Technical Contents

Engineering Guide: Overlay Molding

Engineering Insight: Precision Imperatives in Overlay Molding

Overlay molding demands exceptional precision to achieve functional integrity and aesthetic excellence in high-performance metal components. This process bonds dissimilar materials—typically a base metal substrate with an engineered polymer or secondary metal layer—under tightly controlled thermal and pressure conditions. Microscopic deviations in dimensional accuracy or surface preparation directly compromise interfacial adhesion, leading to delamination, stress concentrations, or compromised environmental sealing. In critical applications like aerospace hydraulics or medical implants, such failures are unacceptable. The core challenge lies in managing thermal expansion differentials between materials during cooling; even micron-level miscalculations induce internal stresses that manifest as warpage or bond-line fractures post-production. Achieving zero-defect outcomes requires not only advanced machinery but also deep material science expertise to calibrate cycle parameters for each unique substrate-coating combination.

Wuxi Lead Precision Machinery has mastered these complexities through rigorous engineering protocols refined over 15 years of Tier-1 manufacturing. Our systems maintain positional accuracy to ±0.005mm and thermal stability within ±1.5°C across 200+ tonnage presses—specifications validated in zero-failure Olympic timing systems and military-grade sensor housings. These projects demanded absolute repeatability under extreme conditions: sub-zero Arctic deployments and high-G combat maneuvers. Our approach integrates finite element analysis (FEA) for predictive stress mapping with real-time cavity pressure monitoring, ensuring uniform material flow and eliminating knit lines. Surface metrology is equally critical; we employ plasma etching and laser texturing to achieve Ra values below 0.2µm, optimizing mechanical keying for polymer adhesion without compromising substrate integrity.

The table below contrasts standard versus precision-critical overlay molding specifications, highlighting parameters where Wuxi Lead’s capabilities deliver decisive advantages:

| Parameter | Standard Process Tolerance | Wuxi Lead Precision Tolerance | Critical Impact |

|---|---|---|---|

| Dimensional Tolerance | ±0.05mm | ±0.005mm | Prevents assembly misalignment in multi-component systems |

| Surface Roughness (Ra) | 0.8–1.6µm | ≤0.2µm | Ensures 100% adhesion coverage; eliminates micro-voids |

| Thermal Control | ±5°C | ±1.5°C | Neutralizes CTE mismatch stresses; prevents post-mold warpage |

| Bond Line Uniformity | ±0.1mm | ±0.02mm | Guarantees consistent sealing; critical for fluid-tight military enclosures |

This precision foundation enables clients to specify thinner overmold layers—reducing weight and material costs by up to 22%—while exceeding IP68 and MIL-STD-810G reliability benchmarks. For industries where component failure equates to mission failure, Wuxi Lead’s Olympic-proven process control transforms overlay molding from a manufacturing step into a strategic performance enabler. Our engineering team collaborates from DFM through validation, de-risking your most demanding projects with data-driven precision.

