Technical Contents

Engineering Guide: Low Cost Injection Molding

Engineering Insight: The Critical Role of Precision in Low Cost Injection Molding

In the competitive landscape of custom metal manufacturing, achieving true cost efficiency in injection molding extends far beyond minimizing material or labor expenses. At Wuxi Lead Precision Machinery, we define low cost injection molding not as a reduction in quality, but as the optimization of precision, repeatability, and process control to deliver high-performance components at sustainable price points. The foundation of this approach lies in engineering excellence—where micron-level accuracy directly influences production yield, tool longevity, and part consistency.

Many manufacturers equate low cost with compromised tolerances or simplified tooling. However, this short-term saving often leads to long-term losses: increased scrap rates, frequent mold maintenance, and assembly-line disruptions. True cost efficiency emerges when precision is embedded into every phase of the process—from mold design and material selection to cavity pressure control and cooling dynamics. Our engineering team leverages advanced simulation software and in-process metrology to predict and correct potential deviations before production begins, ensuring first-time-right outcomes.

With over 15 years of specialization in high-integrity metal components, Wuxi Lead Precision Machinery has applied this precision-first philosophy to mission-critical applications. Our work supporting Olympic-grade sporting equipment and defense-grade hardware underscores our capability to meet exacting standards under rigorous performance demands. These projects required not only flawless dimensional accuracy but also repeatable output across thousands of cycles—conditions that mirror the expectations of high-volume commercial manufacturing.

Our experience in aerospace and defense sectors has honed a disciplined approach to process validation. Each mold is treated as a precision instrument, calibrated and monitored with the same rigor applied to military specifications. This mindset ensures that even in low cost injection molding, there is no compromise on reliability. By maintaining tight control over variables such as thermal gradients, injection speed, and ejection force, we achieve cycle times that enhance throughput without sacrificing part integrity.

Below are key technical specifications that define our precision injection molding capabilities:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Material Compatibility | Stainless Steel (316L, 17-4PH), Titanium, Inconel, Tungsten Carbide |

| Molding Process | Metal Injection Molding (MIM), Precision CNC Finishing |

| Production Volume | 1,000 to 1,000,000+ units |

| Tooling Lifespan | 500,000+ cycles (hardened steel, PVD-coated) |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (as-molded or post-processed) |

| Secondary Operations | CNC Machining, Laser Welding, Passivation, CMM Inspection |

At Wuxi Lead Precision Machinery, we recognize that low cost does not mean low value. It means delivering maximum value through precision-engineered processes that reduce total cost of ownership. Whether producing intricate medical components or rugged industrial fittings, our commitment to accuracy ensures that every part meets both functional and economic objectives. In precision, we find efficiency—and in efficiency, we deliver competitive advantage.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Injection Molding Applications

