Technical Contents

Engineering Guide: Moldeo Por Inyección

Engineering Insight: Precision in Injection Molding (Moldeo por Inyección)

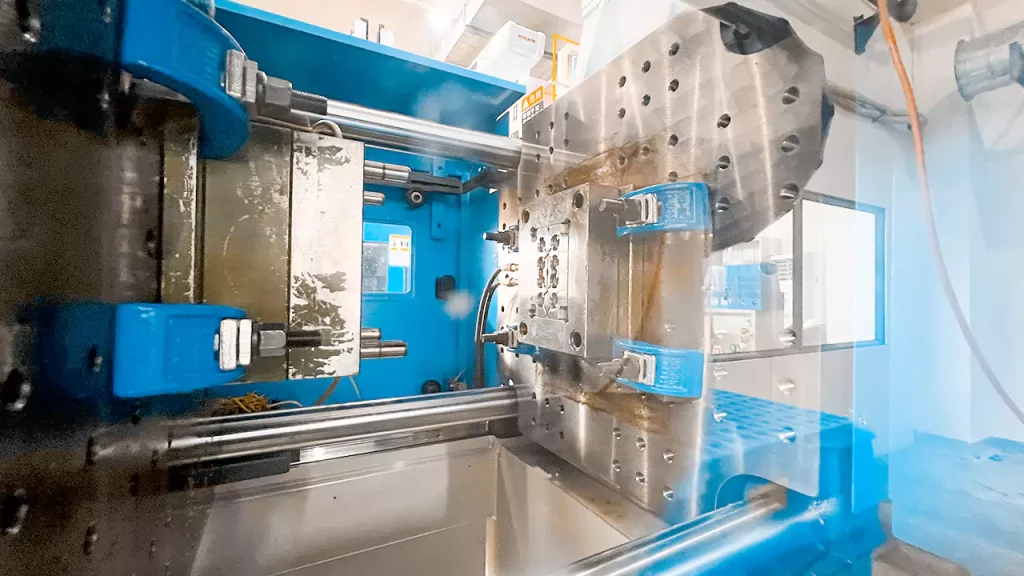

In high-stakes injection molding applications, precision transcends specification sheets; it defines functional integrity, assembly success, and end-product longevity. Micron-level deviations in cavity geometry, runner systems, or cooling channels directly impact material flow, part warpage, dimensional stability, and surface finish. For mission-critical components—particularly in aerospace, defense, and high-performance consumer goods—tolerances below 0.005mm are not optional but fundamental engineering requirements. Achieving this demands more than advanced machinery; it requires deep metallurgical understanding, rigorous process validation, and an uncompromising culture of dimensional control from raw billet to finished tool.

Wuxi Lead Precision Machinery operates at this exacting threshold. Our CNC engineering protocols integrate multi-axis machining centers with in-process metrology, ensuring mold bases, cavities, and cores achieve geometric accuracies consistently within ±0.002mm. This capability is forged through direct experience delivering components where failure is not an option. We engineered precision molds for structural elements within Beijing 2008 Olympic venue systems, subjected to extreme thermal cycling and load demands. Similarly, our military-grade tooling for defense contractors undergoes validation under shock, vibration, and environmental extremes far beyond standard industry testing. These projects demand zero-defect manufacturing, driving our investment in temperature-stabilized machining environments, real-time thermal compensation systems, and proprietary electrode design for micro-texturing.

Material behavior under high-pressure injection is equally critical. Our engineers model polymer flow dynamics specific to each client’s resin formulation, optimizing gate locations and cooling circuits to minimize internal stress and sink. This predictive capability, combined with sub-micron machine repeatability, ensures first-article conformity and eliminates costly trial-and-error cycles. The result is reduced scrap rates, accelerated time-to-market, and molds capable of sustaining 1,000,000+ cycles without degradation—proven across 12,000+ production runs.

