Technical Contents

Engineering Guide: Machine Shop Boston Ma

Engineering Insight: The Critical Role of Precision in Modern Custom Metal Manufacturing

In the competitive landscape of custom metal manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, performance, and safety are built. For industries operating in high-stakes environments such as aerospace, defense, and advanced medical systems, even micron-level deviations can result in catastrophic system failures. This standard of excellence is equally relevant to machine shops serving the Boston, MA region—a hub of innovation where engineering firms, research institutions, and defense contractors demand components engineered to the tightest tolerances.

At Wuxi Lead Precision Machinery, we understand that precision transcends advanced machinery. It is a culture embedded in every stage of the manufacturing process—from material selection and CAD modeling to CNC machining, quality inspection, and final delivery. Our decades-long experience serving clients with Olympic-level engineering demands and mission-critical military applications has refined our ability to deliver components that meet and exceed the most stringent international standards.

The Olympic projects we supported required flawless performance under extreme conditions, where mechanical components had to operate with zero tolerance for failure. Similarly, our work with defense contractors demanded rigorous adherence to MIL-STD specifications, including environmental resilience, traceability, and repeatable precision across production batches. These experiences have shaped our engineering philosophy: precision is not achieved by accident, but through disciplined process control, skilled craftsmanship, and state-of-the-art metrology.

For machine shops in Boston, MA, and beyond, partnering with a global manufacturer like Wuxi Lead ensures access to a proven precision framework backed by real-world validation. Our facility is equipped with multi-axis CNC machining centers, automated inspection systems, and a full suite of testing equipment calibrated to NIST-traceable standards. More importantly, our engineering team applies a failure-mode mindset during design for manufacturability (DFM) reviews, proactively identifying potential risks before production begins.

We recognize that Boston-area manufacturers often face tight development cycles and complex design requirements. By integrating our precision manufacturing capabilities early in the product development phase, clients reduce prototyping iterations, lower long-term costs, and accelerate time to market—without compromising on quality.

The following table outlines key precision capabilities that define our manufacturing standard:

| Specification | Performance Level |

|---|---|

| Dimensional Tolerance | ±0.0001″ (2.5 µm) |

| Surface Finish | As low as Ra 0.4 µm (16 µin) |

| Material Traceability | Full lot-level certification |

| Inspection Equipment | CMM, optical comparators, laser scanners |

| Quality Standards | ISO 9001:2015, MIL-STD-883 compliant |

| Production Capacity | Low volume to mid-scale batch runs |

Precision is not a feature—it is a commitment. At Wuxi Lead Precision Machinery, our legacy in Olympic and military-grade manufacturing continues to drive innovation and uncompromising quality for clients across the globe, including the demanding engineering ecosystem of Boston, MA.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Metal Manufacturing

