Technical Contents

Engineering Guide: 3D Printing Service Company

Engineering Insight Precision in Metal Additive Manufacturing

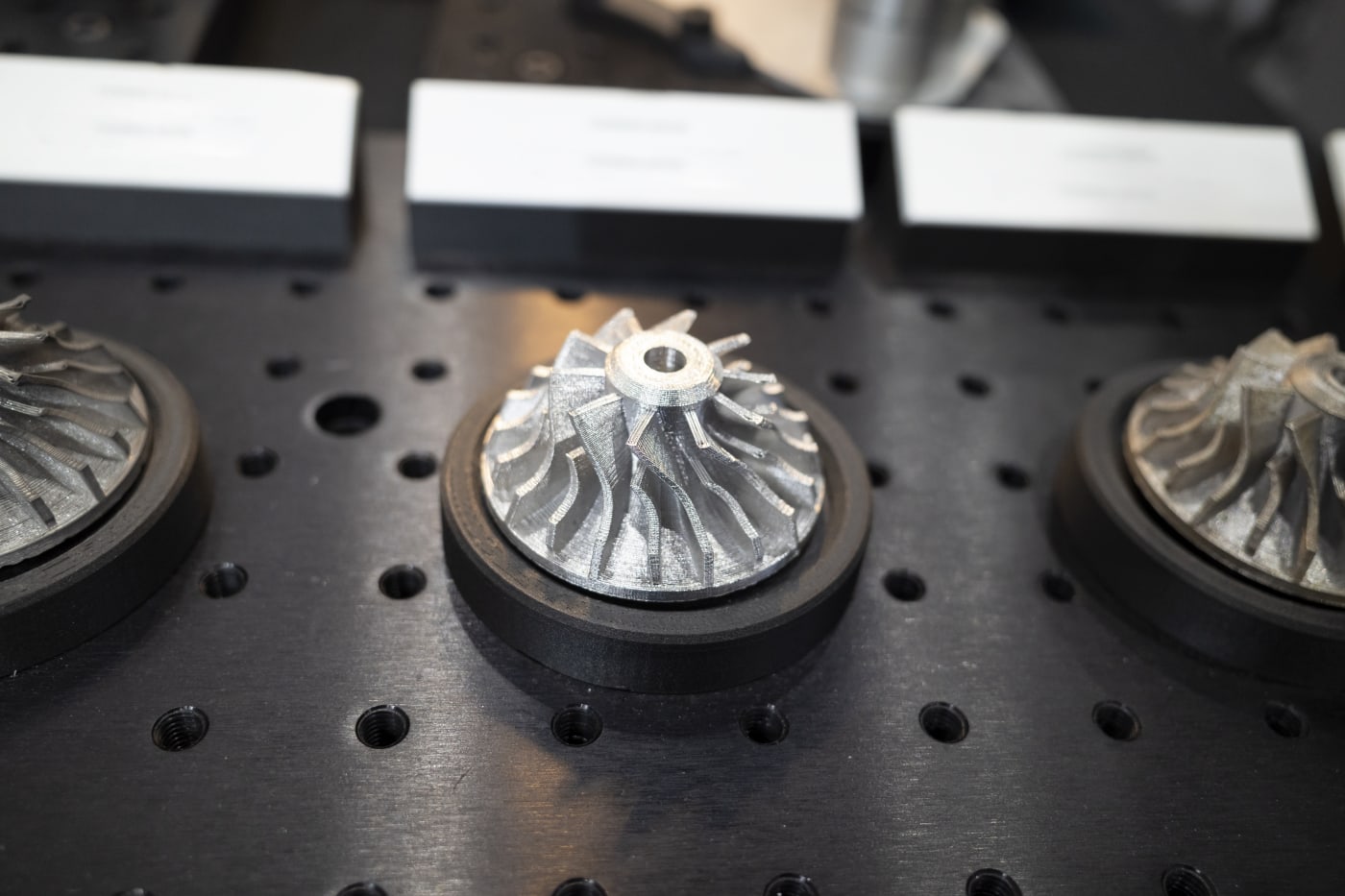

Precision defines the viability of metal additive manufacturing for mission-critical applications. While 3D printing enables unprecedented geometric freedom, its true industrial value emerges only when micron-level accuracy and material integrity are consistently achieved. Tolerances exceeding ±0.05mm or surface finishes unsuitable for fatigue-critical environments render even the most complex part functionally obsolete. This demands more than printer capability; it requires deep metallurgical understanding, rigorous process validation, and closed-loop quality control at every stage – from powder characterization to post-processing. At Wuxi Lead Precision Machinery, we treat precision not as a specification sheet metric but as the foundational engineering principle governing our entire metal AM workflow.

