Technical Contents

Engineering Guide: 3D Printed Steel Parts

Engineering Insight Precision Imperatives in 3D Printed Steel Parts

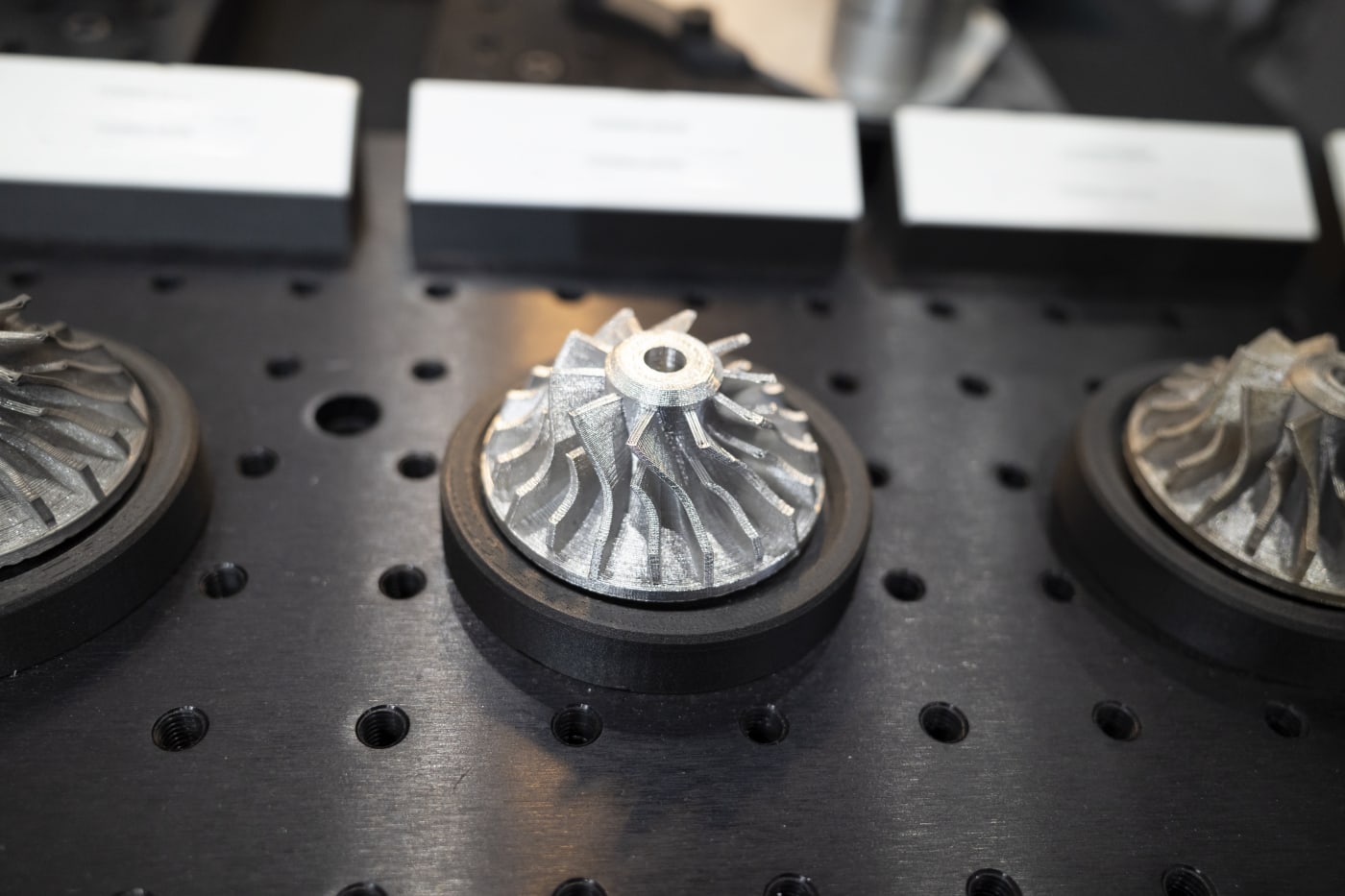

Achieving true dimensional and geometric precision in additively manufactured steel components remains the critical differentiator between functional prototypes and mission-critical production parts. While metal 3D printing unlocks unprecedented design freedom, the complex interplay of thermal dynamics, material phase transformations, and residual stress during the layer-by-layer build process inherently challenges dimensional stability. Sub-micron tolerances required in aerospace actuators, medical implants, or high-pressure fluid systems cannot be an afterthought; they demand rigorous process control from powder characterization through post-processing. Inadequate precision leads to assembly failures, premature wear, or catastrophic part failure under operational loads – risks unacceptable in high-stakes industries. The true measure of an industrial metal AM capability lies not just in building a shape, but in consistently delivering that shape within micron-level specifications, batch after batch, across complex geometries impossible via conventional machining.

