Technical Contents

Engineering Guide: Steel Powder Coating

Engineering Insight Precision in Steel Powder Coating Systems

Precision engineering forms the absolute foundation for successful steel powder coating applications. In high-performance manufacturing sectors, coating failures rarely originate from the powder itself but from insufficient substrate preparation and dimensional inconsistency. Steel components requiring powder coating demand micron-level surface geometry control prior to application. Imperfections such as micro-burrs from machining, inconsistent edge radii, or residual stresses from forming create adhesion weak points where corrosion initiates under thermal cycling or mechanical stress. At Wuxi Lead Precision Machinery, we treat the pre-coating stage as an integrated extension of our CNC fabrication process. Our multi-axis machining centers achieve tolerances down to ±0.005mm, ensuring uniform surface profiles that eliminate shadowing effects during electrostatic application. This precision guarantees consistent coating thickness distribution—critical for maintaining dielectric integrity in electrical enclosures or corrosion resistance in marine hardware. Without this level of substrate accuracy, even the highest-grade powder formulations cannot deliver their engineered performance.

The consequences of inadequate precision become starkly evident in mission-critical applications. Our work supplying components for Olympic infrastructure projects demanded coatings that withstood extreme weather exposure while maintaining exact color consistency across thousands of structural elements. Similarly, military contract components required coatings that survived ballistic testing without delamination under explosive shock loads. In both cases, success hinged on our ability to control steel part geometry to within 10 microns before coating. Variations beyond this threshold caused uneven curing, leading to micro-cracking in field conditions. We enforce rigorous in-process metrology using coordinate measuring machines (CMM) to validate part flatness and edge continuity, directly correlating these metrics to coating adhesion test results per ASTM D3359. This data-driven approach prevents costly rework and ensures zero-defect delivery for clients where failure is not an option.

Our integrated manufacturing capability spans from raw material selection through final coating validation. Below are key precision parameters we control for steel powder coating substrates:

| Parameter | Lead Precision Capability | Typical Industry Standard |

|---|---|---|

| Surface Roughness (Ra) | 0.8 – 1.6 μm | 1.6 – 3.2 μm |

| Dimensional Tolerance | ±0.005 mm | ±0.05 mm |

| Edge Radius Control | ±0.02 mm | Not Controlled |

| Coating Thickness Variation | ±5 μm | ±15 μm |

| Adhesion Rating (ASTM D3359) | 5B (Perfect) | 3B – 4B |

Precision in steel powder coating transcends aesthetic finish—it is a non-negotiable engineering requirement for functional longevity. Wuxi Lead Precision Machinery’s decades of experience in aerospace, defense, and large-scale infrastructure projects prove that coating performance is manufactured long before the powder gun activates. By embedding metrology-driven precision into every machining step, we deliver coated steel components that perform reliably under the most demanding operational conditions. This is how we consistently exceed ISO 14644 cleanroom standards and MIL-STD-810G environmental testing protocols for global clients. Your critical components deserve this level of engineered certainty.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, with a specialized focus on high-performance steel components requiring precision powder coating integration. Our facility combines cutting-edge 5-axis CNC machining with stringent quality control protocols to ensure every part meets exacting industry standards. The synergy between our machining precision and surface treatment processes enables superior adhesion, durability, and finish consistency in powder-coated steel applications.