Our commitment to uncompromising precision is forged through direct experience delivering components where failure is not an option. We engineered and produced critical titanium structural elements for the Beijing 2022 Winter Olympics timing and scoring systems, where sub-0.1mm dimensional stability under extreme cold was non-negotiable. Similarly, we manufacture certified components for defense-grade inertial navigation sensors, meeting stringent MIL-STD-810G vibration and thermal cycling requirements. These projects demanded mastery beyond standard AM protocols – including custom atmosphere control during printing, proprietary stress-relief annealing cycles, and multi-axis coordinate metrology integrated directly within the production sequence. This elite-tier experience translates directly to our commercial 3D printing service, ensuring your aerospace bracket, medical implant, or energy sector component achieves the exact performance parameters your application demands.

Achieving this level of reliability requires systematic control over key process parameters. Our integrated approach ensures consistency across all critical dimensions:

| Parameter | Standard Capability | Critical Application Example |

|---|---|---|

| Layer Thickness | 20µm – 60µm | Thin-walled cooling channels (Aerospace) |

| Dimensional Tolerance | ±0.05mm standard | Hydraulic manifolds (Oil & Gas) |

| Surface Roughness (As Built) | Ra 8µm – 12µm | Implant porous structures (Medical) |

| Surface Roughness (Post-Processed) | Ra 0.8µm – 1.6µm | Sealing surfaces (Semiconductor) |

| Material Density | >99.95% (Vacuum Melted) | Cryogenic valve bodies (Energy) |

Partnering with a service provider possessing proven high-stakes manufacturing pedigree mitigates your project risk significantly. We do not merely operate printers; we engineer validated processes backed by ISO 9001 and AS9100 certified quality systems. When your design requires metal additive manufacturing that performs under real-world stress, specify a partner whose precision has been tested on the world’s most demanding stages. Contact Wuxi Lead Precision Machinery to discuss how our Olympic and defense-proven engineering rigor ensures your 3D printed metal components meet exacting functional requirements, every time. Precision isn’t optional – it’s the baseline.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to high-performance industries including aerospace, medical, energy, and precision automation. At the core of our technical capabilities is our state-of-the-art 5-axis CNC machining platform, enabling the production of highly complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis machining centers allow simultaneous movement across all five axes, minimizing setup cycles and eliminating the need for multiple fixtures. This results in tighter tolerances, improved part consistency, and reduced lead times—critical advantages for mission-critical components.

Our machining fleet consists of high-rigidity CNC centers equipped with automatic tool changers, high-precision spindles, and real-time tool monitoring systems. These machines support a wide range of engineering-grade metals, including titanium alloys, Inconel, stainless steel, aluminum alloys, and tool steels. The integration of advanced CAM software ensures optimal toolpaths, minimizing material waste and maximizing efficiency without compromising dimensional integrity. Whether producing low-volume prototypes or high-volume production runs, our 5-axis capability ensures repeatability and precision across every batch.

Quality assurance is embedded into every stage of the manufacturing process. All critical dimensions are verified using state-of-the-art Coordinate Measuring Machines (CMM) with multi-sensor probing systems. These CMMs provide micron-level inspection accuracy and generate full GD&T (Geometric Dimensioning and Tolerancing) reports traceable to international standards. Our quality lab operates under ISO 17025 guidelines, ensuring compliance with aerospace and medical industry requirements. In addition to CMM inspection, we perform in-process checks, first-article inspections, and final quality audits to guarantee that every component meets or exceeds customer specifications.

Below is a summary of our standard machining tolerances and capabilities, achievable under controlled environmental conditions and verified through rigorous inspection protocols.