At Wuxi Lead Precision Machinery, precision is engineered into every stage of our metal additive workflow. Our integrated approach combines proprietary parameter optimization algorithms with real-time melt pool monitoring and multi-axis in-situ metrology. This allows dynamic correction during builds, minimizing distortion and ensuring first-article conformance. Crucially, precision extends beyond the as-printed state. Our dedicated post-processing suite, featuring multi-axis CNC machining centers, precision grinding, and specialized heat treatment protocols, achieves the final critical tolerances and surface finishes demanded by Tier 1 aerospace and defense partners. We treat the entire value chain – from digital model validation to final inspection certification – as a single precision system.

This commitment to uncompromising accuracy is proven in the most demanding environments. Our 3D printed high-strength steel components have performed flawlessly in precision guidance systems for national defense programs, where micron-level deviations compromise system integrity. Similarly, we supplied mission-critical structural elements for the Beijing 2022 Winter Olympics infrastructure, subjected to extreme cold and dynamic loads, where dimensional stability was non-negotiable for public safety. These projects underscore our capability to deliver steel parts meeting MIL-STD and AS9100 stringent requirements.

The table below illustrates the precision benchmarks achievable with our integrated metal AM and precision machining process for common steel alloys, far exceeding typical as-printed capabilities:

| Specification Parameter | Typical As-Printed AM | Wuxi Lead Precision Final Part (Post-Processed) | Industry Standard Requirement (Aerospace) |

|---|---|---|---|

| Dimensional Accuracy (± mm) | 0.1 – 0.2 | 0.015 – 0.025 | ≤ 0.05 |

| Surface Roughness (Ra, µm) | 10 – 25 | 0.8 – 1.6 | ≤ 3.2 |

| Feature Repeatability (µm) | ± 50 | ± 10 | ≤ ± 25 |

| Internal Geometric Tolerance | Limited Control | IT6 – IT7 | IT7 Minimum |

Precision in 3D printed steel is not merely a technical specification; it is the foundation of reliability, safety, and performance in advanced applications. Partnering with a manufacturer possessing deep process mastery and proven experience in delivering zero-defect parts for Olympic and military programs ensures your steel AM components meet the highest standards of engineering integrity. Wuxi Lead Precision Machinery provides the certified precision that turns innovative designs into dependable reality.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-performance 3D printed steel parts, combining additive innovation with precision subtractive finishing. Our integrated workflow ensures that every component meets the exacting standards required in aerospace, medical, energy, and high-end industrial applications. While 3D printing enables complex geometries and rapid prototyping, we enhance final part integrity and dimensional accuracy through strategic use of 5-axis CNC machining and comprehensive quality control protocols.

All 3D printed steel components undergo post-processing using our state-of-the-art 5-axis CNC machining centers. This critical step ensures superior surface finish, tight tolerance compliance, and the elimination of residual stress distortions that may occur during the additive build process. Our 5-axis systems provide full contouring capability, allowing for precise machining of complex freeform surfaces and internal features that are common in optimized 3D printed designs. With simultaneous multi-axis movement, we achieve seamless integration of critical functional interfaces such as mounting surfaces, sealing zones, and precision bores.

To guarantee consistency and reliability, every production run is supported by rigorous quality assurance procedures. Our coordinate measuring machine (CMM) inspection system performs full geometric dimensioning and tolerancing (GD&T) verification, ensuring alignment with ASME Y14.5 standards. CMM reports are generated for each batch, providing traceable, data-backed validation of part conformity. In addition to dimensional inspection, we offer material certification, hardness testing, and surface roughness analysis upon request.

Our technical capabilities are structured to support both low-volume, high-mix production and scalable batch manufacturing. We work with a range of steel alloys suitable for 3D printing, including 17-4 PH stainless steel, 316L stainless steel, and maraging steel, all processed using laser powder bed fusion (LPBF) technology. Post-build heat treatment, hot isostatic pressing (HIP), and stress relieving are applied as needed to optimize mechanical properties and dimensional stability.