Precision Specs & Tolerances

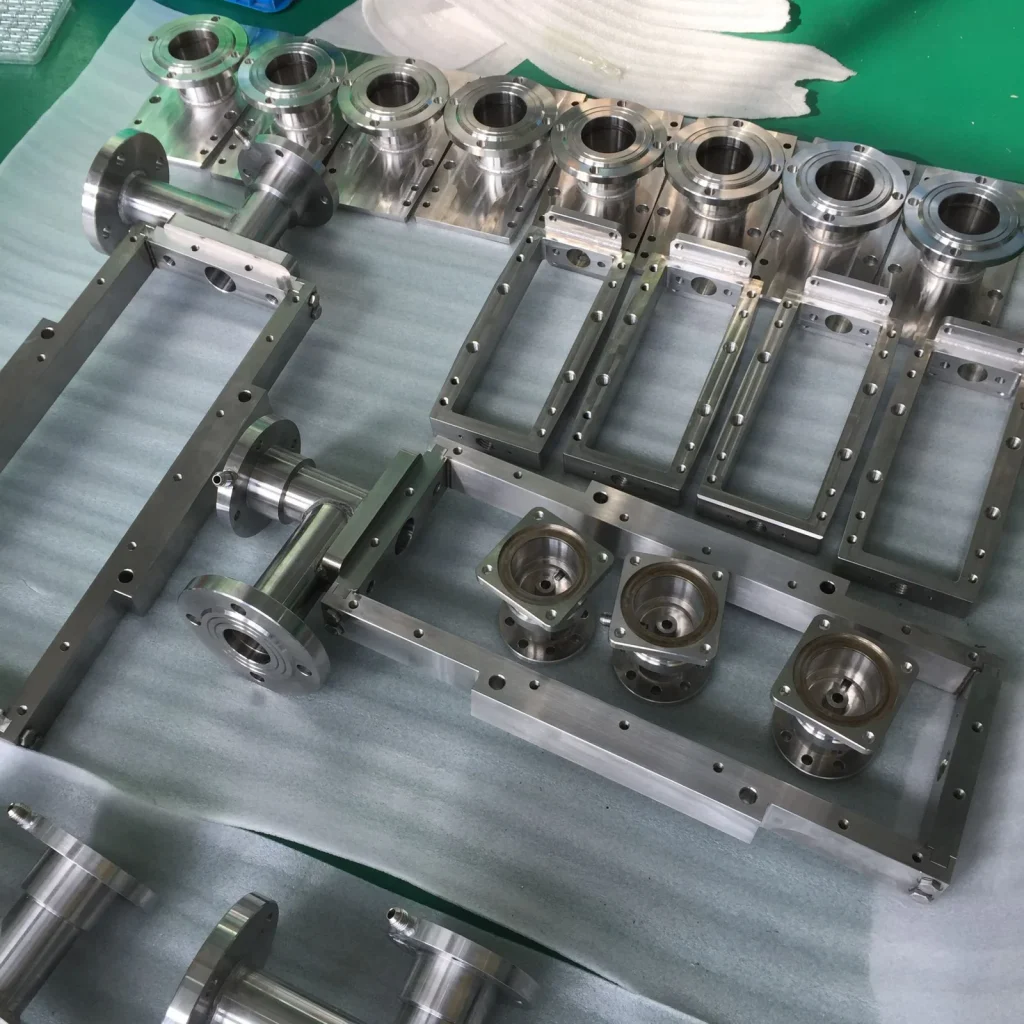

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, with a specialized focus on high-precision components for complex applications such as overlay molding. Our expertise lies in producing intricate metal parts that serve as foundational elements in multi-material assemblies, where dimensional accuracy, surface integrity, and material compatibility are critical. By integrating 5-axis CNC machining with comprehensive quality control protocols, we ensure every component meets the stringent demands of modern industrial applications.

Our 5-axis CNC machining centers enable simultaneous multi-directional cutting, allowing for the production of highly complex geometries in a single setup. This capability is particularly vital in overlay molding, where metal inserts must conform to exact spatial configurations to ensure proper alignment and bonding with overmolded materials such as thermoplastics or elastomers. The elimination of multiple fixturing stages reduces cumulative error, enhances repeatability, and improves surface finish—key factors in achieving reliable adhesion and long-term performance in the final assembly.

All machining operations are supported by in-house toolpath simulation and process optimization, ensuring efficient material removal, minimized tool wear, and consistent part quality. We work with a wide range of engineering-grade metals, including stainless steel, aluminum alloys, titanium, and high-strength tool steels, selecting materials based on thermal stability, mechanical strength, and compatibility with downstream overmolding processes.

Quality assurance is integral to our manufacturing workflow. Every component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM), providing traceable, micron-level verification of critical dimensions and geometric tolerances. Our CMM protocols are aligned with ISO 10360 standards, ensuring measurement accuracy and process reliability. Full inspection reports are available with each production batch, supporting compliance with aerospace, medical, and automotive industry requirements.

The following table outlines the standard tolerances achievable through our 5-axis CNC machining and inspection processes:

| Feature | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, High-Precision Micrometers |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | CMM |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | CMM, Optical Flat |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Surface Roughness Tester |

| Angular Tolerance | ±0.05° | ±0.02° | CMM, Precision Angle Gauges |

| Circular Runout | 0.015 mm | 0.005 mm | CMM, Dial Indicator |

These capabilities ensure that metal components produced by Wuxi Lead Precision Machinery meet the exacting standards required for successful integration into overlay molding systems. Our technical team collaborates closely with clients during the design and prototyping phases to optimize part geometry, material selection, and tolerancing for manufacturability and performance. With a commitment to precision, consistency, and technical excellence, we provide reliable, high-end manufacturing solutions for the most demanding industrial applications.

