Technical Contents

Engineering Guide: Inexpensive Injection Molding

Engineering Insight Precision as the Foundation of Economical Injection Molding

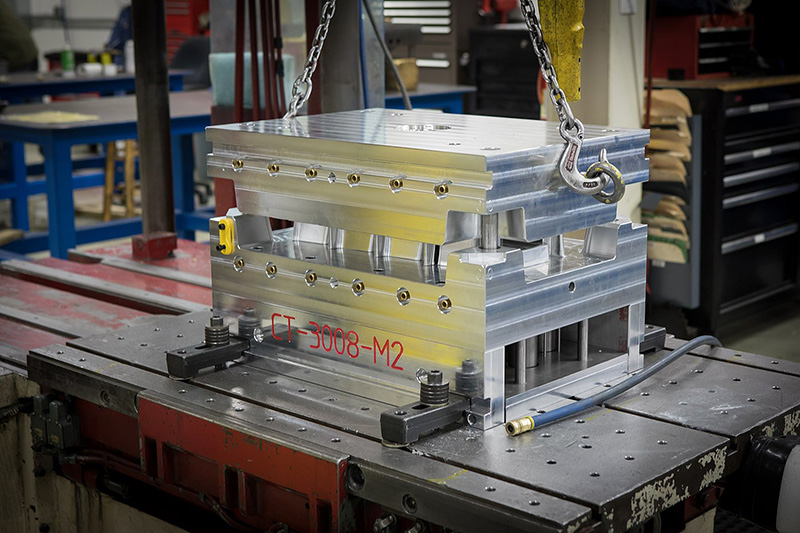

The term “inexpensive injection molding” is frequently misunderstood within high-end manufacturing. True cost efficiency is not achieved through minimal initial tooling expenditure but through exceptional precision engineered into the mold from inception. At Wuxi Lead Precision Machinery, we define economical molding as the elimination of waste across the entire production lifecycle—reducing scrap, minimizing downtime, and ensuring consistent part quality. This outcome is impossible without micron-level accuracy in mold fabrication. Precision engineering directly dictates thermal management, material flow, ejection reliability, and dimensional stability. A mold lacking tight tolerances on critical features like cavities, cores, or cooling channels inevitably leads to part warpage, flash, sink marks, or premature wear. These defects cascade into costly secondary operations, production delays, and rejected batches, rapidly eroding any perceived upfront savings. The initial mold investment must be viewed as the cornerstone of long-term unit cost reduction.

Our experience delivering mission-critical components for the Beijing Winter Olympics infrastructure and specialized naval systems underscores this principle. These projects demanded absolute reliability under extreme conditions, where a single micron deviation could compromise structural integrity or performance. The same rigorous standards apply to commercial injection molding. Precision machining ensures uniform cooling channel placement and surface finish, critical for controlling cycle times and part crystallinity. It guarantees consistent wall thickness transitions, preventing internal stresses. Most significantly, it enables the mold to maintain tolerances over hundreds of thousands of cycles, maximizing its productive lifespan. Sacrificing precision to lower the initial mold quote introduces hidden costs that far exceed the initial savings, impacting yield rates, quality control overhead, and ultimately, customer satisfaction.

Wuxi Lead Precision Machinery leverages advanced 5-axis CNC machining centers, stringent CMM validation protocols, and decades of metallurgical expertise to build molds where precision is non-negotiable. The table below illustrates how specific precision parameters directly influence operational economy:

| Parameter | Standard Mold Tolerance | Precision-Optimized Mold Tolerance | Impact on Cost Efficiency |

|---|---|---|---|

| Cavity/Core Tolerance | ±0.05 mm | ±0.005 mm | Reduces scrap by 15-25%; eliminates fitting |

| Cooling Channel Finish | 3.2 µm Ra | 0.8 µm Ra | Improves thermal transfer; cuts cycle time 8% |

| Parting Line Alignment | ±0.03 mm | ±0.008 mm | Eliminates flash; reduces de-flashing labor |

| Material Utilization | 65-70% | 85-90% | Lowers raw material cost per part by 18-22% |

True economy in injection molding is realized when the mold consistently produces conforming parts at target cycle rates with minimal intervention. This requires precision as the fundamental design criterion, not an afterthought. Wuxi Lead’s commitment to Olympic and military-grade accuracy ensures your mold delivers predictable, low-cost-per-part performance from shot one through its entire service life. Investing in precision engineering is the only proven path to sustainable cost efficiency in high-volume manufacturing.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to support high-performance applications across aerospace, medical, automotive, and industrial sectors. At the core of our production infrastructure is our 5-axis CNC machining technology, which enables us to produce complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis platforms allow simultaneous movement across all axes, reducing setup times, minimizing human error, and ensuring consistent part quality. This capability is particularly critical when manufacturing components for injection molding systems, where tight tolerances and intricate cooling channels are essential for mold longevity and cycle efficiency.

