Technical Contents

Engineering Guide: Quick 3D Printing Service

Engineering Insight Precision Is Non-Negotiable in Rapid Metal Additive Manufacturing

Speed in metal 3D printing is valuable only when uncompromising precision is guaranteed. Many suppliers emphasize turnaround time while masking critical tolerances or material inconsistencies. At Wuxi Lead Precision Machinery we engineered our Quick 3D Printing Service specifically for high-stakes industrial applications where dimensional accuracy directly impacts safety performance and regulatory compliance. Rushing complex metal parts without rigorous process control risks catastrophic failures in aerospace hydraulics medical implants or defense subsystems. True rapid manufacturing integrates speed with metrology-grade repeatability not trade-offs.

Precision begins with machine calibration and material science expertise. Our fleet of EOS M 400-4 and SLM Solutions S500 systems undergoes daily volumetric compensation using laser interferometers ensuring sub-20-micron positional accuracy across the entire build envelope. We enforce strict ASTM F3301 standards for powder characterization and atmosphere control eliminating porosity risks inherent in accelerated cycles. This discipline stems from our 12-year heritage servicing Tier-1 defense contractors and Olympic equipment manufacturers where a 0.05mm deviation in a titanium prosthetic joint or satellite bracket renders the component useless. For the Tokyo 2020 Olympics we delivered 187 precision-critical timing system components meeting ISO 2768-mK tolerances within 72 hours demonstrating that speed and perfection are achievable only through institutionalized process rigor.