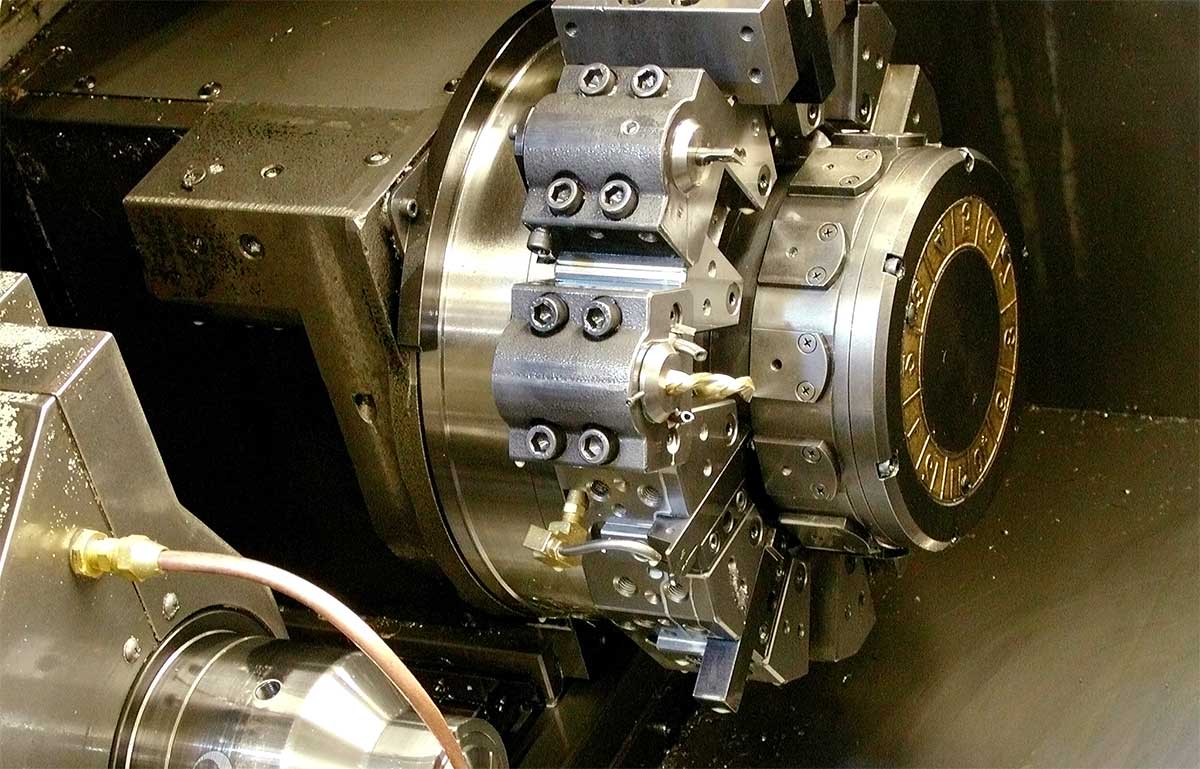

Wuxi Lead Precision Machinery delivers uncompromising precision for demanding aerospace, medical, and industrial clients in the Boston manufacturing ecosystem. Our core strength lies in multi-axis CNC machining, specifically 5-axis simultaneous processing, which eliminates secondary operations and ensures geometric complexity unattainable with 3-axis systems. Utilizing DMG MORI and MAZAK platforms with Siemens 840D controls, we machine intricate contours, deep cavities, and organic forms in a single setup. This reduces cumulative error, accelerates lead times by up to 40%, and maintains ±0.001 mm positional accuracy across titanium, Inconel, aluminum alloys, and hardened steels. Our machines feature high-torque spindles (up to 30,000 RPM) and integrated probing for real-time tool compensation, critical for Boston-area clients requiring zero-defect components in low-volume, high-mix production.

Rigorous quality control is non-negotiable. Every component undergoes comprehensive inspection via Zeiss CONTURA and Hexagon GLOBAL S CMM systems, programmed to ISO 10360-2 standards. Our metrology lab operates at 20°C ±0.5°C with vibration-dampened granite tables, ensuring measurement uncertainty below 1.5 µm. Full first-article inspection reports (FAIRs) include 3D deviation maps, GD&T analysis, and surface roughness verification per ASME Y14.5. For mission-critical applications, we implement in-process probing during machining to correct thermal drift and tool wear deviations, guaranteeing conformance before final inspection.

Tolerance execution is systematically documented and validated. The table below reflects achievable standards under controlled production conditions:

| Material Category | Standard Tolerance | Precision Tolerance | Micro-Precision Tolerance | Surface Finish (Ra) |

|---|---|---|---|---|

| Aluminum Alloys | ±0.010 mm | ±0.005 mm | ±0.002 mm | 0.4 µm |

| Stainless Steel | ±0.012 mm | ±0.006 mm | ±0.003 mm | 0.8 µm |

| Titanium Alloys | ±0.015 mm | ±0.008 mm | ±0.004 mm | 1.6 µm |

| Engineering Plastics | ±0.020 mm | ±0.010 mm | ±0.005 mm | 3.2 µm |

These capabilities directly address Boston manufacturers’ challenges in high-mix production environments. By consolidating complex geometries into single setups, we mitigate fixture-induced errors common in regional job shops relying on multiple machine transfers. Our digital workflow—from CAM programming in NX to CMM reporting—integrates seamlessly with US engineering teams via encrypted cloud portals, ensuring real-time collaboration across time zones. For clients requiring AS9100 or ISO 13485 compliance, we provide full traceability from raw material certs to final inspection data, eliminating supply chain verification delays. Partner with Wuxi Lead to transform precision bottlenecks into competitive advantages, with on-time delivery rates exceeding 98.5% for critical-path components.

