Technical Contents

Engineering Guide: Mould Tooling

Engineering Insight: The Critical Role of Precision in Mould Tooling

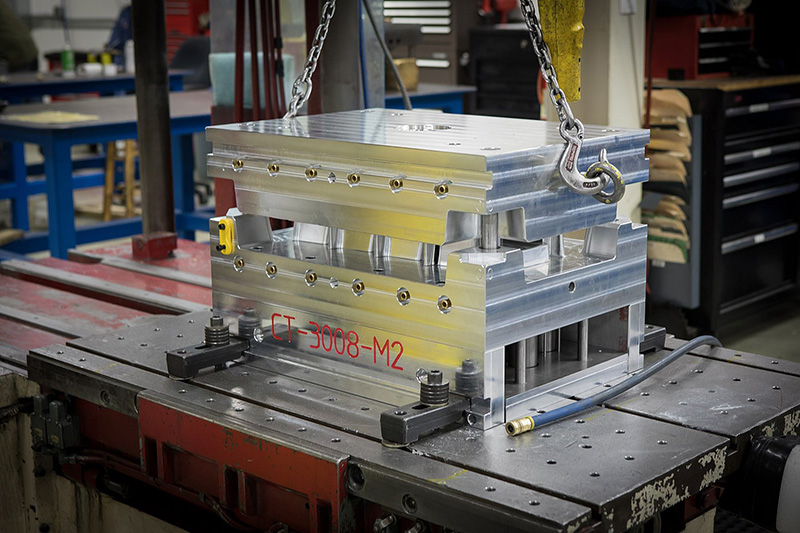

In high-end custom metal manufacturing, mould tooling serves as the foundational element that determines the quality, consistency, and performance of end components. At Wuxi Lead Precision Machinery, we recognize that precision in mould tooling is not merely a technical requirement—it is an engineering imperative. Every micron of deviation can propagate across thousands of production cycles, affecting fit, function, and final product integrity. This is especially critical in industries where performance under extreme conditions is non-negotiable, such as aerospace, defense, and high-performance sporting equipment.

Our experience in delivering mission-critical components for Olympic-grade equipment and military-grade systems has reinforced a fundamental truth: excellence begins at the tooling stage. Mould tools must withstand repeated thermal cycling, mechanical stress, and abrasive wear while maintaining dimensional stability. This demands not only advanced materials and cutting-edge machining techniques but also a deep understanding of material behavior, thermal dynamics, and long-term fatigue resistance.