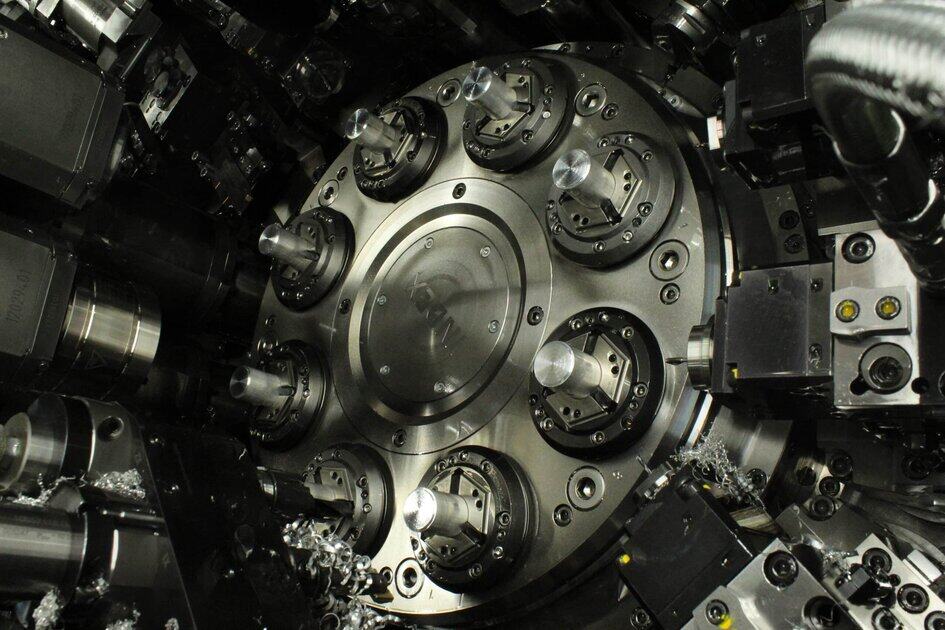

Our 5-axis CNC machining centers provide unparalleled flexibility and accuracy in shaping complex steel geometries. With simultaneous multi-axis movement, we achieve intricate contours, tight internal features, and reduced setup cycles—critical for components used in aerospace, medical, and industrial automation sectors. The use of high-rigidity machine platforms and advanced toolpath optimization software ensures minimal thermal deformation and micron-level repeatability. This precision directly supports the success of downstream powder coating operations by delivering dimensionally stable substrates with consistent surface profiles.

All machined steel components undergo comprehensive inspection via our Coordinate Measuring Machine (CMM) system, which verifies geometric accuracy across critical dimensions. The CMM process is fully automated and aligned with ISO 10360 standards, enabling traceable, repeatable measurement of complex forms. Data from each inspection is documented and integrated into our quality management system, providing full traceability for every production batch. This level of verification ensures that parts arriving at the powder coating stage are within defined tolerances, minimizing rework and enhancing coating uniformity.

To support design engineers and procurement teams, we provide clearly defined tolerance specifications based on our validated manufacturing processes. These tolerances reflect real-world performance across our equipment fleet and QC systems.

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | Up to 300 mm; ±0.02 mm beyond |

| Angular Dimensions | ±0.1° | Verified via CMM |

| Positional Tolerance | ±0.015 mm | GD&T compliant |

| Surface Roughness (Ra) | 0.8 µm (typical) | Adjustable per requirement |

| Feature-to-Feature Alignment | ±0.01 mm | 5-axis compensated |

| Coaxiality | Ø0.02 mm | Full CMM validation |

| Flatness | 0.01 mm per 100 mm | Verified on critical surfaces |

These specifications are maintained across batch sizes, from prototype to high-volume production. Our process control includes pre-coating surface preparation protocols such as micro-blasting and degreasing, ensuring optimal coating adhesion. Wuxi Lead Precision Machinery’s integrated approach—precision machining, metrology-driven quality assurance, and coating-ready finishing—establishes a benchmark in steel component manufacturing for demanding industrial applications.

Material & Finish Options

Material Selection Guide for Powder Coating and Anodizing Applications

Selecting the optimal substrate and finish is critical for component performance, longevity, and cost-effectiveness in precision manufacturing. While powder coating is a versatile finishing process applicable to multiple metals, anodizing is specific to aluminum alloys. Confusion between these processes can lead to suboptimal results. Powder coating provides a durable, decorative, and protective polymer layer electrostatically applied and cured on conductive substrates like steel and aluminum. Anodizing, conversely, is an electrochemical process that thickens aluminum’s natural oxide layer, enhancing corrosion resistance, wear properties, and providing a base for dyeing; it is not applicable to steel or titanium. Understanding material properties and finish compatibility is paramount.