Our core machine specifications validate this precision commitment:

| Parameter | Specification | Industry Impact |

|---|---|---|

| Positioning Accuracy | ±0.001mm | Eliminates flash, ensures seal integrity |

| Repeatability | ±0.0005mm | Guarantees part-to-part consistency |

| Thermal Stability | Δ≤0.5°C across workzone | Prevents dimensional drift during production |

| Surface Finish (Cavity) | Ra 0.025µm (optical) | Meets Class 1 medical/aerospace standards |

| Tool Life Validation | 1,200,000+ cycles | Reduces client downtime and TCO |

Precision injection molding is an engineering discipline, not merely a production step. At Wuxi Lead, our Olympic and military heritage instills the discipline to transform complex geometries into reliable, high-yield manufacturing solutions. We partner with clients to convert stringent tolerances into competitive advantage—because in critical applications, there is no margin for approximation. Contact our engineering team to discuss your most demanding molding challenges.

Precision Specs & Tolerances

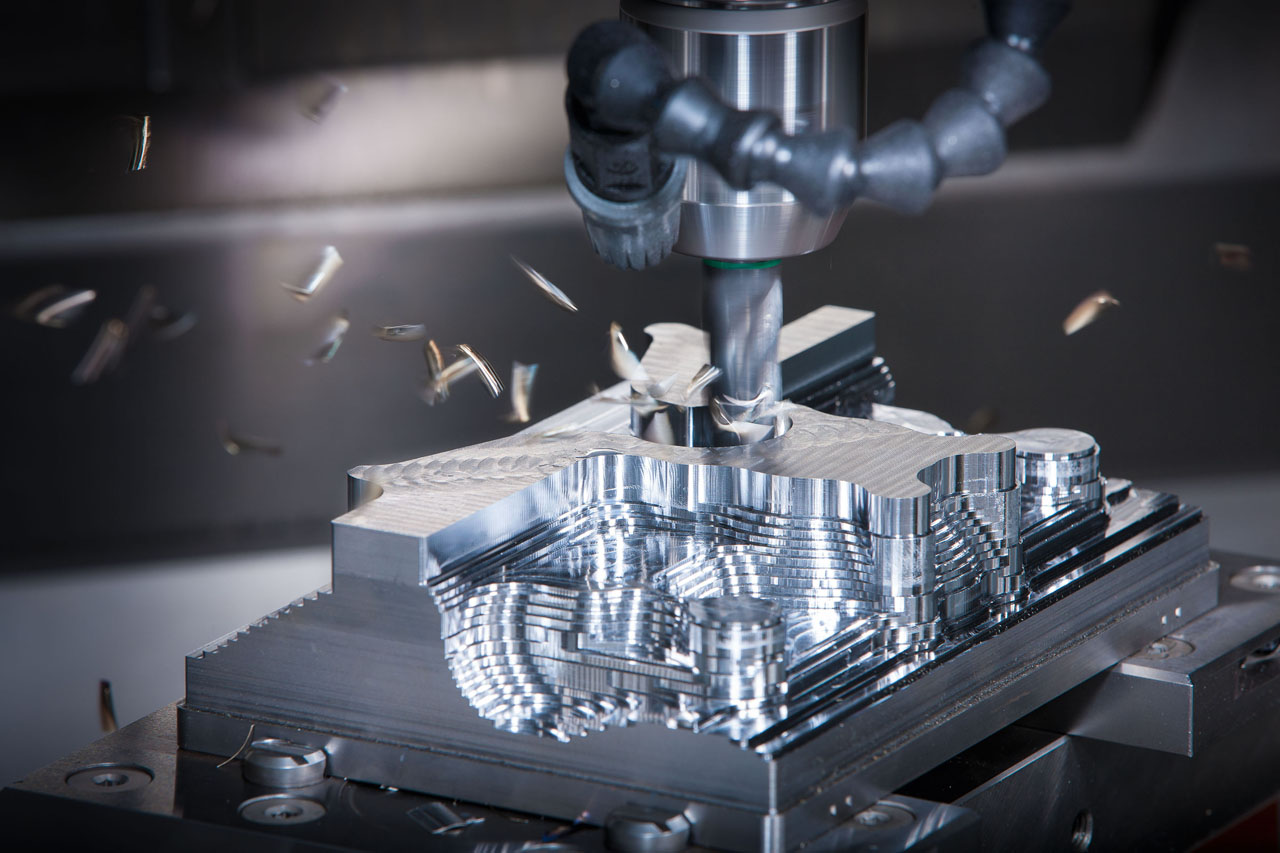

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, serving high-performance industries such as aerospace, medical, automotive, and industrial automation. At the core of our precision engineering is a fully integrated 5-axis CNC machining platform, enabling the production of complex, high-accuracy components from a single setup. This multi-axis technology allows for superior geometric control, reduced cycle times, and minimized human intervention, ensuring repeatability and consistency across production runs.

Our 5-axis CNC systems are equipped with high-speed spindles, automated tool changers, and real-time monitoring software, supporting the machining of a wide range of metals including aluminum alloys, stainless steel, titanium, and specialty alloys. The ability to approach parts from multiple angles in a single operation eliminates the need for multiple fixtures and setups, significantly reducing cumulative error and enhancing surface finish quality. This capability is particularly critical for components requiring intricate contours, deep cavities, or asymmetrical features commonly found in injection molding tooling and high-precision structural parts.

Quality assurance is embedded throughout our manufacturing process. Every component undergoes rigorous inspection using a state-of-the-art Coordinate Measuring Machine (CMM), ensuring dimensional accuracy and compliance with design specifications. The CMM system operates with sub-micron resolution, enabling full 3D verification of critical features such as hole locations, profile tolerances, flatness, and positional alignment. Inspection reports are generated in alignment with ISO 9001 standards and can be customized to meet customer-specific documentation requirements.