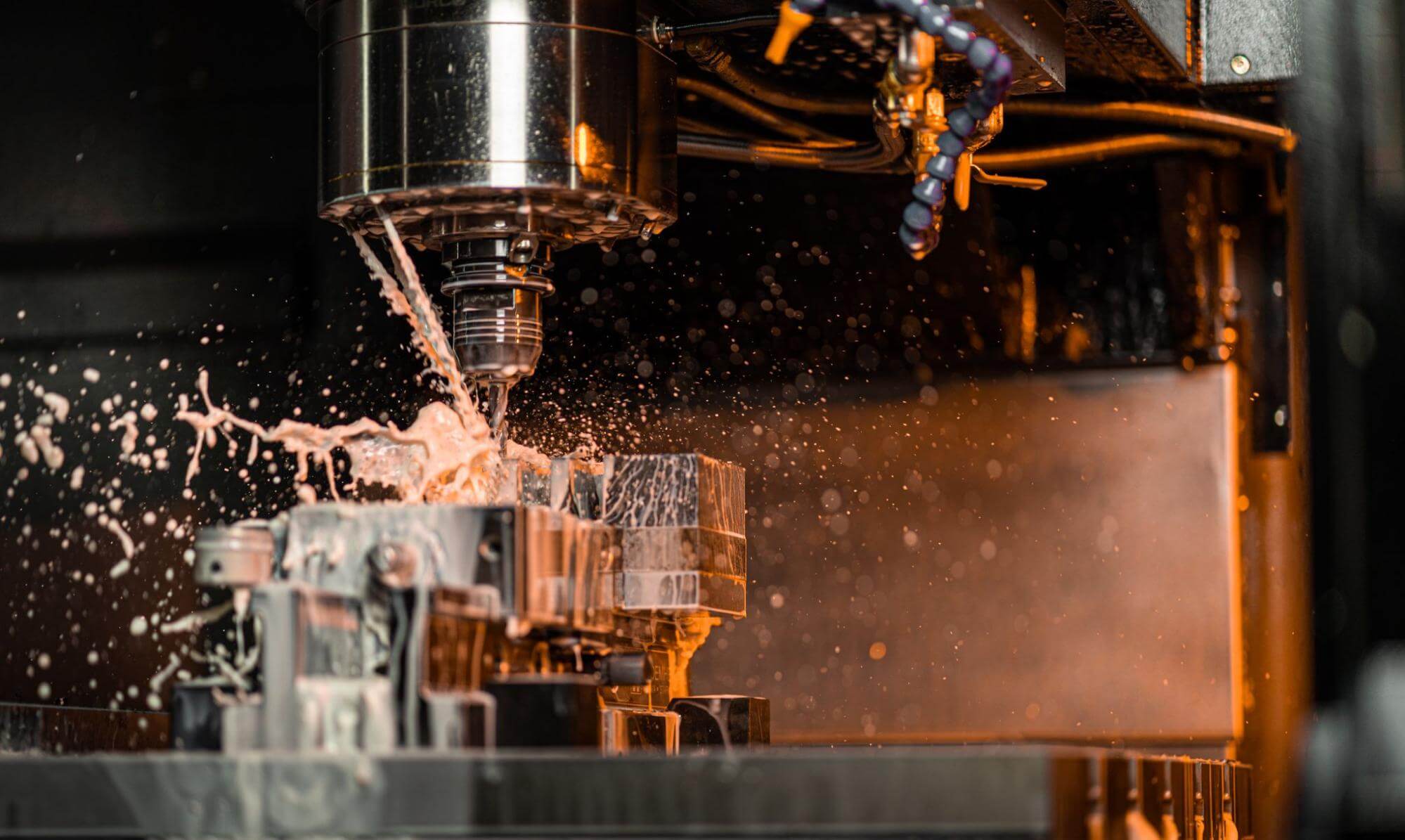

At Lead Precision, our engineering team employs multi-axis CNC machining, high-speed milling, and electrode discharge machining (EDM) to achieve tolerances as tight as ±0.002 mm. We integrate 3D scanning and coordinate measuring machine (CMM) validation into our quality assurance protocols, ensuring that every tool conforms precisely to design specifications before deployment. This level of control enables our clients to achieve repeatable, high-yield production runs with minimal scrap and downtime.

Our work on Olympic-level components—where even micro-defects can impact athletic performance—has honed our ability to balance complexity with reliability. Similarly, our engagements in military applications have required adherence to stringent standards for durability, traceability, and environmental resilience. These experiences have shaped our approach to mould tooling: a fusion of empirical data, advanced simulation, and hands-on expertise.

We understand that every client’s application presents unique challenges. Whether producing intricate cooling channels for high-cycle injection moulds or fabricating robust die-casting tools for automotive powertrain components, our solutions are engineered from the ground up to meet exact functional demands.