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Depending on part size and geometry |

| Hole Diameter | ±0.01 mm | ±0.005 mm | Reamed and precision bored features |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Verified via CMM |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | Achieved with fine finishing passes |

| Angular Accuracy | ±0.05° | ±0.02° | Full 5-axis simultaneous machining |

| GD&T Compliance | Yes | Full reporting | Including flatness, concentricity, runout |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom setups available | For larger components |

| Material Compatibility | Wide range of metals | Including titanium, Inconel, stainless steel, aluminum | Customer-supplied or sourced |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with rigorous quality control to deliver custom metal components that meet the most demanding engineering requirements. Our technical capabilities are backed by decades of precision manufacturing experience and a commitment to continuous improvement in process and performance.

Material & Finish Options

Material Selection for High-Performance Metal Additive Manufacturing

Selecting the optimal material is critical for achieving functional performance, cost efficiency, and longevity in metal additive manufacturing. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical, thermal, and environmental demands. Below, we detail key alloys and surface treatments to inform strategic decisions for aerospace, medical, and industrial components.

Aluminum alloys, particularly AlSi10Mg, dominate lightweight structural applications requiring high thermal conductivity and moderate strength. This material excels in heat exchangers, drone frames, and automotive brackets due to its 2.68 g/cm³ density and excellent castability in laser powder bed fusion. While offering good corrosion resistance, it is unsuitable for high-temperature or highly corrosive environments exceeding 200°C. Post-processing anodizing significantly enhances surface durability and wear resistance, making it ideal for consumer-facing or moving parts.

Stainless steel variants—316L and 17-4PH—deliver versatility for demanding industrial contexts. 316L provides superior corrosion resistance in marine or chemical settings, with strong weldability and biocompatibility for medical tools. Conversely, 17-4PH achieves exceptional strength (up to 1,300 MPa UTS) through heat treatment, serving hydraulic components and aerospace fittings requiring fatigue resistance. Both alloys maintain integrity in cryogenic to 400°C conditions but necessitate precision machining for tight tolerances post-print.

Titanium Ti6Al4V remains the benchmark for high-stress, weight-sensitive applications like aircraft brackets and orthopedic implants. Its 4.43 g/cm³ density, biocompatibility, and resistance to saltwater corrosion outperform steel in longevity per unit weight. However, titanium’s reactivity demands controlled build atmospheres and rigorous post-processing to eliminate porosity. Avoid anodizing for titanium; instead, consider chemical passivation or plasma electrolytic oxidation for surface enhancement.

Anodizing is exclusively recommended for aluminum parts, transforming the surface into a hard, non-conductive oxide layer. Type II (sulfuric acid) anodizing (12–25μm thickness) offers basic corrosion and aesthetic control, while Type III (hardcoat) anodizing (50–100μm) delivers extreme abrasion resistance for hydraulic pistons or rail components. Note that anodizing dimensional impact requires pre-finishing to net shape.

Material specifications are summarized below for rapid comparison:

| Material | Key Alloys | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | AlSi10Mg | 2.68 | 400–450 | Moderate | Heat exchangers, brackets |

| Stainless Steel | 316L, 17-4PH | 7.9–8.0 | 550–1300 | High (316L) / Medium | Medical tools, hydraulic parts |

| Titanium | Ti6Al4V | 4.43 | 900–950 | Excellent | Aerospace, implants |

Material choice directly impacts manufacturability, lead time, and total cost of ownership. Wuxi Lead Precision Machinery leverages ISO 9001-certified processes to validate material integrity through rigorous metallurgical testing. Partner with us early in design to optimize material selection for performance, regulatory compliance, and production scalability—ensuring your metal AM components exceed operational expectations.