The following table outlines our standard achievable tolerances for 3D printed steel parts after CNC finishing and inspection:

| Feature | Standard Tolerance | Precision Capability (Optional) |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.02 mm |

| Positional Tolerance | ±0.05 mm | ±0.03 mm |

| Flatness | 0.05 mm per 100 mm | 0.02 mm per 100 mm |

| Circular Runout | 0.03 mm | 0.01 mm |

| Surface Roughness (CNC finished) | Ra 1.6 µm | Ra 0.8 µm |

| Hole Diameter (reamed) | ±0.025 mm | ±0.01 mm |

Wuxi Lead Precision Machinery is committed to delivering fully validated, production-ready steel components that meet global quality benchmarks. By combining 3D printing flexibility with CNC precision and metrology-grade inspection, we bridge the gap between design ambition and manufacturing reality.

Material & Finish Options

Material Selection Fundamentals for 3D Printed Metal Components

Selecting the optimal material for 3D printed steel parts is critical for balancing performance, cost, and manufacturability in industrial applications. At Wuxi Lead Precision Machinery, we prioritize materials that leverage additive manufacturing’s geometric freedom while meeting stringent mechanical and environmental demands. Aluminum alloys, steel variants, and titanium each serve distinct roles, with surface treatments like anodizing further enhancing functionality. Understanding these options ensures your components deliver reliability under operational stress.

Aluminum alloys, particularly AlSi10Mg, dominate lightweight applications requiring thermal conductivity and moderate strength. Ideal for aerospace brackets or automotive heat exchangers, they offer a superior strength-to-weight ratio but limited high-temperature stability. Steel remains the cornerstone for structural integrity, with maraging steel (e.g., 18Ni300) excelling in tooling and high-stress machinery due to exceptional toughness and hardness post-heat treatment. Stainless steel variants like 17-4PH provide corrosion resistance for fluid handling systems, though weldability constraints require design consideration. Titanium alloys, primarily Ti6Al4V, are indispensable for mission-critical aerospace or medical implants where biocompatibility, extreme strength-to-weight ratios, and corrosion resistance in harsh environments are non-negotiable.

Material properties directly dictate performance ceilings. The comparative specifications below guide initial selection:

| Material | Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Primary Applications |

|---|---|---|---|---|

| AlSi10Mg | 275 | 2.67 | Moderate | Lightweight brackets, heat sinks |

| 17-4PH Stainless | 1000 | 7.8 | High | Valves, pump components |

| 18Ni300 Maraging | 1400 | 8.0 | Moderate | Injection molds, aerospace tooling |

| Ti6Al4V | 830 | 4.43 | Excellent | Aircraft fixtures, medical implants |

Anodizing serves as a vital secondary process exclusively for aluminum 3D printed parts, significantly improving surface durability. This electrochemical treatment creates a hard, wear-resistant oxide layer that enhances corrosion protection and allows for color coding—critical for part identification in complex assemblies. While steel and titanium benefit from alternatives like passivation or thermal spraying, anodizing remains unmatched for aluminum’s functional and aesthetic refinement in precision machinery.

Material choice must align with end-use requirements from the outset. Aluminum suits cost-sensitive, lightweight needs; steel delivers unmatched hardness for industrial tooling; titanium justifies its premium for extreme-performance scenarios. At Wuxi Lead, our engineering team collaborates to validate material-process pairings, ensuring your 3D printed steel parts achieve target specifications without compromise. Contact us to refine your selection strategy for next-generation metal additive projects.

Manufacturing Process & QC

The production process for 3D printed steel parts at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure precision, repeatability, and zero defects across every manufacturing phase. Our methodology integrates advanced digital engineering with state-of-the-art metal additive manufacturing systems, enabling seamless transition from concept to final production.

Design begins with a comprehensive analysis of the client’s technical specifications, operational environment, and functional requirements. Our engineering team utilizes high-fidelity CAD modeling and finite element analysis (FEA) to simulate structural performance, thermal behavior, and load dynamics. This digital validation ensures optimal part geometry, material efficiency, and long-term reliability. Design for Additive Manufacturing (DfAM) principles are applied throughout to eliminate over-engineering, reduce weight, and enhance manufacturability without compromising strength.

Once the design is finalized, we proceed to prototyping using selective laser melting (SLM) technology. Prototypes are produced in-house on our industrial-grade metal 3D printers, allowing rapid physical validation of form, fit, and function. Each prototype undergoes full metrological inspection using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy within ±0.02 mm. Any necessary design refinements are implemented digitally and revalidated before approval for mass production.

Mass production is executed on a scalable fleet of SLM systems operating under strict environmental and quality controls. All builds occur in an argon-inerted chamber to prevent oxidation, ensuring material density exceeding 99.95%. Each layer is monitored in real time using melt pool sensing and thermal imaging to detect anomalies, enabling immediate corrective actions. Post-processing includes controlled stress relief, support removal, heat treatment per ASTM standards, and precision machining where required. Surface finishing options such as bead blasting, polishing, or coating are applied based on application demands.

