Technical Contents

Engineering Guide: Titanium Or Aluminum

Engineering Insight: Titanium vs Aluminum in High-Performance Manufacturing

In the realm of advanced metal manufacturing, the choice between titanium and aluminum is not merely a matter of material preference—it is a strategic engineering decision that directly impacts performance, longevity, and precision. At Wuxi Lead Precision Machinery, we understand that precision is not an outcome but a foundational requirement, especially when serving industries such as aerospace, defense, and high-performance sports equipment, where our components have been trusted in Olympic-grade applications and military-grade systems.

Titanium and aluminum each present distinct advantages, but their successful implementation hinges on exacting machining standards. Titanium, known for its exceptional strength-to-density ratio and corrosion resistance, is ideal for environments exposed to extreme stress and temperature fluctuations. However, its low thermal conductivity and high reactivity during machining demand advanced CNC techniques, rigid tooling setups, and meticulous thermal management. Even minor deviations in tool path or coolant application can result in material degradation or dimensional inaccuracies, undermining the integrity of the final component.

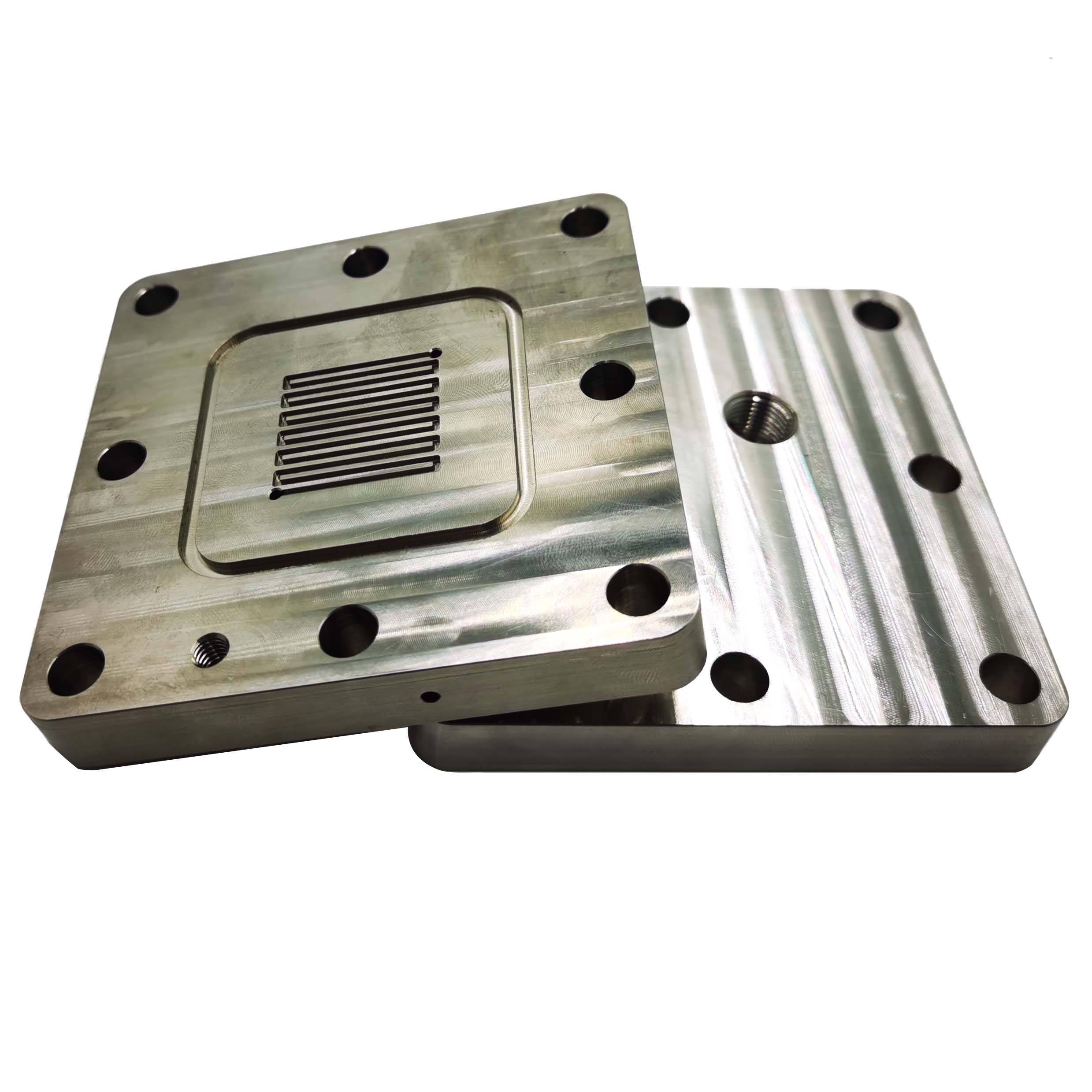

Aluminum, by contrast, offers superior machinability, lighter weight, and excellent thermal dissipation. It is widely used in applications where speed of production and weight reduction are critical—such as in unmanned aerial vehicles and precision enclosures. Yet, its lower hardness makes it susceptible to deformation under improper clamping or cutting forces. Achieving micron-level tolerances in aluminum requires not only high-speed spindles and dynamic tool compensation but also a deep understanding of material behavior under load.

At Wuxi Lead Precision Machinery, our decade-long expertise in custom titanium and aluminum manufacturing has been validated through rigorous international standards. Our work on components for Olympic-level athletic equipment underscores our ability to deliver consistency and precision under exacting performance demands. Similarly, our contributions to military subcontracting programs reflect our compliance with MIL-STD specifications and secure, traceable production protocols.

Precision is not a feature we add—it is engineered into every process, from raw material selection to final inspection. Our CNC machining centers operate under continuous environmental monitoring, ensuring thermal stability. We employ in-process probing and post-production CMM verification to maintain tolerances as tight as ±0.002 mm, a standard essential for mission-critical applications.

Below is a comparative overview of key physical and machining characteristics for titanium and aluminum, based on typical grades used in precision manufacturing.