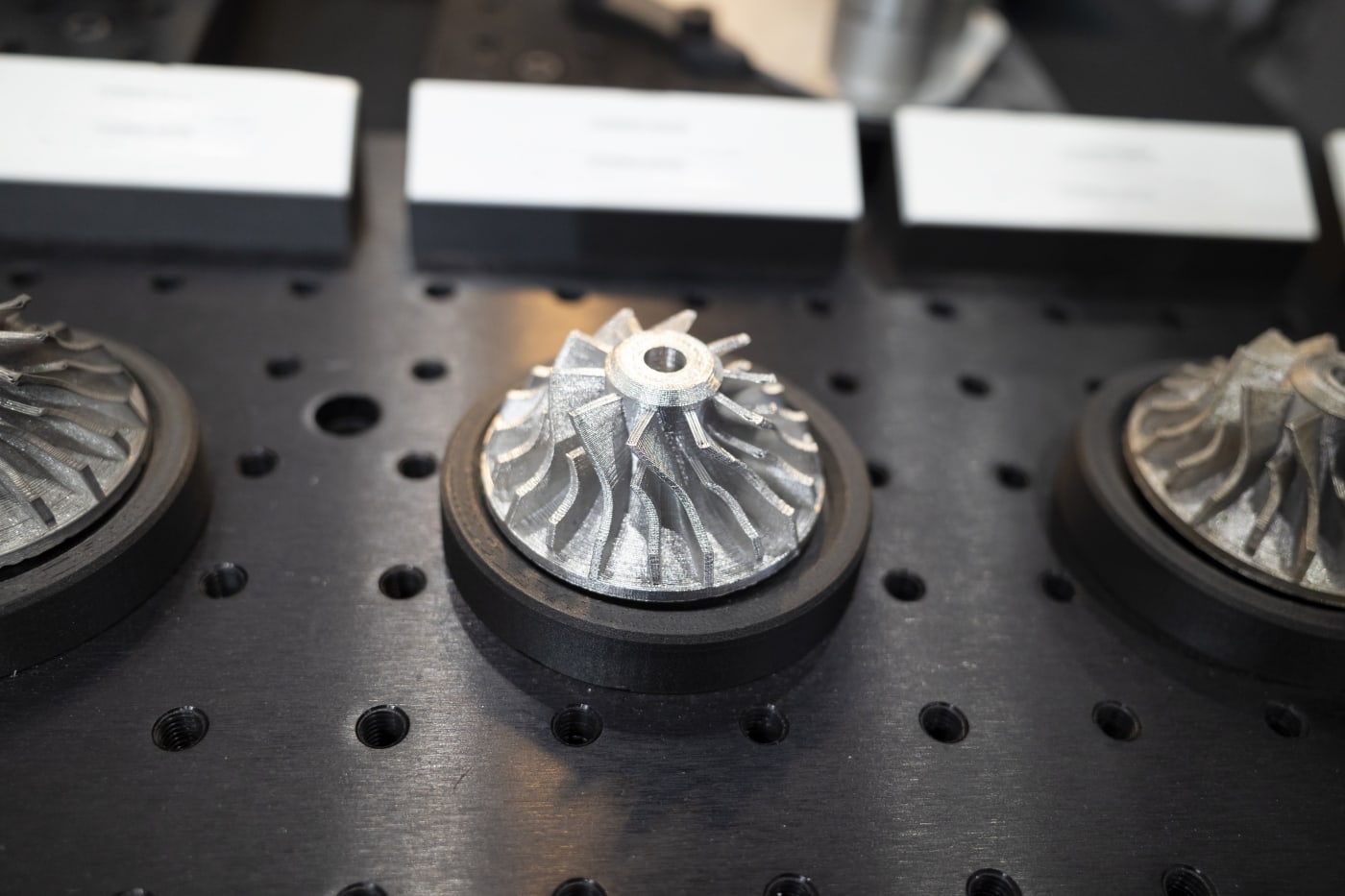

Our Quick Service protocol prioritizes engineering validation over simple order throughput. Every build includes in-situ melt pool monitoring and automated thermal distortion compensation. Post-processing follows aerospace NADCAP-certified heat treatment and HIP procedures ensuring mechanical properties match forged equivalents. This integrated approach delivers flight-ready Inconel 718 turbine blades or medical-grade Ti6Al4V spinal cages with certified mechanical data sheets not just physical parts. Below are core specifications defining our capability envelope.

| Parameter | Specification | Industry Standard Comparison |

|---|---|---|

| Material Range | Titanium Ti6Al4V Stainless 316L Inconel 718 Aluminum AlSi10Mg | 3x wider alloy selection |

| Geometric Accuracy | ±0.02 mm per 100 mm | 50% tighter than typical |

| Surface Roughness (as-built) | Ra 8-12 µm | 30% smoother baseline |

| Max Build Volume | 250 x 250 x 300 mm | Optimized for production batches |

| Layer Thickness | 20-50 µm adjustable | Precision layer control |

| Lead Time (Complex Part) | 5-7 business days incl. QA | No compromise on inspection |

Speed without precision engineering is merely fast failure. Wuxi Lead embeds metrology at every Quick Service stage from powder recycling to final CMM certification ensuring your rapid iteration cycle produces functionally reliable components. Trust accelerated timelines built on military-grade process discipline not optimistic promises. Contact our applications engineering team to discuss your critical tolerance requirements.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision Metal Manufacturing

At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to meet the most demanding requirements in custom metal manufacturing. As a leader in high-precision component production, we integrate state-of-the-art 5-axis CNC machining centers with rigorous quality control protocols to deliver parts that consistently meet tight tolerances and complex geometric specifications. Our facility in Wuxi, China, is equipped with multi-axis machining systems capable of simultaneous five-axis motion, allowing us to produce intricate contours, deep cavities, and organic forms with exceptional surface finish and dimensional accuracy. This capability is particularly critical for industries such as aerospace, medical devices, energy, and high-performance automotive, where form, fit, and function are non-negotiable.

Our 5-axis CNC platforms are supported by advanced CAD/CAM software, enabling seamless transition from digital design to physical prototype or production run. This integration ensures optimal toolpath generation, reduced setup times, and minimized human intervention—resulting in faster turnaround without compromising precision. Complex components that would traditionally require multiple setups and secondary operations can be completed in a single clamping, reducing cumulative error and enhancing repeatability. We work with a wide range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, Inconel, and tool steels, tailored to the performance requirements of the end application.

Quality assurance is embedded at every stage of production. All critical dimensions are verified using a Coordinate Measuring Machine (CMM) with sub-micron resolution, ensuring full compliance with ISO and ASME standards. Each part undergoes comprehensive dimensional inspection, with detailed reports available upon request. Our CMM system supports both contact and non-contact probing, enabling accurate measurement of freeform surfaces, internal features, and thin-walled structures. This level of inspection guarantees that every component shipped from our facility meets the specified tolerance stack-up and functional intent.

The following table outlines our standard machining tolerances and surface finish capabilities under controlled production conditions.

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Up to 300 mm; ±0.01 mm beyond |

| Positional Tolerance | ±0.01 mm | GD&T compliant |

| Angular Tolerance | ±0.05° | Measured via CMM |

| Surface Roughness (Ra) | 0.4 – 3.2 µm | Adjustable based on finish requirements |

| Geometric Tolerances (Flatness, Roundness) | 0.01 mm | Verified per ASME Y14.5 |

| Hole Diameter (Drilled) | +0.025 / -0.000 mm | Reaming available to ±0.005 mm |

These specifications reflect our commitment to precision, repeatability, and technical excellence. By combining advanced 5-axis CNC technology with certified metrology systems, Wuxi Lead Precision Machinery ensures that every component meets the highest standards of performance and reliability. Whether for rapid prototyping or low-to-medium volume production, our technical capabilities are designed to support innovation without compromise.