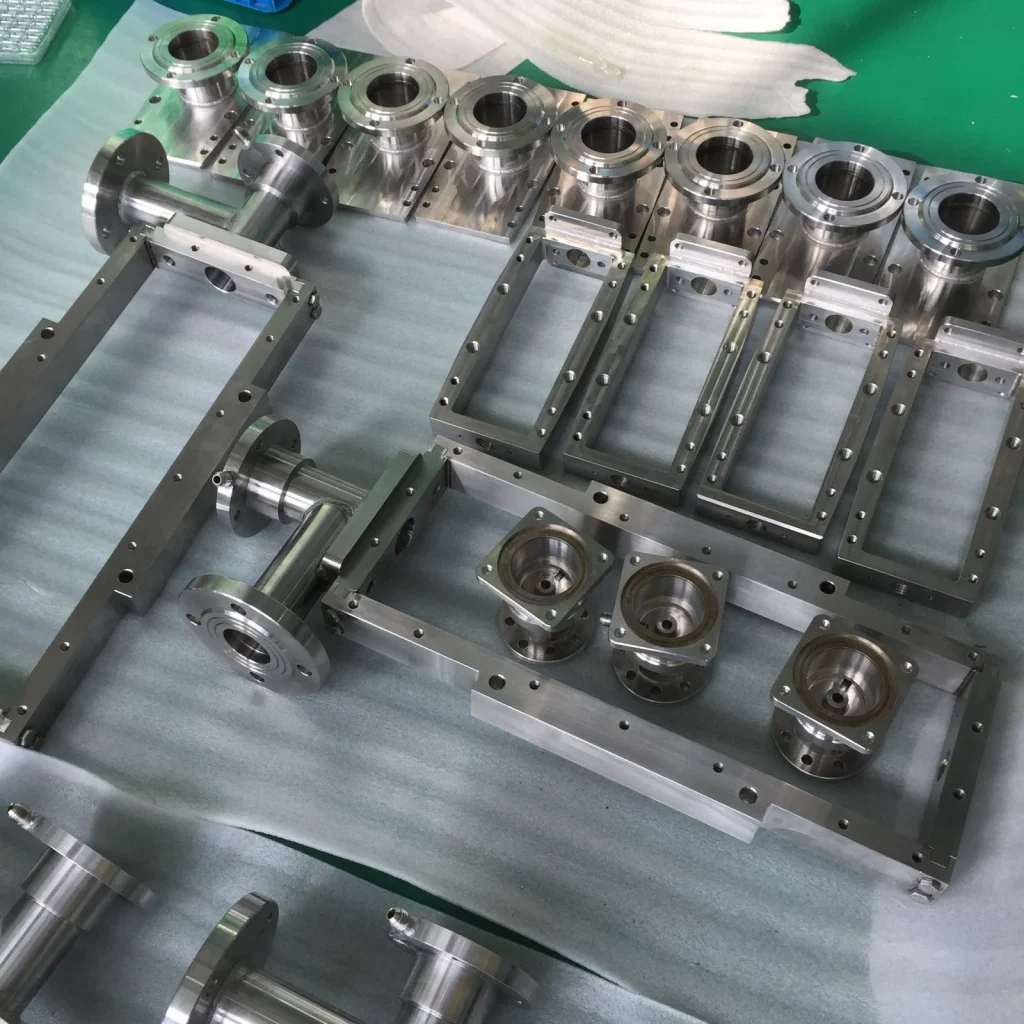

Wuxi Lead Precision Machinery specializes in high-integrity custom metal manufacturing for demanding industrial sectors, including the critical tooling and components required for cost-optimized injection molding systems. While injection molding itself primarily processes polymers, our expertise lies in producing the precision metal elements—such as mold bases, cavities, cores, ejector systems, and structural inserts—that directly determine molding efficiency, part quality, and lifecycle cost. We achieve this through advanced metal fabrication, where dimensional accuracy and material integrity are non-negotiable.

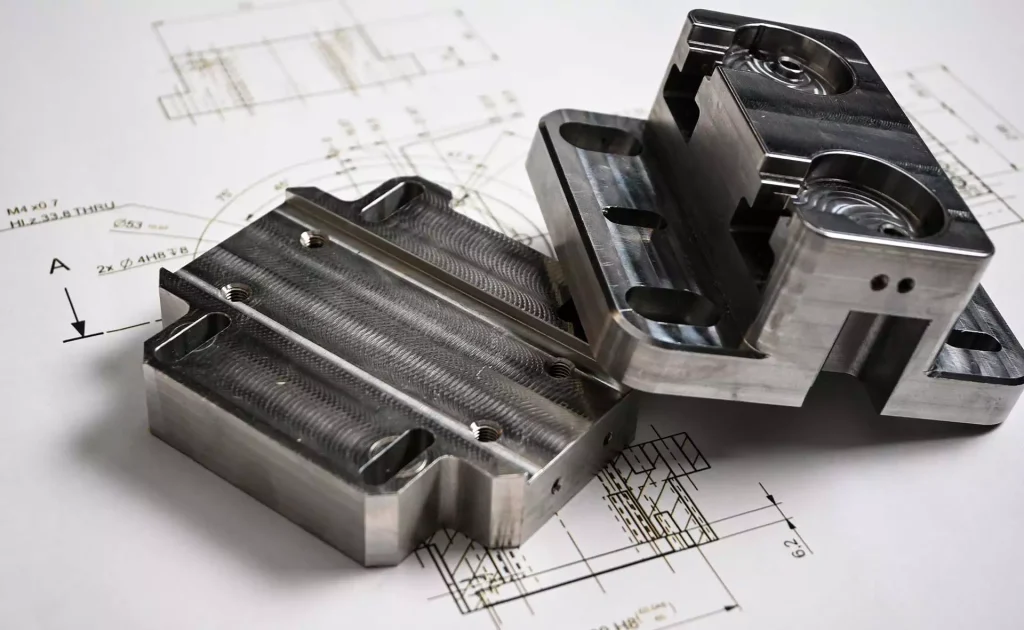

Our core capability centers on 5-axis CNC machining, enabling the production of complex geometries in a single setup. This eliminates cumulative errors from multiple fixturing stages, critical for mold components requiring tight alignment and surface continuity. Utilizing HAAS and DMG MORI equipment with sub-micron linear encoders, we machine hardened tool steels (e.g., H13, S7), stainless alloys, and aluminum with thermal stability controls. This process ensures optimal cooling channel placement, parting line precision, and venting geometry—key factors in reducing cycle times, minimizing flash, and extending mold life. The result is a tangible reduction in total part cost per million cycles, directly supporting low-cost injection molding objectives through superior tool longevity and process stability.