Below is a summary of our core technical capabilities in mould tooling:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 μm (polished to mirror finish if required) |

| Materials | H13, S136, 718H, P20, Titanium Alloys, Inconel variants |

| Machining Technology | 5-axis CNC, High-Speed Milling, Wire & Sinker EDM |

| Quality Assurance | CMM inspection, 3D laser scanning, GD&T reporting |

| Tool Life | Optimized for >100,000 cycles (application-dependent) |

| Standards Compliance | ISO 9001, AS9100 (aerospace), MIL-STD-883 (military) |

Precision mould tooling is not a commodity—it is a strategic asset. At Wuxi Lead Precision Machinery, we combine rigorous engineering discipline with real-world application experience to deliver tooling solutions that perform under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Mould Tooling

Wuxi Lead Precision Machinery delivers uncompromising precision for complex mould tooling applications through integrated advanced manufacturing and rigorous quality control. Our core strength lies in mastering the intricate geometries and stringent tolerances demanded by high-performance injection, die-casting, and blow mould tools. Central to this capability is our investment in state-of-the-art 5-axis CNC machining centers. These systems, featuring high-torque spindles, thermal stability compensation, and sophisticated control systems, enable the production of highly complex cavities, cores, and electrodes in a single setup. This eliminates cumulative alignment errors inherent in multi-setup processes, significantly improving geometric accuracy and surface finish while reducing overall lead times. Material versatility is critical in mould tooling; we expertly machine a wide spectrum of tool steels including P20, H13, S7, 420SS, and specialized pre-hardened or hardened alloys up to 60+ HRC, alongside aluminum and copper alloys for prototyping and specific applications.

Precision machining is only half the equation. Verifiable accuracy is paramount, which is why every critical component undergoes comprehensive inspection using our calibrated Coordinate Measuring Machines (CMM). Our primary inspection platform is the Zeiss CONTURA series, renowned for its metrology-grade accuracy and repeatability. Equipped with advanced scanning probes and temperature-controlled environments, these systems meticulously validate complex 3D profiles, positional tolerances, and critical feature dimensions against the original CAD model. This data-driven QC process provides objective evidence of conformance, ensuring dimensional integrity before tool assembly and guaranteeing consistent part production for our clients. Our inspection protocols extend beyond basic dimensional checks to include critical surface texture analysis and form verification, directly impacting mould performance and part quality.

The following table details our standard and tight tolerance capabilities for key mould tooling features, reflecting the precision achievable through our combined machining and inspection processes. These values represent typical production capabilities under controlled conditions; specific project requirements are always evaluated during the quoting phase.

| Feature Type | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) |

| Positional Tolerance | ±0.015 mm (±0.0006″) | ±0.008 mm (±0.0003″) |

| Profile of Surface | 0.020 mm (0.0008″) | 0.010 mm (0.0004″) |

| Flatness | 0.010 mm / 100 mm | 0.005 mm / 100 mm |

| Hole Diameter (Bored) | +0.010 / -0.000 mm | +0.005 / -0.000 mm |

| Surface Roughness (Ra) | 0.8 μm (32 μin) | 0.4 μm (16 μin) |

Achieving and sustaining these tolerances requires more than just equipment; it demands deep process expertise. Our engineering team applies decades of mould tooling experience to optimize machining strategies, select appropriate tooling and cutting parameters, and implement robust fixturing solutions that minimize deflection and vibration. We understand that thermal management during machining and meticulous control of the production environment are non-negotiable for micron-level consistency. This holistic approach, combining cutting-edge 5-axis technology with Zeiss-grade metrology and seasoned engineering judgment, ensures Wuxi Lead delivers mould tools that meet the highest standards of precision, durability, and performance, directly translating to reduced scrap rates and superior end-part quality for our manufacturing partners.

Material & Finish Options

Material selection in mould tooling is a critical decision that directly influences performance, longevity, and production efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exacting demands of high-precision industries. Our expertise spans aluminum, steel, and titanium—each offering distinct advantages depending on application requirements such as cycle time, part complexity, and environmental exposure.

Aluminum alloys, particularly 7075 and 6061, are widely used in prototyping and low-to-medium volume production due to their excellent machinability and thermal conductivity. These properties enable faster cooling cycles, reducing overall production time. While aluminum lacks the wear resistance of steel, its lightweight nature and cost-efficiency make it ideal for applications where rapid iteration and reduced mould weight are priorities. When enhanced surface durability is needed, aluminum benefits significantly from anodizing—a process that increases surface hardness and corrosion resistance. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with Type III offering superior abrasion resistance for demanding mould environments.