We maintain strict environmental controls in our metrology lab to eliminate thermal drift, ensuring measurement stability. In addition to post-machining CMM validation, in-process inspections are conducted using precision handheld gauges and optical comparators, allowing for immediate correction and continuous process improvement. Our quality management system supports full traceability, with material certifications, process logs, and inspection data archived for every production batch.

The following table outlines our standard machining tolerances, reflecting the precision achievable under controlled conditions. Tighter tolerances can be achieved upon request, depending on part geometry, material, and customer requirements.

| Feature | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Hole Diameter | +0.025 / -0.000 mm | +0.010 / -0.000 mm |

| Positional Tolerance | ±0.02 mm | ±0.005 mm |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Angular Tolerance | ±0.05° | ±0.01° |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with disciplined quality control to deliver custom metal components that meet the most demanding engineering specifications. Our technical capabilities are designed to support prototyping, bridge production, and full-scale manufacturing with uncompromising precision.

Material & Finish Options

Material Selection for High-Performance Injection Molds: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material for injection molds is paramount to achieving production efficiency, part quality, and long-term cost-effectiveness. At Wuxi Lead Precision Machinery, our engineering team emphasizes that material choice directly impacts mold longevity, thermal management, and suitability for specific polymers and production volumes. This decision requires a precise understanding of the synergistic relationship between material properties and your production demands.

Aluminum alloys, particularly 7075-T6, offer significant advantages for prototyping and low-to-medium volume production. Its superior thermal conductivity accelerates cooling cycles, reducing part cycle times substantially compared to steel. Aluminum is also easier and faster to machine, lowering initial tooling costs and lead times. However, its lower hardness and wear resistance make it less suitable for abrasive filled plastics or very high-volume runs exceeding 100,000 shots. Aluminum molds excel where rapid iteration and faster time-to-market are critical.