Material & Finish Options

Material Selection Guide for Precision CNC Machining – Wuxi Lead Precision Machinery

Selecting the right material is critical in custom metal manufacturing, especially for high-performance applications in aerospace, medical, automotive, and industrial equipment sectors. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining services tailored to your engineering requirements, ensuring optimal performance, durability, and cost-efficiency. Our expertise includes working with key engineering metals—aluminum, steel, and titanium—each offering unique mechanical properties and compatibility with surface treatments such as anodizing.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications requiring lightweight components without sacrificing structural integrity. Among the most commonly used grades are 6061 and 7075, with 6061 offering good weldability and moderate strength, while 7075 delivers higher strength, suitable for demanding aerospace environments. Aluminum is particularly well-suited for anodizing, a process that enhances surface hardness and wear resistance while allowing for color coding and improved aesthetics.

Steel, particularly stainless steel grades such as 303, 304, and 17-4 PH, provides superior strength, durability, and resistance to high temperatures and corrosion. Stainless steels are essential in medical devices, food processing, and marine applications where hygiene and long-term reliability are paramount. While steel cannot be anodized like aluminum, it benefits from alternative surface treatments such as passivation, electropolishing, or coating to enhance performance.

Titanium, notably Grade 5 (Ti-6Al-4V), offers an exceptional strength-to-density ratio and outstanding resistance to corrosion, especially in saline or acidic environments. Its biocompatibility makes it a preferred choice for medical implants and aerospace components. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s performance in extreme conditions justifies its use in mission-critical applications.

Below is a comparative overview of key properties for commonly machined materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Anodizing Compatible | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | High | Yes | Enclosures, brackets, automotive parts |

| Aluminum 7075 | 572 | 2.8 | Moderate | Yes | Aerospace structures, military parts |

| Stainless 304 | 505 | 8.0 | Very High | No | Medical devices, food processing |

| Stainless 17-4 PH | 1000 | 7.8 | High | No | Aerospace, high-strength fasteners |

| Titanium Ti-6Al-4V | 950 | 4.4 | Excellent | No | Aircraft engines, prosthetics |

Understanding the interplay between material properties and finishing options ensures optimal component performance. At Wuxi Lead, we support clients in selecting the right combination of base material and surface treatment based on functional requirements, environmental exposure, and lifecycle expectations. Our advanced CNC machining capabilities, combined with rigorous quality control, enable us to deliver precision parts that meet global standards—serving industries from Boston to beyond.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process for custom metal components is engineered for uncompromising quality and seamless integration with demanding clients, including precision machine shops in Boston, MA. We eliminate traditional offshore risks through a rigorously controlled, transparent workflow focused on achieving Zero Defects from initial concept to final shipment. This begins with collaborative Design engineering. Our team works directly with your CAD/CAM files, utilizing Siemens NX and Mastercam to conduct thorough Design for Manufacturability (DFM) analysis. We identify potential machining challenges, material constraints, or tolerance conflicts early, providing actionable feedback within 48 hours. This proactive collaboration ensures the design is optimized for both performance and efficient, error-proof production on our advanced CNC equipment, preventing costly revisions later.

Prototyping is not merely a formality; it is the critical validation phase for Zero Defects. Using the exact production-grade materials and processes intended for volume manufacturing, we produce functional prototypes on our HAAS and DMG MORI 5-axis machining centers. Every prototype undergoes comprehensive metrology: 100% dimensional verification against your CAD model using Zeiss CONTURA CMMs, surface finish analysis, and material property checks. We provide detailed First Article Inspection (FAI) reports per AS9102 standards, including full GD&T validation and traceable measurement data. This phase confirms process capability, validates toolpaths, and secures your approval before committing to mass production, ensuring the foundation for defect-free output is solid.