Throughout the entire production cycle, our zero-defect strategy is enforced through a closed-loop quality management system compliant with ISO 9001:2015 and IATF 16949 standards. Every part is traceable via laser marking, and batch documentation includes material certificates, build logs, and inspection reports. In-process and final inspections cover dimensional conformance, mechanical properties, and microstructure integrity.

The following table outlines key technical specifications for our 3D printed steel components:

| Parameter | Specification |

|---|---|

| Material Options | 316L Stainless Steel, 17-4 PH, Inconel 718, Tool Steel (Maraging) |

| Layer Thickness | 20–50 μm |

| Build Accuracy | ±0.02 mm |

| Surface Roughness (as-built) | Ra 10–15 μm |

| Post-Processed Finish | Ra 0.8–3.2 μm (machined or polished) |

| Density | >99.95% |

| Max Build Volume | 250 × 250 × 325 mm |

| Heat Treatment | Solution annealing, aging, stress relief per specification |

| Quality Standards | ISO 9001:2015, ASTM F75, ASTM F138, ASTM F3001 |

Wuxi Lead Precision Machinery delivers fully validated, mission-critical steel components with uncompromised quality, ensuring performance in aerospace, medical, energy, and high-performance industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Steel Additive Manufacturing

Achieving true industrial viability with 3D printed steel demands more than access to advanced machinery; it requires a strategic partner with deep metallurgical expertise, rigorous process control, and unwavering commitment to precision. At Wuxi Lead Precision Machinery, we bridge the gap between additive design potential and certified, high-performance steel components ready for demanding aerospace, medical, energy, and industrial applications. Our integrated approach, combining state-of-the-art metal additive systems with decades of CNC machining and quality assurance excellence, ensures your printed steel parts meet exacting functional and regulatory standards, not just geometric specifications. We move beyond prototyping to deliver serial production solutions where material integrity, dimensional accuracy, and repeatability are non-negotiable.

Wuxi Lead Precision Machinery operates at the forefront of industrial metal additive manufacturing. Our dedicated steel printing facility utilizes industry-leading laser powder bed fusion systems operating under strictly controlled inert atmospheres. This is coupled with comprehensive in-house capabilities spanning powder characterization, build optimization, precision heat treatment, HIP (Hot Isostatic Pressing), and final CNC machining or surface finishing. Every process step adheres to stringent ISO 9001 and IATF 16949 quality management protocols. Our engineering team collaborates closely with your designers from the initial concept stage, providing critical DfAM (Design for Additive Manufacturing) feedback to optimize part geometry for strength, weight reduction, and manufacturability while ensuring metallurgical soundness. We specialize in transforming complex digital models into certified, fully dense steel components that perform reliably under extreme stress, temperature, and corrosion conditions.

The technical foundation of our steel additive service is defined by measurable performance parameters essential for industrial adoption. We consistently achieve results validated through rigorous internal and third-party testing.

| Parameter | Specification | Industrial Relevance |

|---|---|---|

| Primary Material | 17-4PH Stainless Steel (Custom alloys available) | Aerospace actuators, medical implants, tooling |

| Dimensional Accuracy | ±0.05 mm per 100 mm | Ensures assembly fit and functional interfaces |

| Surface Roughness (As-Built) | Ra 12-25 µm | Optimized for post-processing efficiency |

| Build Volume | 250 x 250 x 325 mm | Accommodates complex medium-scale components |

| Density | >99.95% | Critical for mechanical properties and fatigue life |

| Post-Processing | Full CNC, HIP, H&T, Surface Finishing | Delivers final part certification and performance |

Partnering with Wuxi Lead Precision Machinery means gaining a single-source solution for your most challenging steel additive requirements. We eliminate the risks and inefficiencies of navigating fragmented supply chains by owning the entire process – from raw material validation through final inspection and delivery. Our global logistics network ensures seamless support for international clients, backed by responsive engineering consultation and transparent project management. When component failure is not an option, rely on our proven ability to deliver steel parts that meet the highest benchmarks of quality and performance.

Contact our engineering team today at [email protected] to discuss how Wuxi Lead Precision Machinery can become your trusted partner for high-integrity 3D printed steel components. Share your design challenges and material requirements; we will provide a detailed technical assessment and production plan tailored to your application’s critical demands. Advance your manufacturing capabilities with precision-engineered solutions from China’s leader in industrial additive metal production.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.