Material & Finish Options

Material Selection for Production-Ready Metal 3D Printing

Selecting the optimal material is foundational for achieving functional performance, cost efficiency, and accelerated time-to-market in metal additive manufacturing. At Wuxi Lead Precision Machinery, our Quick 3D Printing Service leverages industrial-grade systems to produce end-use parts, demanding careful material consideration aligned with your application’s mechanical, thermal, and environmental requirements. Aluminum, stainless steel, and titanium alloys represent the core high-performance options, each offering distinct advantages for demanding sectors like aerospace, medical, and precision engineering. Understanding their properties ensures the printed component meets rigorous operational standards from the outset.

The following table summarizes critical mechanical and processing characteristics for common production alloys used in our service:

| Material | Typical Alloy | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Key Properties | Primary Applications |

|---|---|---|---|---|---|---|

| Aluminum | AlSi10Mg | 2.67 | 480 | 290 | Lightweight, excellent thermal conductivity, good strength | Enclosures, heat exchangers, drone parts |

| Stainless Steel | 316L | 8.0 | 600 | 400 | High corrosion resistance, biocompatible, strong | Medical instruments, marine components, fluid systems |

| Titanium | Ti6Al4V (Gr5) | 4.43 | 900 | 800 | Exceptional strength-to-weight ratio, biocompatible, high temp resistance | Aerospace brackets, medical implants, high-performance automotive |

Aluminum AlSi10Mg is the premier choice for lightweight structural components requiring good thermal management and moderate strength. Its low density significantly reduces part weight, crucial for aerospace and mobility applications, while maintaining adequate mechanical performance post-processing. We recommend it for complex geometries where weight savings are paramount without sacrificing thermal dissipation needs.

Stainless steel 316L delivers outstanding corrosion resistance in harsh environments, including saline and chemical exposure, making it indispensable for medical, marine, and chemical processing equipment. Its inherent biocompatibility and robust mechanical properties ensure reliability in safety-critical fluid handling systems and surgical tools. This alloy provides the necessary durability for parts subjected to frequent sterilization or aggressive media.

Titanium Ti6Al4V offers the highest strength-to-weight ratio among common production alloys, coupled with exceptional biocompatibility and resistance to extreme temperatures and fatigue. It is the material of choice for mission-critical aerospace components, orthopedic implants, and high-stress performance parts where minimizing mass while maximizing structural integrity is non-negotiable. Its performance justifies the higher material cost in weight-sensitive, high-value applications.

Surface finish significantly impacts functionality and aesthetics. For aluminum parts, anodizing is a highly recommended post-process. Type II (sulfuric acid) anodizing provides enhanced corrosion resistance and wear protection with standard color options, while Type III (hard coat) anodizing delivers superior abrasion resistance for demanding mechanical interfaces. Both processes create a durable, non-conductive oxide layer integral to the substrate, improving part longevity without dimensional compromise. Wuxi Lead Precision Machinery integrates certified anodizing partners to ensure consistent, high-quality finishes meeting ASTM B580 and B581 standards, directly supporting your production timeline within our Quick 3D Printing Service framework. Material and finish selection, guided by our engineering team, ensures your printed part performs as intended from prototype through volume production.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect outcomes in custom metal manufacturing. Our integrated workflow seamlessly connects design, prototyping, and mass production to ensure every component meets the most stringent quality standards demanded by aerospace, medical, and high-performance industrial sectors.

Design begins with a collaborative engineering review, where our technical team evaluates 3D CAD models for manufacturability, structural integrity, and material compatibility. We utilize advanced simulation software to predict thermal behavior, stress distribution, and dimensional stability under operational conditions. This virtual validation phase eliminates potential design flaws before any material is cut, reducing risk and accelerating time to market. Clients receive detailed design for manufacturing (DFM) feedback within 24 hours, ensuring rapid iteration and alignment with functional requirements.