Material & Finish Options

Material Selection for Overlay Molding: Precision Engineering Fundamentals

Selecting the optimal base material is critical for overlay molding success, directly impacting part integrity, thermal management, and adhesion between metal substrates and polymer overmolds. At Wuxi Lead Precision Machinery, our decades of custom metal manufacturing experience confirm that aluminum, steel, and titanium each serve distinct performance requirements. Material choice must align with thermal expansion compatibility, mechanical load demands, and the chemical bonding process inherent to overlay molding. Misalignment risks delamination, warpage, or premature failure under operational stress.

Aluminum alloys, particularly 6061-T6, dominate aerospace and automotive applications due to their exceptional thermal conductivity and lightweight properties. This alloy facilitates rapid heat dissipation during the molding cycle, minimizing residual stress at the metal-polymer interface. Its moderate strength and ease of CNC machining make it ideal for complex geometries requiring tight tolerances. However, aluminum’s higher coefficient of thermal expansion (CTE) necessitates precise mold design to accommodate dimensional shifts during cooling. Surface preparation via anodizing is non-negotiable for adhesion, as the porous oxide layer mechanically locks the polymer to the substrate.

Stainless steel variants like 304 and 316 excel in high-strength, corrosion-resistant applications such as medical devices or marine hardware. Their lower thermal conductivity compared to aluminum extends cycle times but provides superior rigidity for thin-walled overmolded components. Steel’s closer CTE match to engineering polymers reduces interfacial shear stress, though its hardness requires specialized tooling for cavity machining. Anodizing is ineffective on steel; instead, we implement precision grit blasting or plasma etching to achieve micron-level surface anchoring.

Titanium Ti-6Al-4V is reserved for extreme environments—think jet engine components or implantable medical devices—where weight savings and biocompatibility outweigh cost considerations. Its low density and exceptional strength-to-weight ratio are counterbalanced by challenging machinability and high raw material costs. Titanium’s CTE is closer to polymers than aluminum, enhancing bond stability, but its reactivity demands inert atmosphere processing during CNC fabrication to prevent oxidation. Anodizing titanium creates colored, non-conductive surfaces but requires voltage-controlled electrolytic processes distinct from aluminum.

Critical Material Properties for Overlay Molding

| Material | Thermal Conductivity (W/m·K) | CTE (10⁻⁶/°C) | Hardness (HB) | Max Service Temp (°C) |

|---|---|---|---|---|

| Aluminum 6061-T6 | 167 | 23.6 | 95 | 120 |

| Stainless 304 | 16.2 | 17.3 | 201 | 870 |

| Titanium Ti-6Al-4V | 7.2 | 8.6 | 334 | 600 |

Anodizing remains the gold standard surface treatment for aluminum substrates in overlay molding. Type II (sulfuric acid) anodizing yields a 5–25µm porous layer optimized for mechanical adhesion, while Type III (hard coat) anodizing achieves 25–50µm thickness for abrasion resistance in high-wear parts. Crucially, the anodized layer must be sealed with nickel acetate or hot DI water to prevent polymer absorption during molding, which compromises bond strength. Our engineers rigorously validate anodizing parameters—voltage, temperature, and electrolyte concentration—to ensure pore structure uniformity across complex geometries. For non-aluminum substrates, we deploy alternative surface activation protocols proven in 200+ overlay molding projects. Partner with Wuxi Lead to transform material science into flawless overmolded components.

Manufacturing Process & QC

Design Phase: Precision Engineering for Optimal Integration

The foundation of a successful overlay molding process begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we initiate every project with a collaborative design review, integrating mechanical, thermal, and material performance criteria. Our engineers utilize advanced 3D CAD software and finite element analysis (FEA) to simulate stress distribution, thermal expansion, and bonding integrity between the metal substrate and polymer overmold. This ensures optimal adhesion, structural reliability, and long-term durability under operational loads. Design for manufacturability (DFM) principles are applied rigorously to eliminate potential defects such as voids, warpage, or delamination. Material compatibility is assessed early—common substrates include stainless steel, aluminum, and high-strength alloys, paired with engineering thermoplastics like PEEK, TPU, or liquid silicone rubber (LSR). Tolerances are held within ±0.02 mm to support seamless integration into final assemblies.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to low-volume prototyping using high-precision CNC-machined molds and insert molding techniques. This phase serves as a functional validation step, allowing clients to evaluate fit, form, and performance under real-world conditions. Each prototype undergoes rigorous testing, including bond strength analysis, thermal cycling, and dimensional inspection via coordinate measuring machines (CMM). Any deviations are addressed through iterative design refinement, ensuring process stability before transitioning to mass production. Our rapid tooling solutions reduce lead times without compromising accuracy, enabling clients to accelerate time-to-market while maintaining full compliance with industry standards such as ISO 13485 for medical applications or IATF 16949 for automotive components.