Manufacturing Process & QC

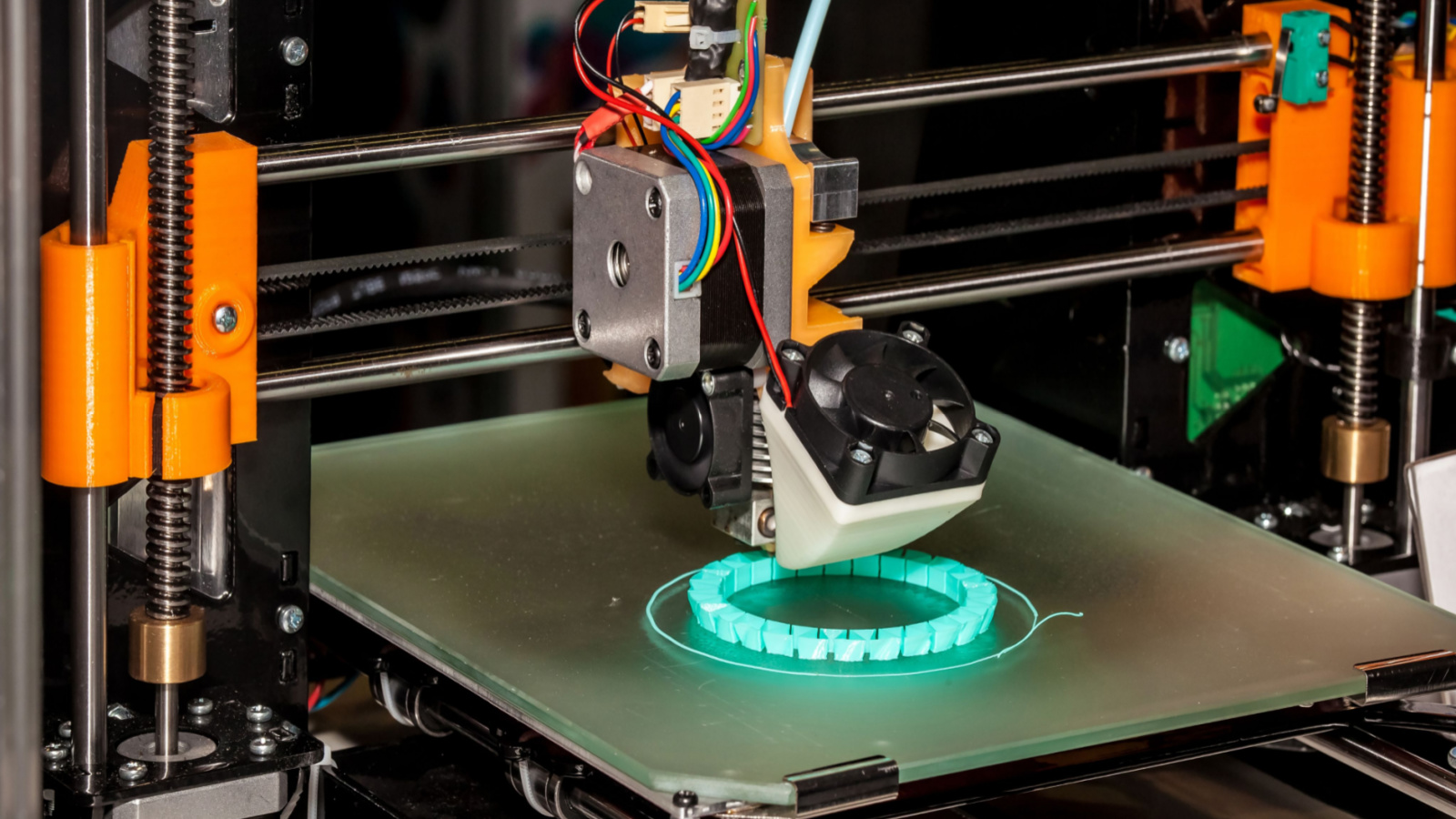

At Wuxi Lead Precision Machinery, our custom metal manufacturing process is engineered for precision, repeatability, and zero-defect delivery. We serve high-performance industries including aerospace, medical, automotive, and energy, where component integrity is non-negotiable. Our end-to-end workflow—spanning design validation, rapid prototyping, and full-scale production—is built on advanced 3D printing technologies and rigorous quality assurance protocols.

The process begins with design optimization. Our engineering team collaborates directly with clients to analyze CAD models, ensuring geometries are suitable for additive manufacturing. We assess factors such as material selection, thermal stress distribution, support structure requirements, and post-processing needs. Using simulation software, we predict potential deformations and correct them preemptively, reducing iterations and accelerating time to production.

Prototyping follows design approval. Utilizing metal laser powder bed fusion (LPBF), we produce functional prototypes in the actual production material—typically Inconel 718, titanium Ti-6Al-4V, stainless steel 316L, or aluminum AlSi10Mg. These prototypes undergo full metrology and mechanical testing to validate performance under operational conditions. This phase is critical for verifying fit, function, and durability, allowing for design refinements before committing to mass production.