Steel, particularly low-carbon varieties like ASTM A36 or AISI 1018, remains the dominant structural material due to its high strength, stiffness, and cost efficiency. It is an excellent substrate for powder coating, which provides robust corrosion protection essential for steel. Proper surface preparation via abrasive blasting is non-negotiable to ensure adhesion. Steel cannot be anodized. For applications demanding extreme strength-to-weight ratios and superior corrosion resistance in harsh environments, titanium alloys like Grade 5 (Ti-6Al-4V) are ideal. Titanium accepts powder coating effectively after stringent surface activation but is incompatible with anodizing in the conventional sense; specialized anodizing exists for coloration but not for significant corrosion enhancement like on aluminum. Aluminum alloys, especially the 6000 series (e.g., 6061-T6), offer an optimal balance of strength, weight, machinability, and corrosion resistance. Aluminum is uniquely suited for both powder coating and anodizing. Anodizing provides exceptional wear and corrosion resistance integral to the metal, while powder coating offers broader color and texture options over a properly prepared anodized or bare aluminum surface.

Material properties directly influence process suitability and final part performance. The following table summarizes key characteristics relevant to finishing:

| Material | Typical Tensile Strength (MPa) | Base Corrosion Resistance | Powder Coating Suitability | Anodizing Suitability |

|---|---|---|---|---|

| Steel (A36) | 400 – 550 | Low (Requires coating) | Excellent (With prep) | Not Applicable |

| Aluminum (6061-T6) | 290 – 330 | Moderate to Good | Excellent | Excellent |

| Titanium (Gr5) | 860 – 900 | Very High | Good (Requires activation) | Limited (Color only) |

Material selection must align with the end-use environment, mechanical requirements, aesthetic goals, and total lifecycle cost. Powder coating offers significant advantages for steel components and is a flexible option for aluminum, providing extensive color and texture choices with robust protection. For aluminum parts where maximum inherent corrosion and wear resistance are critical, anodizing is often the superior primary finish, potentially followed by powder coating for specific aesthetic needs. Wuxi Lead Precision Machinery leverages deep expertise in CNC machining and surface treatment integration. We advise on optimal material-finish pairings early in the design phase, ensuring manufacturability, compliance with industry standards like ISO 9001, and seamless integration within your global supply chain. Consult our engineering team to specify the precise alloy and finish combination that delivers performance and value for your application.

Manufacturing Process & QC

The production process for steel powder coating at Wuxi Lead Precision Machinery follows a disciplined, end-to-end methodology designed to ensure zero defects and superior product consistency. Rooted in precision engineering and advanced manufacturing protocols, our approach spans three critical phases: Design, Prototyping, and Mass Production. Each stage integrates rigorous quality controls, material science expertise, and real-time process monitoring to deliver components that meet the highest industrial standards.

In the Design phase, our engineering team collaborates closely with clients to interpret technical specifications, functional requirements, and environmental conditions. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry for structural integrity, coating adhesion, and manufacturability. Material selection is critical—only high-grade low-carbon steel with controlled surface roughness is approved for powder coating applications. This ensures compatibility with electrostatic deposition and thermal curing processes. Design validation includes thermal expansion modeling and corrosion resistance simulation to preempt field failures.

Prototyping follows a rapid yet meticulous workflow. Using CNC laser cutting, precision bending, and robotic welding, we fabricate initial samples under production-equivalent conditions. Each prototype undergoes comprehensive surface preparation, including sandblasting to Sa 2.5 cleanliness standards, followed by iron phosphate pretreatment. The powder coating is applied using automated electrostatic spray deposition with tribo or corona charging, depending on part geometry. Curing occurs in convection ovens with tightly regulated temperature profiles. Dimensional inspection, adhesion testing (cross-hatch ASTM D3359), and salt spray resistance (ASTM B117, 500+ hours) are performed in-house. Feedback from this phase informs final design adjustments and process tuning.

Mass Production leverages fully automated production lines equipped with IoT-enabled monitoring systems. Every component is traceable via QR codes that log process parameters in real time. Powder coating thickness is continuously measured using non-contact eddy current gauges, maintaining a tolerance of ±5 µm. The curing ovens use PID-controlled heating ramps to ensure uniform cross-linking without under- or over-curing. Final inspection includes automated optical scanning for surface defects and batch sampling for mechanical and environmental testing. Our zero-defect commitment is enforced through Six Sigma principles, statistical process control (SPC), and 100% visual inspection at critical control points.