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool monitoring systems, ensuring precision and repeatability across both prototyping and high-volume production runs. Materials commonly processed include hardened steels, aluminum alloys, stainless steels, titanium, and specialty alloys, all machined under strict environmental controls to prevent thermal distortion. The integration of 5-axis technology allows us to approach parts from multiple angles in a single setup, significantly improving dimensional accuracy and reducing lead times—key advantages when delivering cost-effective yet high-precision injection mold components.

Quality assurance is maintained through a comprehensive inspection protocol anchored by Coordinate Measuring Machine (CMM) verification. Every critical dimension is validated using Zeiss or equivalent high-accuracy CMM systems, ensuring compliance with international standards such as ISO 2768 and ASME Y14.5. Our inspection process includes first-article reporting, in-process checks, and final validation, with full traceability maintained for each production batch. Data from CMM inspections is documented and shared with clients to provide complete transparency and support design validation.

To ensure alignment with customer expectations, we adhere to defined tolerance standards across key machining parameters. These specifications reflect our commitment to delivering reliable, repeatable results in support of injection molding applications where precision directly impacts part quality and production efficiency.

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Depending on part size and geometry |

| Hole Diameter | ±0.015 mm | ±0.008 mm | Reamed or precision bored |

| Positional Tolerance | ±0.020 mm | ±0.010 mm | As per GD&T callouts |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achieved via fine finishing passes |

| Angular Tolerance | ±0.1° | ±0.05° | Verified with CMM and optical probes |

| Flatness | 0.03 mm per 100 mm | 0.01 mm per 100 mm | Controlled with stress-relieved materials |

By combining advanced 5-axis CNC machining with rigorous CMM-based quality control, Wuxi Lead Precision Machinery provides a technically robust solution for manufacturers seeking high-precision metal components without the overhead typically associated with premium-grade tooling. Our capabilities are optimized to support cost-efficient injection mold production, ensuring performance, durability, and repeatability in demanding production environments.

Material & Finish Options

Material Selection for Cost-Optimized Metal Components

Selecting the right material is critical for balancing performance, longevity, and cost in metal manufacturing. While “inexpensive injection molding” typically references plastic processes, Wuxi Lead Precision Machinery specializes in custom metal solutions where material choice directly impacts tooling life, part complexity, and secondary operations. For metal components requiring high-volume production—such as via die casting or metal injection molding (MIM)—aluminum, steel, and titanium present distinct trade-offs. Aluminum alloys offer the lowest material and machining costs, making them ideal for lightweight structural parts like housings or brackets. Steel provides superior hardness and wear resistance for high-stress applications such as gears or tooling inserts, though it demands more robust tooling. Titanium excels in extreme environments (e.g., aerospace or medical) due to its strength-to-weight ratio and corrosion resistance but rarely aligns with cost-sensitive projects due to expensive raw material and加工 requirements.

The table below summarizes key properties to guide selection:

| Material | Typical Grades | Hardness (HB) | Corrosion Resistance | Relative Cost | Best For |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 95–150 | Moderate (anodized) | Low | Enclosures, brackets, heat sinks |

| Steel | 4140, 1045, 304 SS | 150–250 | Low (carbon) / High (SS) | Medium-High | Shafts, molds, high-wear parts |

| Titanium | Ti-6Al-4V | 300–360 | Excellent | Very High | Aerospace, medical implants |

Anodizing is a vital finish for aluminum components, enhancing surface durability and corrosion resistance without significantly increasing costs. This electrochemical process creates a porous oxide layer that can be dyed for identification or sealed for maximum protection. Type II (sulfuric acid) anodizing is standard for general use, while Type III (hard coat) suits high-wear applications. Crucially, anodizing is exclusively applicable to aluminum alloys; steel requires plating (e.g., zinc or chrome), and titanium uses specialized treatments like nitriding—both increasing project expenses.

At Wuxi Lead, our engineers prioritize material efficiency to minimize waste and machining time. For cost-driven projects, we recommend aluminum 6061-T6 with Type II anodizing as the optimal starting point. It delivers 80% of the performance of premium alloys at half the cost, with rapid machinability and seamless finish compatibility. Steel becomes viable only when hardness exceeds 200 HB is non-negotiable, while titanium should be reserved for regulatory or environmental mandates. Always factor in secondary operations early—our quoting team integrates material, finish, and tolerances to eliminate hidden costs. Partner with us to transform material constraints into competitive advantages.

