advanced CAD software to develop 3D models that simulate real-world performance, including thermal expansion, compression set, and sealing dynamics. Finite element analysis (FEA) is employed to predict stress distribution and material behavior under operational loads. This digital validation ensures that every mold design is optimized before physical production begins. Tolerances are defined to ISO 2768-mK or tighter, depending on application needs, and material selection—such as silicone, EPDM, nitrile, or fluorocarbon—is matched precisely to chemical resistance, temperature range, and mechanical demands.

Prototyping follows design finalization and serves as the critical validation step. Using CNC-machined metal cores and cavities, we produce short-run samples under actual molding conditions. This phase allows for empirical testing of compression molding, transfer molding, or injection molding parameters. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM), followed by functional testing for compression deflection, sealing integrity, and durability. Any deviations are traced to root causes using statistical process control (SPC) methodologies, and design or process adjustments are implemented before progression. This iterative verification ensures that the mold performs as intended in real-world conditions.

Mass Production is initiated only after full approval of the prototype and process documentation. Our automated rubber molding lines operate under tightly monitored conditions, with real-time monitoring of temperature, pressure, and cure time. Each batch is traceable through serialized lot numbering, and in-process inspections occur at defined intervals. Final inspection includes 100% visual checks and sampling-based physical testing per ASTM D2000 or client-specific standards. All molds are cleaned, packaged in anti-corrosion materials, and shipped with full certification, including material test reports and dimensional compliance data.

This end-to-end process guarantees zero defects by embedding quality into every phase. At Wuxi Lead Precision Machinery, we do not rely on post-production inspection alone—quality is engineered in from the start.

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.05 mm to ±0.1 mm (based on part size) |

| Material Options | Silicone, Nitrile (NBR), EPDM, FKM, Neoprene |

| Hardness Range (Shore A) | 40 to 90 |

| Process Capabilities | Compression Molding, Transfer Molding, Injection Molding |

| Standard Compliance | ISO 9001, ASTM D2000, ISO 2768 |

| Tooling Materials | H13, P20, 420 Stainless Steel (polished to SPI-S1 or better) |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production) | 25–45 days, depending on complexity and volume |

Why Choose Wuxi Lead Precision

Elevate Your Rubber Mold Production Through Precision Engineering

In high-stakes manufacturing, rubber mold performance directly impacts your production yield, part consistency, and operational costs. Substandard molds lead to flashing, premature wear, and costly downtime—issues rooted in inadequate material selection or imprecise machining tolerances. At Wuxi Lead Precision Machinery, we engineer solutions where material science meets micron-level accuracy. Our CNC-machined mold bases and cavities eliminate dimensional drift, ensuring rubber compounds maintain integrity cycle after cycle. This precision extends mold life by up to 40% while reducing scrap rates in critical applications like automotive seals, medical devices, and aerospace gaskets.

We specialize in matching rubber formulations to your exact operational demands. Whether you require extreme temperature resilience for silicone molding or chemical resistance for aggressive elastomers, our team validates material properties against real-world stress factors. Below are key specifications we rigorously control to guarantee your mold’s performance:

| Specification | Range/Value | Impact on Production |

|---|---|---|

| Hardness Tolerance | ±2 Shore A | Prevents inconsistent compression set |

| Surface Finish (Ra) | 0.4–0.8 μm | Eliminates part sticking and surface defects |

| Thermal Stability | -60°C to +300°C | Maintains dimensional stability under cycling |

| Compression Set (ASTM D395) | <15% at 150°C | Ensures long-term sealing performance |

| Lead Time (Prototype) | 15–20 business days | Accelerates time-to-market validation |

Partnering with Lead Precision means accessing China’s advanced manufacturing infrastructure without compromising on Western engineering standards. Our ISO 9001-certified facility integrates 5-axis milling, wire EDM, and CMM validation to hold tolerances to ±0.005 mm—critical for complex geometries in multi-cavity molds. We collaborate from initial material selection through DFM analysis, ensuring your rubber compound interacts flawlessly with the mold’s thermal dynamics and ejection system. This holistic approach minimizes trial-and-error iterations, saving weeks in development and tens of thousands in wasted material.

Your production challenges demand more than generic mold suppliers. They require a partner who understands how rubber behaves under pressure, heat, and cyclic fatigue—and how precision machining mitigates those variables. We do not sell molds; we deliver production certainty. With dedicated project managers fluent in English and German, and a track record of serving Tier-1 automotive and medical OEMs, we ensure seamless communication and compliance with your quality protocols.

Do not let mold-related inefficiencies erode your margins or delay critical launches. Contact our engineering team today to discuss how tailored material and machining solutions can transform your rubber molding outcomes. Email [email protected] with your application details and material requirements. We will respond within 24 business hours with a technical assessment and actionable next steps. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.