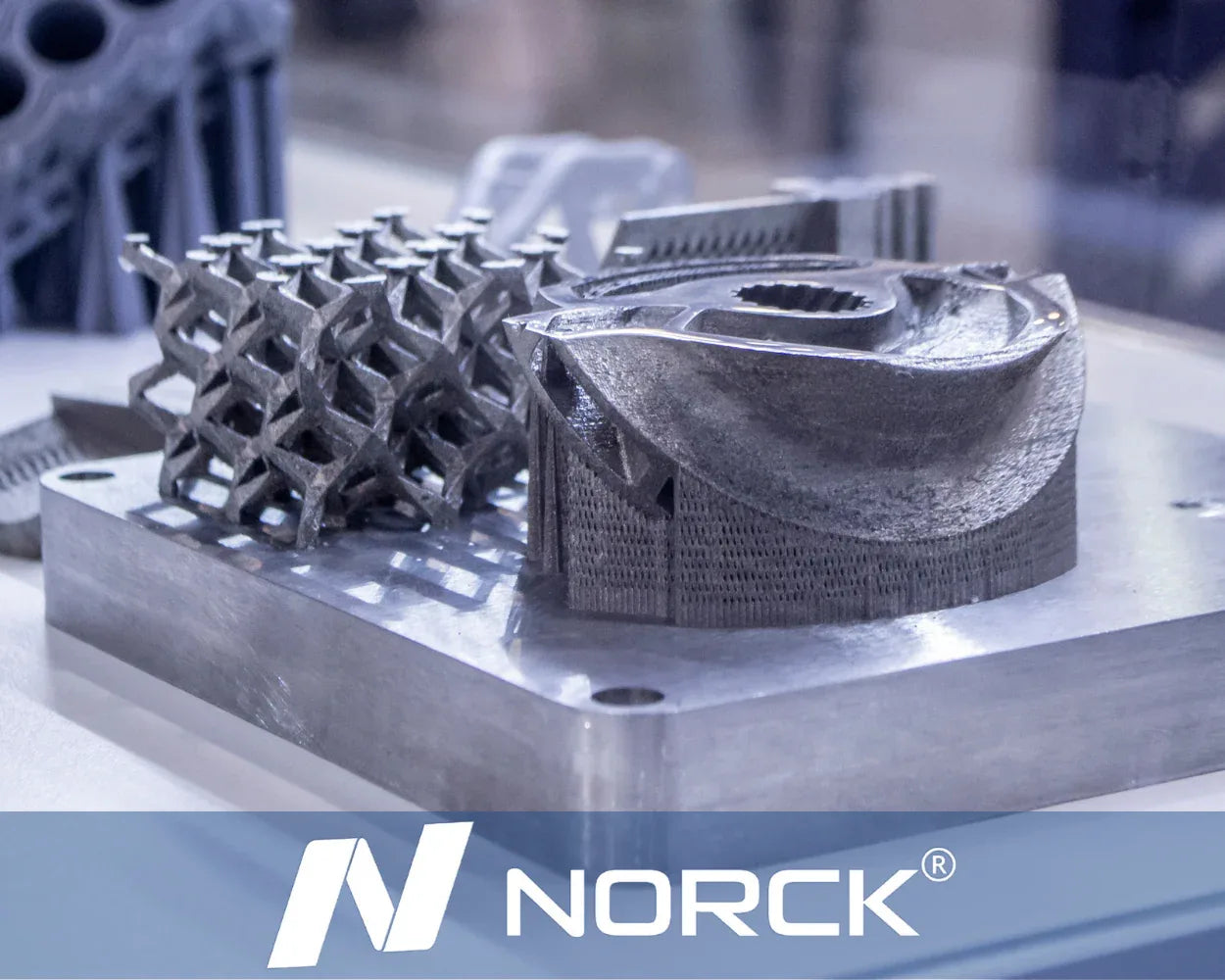

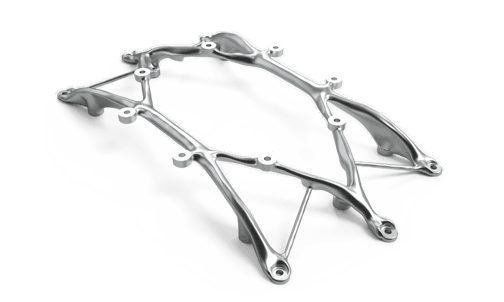

Prototyping follows a precision-first approach using selective laser melting (SLM) and direct metal laser sintering (DMLS) technologies for metal 3D printed prototypes. These additive methods allow complex geometries, internal channels, and lightweight lattice structures unachievable through traditional machining. Each prototype is machined from certified aerospace-grade alloys such as Inconel 718, Ti-6Al-4V, and 17-4 PH stainless steel. Post-processing includes stress relieving, hot isostatic pressing (HIP), precision CNC milling for critical surfaces, and surface finishing to achieve Ra values as low as 0.4 µm. All prototypes undergo full metrology inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify dimensional accuracy within ±0.02 mm.