Manufacturing Process & QC

Design: Engineering Precision from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of inexpensive injection molding begins with precision engineering in the design phase. We understand that cost efficiency is not achieved by cutting corners, but by optimizing design for manufacturability. Our engineering team collaborates closely with clients to analyze part geometry, material selection, and functional requirements. Utilizing advanced 3D CAD software and mold flow simulation tools, we identify potential stress points, warpage risks, and cooling inefficiencies before any metal is cut. This proactive approach ensures that the mold design supports both high repeatability and low cycle times, directly contributing to reduced per-unit costs. Every design is reviewed for draft angles, wall thickness uniformity, and gate placement to eliminate defects such as sink marks or short shots. The result is a robust, production-ready design that balances performance, cost, and durability.

Prototyping: Validating Performance with Zero Defects

Once the design is finalized, we move into the prototyping stage—where theoretical models meet physical reality. Wuxi Lead employs high-precision CNC machining and rapid tooling techniques to produce functional prototypes using the same alloys and tolerances intended for mass production. These prototypes undergo rigorous testing, including dimensional inspection via CMM (Coordinate Measuring Machine), material property verification, and fit/function assessment in real-world assemblies. Our zero-defect philosophy drives every test cycle. Any deviation—even within acceptable industry tolerances—is analyzed and corrected. This stage is critical for validating the mold’s performance under actual injection parameters such as pressure, temperature, and cooling rate. Feedback from prototyping is used to fine-tune the mold design, ensuring optimal filling, packing, and ejection behavior. Clients receive detailed reports and sample parts for approval, confirming that the process is fully validated before scaling.

Mass Production: Consistency Through Automation and Control

With design and prototyping complete, we transition to high-volume manufacturing with full automation and real-time process monitoring. Our production lines integrate robotic part handling, closed-loop temperature control, and in-mold sensors to maintain consistency across millions of cycles. Each mold is built from premium hardened steel or aluminum alloys, selected based on production volume and part complexity, ensuring longevity and minimal maintenance. Throughout production, statistical process control (SPC) systems continuously track key variables, enabling immediate correction of any drift. Every batch is subject to 100% visual inspection and random sampling for dimensional accuracy and mechanical performance. Our facility adheres to ISO 9001 standards, with full traceability from raw material to final shipment.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.005 mm – ±0.025 mm |

| Material Options | Aluminum 6061, 7075; Steel 420, H13; Stainless Steel 304, 316 |

| Mold Life | 100,000 – 1,000,000 cycles |

| Lead Time (Prototype) | 10–18 days |

| Lead Time (Production Tooling) | 25–40 days |

| Production Capacity | Up to 500,000 units/month |

| Quality Standard | ISO 9001:2015, PPAP, FAI Reporting |

This end-to-end process ensures that inexpensive injection molding does not compromise quality. At Wuxi Lead Precision Machinery, we deliver high-performance metal components at competitive costs—built right the first time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Engineered Value in Metal Injection Molding

The term “inexpensive injection molding” often misleads industrial buyers into prioritizing initial quotes over total cost of ownership. At Wuxi Lead Precision Machinery, we redefine affordability through precision engineering that eliminates hidden expenses—scrap rates, rework delays, and supply chain disruptions. Our custom metal manufacturing solutions deliver true cost efficiency by integrating advanced CNC machining with proprietary molding processes, ensuring every component meets aerospace and medical-grade tolerances without premium pricing.

Lead Precision’s competitive advantage stems from vertical integration. We control the entire production ecosystem: from raw material sourcing and in-house tooling design to high-speed molding and post-processing. This eliminates third-party markups while guaranteeing consistency. Unlike commodity molders, we specialize in complex metal alloys—stainless steel, titanium, and aluminum—using multi-cavity molds that reduce per-part costs by up to 40% for volumes of 10,000+ units. Our engineers optimize wall thickness, gate placement, and cooling channels during the design phase, preventing defects that inflate costs downstream.

Consider the tangible savings our clients achieve:

| Specification | Lead Precision Standard | Industry Average | Impact on Cost Efficiency |

|---|---|---|---|

| Tolerance Range | ±0.005 mm | ±0.025 mm | 70% fewer rejected parts |

| Material Waste | < 3% | 8–12% | 30% lower material spend |

| Lead Time (Tooling) | 15–20 days | 30–45 days | Accelerated time-to-market |

| Minimum Order Quantity | 500 units | 5,000 units | Reduced inventory risk |

| Surface Finish Options | Ra 0.2–1.6 μm standard | Ra 3.2 μm base | Eliminates secondary ops |

This precision-driven approach transforms “inexpensive” from a price point into a strategic outcome. When your project demands zero-defect reliability for hydraulic fittings, surgical instruments, or automotive sensors, our ISO 13485 and IATF 16949-certified facility ensures compliance without cost overruns. We invest in your success through DFM analysis at no upfront cost—identifying savings opportunities before tooling begins.

Stop compromising between quality and budget. Partner with an engineer-led manufacturer that treats your cost targets as our technical challenge. Contact our engineering team directly to audit your current molding workflow and receive a tailored cost-reduction roadmap.

Contact [email protected] today for a precision cost analysis. Let’s build value, not just parts.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.