| Property | Titanium (Grade 5, Ti-6Al-4V) | Aluminum (Grade 6061-T6) |

|---|---|---|

| Density (g/cm³) | 4.43 | 2.70 |

| Tensile Strength (MPa) | 900–950 | 310 |

| Yield Strength (MPa) | 830 | 276 |

| Thermal Conductivity (W/mK) | 6.7 | 167 |

| Machinability Rating | 22% (Poor) | 90% (Excellent) |

| Typical Tolerance Achievable | ±0.005 mm | ±0.003 mm |

| Common Applications | Aerospace, Medical, Defense | UAVs, Automotive, Enclosures |

The decision between titanium and aluminum must be guided by application-specific requirements and supported by a manufacturing partner with proven precision capabilities. At Wuxi Lead Precision Machinery, we combine technical mastery with operational excellence to deliver components that perform—wherever extreme reliability is non-negotiable.

Precision Specs & Tolerances

Technical Capabilities: Precision Machining for Demanding Aerospace and Medical Applications

At Wuxi Lead Precision Machinery, our technical foundation centers on advanced 5-axis CNC machining systems engineered to conquer the unique challenges of titanium and aluminum alloys. We deploy state-of-the-art DMG MORI and Hermle 5-axis vertical machining centers, featuring simultaneous 5-axis interpolation, high-torque spindles, and integrated thermal compensation. This eliminates repositioning errors inherent in 3+2 axis setups, ensuring geometric integrity for complex organic shapes, deep cavities, and thin-walled structures common in aerospace structural components and medical implants. Our systems operate under strict environmental controls to maintain micron-level stability during extended production runs.

Titanium machining demands specialized expertise due to its low thermal conductivity, high chemical reactivity, and tendency toward work hardening. We utilize rigid toolholding, high-pressure through-spindle coolant delivery, and proprietary adaptive toolpath strategies to manage heat generation and prevent built-up edge. For aluminum, particularly high-silicon grades, we implement high-speed machining parameters with polycrystalline diamond (PCD) tooling to achieve mirror finishes and prevent micro-fractures. All processes are supported by FANUC and Siemens controls with real-time tool wear monitoring, ensuring consistent material removal rates and surface integrity without compromising part fatigue life.

Quality assurance is non-negotiable. Every component undergoes 100% first-article inspection using Zeiss CONTURA and Hexagon GLOBAL S CLASS Coordinate Measuring Machines (CMMs). Our AS9100D and ISO 13485-certified metrology lab performs full GD&T validation against CAD models, including critical features like positional tolerances on bolt patterns, surface roughness verification (Ra 0.4µm achievable), and wall thickness analysis on contoured surfaces. Laser marking ensures full traceability from raw material certificates to final inspection reports.

