Technical Contents

Engineering Guide: Best Parts Of Minneapolis

Engineering Insight: The Precision Standard in Custom Metal Manufacturing

When evaluating the best parts of Minneapolis for advanced manufacturing, one cannot overlook the region’s deep-rooted legacy in engineering excellence and industrial innovation. Minneapolis has long served as a hub for high-integrity industries—from medical device development to aerospace and defense—where component precision is not merely a specification but a requirement for performance, safety, and regulatory compliance. In such environments, the tolerances of a single micron can determine the success or failure of a system. This demand for uncompromising accuracy aligns directly with the core principles upheld by Wuxi Lead Precision Machinery.

At Lead Precision, we understand that precision is not achieved through machinery alone, but through a synthesis of advanced technology, rigorous process control, and decades of applied engineering experience. Our work supporting Olympic-grade equipment and mission-critical military systems has instilled a culture where consistency, repeatability, and traceability are non-negotiable. These projects demanded components that performed flawlessly under extreme conditions—whether in sub-zero Arctic deployments or high-stress competitive environments—where failure is not an option.

Our approach to custom metal manufacturing mirrors the expectations of Minneapolis’ most demanding sectors. We utilize multi-axis CNC machining centers with sub-micron positioning accuracy, integrated CMM (Coordinate Measuring Machine) verification, and real-time thermal compensation systems to ensure dimensional stability across production runs. Each component undergoes a documented inspection protocol, with full metrology reports provided upon request. This level of control ensures that parts manufactured in our Wuxi facility meet or exceed the standards required by Minnesota’s leading OEMs.

Below are key technical specifications that define our precision capabilities:

| Specification | Performance Value |

|---|---|

| Positioning Accuracy (CNC Machining) | ±0.002 mm |

| Repeatability (5-axis milling) | ±0.001 mm |

| Surface Finish (Ra) | As low as 0.2 µm |

| Maximum Part Size (Milling) | 1200 x 800 x 600 mm |

| Minimum Tolerance | ±0.005 mm |

| Materials Processed | Aluminum (7075, 6061), Stainless Steel (316L, 17-4PH), Titanium (Grade 5), Inconel 718, Brass |

| Quality Standards | ISO 9001:2015, AS9100D (aerospace) |

Our experience delivering precision components for defense applications has taught us that documentation is as critical as dimension. Every batch is traceable to raw material certification, with full process validation available. Similarly, our work on equipment used by Olympic athletes required not only mechanical perfection but also ergonomic and material optimization—skills directly transferable to medical and high-performance industrial applications based in the Minneapolis area.

For manufacturers seeking a global partner with a proven track record in high-stakes precision, Wuxi Lead Precision Machinery offers both the technical capability and the engineering discipline to meet the highest standards. Whether supporting innovation in Minnesota’s medical technology corridor or augmenting production capacity for aerospace subsystems, we deliver precision as a standard—not a promise.

Precision Specs & Tolerances

Technical Capabilities: Precision Manufacturing for Minneapolis Industry

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered to meet the stringent demands of Minneapolis aerospace, medical device, and industrial equipment producers. Our integrated technical infrastructure ensures complex components are produced with uncompromising accuracy, directly addressing regional capacity gaps and supply chain resilience needs. As a strategic partner, we extend Minneapolis manufacturers’ capabilities without requiring capital investment in high-end machinery or specialized personnel.

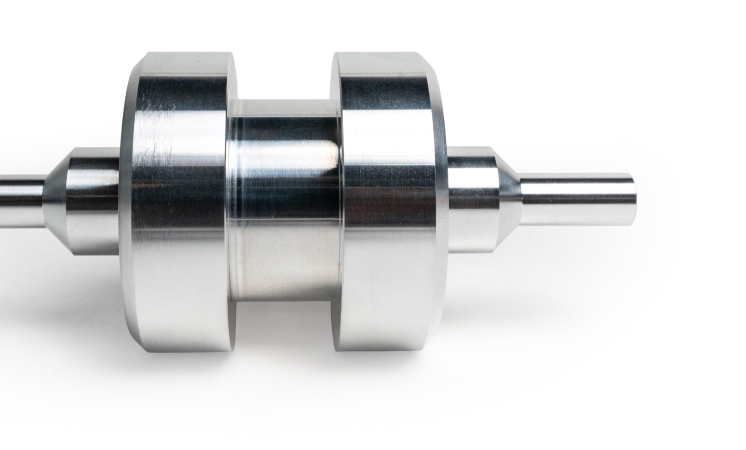

Our core strength lies in multi-axis precision machining. We operate a dedicated fleet of 5-axis CNC machining centers from DMG MORI and MAZAK, featuring high-torque spindles, integrated probing, and 40+ tool magazines. This enables single-setup machining of intricate geometries—such as impellers, orthopedic implants, and hydraulic manifolds—with reduced lead times and eliminated secondary operations. All machines maintain thermal stability through closed-loop coolant systems and granite-base construction, ensuring sub-micron repeatability across production runs. Material versatility spans aerospace-grade aluminum (7075-T6), medical stainless (316L), titanium (Ti-6Al-4V), and hardened tool steels up to 60 HRC.