Mass Production leverages the validated process under our integrated Quality Management System (ISO 9001:2015 certified). Zero Defects is achieved through layered controls: real-time in-process monitoring with Renishaw probes on every machine, automated statistical process control (SPC) tracking critical dimensions, and 100% post-machining inspection of high-risk features. Our production cells are dedicated to specific part families, minimizing setup variables. Final inspection involves full CMM reporting for batch certification, rigorous visual and functional checks, and meticulous packaging validation. Every component is traceable to raw material certs, machine logs, and operator records. This systematic approach guarantees consistent conformance to the tightest tolerances demanded by Boston’s aerospace, medical, and robotics sectors.

Key process specifications ensure predictable, high-precision outcomes:

| Parameter | Capability Range | Verification Method | Frequency |

|---|---|---|---|

| Dimensional Tolerance | ±0.0001″ (2.5 µm) | Zeiss CMM / Optical Comparator | 100% FAI; SPC in batch |

| Surface Finish | Ra 0.4 µm (16 µin) | Profilometer | Per drawing requirement |

| Material Traceability | Full Mill Certs + UTM | Documented in Batch Record | 100% |

| GD&T Compliance | Per ASME Y14.5 | CMM with GD&T Analysis Software | FAI; Critical features |

| In-Process Control | SPC Charts | Real-time Monitoring Software | Continuous |

For Boston machine shops requiring flawless, complex metal components, Wuxi Lead delivers the precision, reliability, and documentation rigor expected of a domestic partner, backed by our unwavering Zero Defects commitment. We bridge the geographical gap with engineering partnership and process transparency.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When your Boston-based manufacturing operation demands precision, consistency, and scalability, aligning with a global leader in custom metal manufacturing becomes a strategic imperative. At Wuxi Lead Precision Machinery, we specialize in delivering high-tolerance CNC machining, sheet metal fabrication, and assembly solutions tailored to the rigorous standards of aerospace, medical, robotics, and industrial automation sectors. Our engineering team in Wuxi, China, operates with the same precision mindset as the finest machine shops in Boston, MA—ensuring seamless integration with your supply chain, regardless of geography.

We understand that Boston manufacturers require more than just parts—they require reliability, technical collaboration, and on-time delivery. That’s why we’ve built our facility around ISO 9001-certified processes, advanced 5-axis CNC centers, and real-time quality inspection systems. Every component we produce undergoes stringent dimensional verification using CMM and optical measurement technologies, ensuring conformity to your exact specifications. Whether you need rapid prototyping or high-volume production runs, our agile manufacturing model supports low to mid-volume batches with the same attention to detail.

Our partnership approach begins with engineering alignment. We don’t just interpret drawings—we proactively engage in Design for Manufacturability (DFM) reviews to optimize cost, lead time, and performance. This collaborative process reduces iterations, minimizes waste, and accelerates time to market. With digital workflow integration, we offer full traceability from raw material to finished part, providing you with complete transparency and audit-ready documentation.

By partnering with Wuxi Lead Precision Machinery, Boston machine shops and OEMs gain access to a globally connected, yet locally responsive, manufacturing partner. We manage logistics efficiently through consolidated shipping and customs coordination, ensuring predictable delivery cycles without compromising quality. Our clients in the Northeast U.S. consistently achieve 20–30% cost savings compared to domestic sourcing, without sacrificing precision or service.

Explore how we can support your next production challenge. Contact us today at [email protected] to initiate a technical consultation, request a quote, or submit a DFM package. Let’s build precision together.

Technical Capabilities Overview

| Specification | Detail |

|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis milling; turning with live tooling |

| Tolerances | As tight as ±0.0002″ (5 µm) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Copper, Plastics (PEEK, Delrin) |

| Max Work Envelope | 2000 x 1000 x 800 mm (78.7 x 39.4 x 31.5 in) |

| Sheet Metal Fabrication | Laser cutting, CNC punching, bending, welding (TIG, MIG, spot) |

| Finishes | Anodizing (Type II, Type III), Plating, Powder Coating, Passivation, Bead Blasting |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, Full CMM reporting |

| Lead Times | Prototypes: 7–10 days; Production: 15–25 days (varies by complexity) |

| Certifications | ISO 9001, RoHS compliant, ITAR-registered (upon request) |

Contact [email protected] to begin your next precision manufacturing project with confidence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.