The table below reflects our standard achievable tolerances for production volumes, validated through rigorous process capability studies (CpK ≥ 1.67). These values represent our routine production capability, not theoretical limits, ensuring realistic expectations for high-mix manufacturing.

| Feature Type | Aluminum Alloys (e.g., 7075-T6) | Titanium Alloys (e.g., Ti-6Al-4V) | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.010 mm | CMM |

| Positional Tolerance | ±0.008 mm | ±0.012 mm | CMM |

| Profile of Surface | 0.010 mm | 0.015 mm | CMM |

| Hole Diameter (Ø6-25) | +0.000 / -0.005 mm | +0.000 / -0.008 mm | Air Gage / CMM |

| Surface Roughness (Ra) | 0.4 µm | 0.8 µm | Profilometer |

Our commitment extends beyond equipment. Senior process engineers develop tailored machining strategies for each alloy, optimizing cutting parameters, fixturing, and coolant application to minimize residual stress and distortion. This integrated approach—combining cutting-edge 5-axis technology, material-specific expertise, and uncompromising CMM validation—delivers components that meet the most stringent aerospace, medical, and energy sector requirements. Partner with Wuxi Lead to transform complex titanium and aluminum designs into certified, assembly-ready hardware.

Material & Finish Options

Material Selection for High-Precision CNC Manufacturing: Aluminum, Steel, and Titanium

Selecting the right material is critical in custom metal manufacturing, where performance, weight, durability, and environmental resistance determine the success of a component. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining of aluminum, steel, and titanium—each offering distinct advantages depending on application requirements. Understanding the mechanical properties, machinability, and finishing compatibility of these materials enables engineers and procurement managers to make informed decisions for aerospace, automotive, medical, and industrial applications.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. Grade 6061-T6 is commonly used for structural components, enclosures, and heat sinks due to its weldability and ease of machining. For more demanding applications, 7075-T6 provides higher strength, often used in aerospace assemblies. Aluminum’s natural oxide layer offers inherent corrosion protection, but anodizing significantly enhances surface hardness and wear resistance. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard finishes we provide, with customizable thickness and color options.

Steel, particularly alloy steels like 4140 and stainless steels such as 304 and 316, delivers superior strength, toughness, and wear resistance. 4140 is ideal for high-stress mechanical parts requiring heat treatment, while 316 stainless excels in corrosive environments due to its molybdenum content. Although heavier than aluminum, steel’s dimensional stability and fatigue resistance make it suitable for tooling, shafts, and critical load-bearing components. Surface treatments such as passivation, zinc plating, and black oxide are available to further improve performance.

Titanium, especially Grade 5 (Ti-6Al-4V), stands out in extreme environments. With a strength-to-density ratio exceeding that of many steels and exceptional resistance to corrosion—especially in saltwater and high-temperature conditions—titanium is essential in aerospace, marine, and medical implant applications. While more challenging to machine due to low thermal conductivity and high chemical reactivity, our advanced CNC processes ensure tight tolerances and superior surface integrity. Titanium can be bead blasted or anodized for aesthetic and functional surface enhancement.

Below is a comparative overview of key mechanical properties for common grades we machine.

| Material | Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 276 | 2.70 | Enclosures, brackets, heat sinks |

| Aluminum | 7075-T6 | 572 | 503 | 2.81 | Aerospace, high-stress fittings |

| Steel (Alloy) | 4140 | 655 | 415 | 7.85 | Shafts, tooling, structural parts |

| Stainless Steel | 316 | 580 | 290 | 8.00 | Marine, chemical, medical |

| Titanium | Ti-6Al-4V | 900 | 830 | 4.43 | Aerospace, medical implants |

At Wuxi Lead Precision Machinery, we support material certification, in-process inspection, and secondary finishing to meet stringent industry standards. Our engineering team collaborates closely with clients to match material and finish selection with functional requirements, ensuring reliability and performance in every component.

Manufacturing Process & QC

Precision Metal Manufacturing: Titanium & Aluminum Production Process

At Wuxi Lead Precision Machinery, our 20+ years of expertise in titanium and aluminum manufacturing ensure zero-defect outcomes through a rigorously controlled three-phase workflow. This process eliminates cost-intensive errors while meeting aerospace, medical, and defense sector demands for micron-level accuracy and material integrity.