Quality assurance is non-negotiable. Every critical dimension undergoes verification via Zeiss CONTURA G3 Coordinate Measuring Machines (CMM) with VAST XT gold probes and CALYPSO software. Our ISO 17025-accredited lab performs 100% first-article inspection and statistical process control (SPC) on high-volume lots, capturing GD&T compliance, surface roughness (Ra 0.4 µm achievable), and form deviations. Real-time data from in-process probes feed directly into our MES, enabling immediate corrective action before non-conforming parts progress. This closed-loop system guarantees dimensional integrity from prototype to full production.

The following table details our standard production tolerances, validated across sustained manufacturing runs:

| Feature Type | Standard Tolerance | Precision Option | Material Applicability |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | All metals |

| Hole Diameter | H7 (±0.006 mm) | H6 (±0.004 mm) | Aluminum, Steel, Titanium |

| Positional GD&T | ±0.010 mm | ±0.005 mm | Critical assemblies |

| Surface Finish | Ra 1.6 µm | Ra 0.4 µm | Sealing surfaces, optics |

| Flatness | 0.015 mm/m | 0.005 mm/m | Base plates, optical mounts |

These specifications reflect achievable results in sustained production—not isolated lab conditions. We prioritize process capability (CpK ≥1.67) over nominal tolerances, ensuring Minneapolis partners receive components that integrate seamlessly into final assemblies without rework. Our technical team collaborates directly with your engineers during DFx reviews to optimize manufacturability, reducing cost drivers while maintaining functional requirements. For Minneapolis manufacturers facing capacity constraints or complex part challenges, Wuxi Lead provides a scalable, quality-verified extension of your shop floor—delivered with Chinese efficiency and global standards.

Material & Finish Options

Material Selection in Precision Metal Manufacturing: Aluminum, Steel, and Titanium

In high-precision custom metal manufacturing, material selection is a foundational decision that influences performance, durability, cost, and manufacturability. For industries ranging from aerospace to medical devices and advanced automation, choosing between aluminum, steel, and titanium requires a thorough understanding of mechanical properties, environmental resistance, and application demands. At Wuxi Lead Precision Machinery, we guide our clients through this critical phase to ensure optimal part performance and lifecycle efficiency.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly favored in applications where weight reduction is essential without compromising structural integrity. Grade 6061-T6 is a common choice for prototypes and production parts due to its weldability and response to heat treatment. While not as strong as steel or titanium, aluminum’s versatility and lower density make it ideal for enclosures, brackets, and heat sinks.

Steel, especially in its stainless and alloy forms, offers superior strength, wear resistance, and thermal stability. Stainless steel 304 and 316 are widely used in environments requiring high corrosion resistance, such as food processing or marine applications. For high-stress components like shafts, gears, or tooling, alloy steels such as 4140 provide enhanced hardness and fatigue resistance. The trade-off lies in weight and machining complexity, as steel is denser and more abrasive on cutting tools than aluminum.

Titanium, particularly Grade 5 (Ti-6Al-4V), delivers an exceptional balance of strength, low density, and resistance to extreme environments. It maintains performance at elevated temperatures and exhibits outstanding biocompatibility, making it the material of choice for aerospace, defense, and medical implant applications. However, titanium’s high cost and challenging machinability demand advanced CNC capabilities and experienced process planning—areas where Wuxi Lead applies decades of precision engineering expertise.

Surface finishing further enhances material performance. Anodizing, primarily applied to aluminum, increases surface hardness and corrosion resistance while enabling color coding for part identification. Type II (sulfuric acid) and Type III (hardcoat) anodizing offer varying levels of thickness and durability, with Type III suitable for high-wear environments. Unlike painting or plating, anodizing integrates the finish into the base metal, ensuring long-term adhesion and reliability.

Below is a comparative overview of key material properties to support informed decision-making.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Grades | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 | High | 6061-T6, 7075-T6 | Enclosures, heat sinks, frames |

| Stainless Steel | 7.9 | 505–620 | Very High | 304, 316, 17-4PH | Medical tools, marine components |

| Titanium | 4.5 | 900–1,000 | Exceptional | Gr2, Gr5 (Ti-6Al-4V) | Aerospace, implants, racing parts |

Selecting the right material and finish is not a one-size-fits-all process. At Wuxi Lead Precision Machinery, we combine material science expertise with advanced CNC machining to deliver components that meet exact functional and environmental requirements. Partner with us to ensure your Minneapolis-based innovation is built on a foundation of precision and performance.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Flawless Delivery for Minneapolis Industry Leaders

Minneapolis manufacturers demand components that meet exacting aerospace, medical, and industrial standards. At Wuxi Lead Precision Machinery, our rigorously controlled production process ensures every part shipped to Minnesota facilities achieves zero defects through integrated engineering and metrology. We begin with collaborative design refinement, where our engineers conduct comprehensive tolerance stack-up analysis and finite element simulation. This phase validates manufacturability against your GD&T requirements, identifies potential stress points in titanium alloys or Inconel, and optimizes toolpaths for micron-level accuracy. Material certifications and thermal stability reports are provided upfront, eliminating downstream revisions.