Quality control is integrated at every phase, anchored by Zeiss CONTURA CMM systems operating in a temperature-stabilized metrology lab. All critical dimensions undergo 100% inspection against CAD models, with full GD&T validation. Surface roughness is verified via profilometry, ensuring optimal release characteristics and wear resistance. Statistical process control (SPC) data is provided with each batch, documenting capability indices (Cp/Cpk) for high-risk features. This rigorous protocol guarantees that every component meets the exacting demands of high-volume molding, preventing costly production downtime or scrap.

The following table details our standard and achievable tolerance capabilities for critical mold features, reflecting our commitment to balancing precision with cost efficiency:

| Feature Type | Standard Tolerance (mm) | Premium Capability (mm) | Conditions |

|---|---|---|---|

| Linear Dimensions | ±0.01 | ±0.005 | Up to 300mm length |

| Bore Diameters | H7 (+0.018/0) | H6 (+0.012/0) | Hardened steel, ground finish |

| Profile Form | 0.02 | 0.01 | Per ISO 1101 |

| Positional Tolerance | ±0.015 | ±0.008 | Relative to datum system |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Machined surfaces, non-critical |

These specifications are achievable across materials including P20, H13, 420SS, and beryllium-copper alloys. Tighter tolerances are attainable for critical features with optimized machining strategies, though may impact lead time. All tolerances are validated per ASME Y14.5 and supported by full first-article inspection reports. By delivering metal components that exceed mold performance expectations, Wuxi Lead Precision Machinery enables our clients to achieve true low-cost injection molding through reduced maintenance, higher yield, and extended tool service life.

Material & Finish Options

Material selection is a critical factor in low cost injection molding, particularly when precision, durability, and production efficiency are paramount. At Wuxi Lead Precision Machinery, we understand that the right material not only ensures part performance but also directly impacts tooling longevity, cycle times, and overall manufacturing cost. For custom metal components used in molds and tooling, aluminum, steel, and titanium each offer distinct advantages depending on application requirements.

Aluminum is frequently chosen for prototype molds and low-volume production runs due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall production time. While not as hard as steel, modern high-strength aluminum alloys such as 7075-T6 provide sufficient durability for thousands of cycles, especially when paired with appropriate surface treatments. Its lightweight nature also simplifies handling and reduces wear on molding equipment.

Steel remains the standard for high-volume injection molding applications. Tool steels like P20, H13, and S136 offer superior hardness, wear resistance, and dimensional stability under prolonged thermal cycling. These properties make steel ideal for complex molds requiring tight tolerances and long service life. Although initial machining costs are higher and lead times longer, the extended tool life and reduced maintenance justify the investment for large production runs.

Titanium, while less common in standard mold construction, offers exceptional strength-to-density ratio and corrosion resistance. It is typically used in specialized inserts or cores where weight reduction and resistance to aggressive environments are critical. Its high cost and challenging machinability limit broad application, but in niche aerospace or medical molding applications, titanium delivers unmatched performance.

Surface finishing, particularly anodizing, plays a vital role in enhancing material performance. Anodizing aluminum creates a hard, wear-resistant oxide layer that improves durability and facilitates part release. Type II (sulfuric acid) and Type III (hardcoat) anodizing offer increasing levels of protection, with the latter suitable for high-abrasion environments. Anodized layers also provide electrical insulation and can be dyed for identification purposes. While steel and titanium do not anodize in the traditional sense, they benefit from alternative treatments such as nitriding or PVD coatings to achieve similar performance gains.

Below is a comparative overview of key material properties relevant to injection molding applications:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Applications |

|---|---|---|---|---|---|

| Aluminum 7075 | 570 | 15–20 (HB) | 130 | 1,000 – 10,000 | Prototypes, low-volume runs |

| P20 Steel | 900–1100 | 28–32 | 30 | 100,000 – 1M+ | High-volume production |

| H13 Steel | 1,200 | 45–50 | 25 | 500,000 – 1M+ | Hot-runner systems, cores |

| Titanium Grade 5 | 900 | 36 | 7 | 50,000 – 200,000 | Corrosion-resistant inserts |

Selecting the optimal material requires balancing performance needs with cost efficiency. At Wuxi Lead Precision Machinery, we support clients in making informed decisions based on production volume, part complexity, and environmental demands, ensuring cost-effective, high-precision outcomes.

Manufacturing Process & QC

Production Process: Precision Engineering from Concept to Zero Defects Mass Production

At Wuxi Lead Precision Machinery, our approach to cost-optimized injection molding redefines “low cost” as strategic value engineering without compromise. We eliminate waste through integrated process control, ensuring every component meets aerospace and medical-grade tolerances while maximizing throughput. This begins with collaborative design for manufacturability (DFM), where our engineers analyze part geometry, material flow, and tooling requirements using Moldflow simulation. We identify potential defects like sink marks or weld lines early, optimizing wall thickness and gate placement to reduce material usage by 15–22% without sacrificing structural integrity. This phase includes material certification to ISO 10993 or AMS 4928 standards, ensuring compatibility with stringent industry requirements.