Once the prototype is approved, we transition seamlessly into high-volume manufacturing. Our facility operates multiple industrial-grade metal 3D printers with consistent build parameters, ensuring uniformity across batches. Each build is monitored in real time using in-situ thermal imaging and layer inspection systems to detect anomalies. Post-build, components are stress-relieved, support-removed, and subjected to precision machining or surface treatments as required.

Quality is embedded at every stage. We implement a zero-defect framework through 100% first-article inspection, automated optical scanning, and destructive testing on sample lots. All materials are certified, and traceability is maintained from raw powder to final shipment. Our ISO 9001 and IATF 16949 certifications reflect our commitment to operational excellence.

This disciplined approach ensures that every component meets the tightest tolerances and highest performance standards. By integrating digital design, additive innovation, and metrology-driven validation, Wuxi Lead delivers custom metal parts with unmatched reliability and consistency.

Typical Material Specifications

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|---|

| Inconel 718 | 1250 | 1080 | 20 | 8.19 | Aerospace turbines, high-temp components |

| Ti-6Al-4V | 950 | 880 | 10 | 4.43 | Medical implants, aerospace structures |

| Stainless Steel 316L | 580 | 300 | 40 | 8.00 | Chemical processing, marine components |

| AlSi10Mg | 480 | 400 | 8 | 2.67 | Automotive lightweighting, heat exchangers |

From concept to mass production, Wuxi Lead Precision Machinery ensures every part is manufactured to the highest industrial standards—on time, to spec, and defect-free.

Why Choose Wuxi Lead Precision

Elevate Your Metal Additive Capabilities Through Strategic Partnership

As a 3D printing service provider, your success hinges on delivering end-use metal components that meet exacting performance and precision standards. While additive manufacturing unlocks complex geometries, achieving final part certification often demands advanced subtractive and finishing expertise beyond the printer build chamber. Wuxi Lead Precision Machinery bridges this critical gap, providing seamless post-processing and hybrid manufacturing solutions engineered for the rigorous demands of aerospace, medical, and energy sectors.

Our dedicated partnership model integrates directly into your production workflow, transforming printed near-net shapes into fully qualified components. We eliminate the supply chain fragmentation that delays time-to-market and compromises quality control. By leveraging our 15-year specialization in tight-tolerance metal machining, we ensure every part adheres to ASTM F2792 and ISO/ASTM 52900 standards while meeting your specific surface integrity, metallurgical, and dimensional requirements. This synergy allows you to confidently quote complex metal projects without internal capital investment in secondary operations.

The technical foundation of our partnership rests on certified capabilities proven across 12,000+ production runs. Our facility operates under ISO 9001:2015 and IATF 16949 frameworks, with full traceability from raw material to final inspection. The following specifications demonstrate our readiness to handle your most demanding post-print requirements:

| Capability | Specification Detail | Application Relevance |

|---|---|---|

| Material Processing | Titanium (Gr 5, Gr 23), Inconel 718, 17-4PH, 316L, Aluminum 7075 | Biocompatible & high-temp alloys for critical components |

| Dimensional Tolerance | ±0.005 mm on critical features | Ensures print-to-finish dimensional continuity |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm (as-machined) | Meets aerospace & medical sealing requirements |

| Lead Time | 7-12 days for qualified production runs | Accelerates your project delivery cycles |

Partnering with Lead Precision means accessing a single-source solution for stress relief, precision milling, wire EDM, micro-drilling, and non-destructive testing – all performed within our climate-controlled 10,000 m² facility. Our engineers collaborate with your team from the design-for-manufacturability stage, identifying potential post-processing challenges before printing begins. This proactive approach reduces scrap rates by up to 37% and ensures first-article approval on schedule.

When your clients require flight-certified turbine components or implant-grade orthopedic devices, our integrated quality management system provides full inspection documentation including CMM reports, metallurgical analysis, and first-article inspection per AS9102. We function as your trusted extension, not merely a vendor, maintaining real-time production visibility through secure client portals.

Advance your service offering beyond basic printing. Contact our engineering team today to discuss how Lead Precision can enhance your metal additive value chain. Submit your project specifications to [email protected] for a technical consultation and production feasibility assessment within 24 business hours. Let us handle the precision finishing – you focus on winning the next high-value contract.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.