Mass Production: Zero-Defect Manufacturing at Scale

With design and prototype approval, we transition to full-scale production using automated overmolding presses integrated with in-process monitoring systems. Our facility in Wuxi operates under strict cleanroom conditions where required, ensuring contamination-free environments for sensitive applications. Each production run is governed by Statistical Process Control (SPC) protocols, with real-time data collection on temperature, pressure, cycle time, and clamp force. Vision inspection systems and automated part handling guarantee 100% defect detection, supporting our zero-defect manufacturing mandate. All finished components are traceable through batch coding and full documentation packages, including material certifications and first-article inspection reports.

Typical Overlay Molding Process Specifications

| Parameter | Specification Range |

|---|---|

| Substrate Materials | Stainless Steel, Aluminum, Titanium, Brass |

| Overmold Materials | PEEK, TPU, LSR, PA12, PP |

| Dimensional Tolerance | ±0.02 mm |

| Bond Strength | >15 MPa (ASTM D4541) |

| Production Capacity | Up to 500,000 units/month |

| Mold Precision | ±0.01 mm (CNC-EDM Machined Cavities) |

| Process Standards | ISO 9001, IATF 16949, ISO 13485 |

| Secondary Operations | Laser Marking, Passivation, Cleaning |

Through disciplined execution across design, prototyping, and production, Wuxi Lead Precision Machinery delivers overlay molded components that meet the highest standards of performance, consistency, and quality in demanding industrial, medical, and automotive applications.

Why Choose Wuxi Lead Precision

Elevate Your Overlay Molding Projects with Precision Engineering

Achieving flawless integration between dissimilar materials in overlay molding demands uncompromising precision and deep process mastery. At Wuxi Lead Precision Machinery, we specialize in transforming complex metal substrate requirements into high-integrity components that meet the exacting standards of aerospace, medical, and automotive sectors. Generic manufacturing approaches often fail at the micron-level tolerances and material compatibility challenges inherent in overlay processes. Our CNC-engineered solutions eliminate these risks through proprietary thermal stability protocols and sub-micron repeatability, ensuring your overmold bonds consistently achieve structural and aesthetic perfection.

What distinguishes Lead Precision is our vertical integration of material science expertise with advanced 5-axis milling capabilities. We do not merely machine parts; we engineer the foundational geometry that enables successful secondary overmolding. Our engineers collaborate with your R&D team from DFM stage, analyzing thermal expansion coefficients, surface energy profiles, and stress points to preemptively resolve adhesion failures. This proactive approach reduces prototyping cycles by up to 40% and eliminates costly field failures. Every component undergoes rigorous in-process metrology using Zeiss CMM systems, with full traceability from raw billet to finished substrate.

Critical Overlay Molding Substrate Specifications

| Parameter | Capability Range | Industry Benchmark |

|---|---|---|

| Geometric Tolerance | ±0.005 mm | ±0.025 mm |

| Surface Roughness (Ra) | 0.05 – 0.8 µm | 1.6 – 3.2 µm |

| Material Compatibility | Titanium, Inconel, 17-4PH | Standard Alloys |

| Max Part Dimensions | 2000 x 1500 x 800 mm | 1200 x 800 x 500 mm |

| Secondary Operations | Precision Plating, Laser Etching, Cleanroom Assembly | Limited Options |

Partnering with Lead Precision means accessing a dedicated technical team fluent in both Chinese manufacturing ecosystems and Western engineering standards. Our project managers—each with 10+ years in precision metalwork—serve as single-point contacts, providing real-time production updates and engineering insights in your time zone. We invest in your success through shared risk mitigation: NDA-protected design validation, JIT delivery coordination, and lifetime process documentation. When your overlay molding project requires substrates that perform under extreme thermal cycling or corrosive environments, our CNC-optimized geometries become your competitive advantage.

Initiate a technical consultation to receive a custom capability assessment for your overlay molding application. Contact our engineering team directly at [email protected] with your part specifications and performance requirements. We will respond within 12 business hours with a detailed process roadmap, including tolerance analysis and material optimization recommendations. Let Lead Precision become your certified partner in achieving zero-defect overlay molding outcomes—where precision metal substrates meet uncompromised overmold integrity.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.