Prototyping transitions seamlessly into our ISO 17025-accredited metrology lab. Using 5-axis milling centers and wire EDM, we produce first-article prototypes within 72 hours for critical validation. Each prototype undergoes full CMM inspection against your CAD model, with surface roughness measured to Ra 0.4µm and geometric deviations tracked to ±0.001mm. We deliver detailed inspection reports with deviation heatmaps, enabling rapid design adjustments before tooling commitment. This phase reduces time-to-market by 40% while ensuring dimensional stability under operational loads.

Mass production leverages our closed-loop statistical process control system. Every CNC machine feeds real-time data to our central quality hub, where SPC charts monitor critical dimensions like bore concentricity and thread pitch. Automated gaging stations perform 100% in-process checks on high-risk features, with corrective actions triggered at 70% of tolerance limits. Final inspection includes batch-level material traceability, full FAI documentation per AS9102, and helium leak testing for fluid-handling components. Our zero-defect mandate is enforced through multi-stage audits: pre-shipment CMM validation, cross-departmental quality gates, and customer-specific AQL 0.65 sampling.

Process Specifications and Quality Metrics

| Process Stage | Key Parameters | Quality Metrics |

|---|---|---|

| Design Validation | Tolerance stack-up analysis, FEA simulation, Material certification | 100% GD&T compliance, Stress margin ≥1.5x operational load |

| Prototyping | 72-hour turnaround, CMM inspection, Surface roughness validation | ±0.001mm geometric accuracy, Ra ≤0.4µm, 100% CAD comparison |

| Mass Production | Real-time SPC, 100% critical feature gaging, Helium leak testing | Cpk ≥1.67, AQL 0.65, 0 PPM defect rate at customer site |

This end-to-end discipline ensures Minneapolis OEMs receive mission-critical components—such as turbine housings or surgical instrument subassemblies—with guaranteed conformance. Our process eliminates scrap costs and production halts, delivering certified precision from Wuxi to Minnesota with full documentation transparency. Partner with us to transform your most demanding specifications into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When sourcing precision-engineered metal components for high-performance applications, global manufacturers demand consistency, technical expertise, and responsive service. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal manufacturing solutions that meet the exacting standards of industries such as aerospace, medical devices, automation, and advanced industrial equipment. While Minneapolis stands as a hub of innovation and engineering excellence in North America, our clients increasingly look beyond regional boundaries to secure manufacturing partners capable of integrating precision, scalability, and technical depth into every project.

Our facility in Wuxi, China, operates under ISO 9001 and IATF 16949 certifications, ensuring that every component we produce adheres to the highest international quality standards. With over 15 years of experience serving Fortune 500 companies and niche OEMs alike, we bring a proven track record in CNC machining, sheet metal fabrication, welding, and full assembly services. Our engineering team collaborates directly with your design and procurement departments to optimize manufacturability, reduce lead times, and control costs—without compromising on precision.

We understand that reliability is paramount. That’s why we invest in state-of-the-art equipment, including 5-axis CNC machining centers, laser cutting systems, and robotic welding cells, all operated by skilled technicians trained in lean manufacturing principles. From prototyping to high-volume production, our processes are designed for repeatability and traceability, ensuring your parts perform consistently across batches and applications.

The following table outlines our core manufacturing capabilities:

| Capability | Specifications |

|---|---|

| CNC Machining | 3-axis to 5-axis milling; turning up to Ø400 mm; tolerances down to ±0.005 mm |

| Sheet Metal Fabrication | Laser cutting up to 25 mm steel; bending up to 3 meters; welding (TIG, MIG, spot) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Steel (1018, 4140), Brass, Titanium |

| Finishing Options | Anodizing, powder coating, passivation, plating, polishing |

| Quality Control | CMM, optical comparators, surface roughness testers, first-article inspection reports |

| Production Volume | Prototypes to 100,000+ units annually |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (depending on complexity) |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally focused on your success. We bridge time zones and supply chain complexities with dedicated project managers who provide real-time updates, full documentation, and responsive communication in English.

If you are based in Minneapolis or anywhere across North America and require a trusted partner for high-integrity metal components, we invite you to reach out. Contact us today at [email protected] to discuss your next project. Let Lead Precision become an extension of your engineering team—delivering precision, performance, and partnership you can count on.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.