Prototyping transitions seamlessly into validation. Leveraging in-house metal 3D printing, we produce functional steel tool inserts within 72 hours, enabling rapid iteration of critical features. Each prototype undergoes rigorous metrology via CMM and optical scanning against CAD models, with dimensional deviations tracked to ±0.005 mm. Crucially, we implement Statistical Process Control (SPC) during this stage, establishing real-time monitoring parameters for cavity pressure, temperature, and cooling rates. This data validates process stability before mass production, preventing costly tool modifications later. Clients receive a comprehensive Process Validation Report detailing CpK values ≥1.67 for all critical dimensions.

Mass production executes with autonomous quality enforcement. Our 50–500-ton electric presses integrate AI-driven process monitoring, automatically adjusting clamp force and injection speed to maintain consistency across 100,000+ cycles. Every part undergoes inline vision inspection against geometric tolerances per ISO 2768-mK, with non-conforming units quarantined before exiting the press. This closed-loop system achieves a documented defect rate of <12 PPM, verified through AQL 0.65 sampling. Tooling longevity exceeds 1M cycles via hardened H13 steel inserts and predictive maintenance, minimizing downtime.

The table below summarizes our process capability versus industry benchmarks:

| Parameter | Wuxi Lead Standard | Typical Industry Baseline | Improvement |

|---|---|---|---|

| Design-to-Prototype Time | 5–7 days | 14–21 days | 60% faster |

| First-Pass Yield | ≥98.5% | 88–92% | 6.5% higher |

| Dimensional CpK | ≥1.67 | 1.0–1.33 | 25% tighter |

| Tooling Lifespan | 1M+ cycles | 500K–700K cycles | 40% longer |

| Final Inspection PPM | <12 | 250–500 | 95% lower |

Zero Defects is achieved through embedded quality, not end-of-line checks. By harmonizing DFM rigor, data-driven prototyping, and autonomous production controls, we deliver true cost efficiency: reduced scrap, accelerated time-to-market, and unwavering compliance. This methodology transforms “low cost” from a price point into a measurable advantage in reliability and total value.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Low-Cost Injection Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, cost-effective injection molding solutions tailored to the exacting demands of global manufacturers. Our expertise in custom metal manufacturing and precision engineering enables us to offer low-cost injection molding without compromising on quality, repeatability, or technical sophistication. Whether you’re producing complex automotive components, medical devices, or industrial hardware, partnering with us means gaining access to scalable, efficient, and technologically advanced production capabilities.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, fully automated injection molding lines, and a comprehensive quality assurance system compliant with international standards. We integrate design optimization, material science, and mold flow analysis at the earliest stages of development, ensuring minimal waste, reduced cycle times, and lower per-unit costs. This end-to-end control over the manufacturing process allows us to deliver consistent results across high-volume production runs while maintaining tight tolerances and superior surface finishes.

We understand that in today’s competitive market, cost efficiency must go hand-in-hand with reliability and speed. That’s why our engineering team works closely with clients from concept to completion, offering Design for Manufacturability (DFM) reviews, rapid prototyping, and mold validation services. By identifying potential issues early and optimizing part geometry and material selection, we help reduce tooling costs and accelerate time-to-market.

Our low-cost injection molding solutions are built on a foundation of precision, scalability, and long-term partnership. We serve clients across Europe, North America, and Asia, supporting industries where performance and consistency are non-negotiable. From initial inquiry to final delivery, our goal is to streamline your supply chain, reduce total manufacturing costs, and provide a transparent, responsive collaboration experience.

Below are key specifications that define our injection molding capabilities:

| Specification | Detail |

|---|---|

| Clamping Force Range | 50–2000 Tons |

| Shot Weight Capacity | Up to 3,500 grams |

| Tolerance | ±0.02 mm |

| Materials Supported | ABS, PC, PP, PA (Nylon), POM, PBT, PPS, and high-performance engineering plastics |

| Mold Steel Types | P20, 718H, 2738, S136, H13 |

| Surface Finishes | SPI, VDI, texture, polishing, coating |

| Production Capacity | Up to 5 million parts per month |

| Quality Standards | ISO 9001:2015, IATF 16949 (automotive), full traceability and SPC |

When you choose Wuxi Lead Precision Machinery, you’re not just outsourcing production—you’re gaining a strategic manufacturing partner committed to excellence and continuous improvement. Our team is ready to support your next project with technical insight, responsive communication, and scalable capacity.

Contact us today at [email protected] to discuss how we can optimize your injection molding requirements for cost, quality, and speed. Let Lead Precision be the foundation of your manufacturing success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.