All processes adhere to ISO 9001 and IATF 16949 standards. The integration of design intelligence, prototyping rigor, and closed-loop production control ensures that every steel component we deliver exhibits flawless coating integrity, long-term durability, and exacting dimensional precision.

| Parameter | Specification |

|---|---|

| Substrate Material | Low-carbon steel (Q195-Q235) |

| Surface Preparation | Sandblasting (Sa 2.5), Iron Phosphate Coating |

| Coating Type | Epoxy-Polyester Hybrid, TGIC-Free Polyester |

| Film Thickness | 60–90 µm (standard), customizable |

| Curing Conditions | 180°C for 15 minutes (typical) |

| Adhesion Rating | 5B (ASTM D3359) |

| Salt Spray Resistance | ≥500 hours (ASTM B117) |

| Hardness (Pencil) | 2H minimum |

| Bend Test | 2 mm mandrel, no flaking (ISO 6860) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Steel Powder Coating Excellence

In high-stakes industrial applications, substandard powder coating on steel components leads to premature corrosion, dimensional instability, and costly field failures. Generic coating providers often lack the metallurgical expertise to ensure adhesion integrity across complex geometries or under extreme operational stress. At Wuxi Lead Precision Machinery, we engineer powder coating solutions as an integrated extension of your manufacturing process—not as a standalone finish. Our ISO 9001-certified facility combines robotic precision application with substrate-specific pretreatment protocols, guaranteeing coatings that withstand 2,000+ hours of salt spray testing while maintaining micron-level dimensional tolerance. This eliminates rework cycles and extends product lifecycle in aerospace, heavy machinery, and energy infrastructure sectors.

Our technical differentiators stem from decades of refining powder coating for mission-critical steel components. We deploy multi-stage zinc phosphate conversion coatings before electrostatic application, ensuring molecular bonding that resists chipping at -40°C or continuous 180°C exposure. Unlike competitors using off-the-shelf powders, we collaborate with AkzoNobel and PPG to formulate proprietary resin blends matching your steel alloy’s thermal expansion coefficient. The result is a finish that performs as predictably as the underlying metal.

Key Technical Specifications for Steel Powder Coating

| Parameter | Standard Capability | Premium Option | Testing Standard |

|---|---|---|---|

| Coating Thickness | 60–120 μm | 40–180 μm (±5 μm) | ASTM D7091 |

| Adhesion Rating | 5B (Crosshatch) | 5B (T-Bend ≤1T) | ASTM D3359 |

| Salt Spray Resistance | 1,000 hours | 2,000+ hours | ASTM B117 |

| Temperature Resistance | -30°C to 150°C | -40°C to 180°C | ISO 2813 |

| Curing Cycle | 10–15 min @ 190°C | Custom ramp/soak profiles | ISO 2409 |

Partnering with Lead Precision means accessing a closed-loop quality system where every batch undergoes real-time FTIR spectroscopy and DSC thermal analysis. Our CNC-integrated coating cells process parts directly from machining centers, eliminating handling-induced contamination. For OEMs facing supply chain volatility, we offer consignment inventory programs with JIT delivery—reducing your warehousing costs by up to 35% while ensuring 99.8% on-time shipment.

Your next project demands more than a vendor; it requires an engineering ally who treats your coating specifications as non-negotiable. We commit to delivering first-article approval within 14 days through our rapid prototyping lab, backed by lifetime technical support from our materials science team. Do not settle for coatings that merely meet minimum standards—demand finishes that outperform your operational requirements.

Contact our engineering team today at [email protected] to schedule a confidential consultation. Specify your steel grade, environmental exposure conditions, and dimensional critical zones. We will provide a tailored process validation report within 72 hours—proving how Lead Precision becomes your competitive advantage in durability and precision. The final layer of your product’s reliability starts here.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.