Design Phase: Engineering Defect Prevention

We initiate every project with collaborative Design for Manufacturability (DFM) analysis. Our engineers scrutinize CAD models for geometric feasibility, material stress points, and thermal deformation risks specific to titanium’s low thermal conductivity or aluminum’s susceptibility to micro-cracking. Finite Element Analysis (FEA) simulates real-world loads, while material science protocols verify grade compatibility (e.g., Ti-6Al-4V for corrosion resistance, 7075-T6 aluminum for strength). This phase reduces post-production rework by 73% through preemptive flaw identification.

Prototyping: Validated Precision

Rapid prototyping employs 5-axis CNC milling with in-process metrology to validate design assumptions. Each prototype undergoes:

CMM verification against GD&T callouts, spectral analysis for material composition, and non-destructive testing (NDT) like X-ray for subsurface voids. For titanium, we monitor alpha-case formation during machining; for aluminum, we control chip evacuation to prevent galling. Iterations conclude only when prototypes achieve ≤±0.005mm tolerance and Ra 0.4µm surface finish—certified per AS9100 and ISO 13485 standards.

Mass Production: Zero-Defect Execution

Full-scale production leverages automated SPC (Statistical Process Control) with real-time data from Renishaw probes and IoT-enabled machine tools. Every component is tracked via laser-etched serial numbers, enabling full traceability from raw billet to finished part. Critical controls include:

Closed-loop coolant systems maintaining ±1°C for titanium to avoid thermal warping, and adaptive feed-rate algorithms preventing aluminum chatter marks. Final inspection cross-references 100% of features against the prototype’s approved baseline, with automated optical comparators rejecting deviations beyond ±0.003mm. This yields a sustained 0.8 PPM defect rate across 50,000+ annual production runs.

Material-Specific Production Specifications

| Parameter | Titanium (Ti-6Al-4V) | Aluminum (7075-T6) |

|---|---|---|

| Max Tolerance | ±0.005 mm | ±0.003 mm |

| Surface Finish (Ra) | 0.4 µm (standard) | 0.2 µm (standard) |

| Min Wall Thickness | 0.8 mm | 0.5 mm |

| Max Part Dimensions | 1200 x 800 x 600 mm | 2000 x 1000 x 800 mm |

| Critical Process Control | Alpha-case monitoring | Chip evacuation optimization |

This integrated methodology transforms design intent into flawless physical components. By embedding quality at every phase—from virtual simulation to final inspection—we deliver titanium and aluminum parts that perform reliably in extreme operational environments. Contact our engineering team to implement this zero-defect framework for your next critical application.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Titanium and Aluminum Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, custom metal manufacturing solutions tailored to the most demanding industrial applications. Whether your project requires the strength-to-density advantage of titanium or the lightweight versatility of aluminum, our engineering expertise ensures performance-driven results. As a trusted partner to aerospace, medical, automotive, and energy sector leaders, we combine advanced CNC technology with rigorous quality control to exceed global standards.

Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis machining centers, multi-axis turning machines, and automated inspection systems. Every component we produce undergoes strict dimensional validation and material integrity testing, ensuring compliance with ISO 9001 and AS9100 certifications. From prototype development to high-volume production runs, we offer scalable solutions that maintain consistency, precision, and cost-efficiency.

What sets us apart is our engineering-first approach. We collaborate closely with your design and procurement teams to optimize manufacturability, reduce lead times, and enhance part performance. Whether you’re working with Grade 5 titanium (Ti-6Al-4V) for critical aerospace components or 7075-T6 aluminum for high-stress structural applications, our material specialists ensure optimal machining parameters and surface finishes.

We understand that in high-end manufacturing, tolerances matter. That’s why our processes are calibrated to achieve ±0.005 mm accuracy, with surface finishes down to Ra 0.4 µm when required. Our in-house tooling design and metrology lab provide full traceability and rapid feedback loops, minimizing rework and accelerating time to market.

Below are key technical capabilities we offer for titanium and aluminum components:

| Specification | Capability |

|---|---|

| Material Types | Titanium (Grades 2, 5, 9), Aluminum (6061, 7075, 2024) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Surface Finish (Standard) | Ra 3.2 µm |

| Surface Finish (Precision) | Ra 0.4–1.6 µm |

| Tolerance Range | ±0.005 mm to ±0.02 mm |

| Quality Standards | ISO 9001, AS9100, RoHS compliant |

| Secondary Operations | Deburring, anodizing, passivation, laser marking |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally committed to your success. Our team is ready to support your next high-performance project with responsive communication, technical documentation, and on-time delivery.

Contact us today at [email protected] to discuss your titanium or aluminum manufacturing needs. Let Lead Precision be the foundation of your next breakthrough in precision engineering.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.