Steel remains the standard for high-volume production tooling. Tool steels such as H13, P20, and S136 provide exceptional hardness, wear resistance, and thermal stability. H13 is favored in hot work applications due to its ability to retain strength at elevated temperatures, while P20 is commonly used for injection moulds requiring good polishability and moderate hardness. Stainless variants like S136 offer superior corrosion resistance, making them ideal for medical or food-grade applications where hygiene is paramount. Steel tooling typically undergoes heat treatment to optimize hardness and is often finished with coatings or polishing to achieve mirror surfaces or texture replication.

Titanium, though less common in general mould construction, is selected for specialized applications requiring extreme strength-to-density ratios and corrosion resistance. Its biocompatibility and inertness make it suitable for aerospace and medical mould tooling where contamination must be minimized. Machining titanium requires advanced CNC capabilities due to its low thermal conductivity and high chemical reactivity, but the resulting tool life and performance justify the investment in critical environments.

Surface finishing, particularly anodizing for aluminum, plays a pivotal role in extending tool life and ensuring part quality. Anodized layers are integral to the base metal, not applied coatings, which prevents flaking and delamination. The porous nature of anodized surfaces also allows for dyeing, enabling visual identification of tool sets or stages in production.

Below is a comparative overview of key materials used in mould tooling:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 40–45 | 130 | Moderate (improved with anodizing) | Prototyping, low-volume production |

| H13 Steel | 48–52 | 35 | Good | High-temp injection moulding |

| P20 Steel | 28–32 | 30 | Fair | General-purpose moulds |

| S136 Steel | 50–54 | 25 | Excellent | Corrosion-sensitive environments |

| Titanium Gr5 | 35–40 (as machined) | 7 | Outstanding | Aerospace, medical precision tools |

Selecting the optimal material requires balancing performance, cost, and production volume. At Wuxi Lead Precision Machinery, we support clients in making informed decisions based on application-specific demands, ensuring reliability and precision in every mould system we produce.

Manufacturing Process & QC

Precision Mould Tooling: The Zero-Defect Production Process

At Wuxi Lead Precision Machinery, we engineer mould tooling where failure is non-negotiable. Defective tooling cascades into production delays, scrap waste, and reputational damage for our clients. Our rigorously validated process—Design, Prototyping, Mass Production—ensures zero-defect delivery by embedding precision at every phase. This methodology eliminates reactive corrections, securing your timeline and ROI from inception to high-volume output.

Design begins with parametric 3D modeling in Siemens NX, integrating your functional requirements with manufacturability analysis. Finite Element Analysis (FEA) simulates thermal distribution, stress points, and ejection forces under real-world conditions, identifying potential failure modes before metal is cut. We collaborate with your engineering team to refine cooling channel layouts and venting systems, optimizing cycle times and part integrity. Critical tolerances are locked using Geometric Dimensioning and Tolerancing (GD&T) standards, ensuring alignment with your final component specifications. This phase concludes with a digital sign-off, validating that the virtual tool meets all performance criteria.

Prototyping transforms the digital model into a physical stress test. We machine a single-cavity prototype tool from pre-hardened P20 or H13 steel using 5-axis CNC milling with ±0.005 mm repeatability. This tool undergoes 500+ validation cycles on our in-house injection moulding presses, producing parts subjected to full metrology. Coordinate Measuring Machine (CMM) scans, optical comparators, and material flow analysis verify dimensional accuracy, surface finish, and structural consistency against your CAD data. Any deviation triggers immediate root-cause analysis and design iteration—never a compromise. Only when 100% of parts meet spec does the tool advance to production.