Hardened tool steels, such as H13 and S136, represent the industry standard for high-volume, production-critical applications. These steels provide exceptional hardness, wear resistance, and dimensional stability under prolonged thermal cycling. H13 offers excellent toughness for cores and cavities, while corrosion-resistant grades like S136 are essential for molding PVC or other corrosive materials. Steel molds deliver the longest service life, often exceeding 500,000 to 1,000,000+ shots, justifying their higher initial investment through reduced downtime and maintenance costs over the mold’s lifecycle. They are the foundation for demanding, high-precision manufacturing.

Titanium alloys, primarily Ti-6Al-4V, present a specialized solution for extreme conditions. Their exceptional strength-to-weight ratio, outstanding corrosion resistance, and biocompatibility make them ideal for molding highly corrosive materials or in medical applications requiring absolute material purity. While significantly more expensive and challenging to machine than steel, titanium’s unparalleled resistance to chemical attack and thermal stability in aggressive environments provides a unique value proposition where conventional materials fail. Its use is typically reserved for niche, high-value applications.

Anodizing is a critical surface treatment specifically for aluminum molds. This electrochemical process creates a hard, wear-resistant oxide layer on the aluminum surface, significantly enhancing its durability against abrasion and galling during ejection. Type III (Hard Anodize) is standard for mold components, providing a dense, thick coating (typically 25-50 µm) that improves release properties and extends the functional life of aluminum tooling in moderate production scenarios. It is not applicable to steel or titanium molds, which rely on their inherent hardness or alternative coatings like PVD.

The following table summarizes key comparative properties for common mold materials:

| Material | Typical Hardness | Corrosion Resistance | Best Application Volume Range |

|---|---|---|---|

| Aluminum 7075-T6 | 150 HB | Low | Prototypes, < 100,000 shots |

| H13 Tool Steel | 48-52 HRC | Moderate | Medium to High Volume |

| S136 Stainless | 50-54 HRC | High | High Volume, Corrosive Resins |

| Titanium Ti-6Al-4V | 36 HRC | Exceptional | Specialized, Extreme Environments |

Material selection is not merely a technical specification; it is a strategic investment. Partnering with Wuxi Lead ensures your mold material and finish are precisely engineered to maximize lifecycle value, minimize total cost of ownership, and consistently deliver the precision your injection molding process demands. Our expertise guides you to the optimal solution for your specific polymer, part geometry, and production requirements.

Manufacturing Process & QC

Design: Precision Engineering at the Core

The foundation of flawless injection molding begins with intelligent, data-driven design. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to transform conceptual requirements into manufacturable, high-performance metal components. Utilizing advanced 3D CAD and finite element analysis (FEA) software, we simulate material flow, thermal distribution, and structural integrity under operational loads. This virtual prototyping ensures optimal gate placement, cooling channel design, and mold geometry—critical factors in eliminating defects such as warpage, sink marks, or incomplete fills. Every design is validated against strict dimensional tolerances and functional performance criteria before progressing, ensuring alignment with both application demands and production scalability.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move to rapid prototyping using high-precision CNC-machined mold inserts and short-run molding trials. This phase is not a mere form check—it is a comprehensive validation of the entire process chain. Prototypes are subjected to rigorous metrology, including CMM (Coordinate Measuring Machine) inspection, surface roughness analysis, and mechanical testing. We analyze fill patterns, cycle consistency, and part repeatability under real production conditions. Any deviations are traced back to root causes—be it material viscosity, ejection dynamics, or thermal gradients—and corrected in the mold or process parameters. This iterative approach ensures that the transition to mass production is seamless, with zero surprises.

Mass Production: Sustained Excellence Through Control

With a fully validated process, we initiate high-volume manufacturing under a Zero Defects framework. Our automated molding cells integrate real-time monitoring systems that track pressure, temperature, injection speed, and clamp force for every cycle. Any parameter drift outside the established control limits triggers immediate alerts, enabling proactive correction. Each component undergoes 100% in-line dimensional verification via vision systems and selective destructive testing in our on-site lab to ensure long-term consistency. We employ Six Sigma methodologies and SPC (Statistical Process Control) charts to continuously refine performance and eliminate variation.