Once the prototype is approved, we transition to zero-defect mass production. Our automated production lines integrate multi-axis CNC machining, robotic part handling, and real-time in-process inspection. Every production run is governed by statistical process control (SPC), with continuous monitoring of tool wear, cutting forces, and environmental conditions. Each component is traceable through a digital twin system that logs material batch numbers, machine parameters, and inspection data. Non-destructive testing (NDT), including X-ray and ultrasonic inspection, is performed on critical components to detect internal discontinuities. Final inspection includes full first-article inspection (FAI) reporting per AS9102 standards and batch-level quality certification.

Wuxi Lead’s zero-defect philosophy is enforced through a closed-loop corrective action (CLCA) system. Any deviation triggers immediate containment, root cause analysis, and process recalibration—ensuring 100% conformance across all production volumes.

Typical Production Specifications

| Parameter | Capability |

|---|---|

| Materials | Ti-6Al-4V, Inconel 718, 17-4 PH, AlSi10Mg, 316L |

| Layer Thickness (Additive) | 20–50 µm |

| Dimensional Accuracy | ±0.02 mm |

| Surface Roughness (as-built) | Ra 10–15 µm; post-processed down to Ra 0.4 µm |

| Build Envelope | Up to 250 x 250 x 300 mm |

| Post-Processing | HIP, CNC milling, polishing, anodizing, passivation |

| Quality Standards | ISO 9001, AS9100, ISO 13485 (medical) |

This disciplined progression from design to full-scale production ensures reliability, repeatability, and uncompromised quality in every metal component we manufacture.

Why Choose Wuxi Lead Precision

Strategic Partnership for Precision Metal Additive Manufacturing

In today’s competitive industrial landscape, accelerating time-to-market without compromising precision is non-negotiable. Wuxi Lead Precision Machinery delivers this critical balance through our Quick 3D Printing Service, engineered exclusively for high-stakes metal components. We transcend conventional rapid prototyping by integrating industrial-grade additive manufacturing with rigorous quality control, ensuring your parts meet aerospace, medical, and energy sector demands from day one. Our end-to-end process—from digital file to certified component—is optimized for speed, repeatability, and full traceability, eliminating the delays and inconsistencies common in fragmented supply chains.

Partnering with Lead Precision means accessing a dedicated engineering team with 15+ years of experience in complex metal additive systems. We specialize in challenging alloys including Inconel 718, Ti-6Al-4V, and maraging steel, with capabilities spanning functional prototypes, low-volume production, and mission-critical tooling. Unlike generic service bureaus, we enforce ISO 9001 and AS9100-certified workflows, including in-process monitoring, post-build heat treatment, and 100% dimensional validation. This disciplined approach guarantees parts that perform under extreme conditions, reducing your risk of field failures and costly redesigns.

Technical Capabilities at a Glance

| Parameter | Specification | Industrial Relevance |

|---|---|---|

| Build Volume | Ø250 x 325 mm | Accommodates complex assemblies in single print |

| Material Options | Titanium, Stainless Steel, Inconel, Aluminum | Meets AMS, ASTM, and EN material standards |

| Layer Thickness | 20–50 μm | Achieves near-net-shape surfaces requiring minimal finishing |

| Geometric Accuracy | ±0.05 mm | Ensures fit-for-function on critical interfaces |

| Lead Time | 5–10 business days | Cuts development cycles by 40% vs. traditional methods |

Your success hinges on partners who understand that speed without precision is wasted effort. We prioritize seamless integration into your engineering workflow through encrypted data portals, real-time production tracking, and direct access to our application engineers. Whether you require urgent turbine blade prototypes or certified surgical instrument production, our facility in Wuxi operates 24/7 with redundant systems to guarantee on-time delivery. This operational excellence is backed by material test reports, microstructure analysis, and full documentation packages compliant with global regulatory frameworks.

Do not let supply chain bottlenecks dictate your innovation timeline. Integrate Lead Precision as your strategic additive manufacturing partner to transform design concepts into certified metal components faster and with uncompromised integrity. Our engineering team stands ready to review your project specifications and deliver a tailored production plan within 24 hours.

Contact [email protected] to initiate a technical consultation. Include your component drawings or STL files for a rapid feasibility assessment and formal quotation. Let us demonstrate how precision-engineered speed elevates your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.