Mass Production leverages our ISO 9001-certified workflow with embedded Statistical Process Control (SPC). Each production tool is machined on Makino or DMG MORI centres monitored by real-time tool wear sensors and thermal compensation systems. Every cavity undergoes 100% post-machining inspection via CMM and surface roughness testers. During moulding, in-mould pressure sensors and automated vision systems track part conformity per cycle, feeding data to our central SPC dashboard. This closed-loop system detects micro-drifts before they affect output, ensuring ±0.01 mm tolerance stability across 500,000+ shots. Final tools ship with full traceability dossiers, including material certs, inspection reports, and process capability indices.

Our commitment to zero defects is quantifiable. Below are the core specifications governing every tool we deliver

| Parameter | Specification | Validation Method |

|---|---|---|

| Dimensional Tolerance | ±0.01 mm (critical features) | CMM, Optical Comparator |

| Surface Roughness (Ra) | 0.2–0.8 μm (cavity/core) | Profilometer |

| Hardness | HRC 48–52 (H13), HRC 28–32 (P20) | Rockwell Tester |

| Cooling Efficiency | ±2°C uniformity across cavity surface | Thermal Imaging, Flow Simulation |

| Production Lifespan | 500,000+ cycles (defect-free) | SPC Monitoring, Endurance Test |

This uncompromising sequence—validated design, destructive prototyping, and sensor-driven mass production—transfers risk from your floor to our process. Wuxi Lead doesn’t manufacture tools; we deliver certainty. Contact our engineering team to integrate this zero-defect framework into your next project.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced Mould Tooling Solutions

When precision, durability, and performance define your manufacturing success, partnering with a trusted leader in custom metal manufacturing becomes critical. At Wuxi Lead Precision Machinery, we specialize in high-end mould tooling engineered to meet the exacting demands of industries ranging from automotive and aerospace to medical devices and consumer electronics. Our commitment to excellence is reflected in every tool we produce—each one designed not just to meet specifications, but to exceed expectations in real-world production environments.

With over a decade of expertise in CNC machining, EDM, and surface grinding, our team delivers mould tools that combine micron-level accuracy with superior material integrity. We understand that mould tooling is not a standalone component—it is the foundation of your production line. That’s why we invest in advanced simulation software, rigorous quality control protocols, and continuous process optimization to ensure every tool performs flawlessly under high-cycle, high-pressure conditions.

Our facility in Wuxi, China, is equipped with state-of-the-art machinery and staffed by engineers with deep domain knowledge in tool steel selection, thermal treatment, and cavity design. From initial concept and 3D modeling to final inspection and delivery, we maintain full control over the manufacturing process. This vertical integration allows us to respond swiftly to design changes, maintain tight tolerances, and deliver consistent quality across large production runs.

We serve global clients who demand reliability, scalability, and technical collaboration. Whether you require single-cavity prototypes or multi-cavity production tools, our engineering team works closely with yours to optimize design for manufacturability, reduce cycle times, and extend tool life. Our clients benefit from faster time-to-market, reduced maintenance costs, and improved part consistency.

Below are key specifications that define our mould tooling capabilities:

| Specification | Detail |

|---|---|

| Material Options | P20, 718H, S136, H13, NAK80, and custom alloys |

| Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished or textured) |

| Maximum Part Size | 1200 mm × 800 mm × 600 mm |

| Machining Centers | 3-axis, 4-axis, 5-axis CNC with automatic tool changers |

| Quality Assurance | CMM inspection, laser scanning, GD&T reporting |

| Lead Time | 15–25 days (prototype), 25–45 days (production) |

| Industries Served | Automotive, Medical, Electronics, Packaging, Aerospace |

At Wuxi Lead Precision Machinery, we don’t just manufacture mould tools—we engineer long-term manufacturing advantages. Our approach is built on transparency, technical partnership, and a relentless focus on your operational goals.

To discuss your next project or request a detailed quotation, contact us today at [email protected]. Let us help you achieve precision that performs, batch after batch.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.