All production stages are supported by full traceability—each mold, batch, and inspection report is digitally logged for audit and quality assurance. This closed-loop system ensures that every part shipped meets the exact specifications agreed upon during design.

Below are key process specifications maintained throughout production:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.02 mm (depending on part size) |

| Surface Roughness (Ra) | 0.1 µm to 1.6 µm (customizable) |

| Material Options | Stainless Steel (316L, 17-4PH), Titanium, Tool Steels, Hard Alloys |

| Mold Life | 500,000 to 1,000,000 cycles |

| Cycle Time Control | ±0.5 seconds repeatability |

| Defect Rate (PPM) | < 50 parts per million |

| Quality Standards | ISO 9001, IATF 16949, Full FAI Reports |

From design through mass production, Wuxi Lead Precision Machinery delivers injection-molded metal components with uncompromising quality, engineered for mission-critical applications across aerospace, medical, and high-performance industrial sectors.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Injection Molding Excellence

In the demanding landscape of high-precision metal component manufacturing, selecting a partner capable of transforming complex designs into flawless production realities is non-negotiable. Wuxi Lead Precision Machinery stands as your definitive solution for metal injection molding (MIM), where advanced engineering converges with rigorous quality control to deliver components that exceed aerospace, medical, and automotive industry benchmarks. We recognize that your success hinges on dimensional accuracy, material integrity, and on-time delivery—elements we engineer into every project from initial concept through final inspection. Our integrated facility in Wuxi, China, leverages 15+ years of specialized MIM expertise, eliminating the communication gaps and quality inconsistencies inherent in fragmented supply chains.

What distinguishes Lead Precision is our proprietary approach to process optimization. Unlike conventional MIM providers, we deploy in-house CNC-machined tooling with sub-5-micron tolerances, coupled with real-time sintering analytics that ensure material homogeneity and mechanical consistency. This precision-driven methodology reduces scrap rates by up to 40% while enabling geometries previously deemed unmanufacturable—thin walls under 0.5mm, micro-features, and multi-material assemblies. Our ISO 13485 and IATF 16949 certified systems guarantee traceability from raw material batch to finished part, with full 3D metrology reports provided for every production run. For global clients, this translates to accelerated time-to-market without compromising regulatory compliance.

The strategic advantage of partnering with us extends beyond technical capability. By operating within China’s most advanced manufacturing ecosystem, we deliver significant cost efficiency without sacrificing quality. Our vertical integration—spanning feedstock formulation, molding, debinding, sintering, and secondary CNC finishing—eliminates third-party dependencies, ensuring seamless scalability from prototypes to million-part volumes. This control over the entire value chain allows us to offer NRE reductions of 25–30% compared to Western competitors, while maintaining lead times 20% shorter through optimized logistics.

Critical Metal Injection Molding Specifications at Lead Precision

| Parameter | Capability Range | Standard Tolerance | Material Options |

|---|---|---|---|

| Part Weight | 0.1g – 250g | ±0.3% | 17-4PH, 316L, 420F, Ti-6Al-4V, Custom Alloys |

| Dimensional Accuracy | Up to 150mm | ±0.005mm | |

| Wall Thickness | 0.3mm – 15mm | ±5% | |

| Surface Roughness (Ra) | As-molded | 0.8–1.6μm | |

| Secondary Operations | CNC milling, laser welding, plating | ±0.002mm |

Your next breakthrough component demands a partner who views precision as a science, not an aspiration. At Wuxi Lead Precision Machinery, we commit to becoming an extension of your engineering team—proactively solving challenges before they impact your production schedule. Contact us today to discuss how our MIM solutions can resolve your most stringent design requirements while optimizing total project economics.

Initiate your precision manufacturing partnership by emailing [email protected]. Our engineering team will respond within 4 business hours with a tailored capability assessment and timeline for your specific application. Trust Lead Precision to deliver metal injection molding where excellence is measured in microns, not compromises.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.